Patents

Literature

306results about How to "Precise angle of rotation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

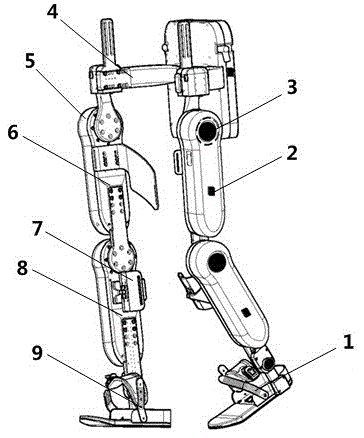

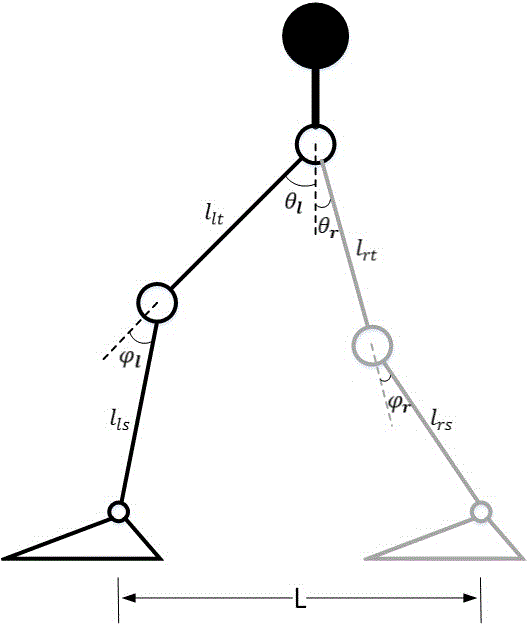

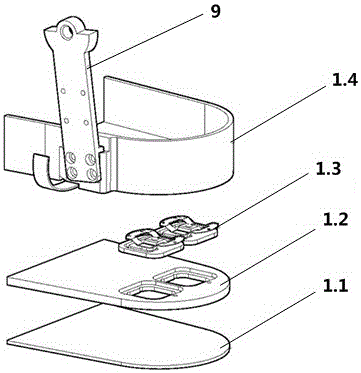

Exoskeleton gait analysis system and method based on multi-sensor fusion

InactiveCN106176149AImprove real-time performancePrecise angle of rotationProgramme-controlled manipulatorDiagnostic signal processingData informationData acquisition

The invention discloses an exoskeleton gait analysis system and method based on multi-sensor fusion. The exoskeleton gait analysis system based on multi-sensor fusion comprises outer bones, attitude and heading devices, intelligent shoes, encoders and microprocessors. The outer bones include hip joint parts, thigh mechanical bones, knee joint parts, shank mechanical bones and ankle joint parts. The microprocessors are used for analyzing and processing motion state data generated in the walking process of the outer bones. The exoskeleton gait analysis method based on multi-sensor fusion includes the steps that outer bone motion state data collected by the attitude and heading devices, the intelligent shoes and encoders are subjected to denoising and analysis processing and then transmitted to an upper computer, the upper computer adjusts walking gait and speed according to all outer bone data information, and stability and safety during walking of the outer bones are ensured. The system is simple and light, data collection is efficient, control responding is sensitive, and wearing comfort of the outer bones and safety guarantee ability of a wearer in the walking process are greatly improved.

Owner:UNIV OF ELECTRONICS SCI & TECH OF CHINA

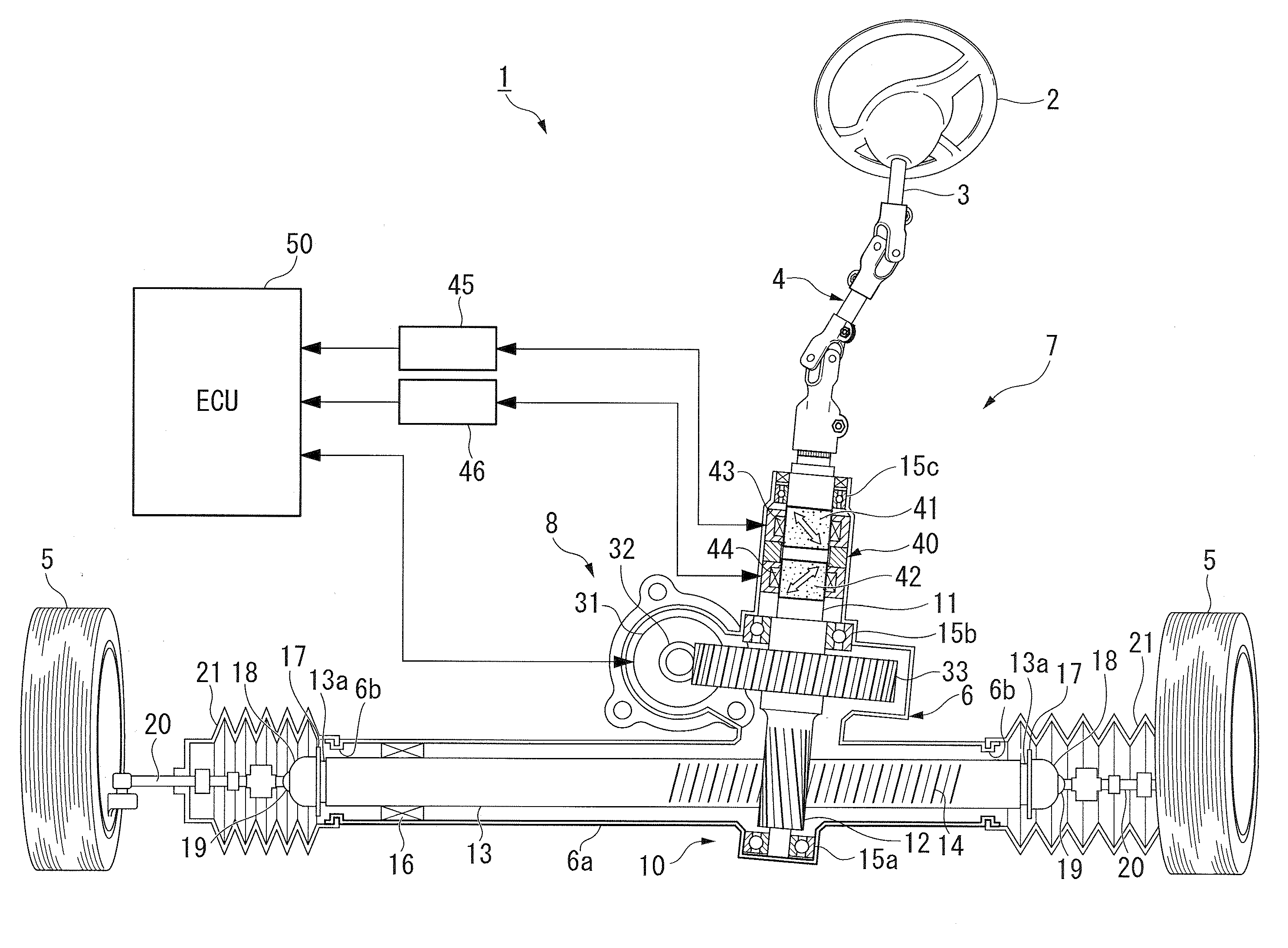

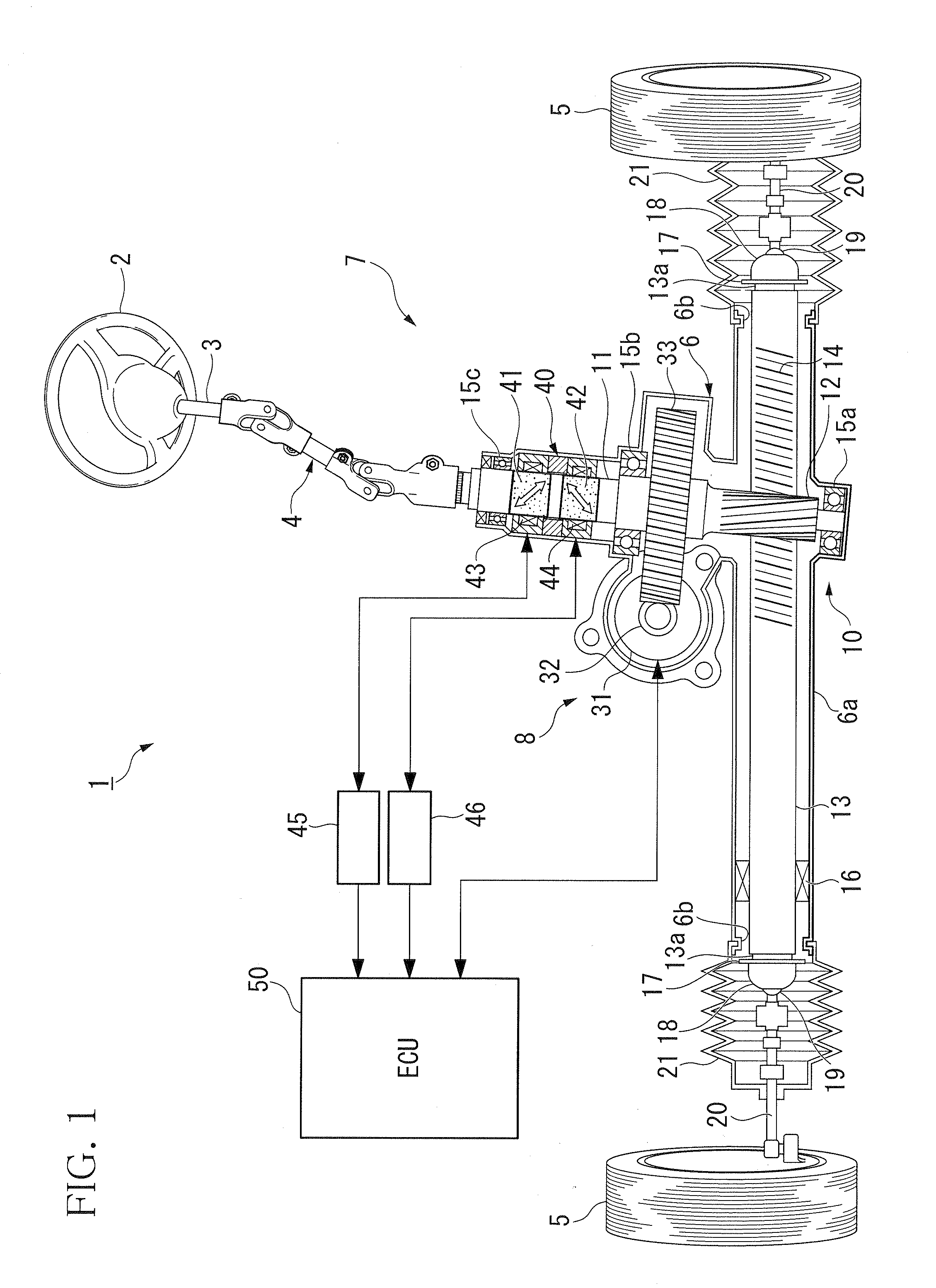

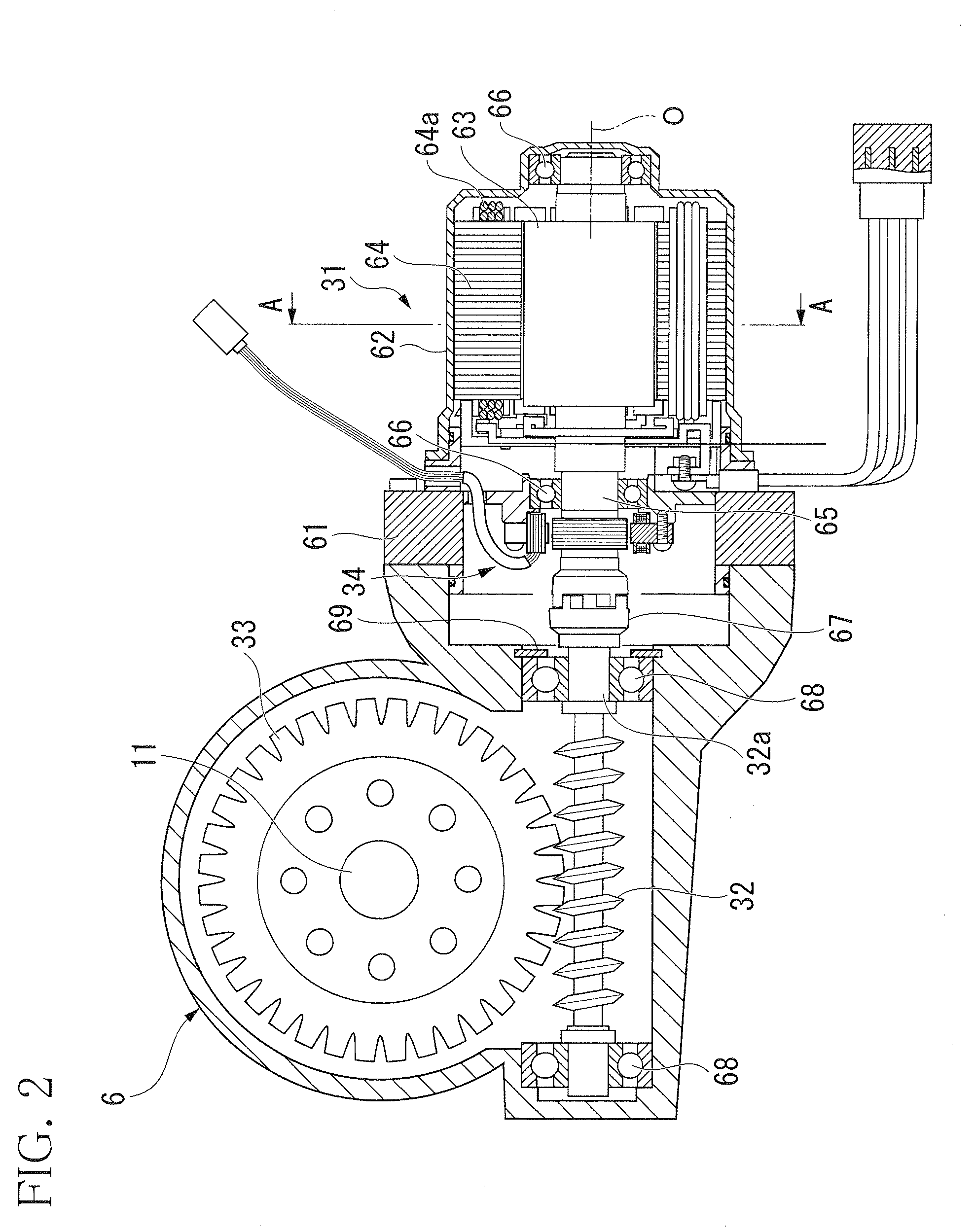

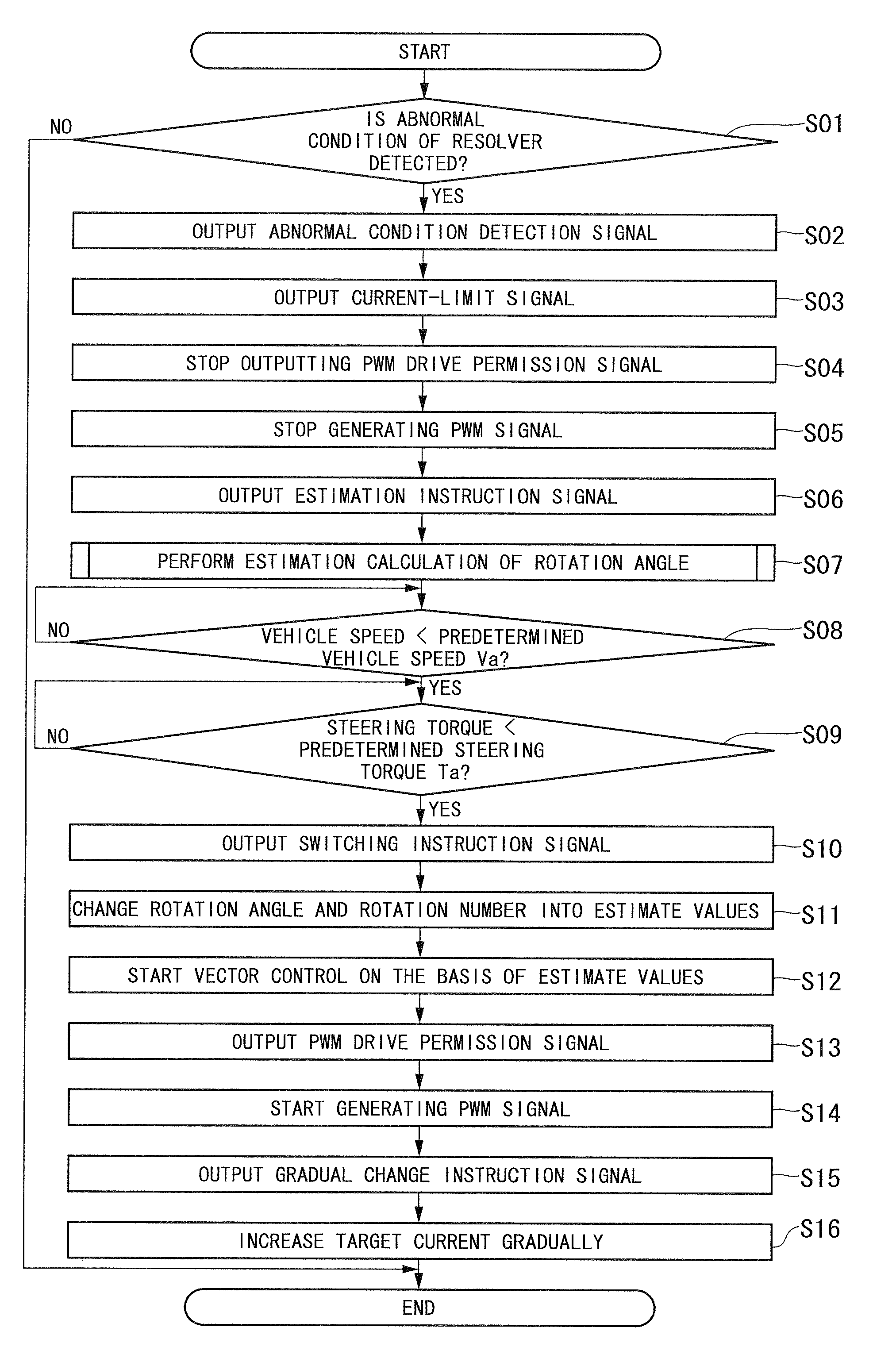

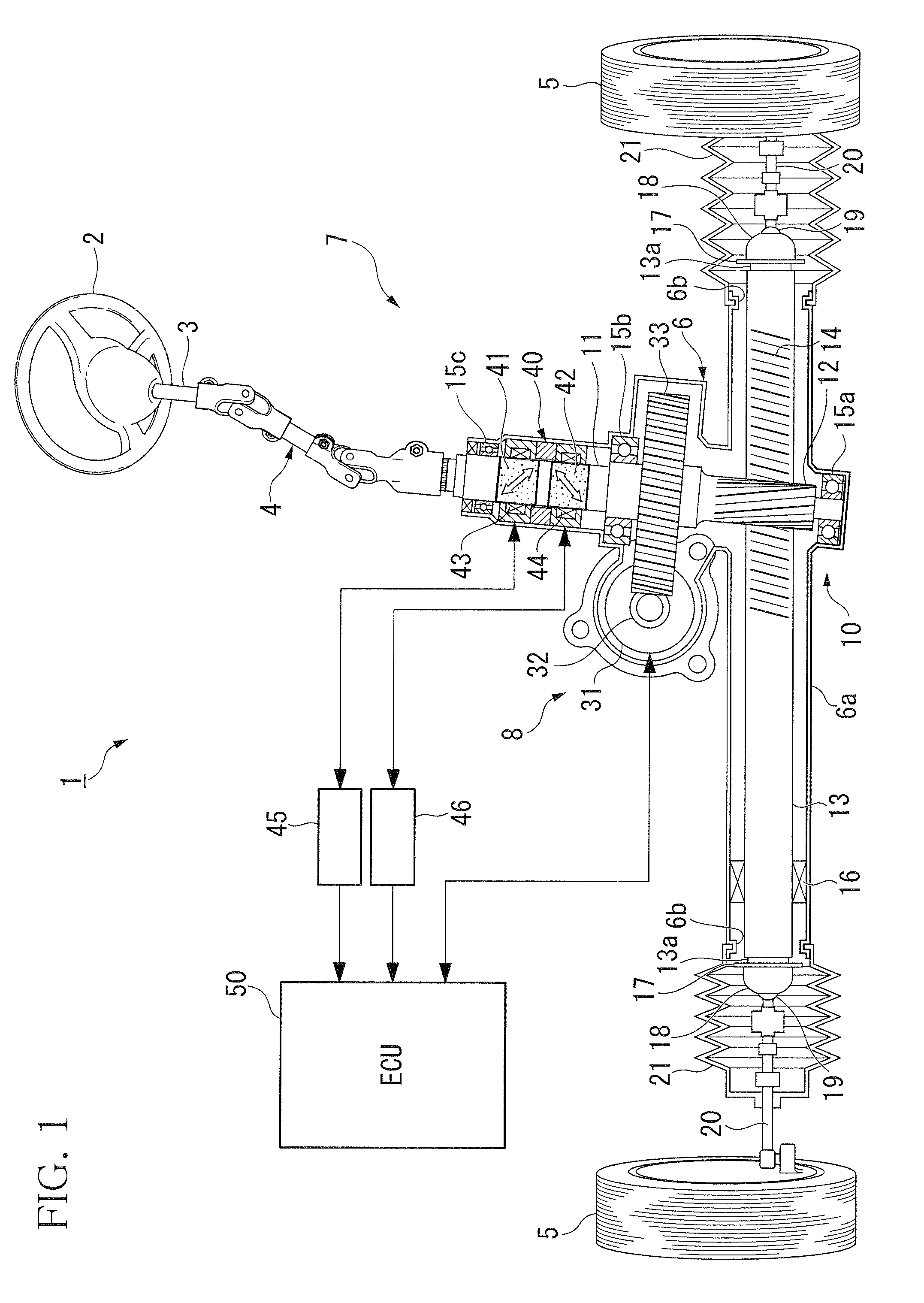

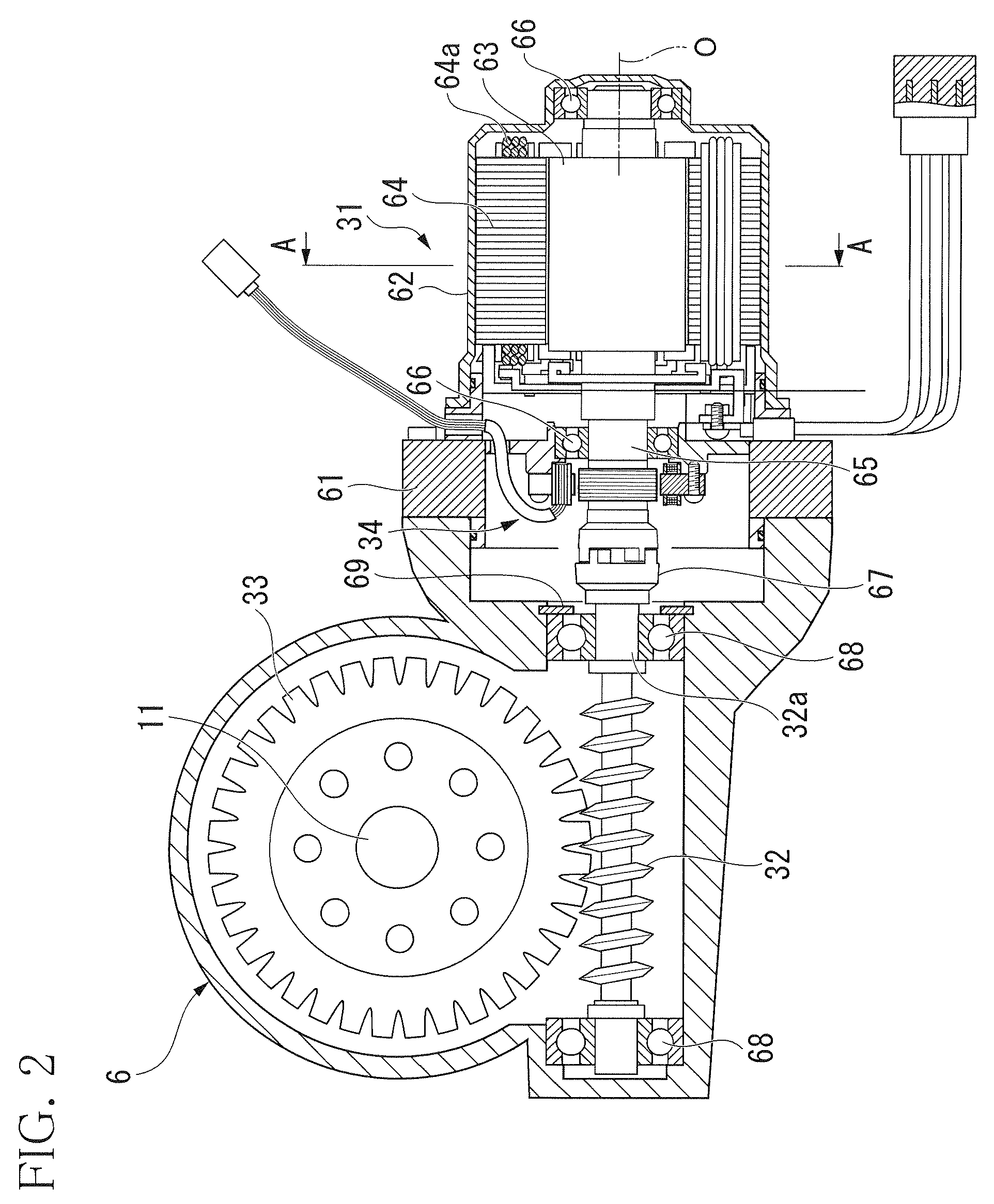

Motor control device and electric steering system

InactiveUS20110035114A1Precise angle of rotationAvoid discomfortCommutation monitoringDigital data processing detailsMotor controlEngineering

A motor control device includes: a rotation angle detection portion that detects a rotation angle of a motor and outputs a rotation angle signal; an abnormal condition detection portion that detects the presence or absence of an abnormal condition of the rotation angle detection portion; a rotation angle estimation portion that estimates the rotation angle of the motor and outputs an estimate rotation angle signal; and a driving control portion that controls driving of the motor on the basis of the rotation angle signal, which is output from the rotation angle detection portion, when the abnormal condition detection portion does not detect an abnormal condition of the rotation angle detection portion, and controls driving of the motor on the basis of the estimate rotation angle signal, which is output from the rotation angle estimation portion, when the abnormal condition detection portion detects an abnormal condition of the rotation angle detection portion.

Owner:HONDA MOTOR CO LTD

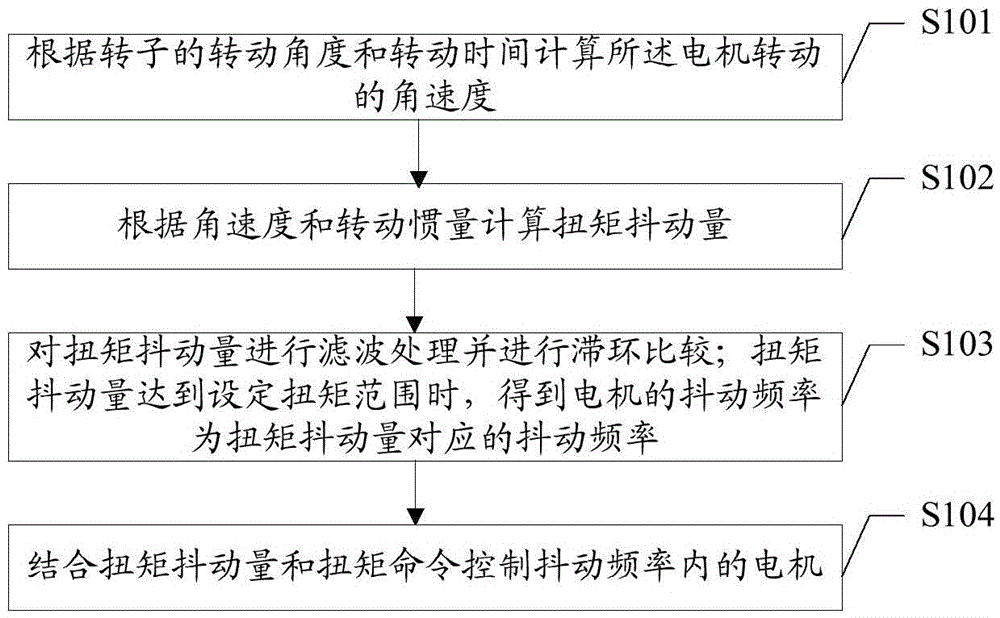

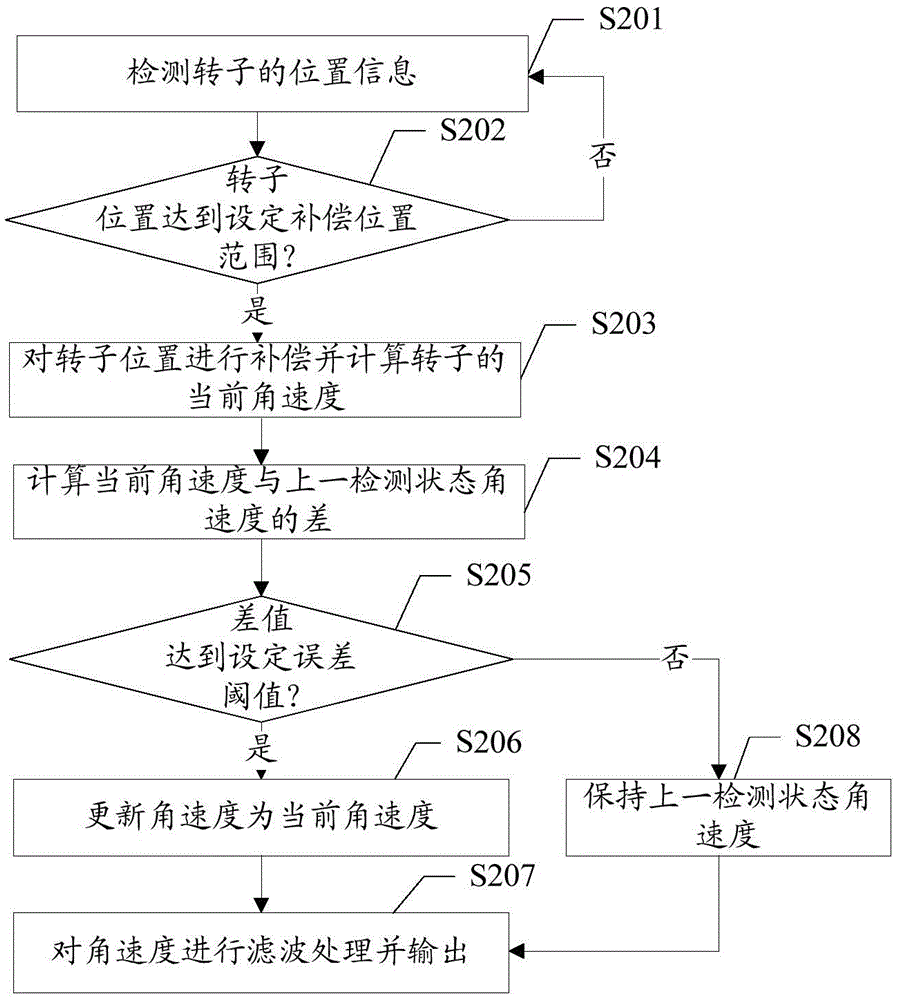

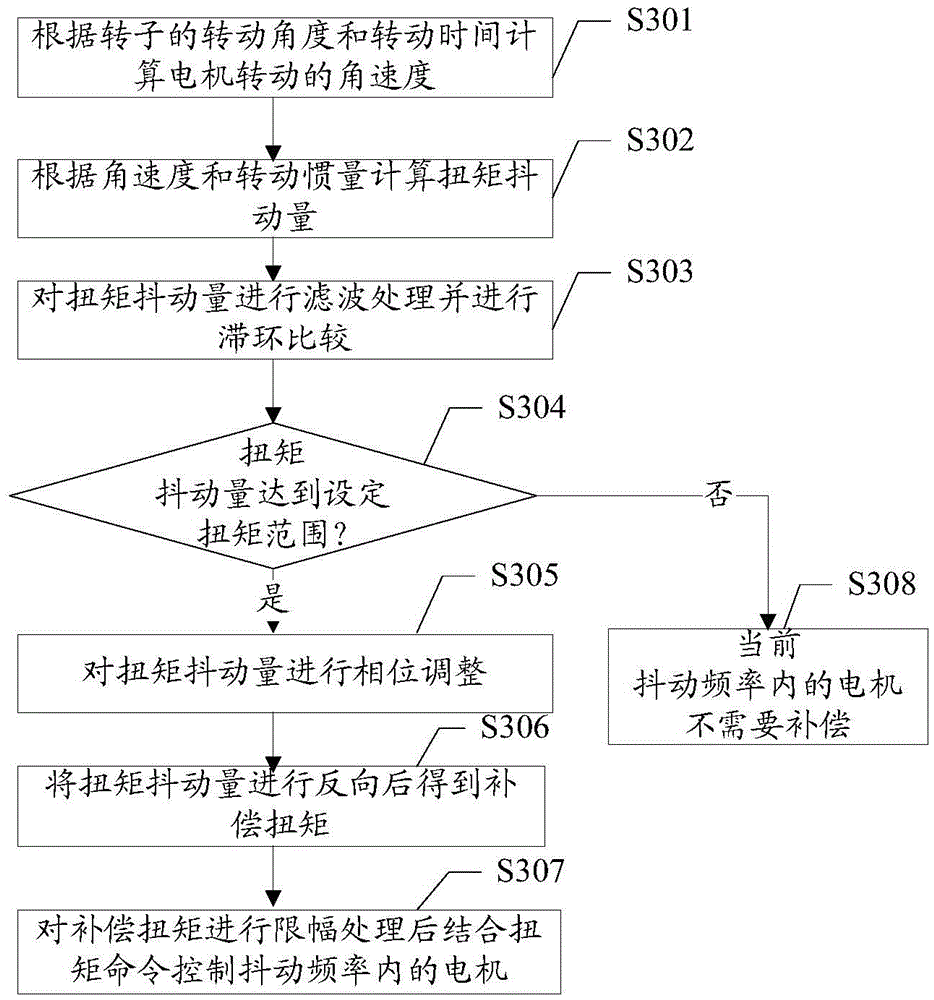

Motor shaking restraining method and device for electric automobile

ActiveCN106809051ASuppress motor vibrationImprove comfortSpeed controllerElectric energy managementHysteresisRotary inertia

The invention relates to a motor shaking restraining method and device for an electric automobile. The motor shaking restraining method for the electric automobile comprises the following steps: according to the rotating degree and the rotating time of a rotor, calculating the rotating angular speed of the motor; according to the angular speed and the rotary inertia, calculating torque shaking capacity; performing filtering treatment and hysteresis loop comparison on the torque shaking capacity; when the torque shaking capacity reaches the set torque range, obtaining the motor shaking frequency which is the shaking frequency corresponding to the torque shaking capacity; combining the torque shaking capacity with a torque command, and controlling the motor within the shaking frequency. According to the motor shaking restraining method and device for the electric automobile disclosed by the invention, the shaking frequency section of the motor is calculated, and the corresponding torque shaking capacity is combined with the torque command, so that the rotation of the motor is controlled, and the motor shaking of a low-frequency electric automobile is effectively restrained.

Owner:SAIC MOTOR

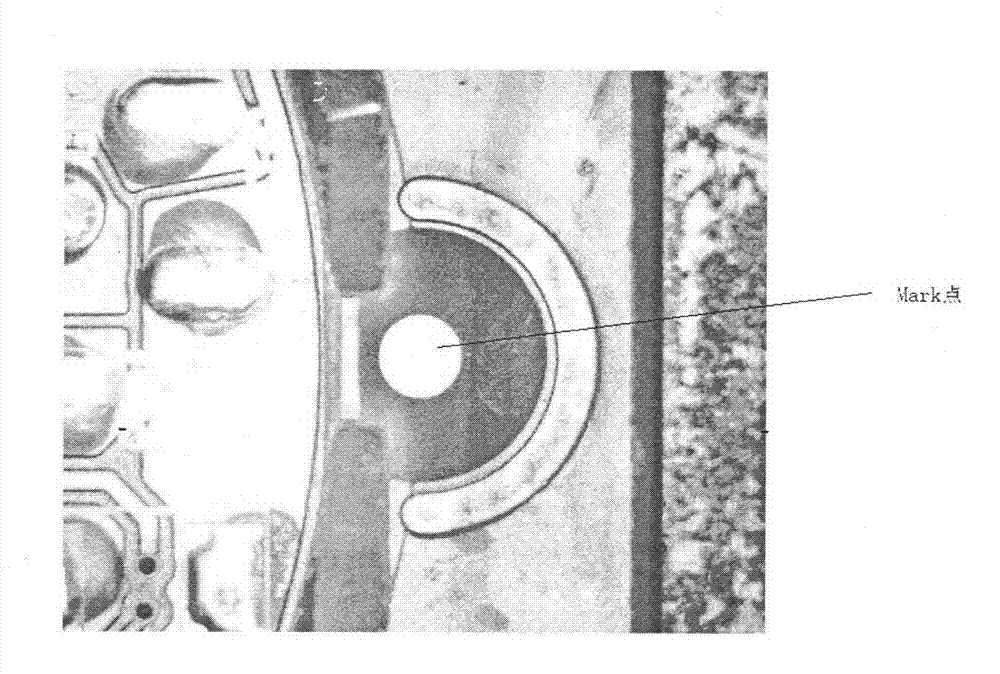

Method for locating Mark points on PCB (printed circuit board) by utilizing outline gravity center method

ActiveCN102930266AHigh precisionThe accuracy is at the sub-pixel level, and the compensation accuracy is highCharacter and pattern recognitionGravity centerEngineering

The invention discloses a method for locating Mark points on a PCB (printed circuit board) by utilizing an outline gravity center method. The method is characterized by comprising the following steps: on the basis of taking a Mark point extracted in initial programming as a datum point, taking the outline gravity center of the Mark point of the board to be detected, comparing the outline gravity center of the Mark point with the gravity center of the datum point, and performing PCB compensation by virtue of offset between the two gravity centers. The method is used for performing the PCB compensation by extracting the outline gravity center of the Mark point on the PCB and utilizing the offset between the gravity centers of the datum Mark point and the Mark point to be detected. The gravity centers are obtained by binary images and are easy and feasible to obtain. The algorithm is independent from the shapes of the Mark points, is not influenced by the intensity of illumination, achieves sub-pixel-level precision, and is high in compensation precision.

Owner:廖怀宝

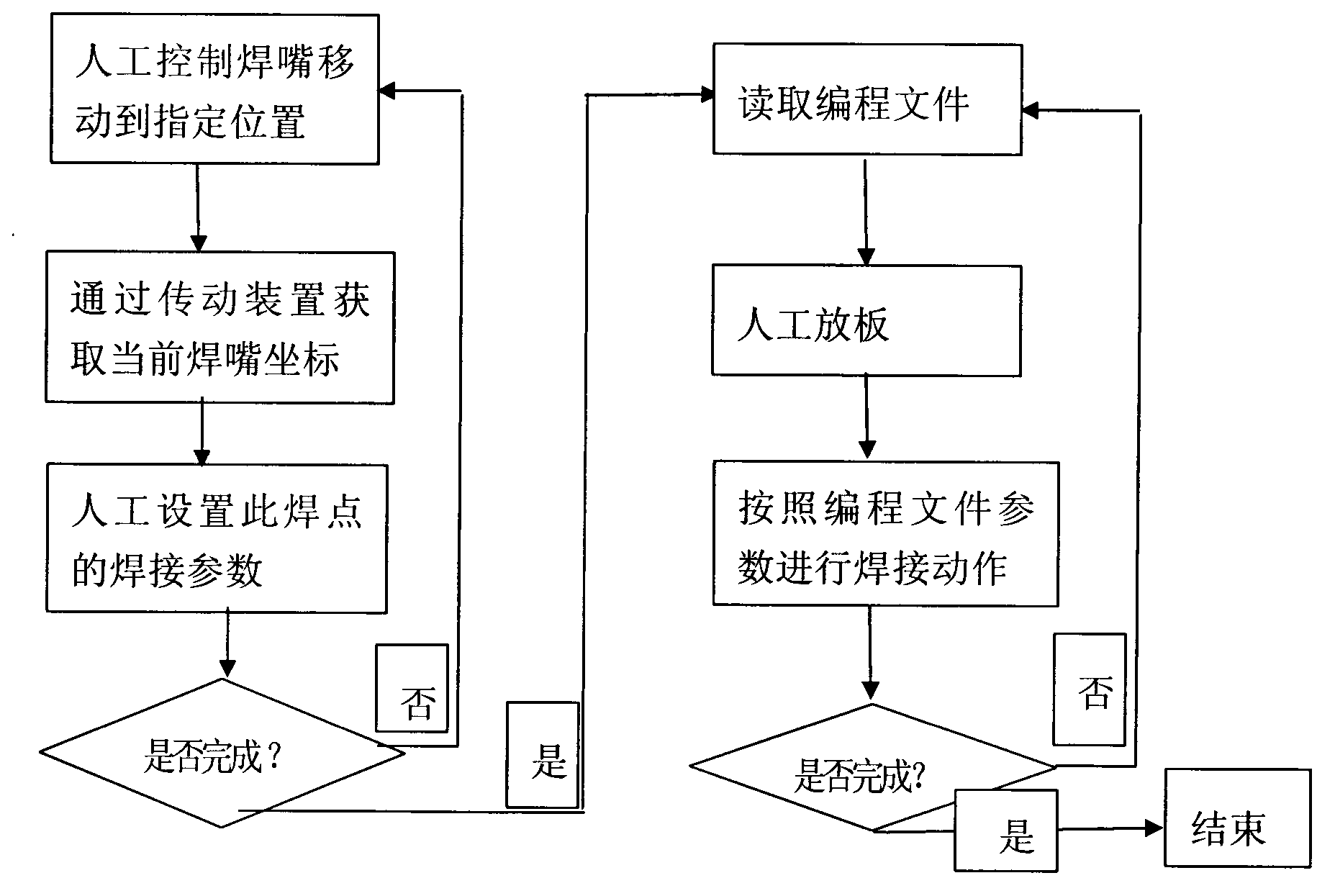

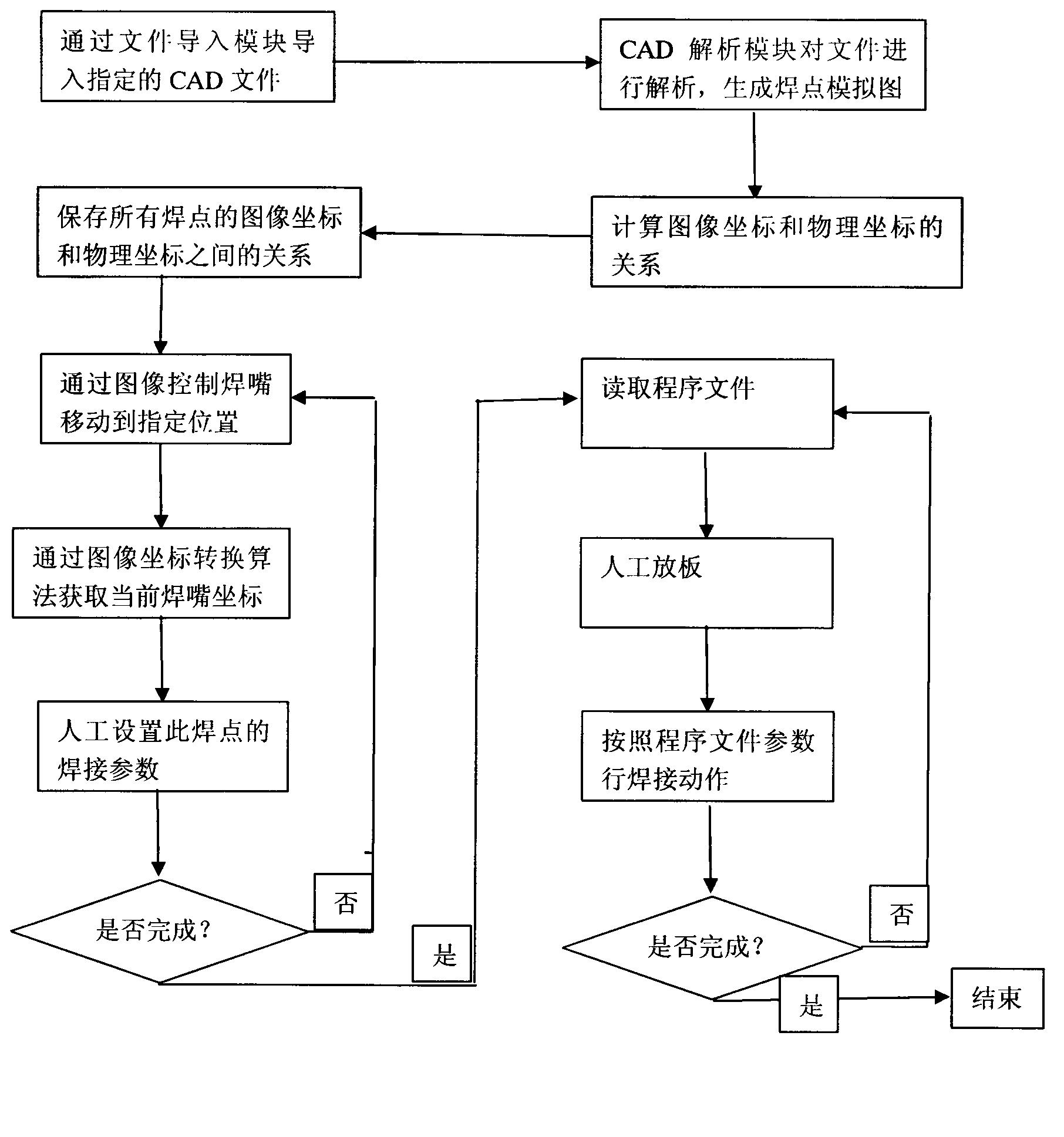

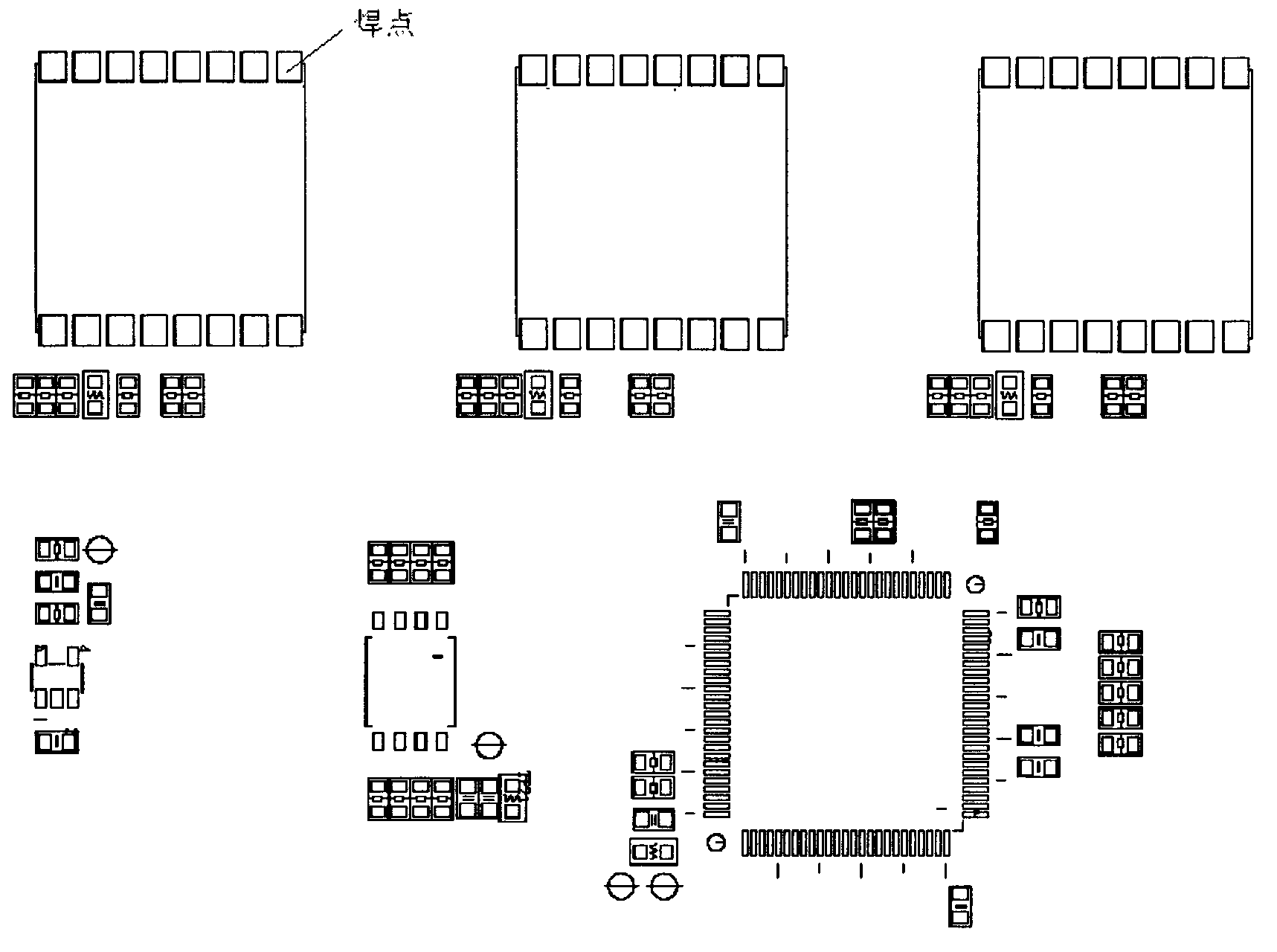

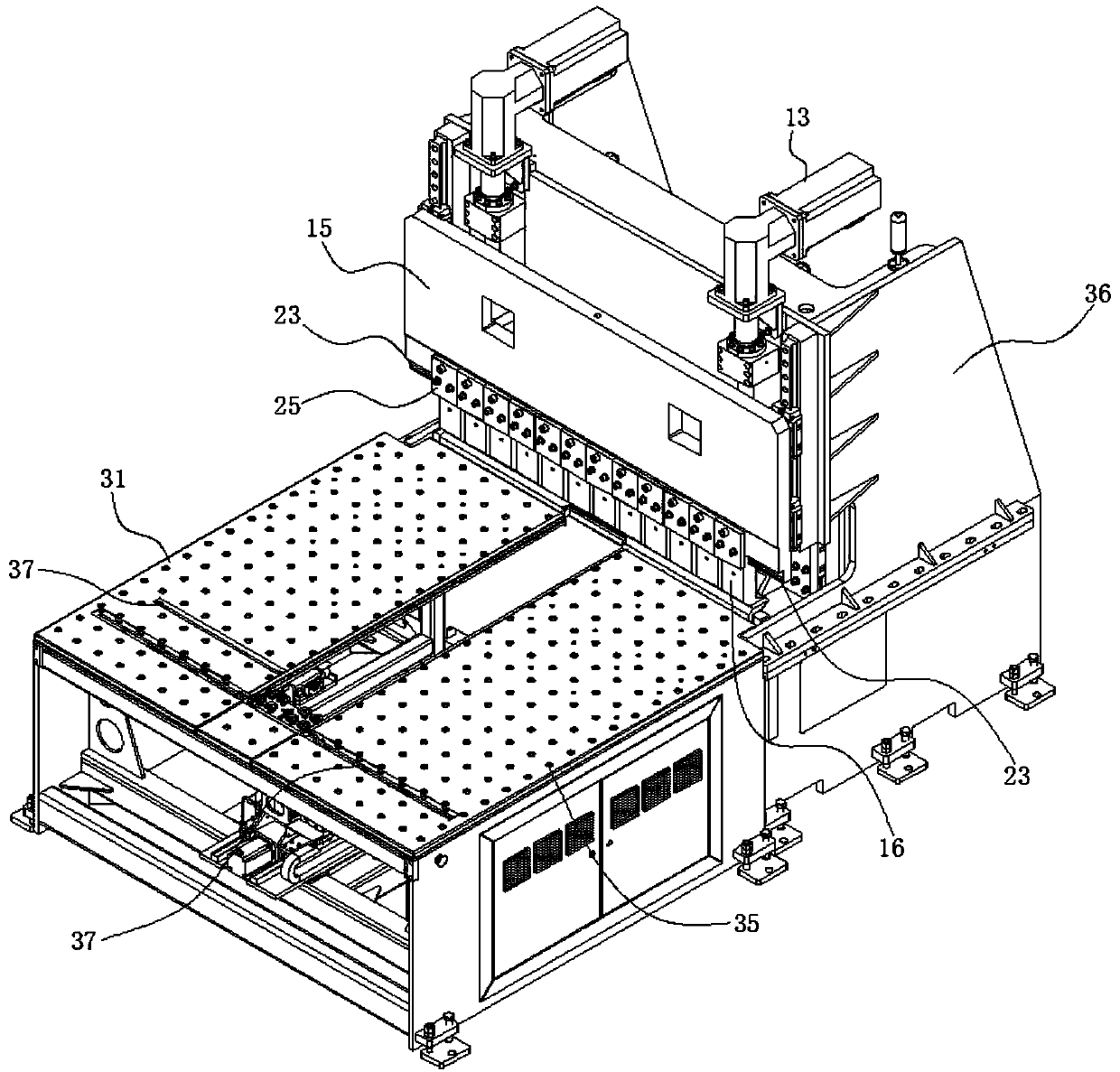

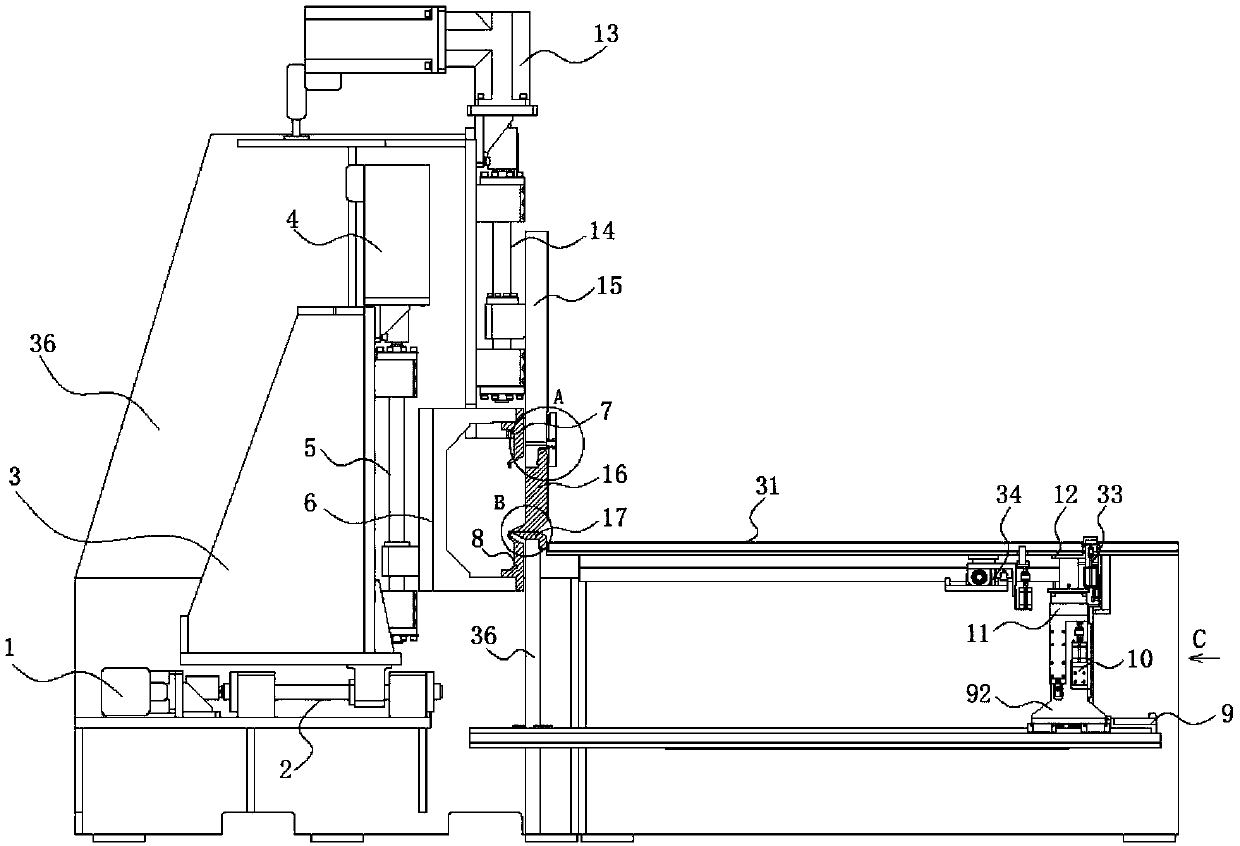

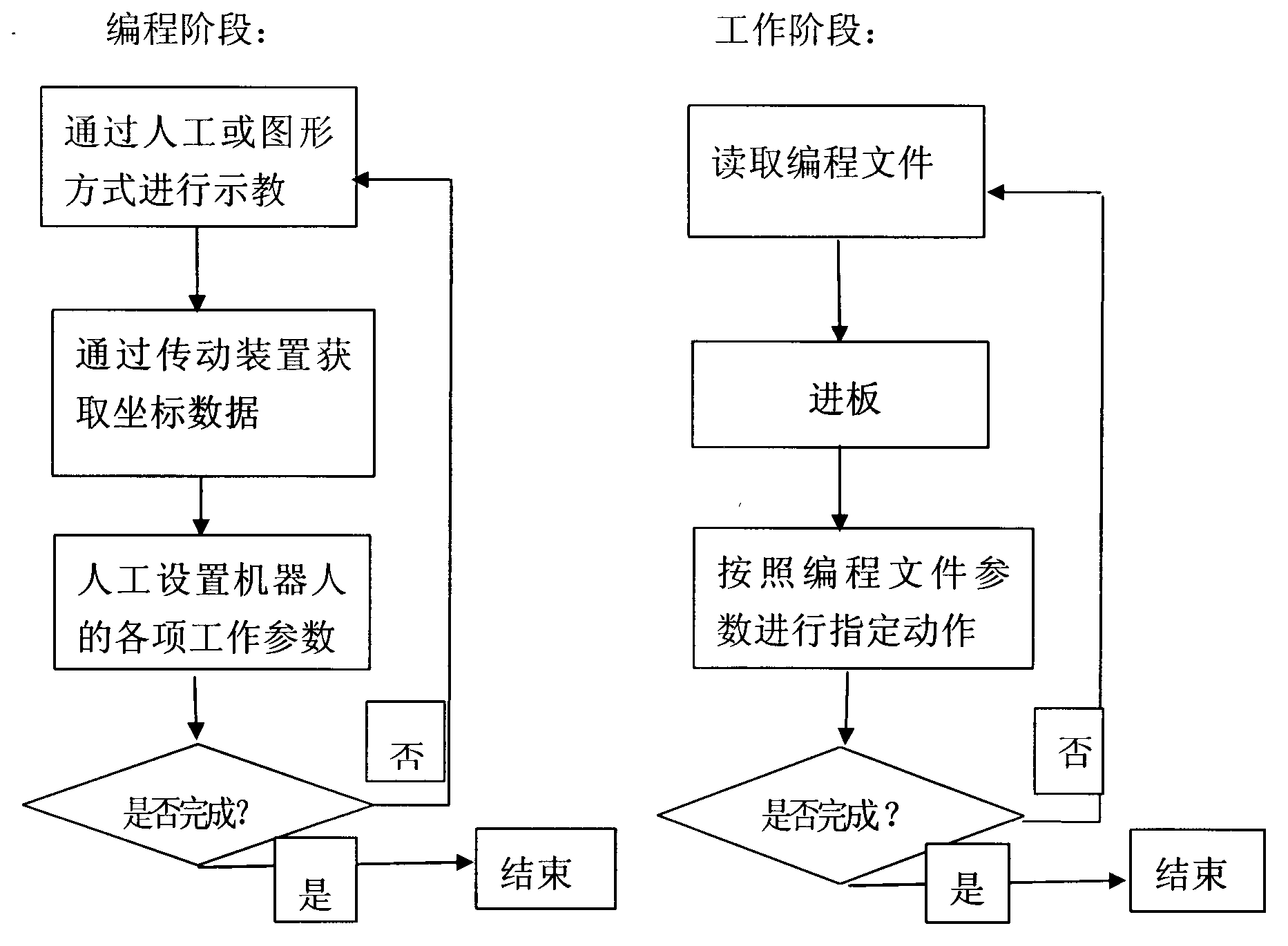

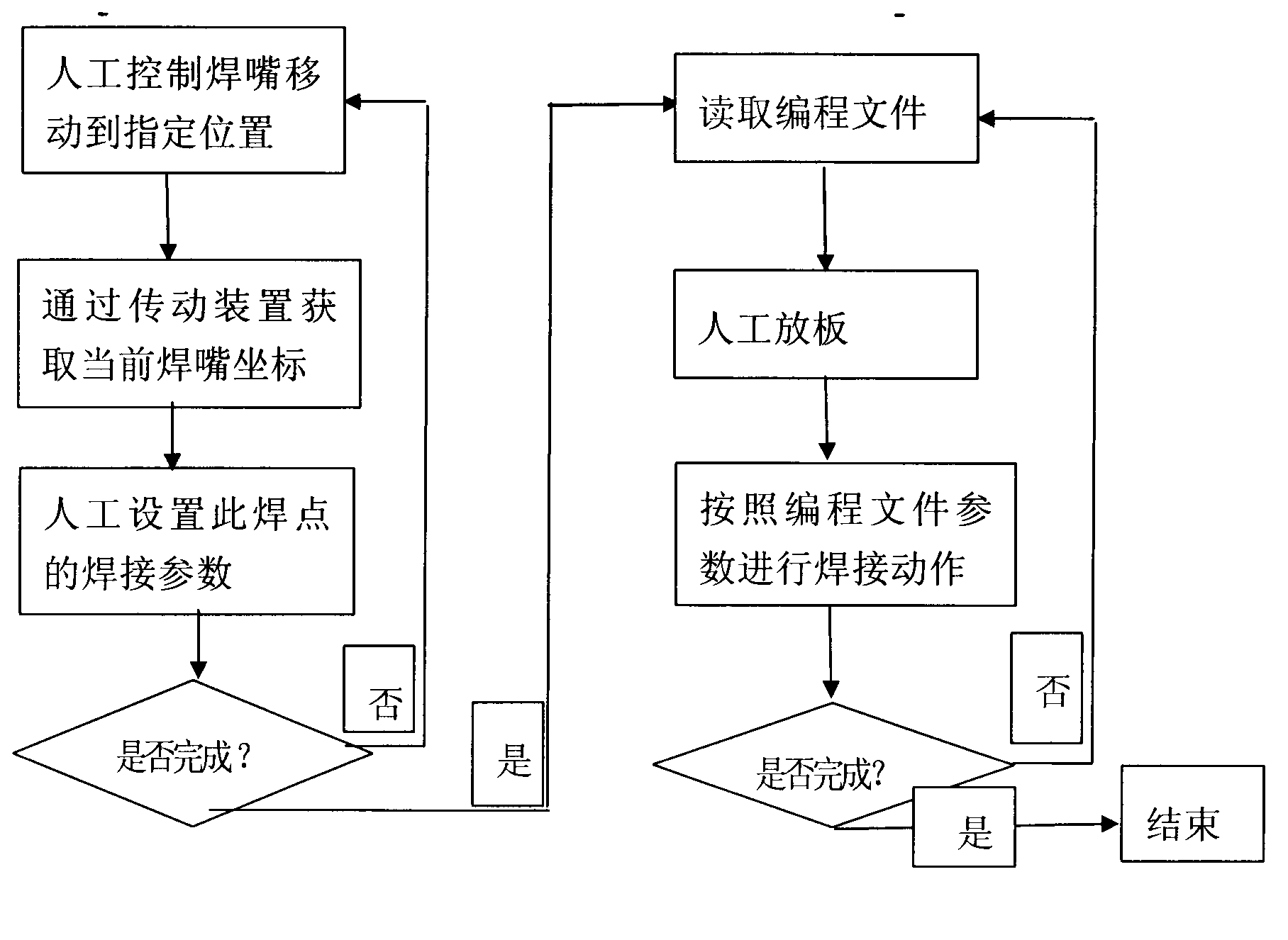

Method for improving programming speed and precision of soldering robot by using computer-aided design (CAD) file

ActiveCN102990179APrecise angle of rotationAccurate compensationMetal working apparatusGraphicsComputer Aided Design

The invention discloses a method for improving programming speed and precision of a soldering robot by using a computer-aided design (CAD) file. The method comprises the following steps of: (1) introducing the CAD file comprising a printed circuit board (PCB) into a programming file; (2) analyzing the CAD file, and converting the programming file into a supportable file format; (3) generating a corresponding CAD graph in the programming file, wherein the graph comprises precise position information of all the welding disks; (4) processing the generated CAD graph, and constructing a relation between graph coordinates and object coordinates; (5) selecting a welding point to be welded on the processed CAD graph, obtaining actual physical coordinates according to the coordinate conversion relation obtained in step (4), and moving a welding nozzle to a position with the actual physical coordinates so as to perform parameter setting and welding; and (6) finding other welding points by the method in step (5), and welding. By adopting the method, a camera is not required to shoot a thumbnail, and the programming time is shortened; the rotating angle of the PCB can be accurately calculated and can be compensated; and the welding precision is improved.

Owner:廖怀宝

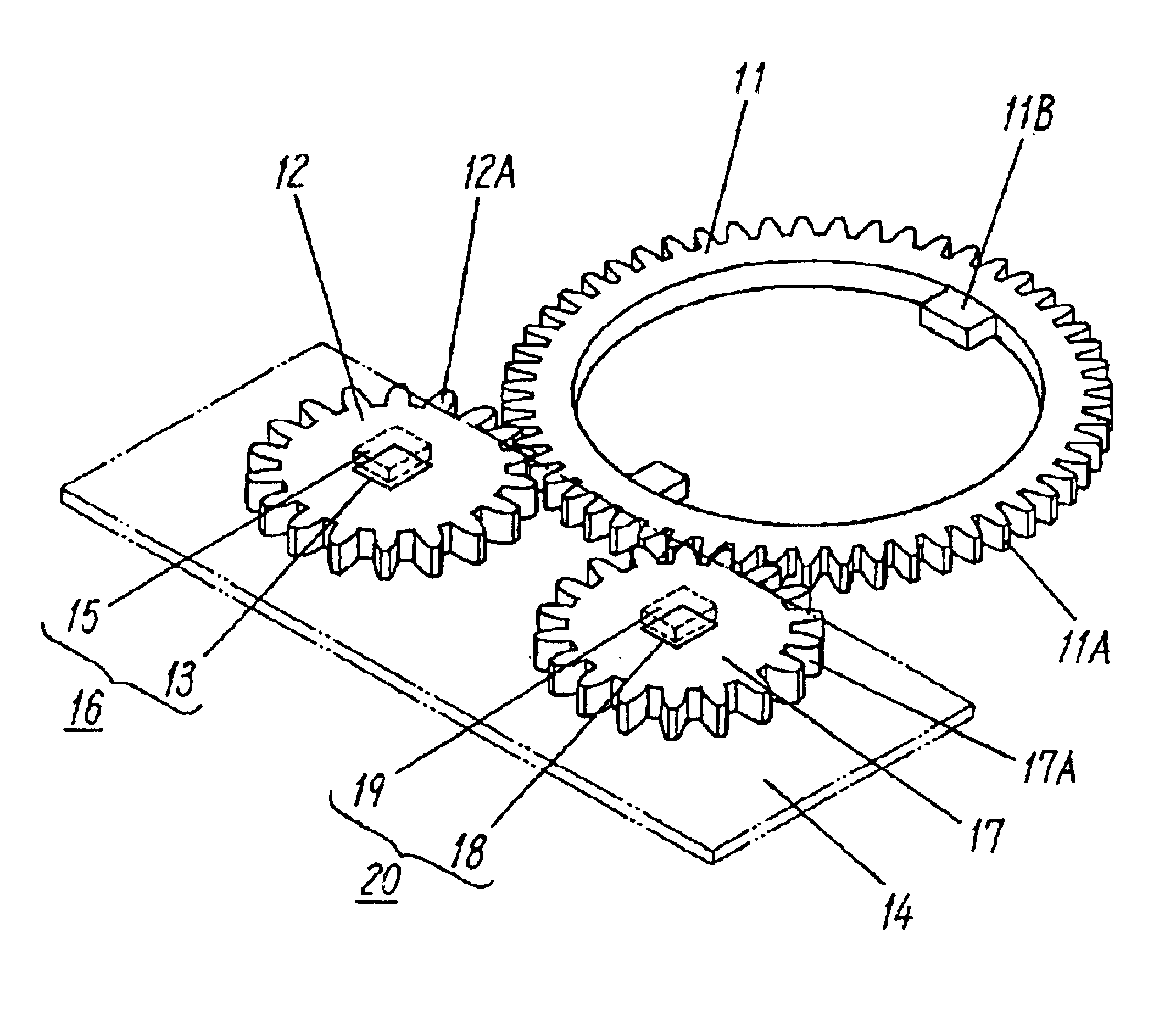

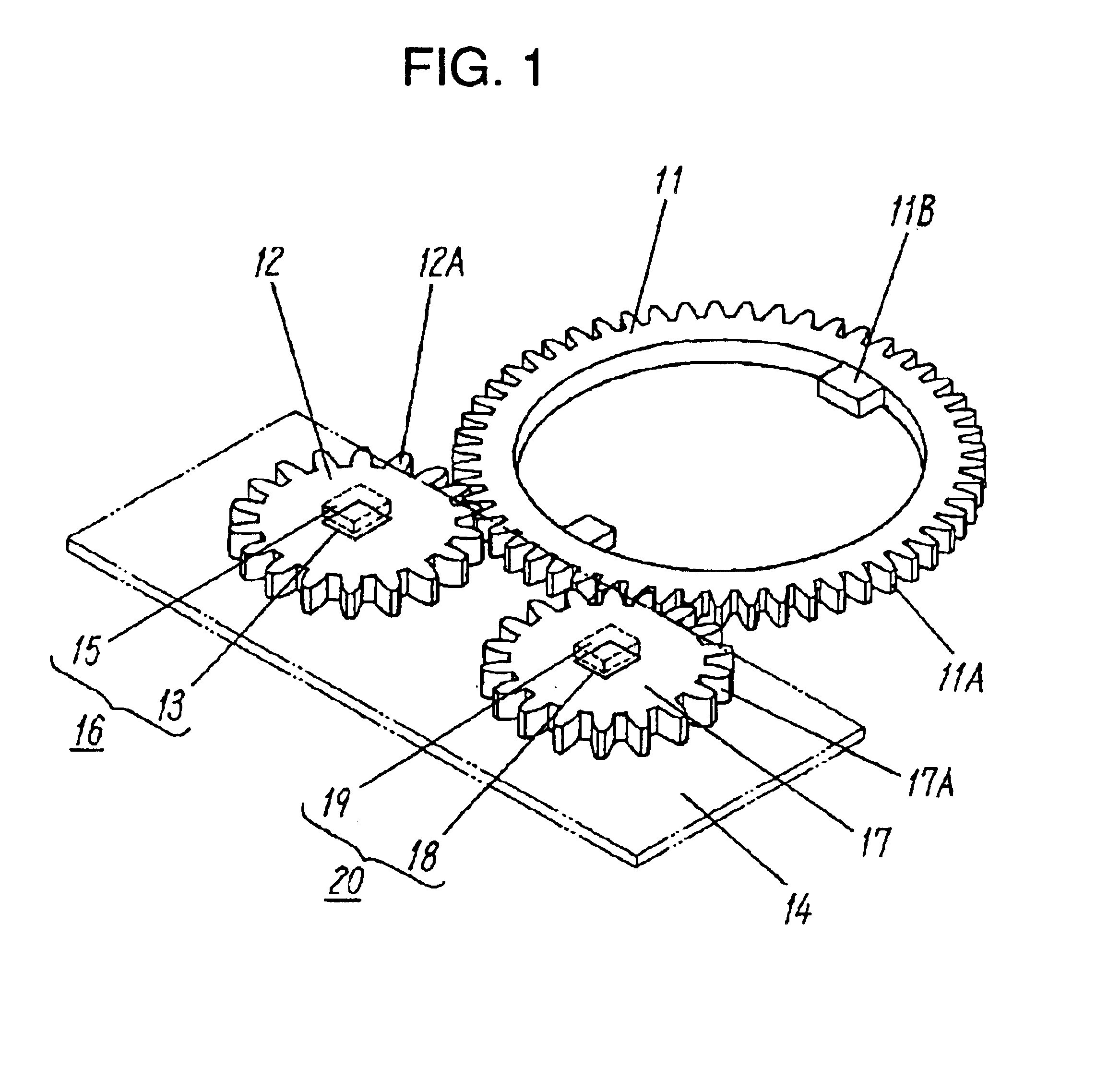

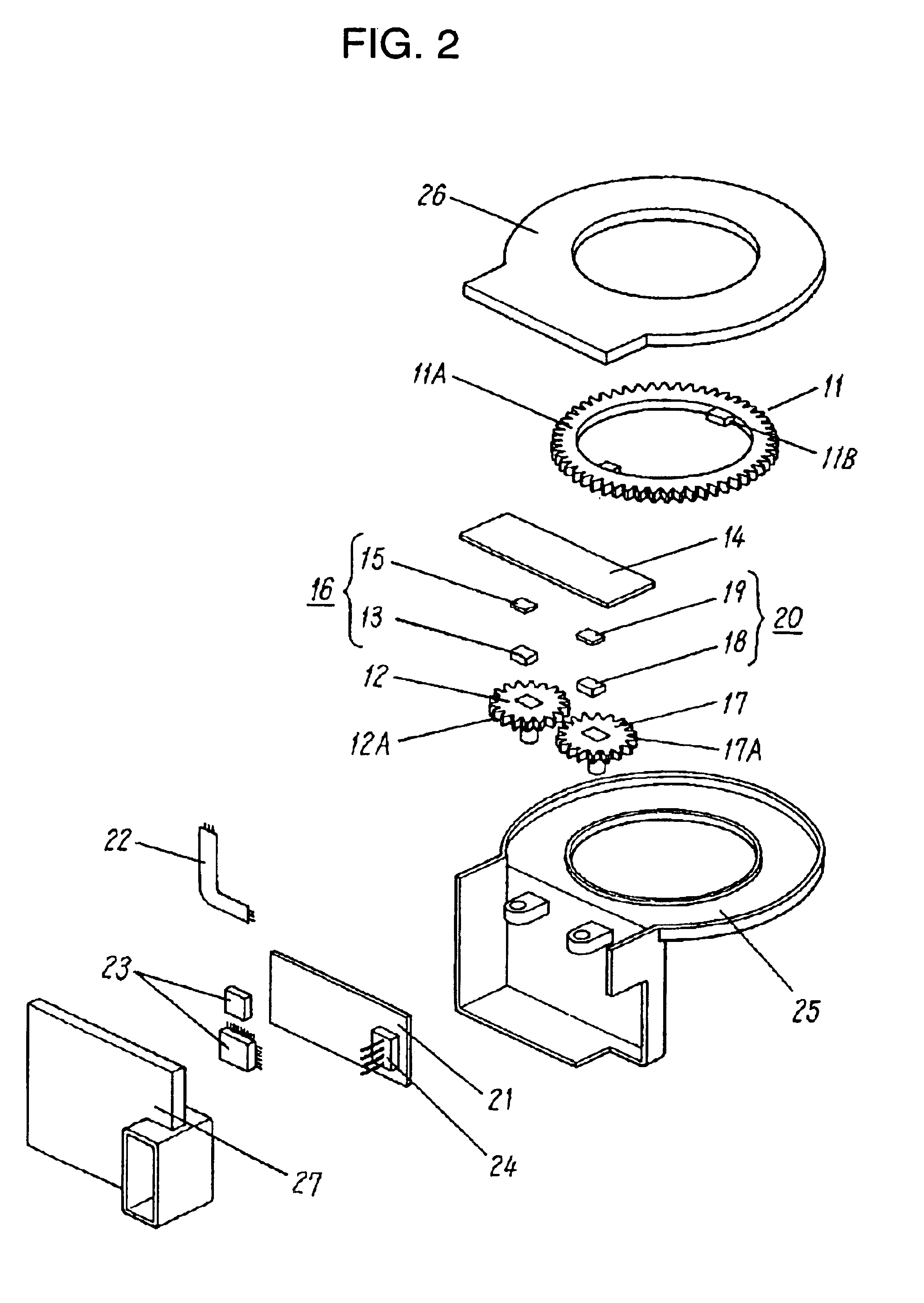

Rotation angle detector

InactiveUS6909282B2Simple structurePrecise angle of rotationSolid-state devicesMagnetic field measurement using galvano-magnetic devicesControl unitPhysics

A rotation angle detector includes a rotor, first and second detecting elements which rotate according to a rotation of the rotor, first and second detecting units for detecting rotations of the first and second detecting elements, respectively, and a control unit for detecting a rotation angle of the rotor based on a first signal when a difference between the first and second signals output from the first and second detecting units ranges within a predetermined range. The rotation angle detector has a simple structure and detects the rotation angle of the rotor accurately

Owner:PANASONIC CORP

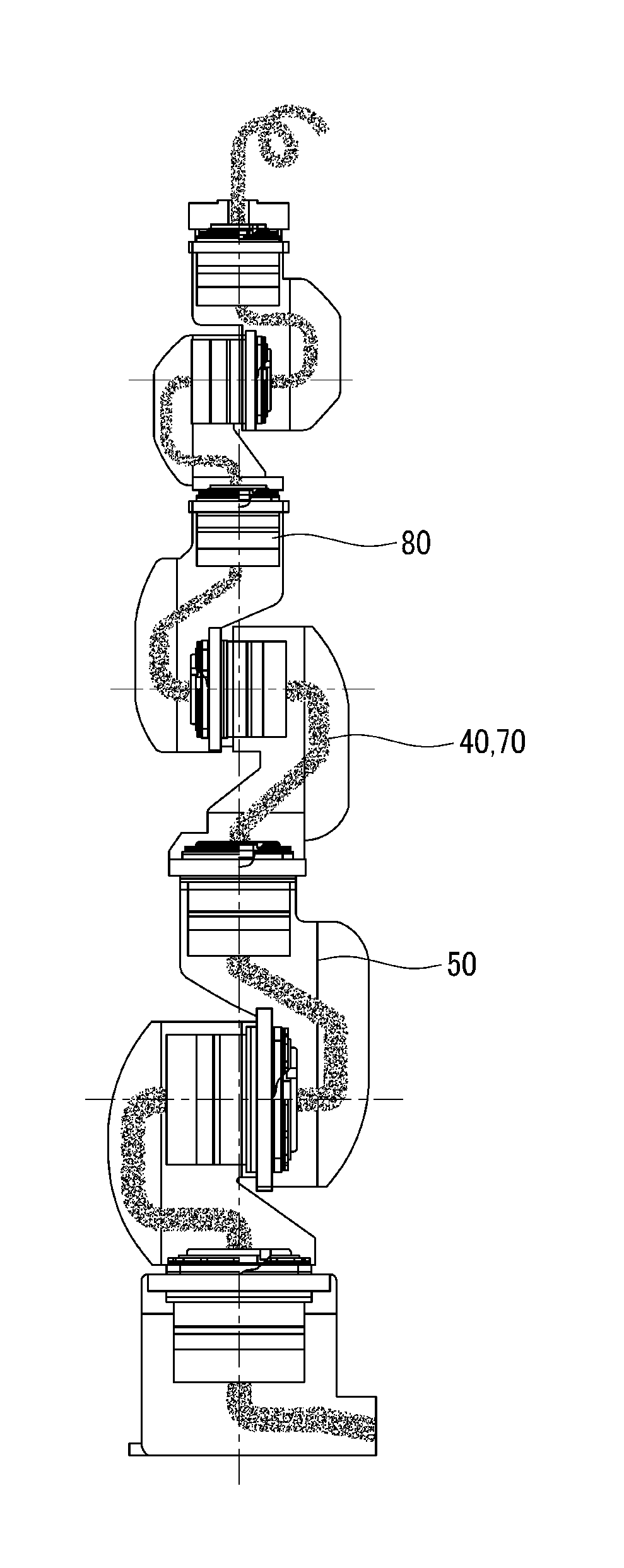

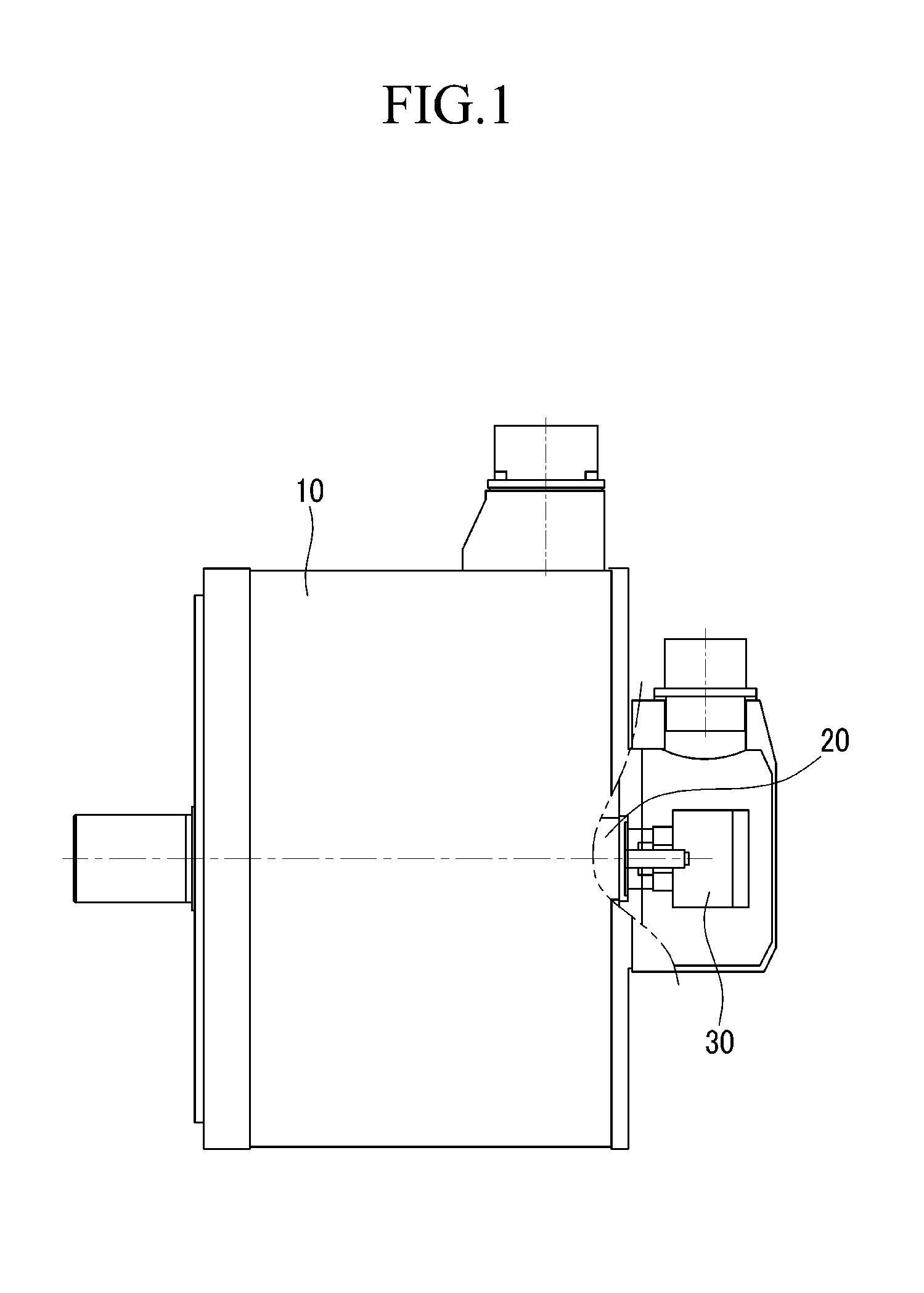

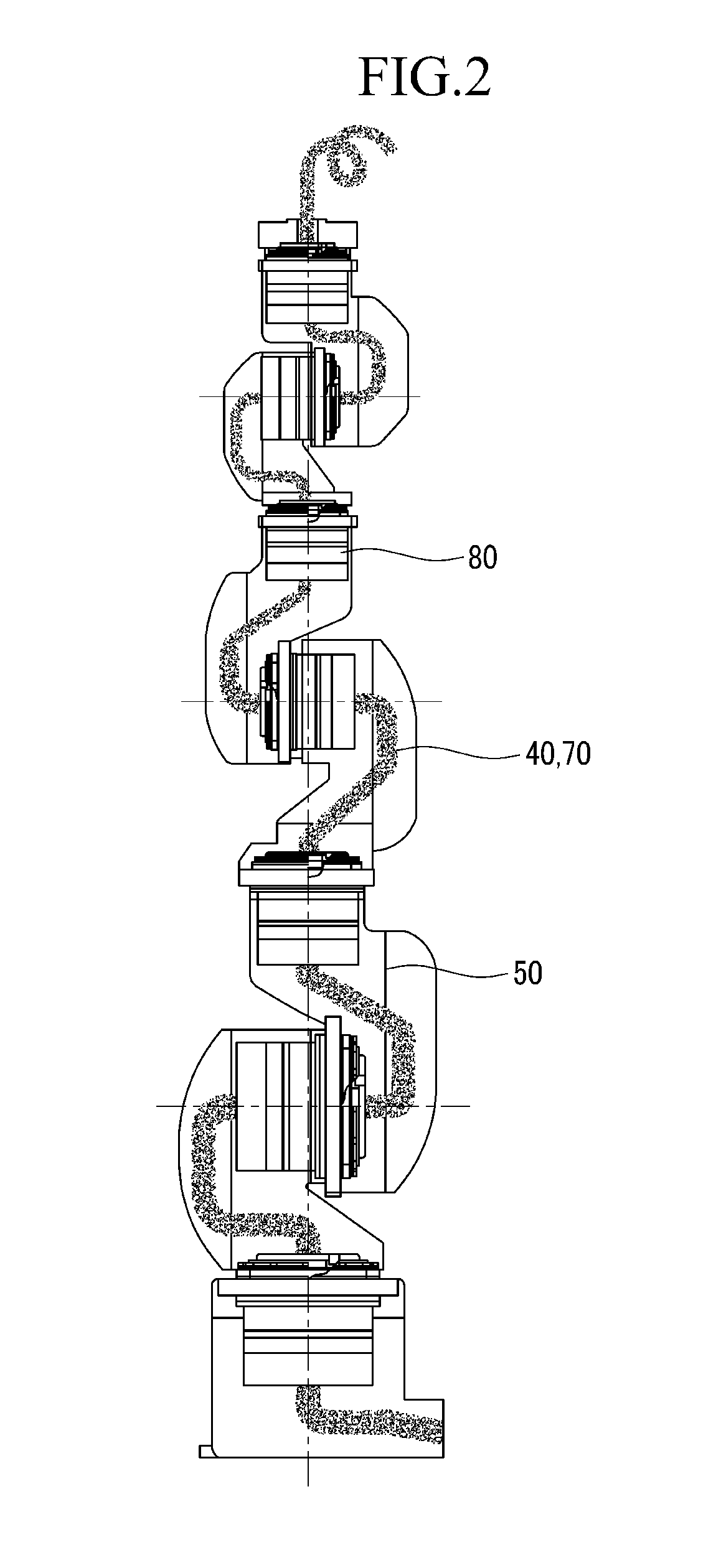

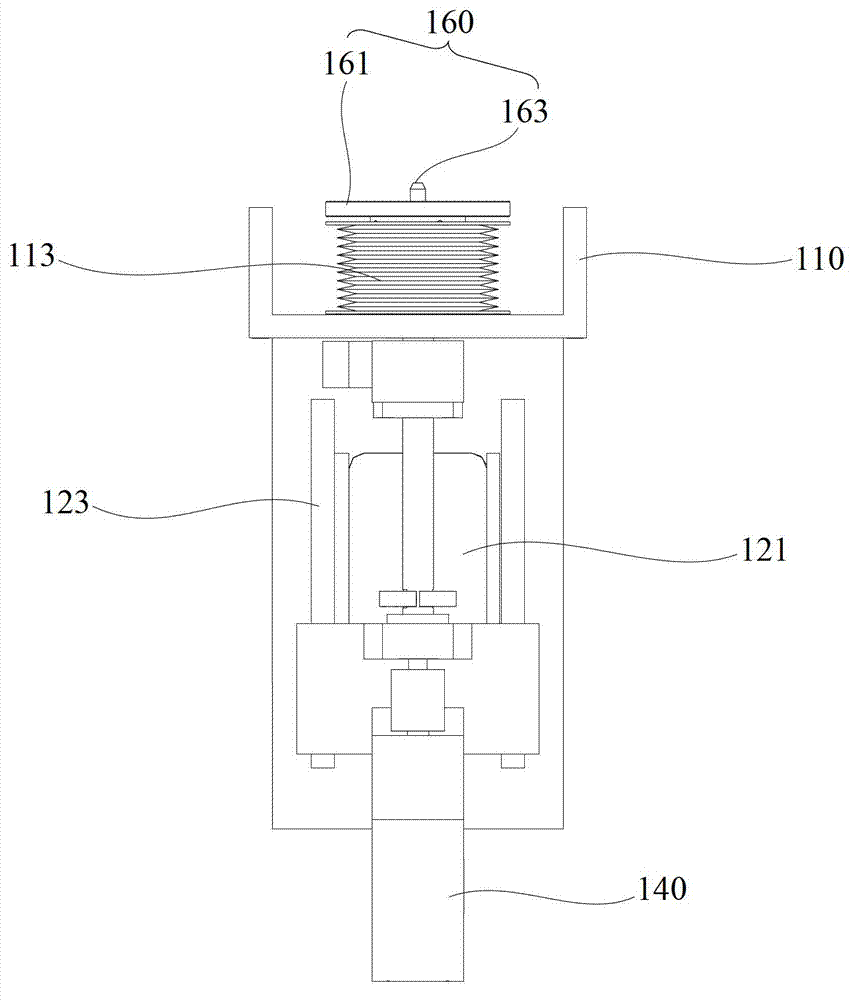

Hollow driving module

ActiveUS20130257230A1Precise angle of rotationCable twist is preventedDC commutatorStructural associationReduction driveTorque transmission

The present invention relates to a hollow driving module comprising a hollow driving module including a hollow motor including a stator, a rotor rotating with respect to the stator and having a perforated center portion, and a rotation shaft disposed at and coupled to the perforated center portion of the rotor; a decelerator connected with the rotation shaft positioned at an output side of the hollow motor to decelerate rotation of the rotation shaft; a torque transmission unit being connected to an output side of the decelerator to be driven by a decelerated rotation angle; a first encoder positioned at an input side opposite to a side connected with the decelerator of the hollow motor; a second encoder positioned at a side opposite to a side connected with the hollow motor of the first encoder; and a link connection means connecting the second encoder with the torque transmission unit.

Owner:KOREA INST OF MACHINERY & MATERIALS

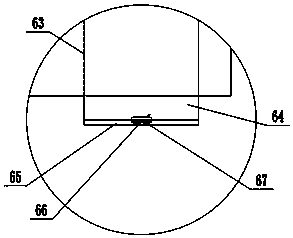

Method for positioning Mark points of PCB (printed circuit board) by image matching

ActiveCN102873420AHigh compensation accuracyPrecise angle of rotationSoldering apparatusReference imageImage matching

The invention discloses a method for positioning Mark points of a PCB (printed circuit board) by image matching. The method is characterized by comprising steps of using a group of Mark point region images shot during programming as reference images; searching by the aid of the images in a scanning manner when detection is carried out; determining that a detected image contains detected Mark points when the size and the shape of the searched image are identical to those of the reference Mark point images; and finally compensating the PCB by deflection among reference Mark points and the detected Mark points. The method has the advantages that comparison is carried out on the basis of image matching, an algorithm and shapes of the Mark points are irrelevant, compensation precision is high, and the problem of inaccurate welding of the PCB due to the fact that the PCB is deflected when the PCB is compensated and then is welded is avoided.

Owner:廖怀宝

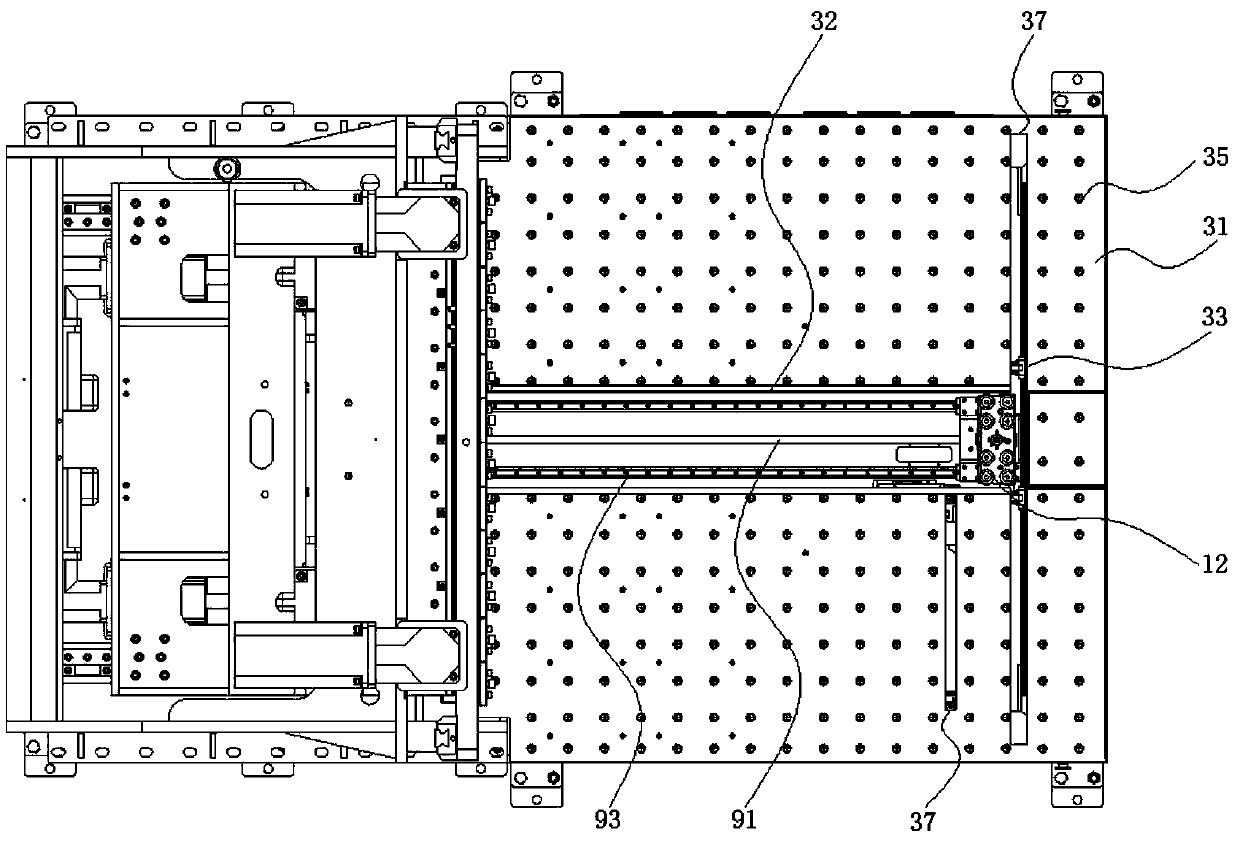

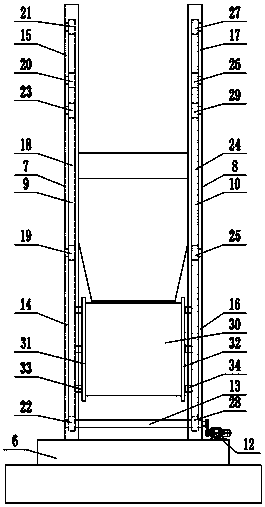

Multi-shaft drive bending machine and bending method thereof

PendingCN110538899AImprove work efficiencyReasonable and reliable structureShaping toolsMetal-working feeding devicesDischarge - actionPress brake

The invention discloses a multi-shaft drive bending machine which comprises a bending system and an integrated feeding and discharging system. The bending system comprises a horizontal bending drive device. A horizontal bending shaft arranged in the horizontal direction is installed on the horizontal bending drive device. A linkage support is installed on the horizontal bending shaft. An up and down bending drive device is further arranged at the upper end of the linkage support. An up and down bending shaft installed in the vertical direction is installed on the up and down bending drive device. A bending cutter support is installed at the shaft end of the up and down bending shaft. An upper bending cutter and a lower bending cutter are installed at the upper end and the lower end of thebending cutter support correspondingly, wherein the upper bending cutter and the lower bending cutter correspond in upper and lower position. According to the multi-shaft drive bending machine, by means of coordinative matching and adjusting of bending drive, the upper bending cutter and the lower bending cutter can reach different positions, a down pressing drive lifting device cooperates to control down pressing fixing and loosening of an upper pressing cutter and feeding and discharging action of feeding and discharging drive, and bending of bent parts in any shape, at any angle and with any flexible radian is completed.

Owner:南京蓝昊智能科技有限公司

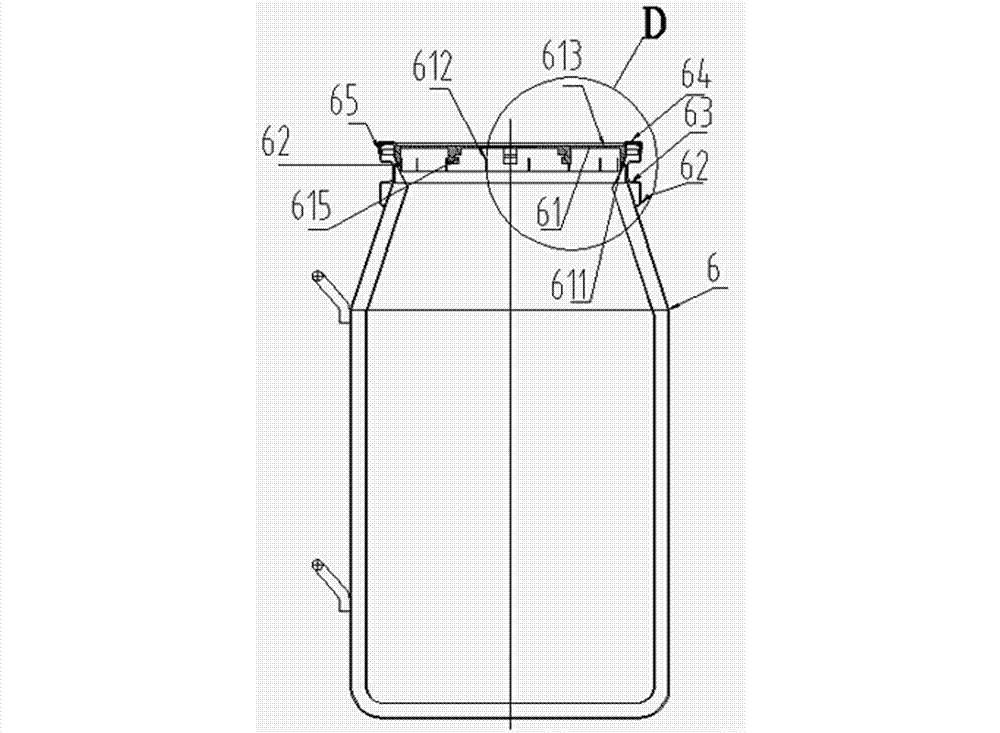

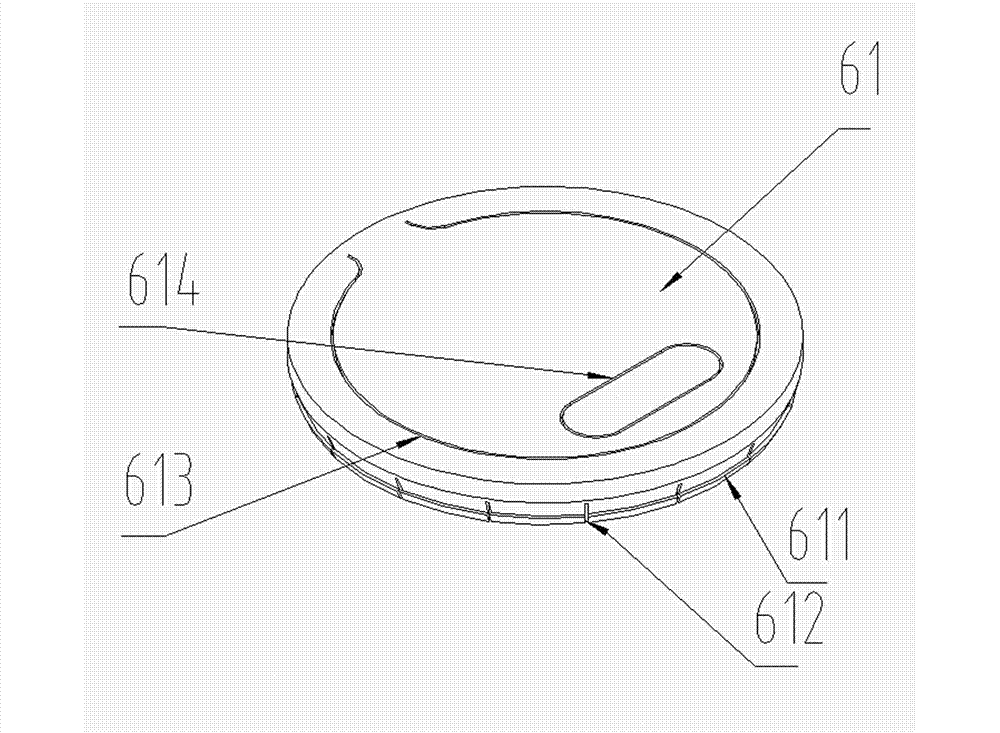

Packaging machine capable of being applied to sampling industry

ActiveCN102730212ASimple structureEasy to controlClosure with auxillary devicesCans/barrels/drumsControl systemProcess engineering

The invention discloses a packaging machine capable of being applied to the sampling industry. The packaging machine comprises a machine frame, wherein a sample inlet mechanism, an automatic cover pressing device, a sample discharge mechanism, a conveying mechanism and a control system are mounted on the machine frame; a plurality of sealable charge buckets are arranged on the conveying mechanism; the motion trails of the charge buckets on the conveying mechanism are connected in series with the sample inlet mechanism, the automatic cover pressing device and the sample discharge mechanism in sequence; and the bucket covers of the charge buckets are pressed to the tops of the charge buckets through the automatic cover pressing device, and mineral samples in the charge buckets are packaged in a sealed way. The packaging machine has the advantages of simple structure, easiness in control process, high running reliability, low fault rate, good sealing property and the like.

Owner:长沙通发高新技术开发有限公司

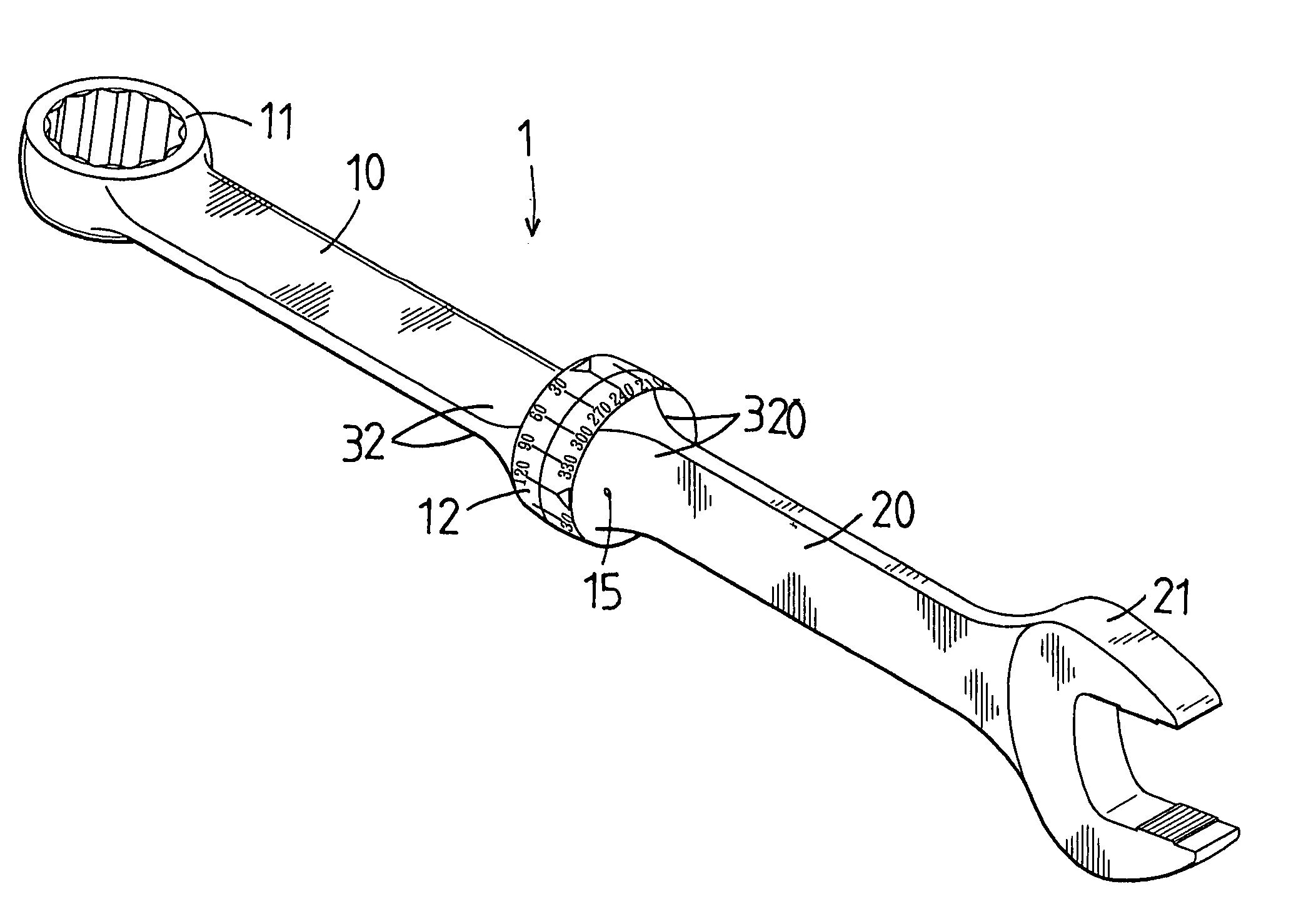

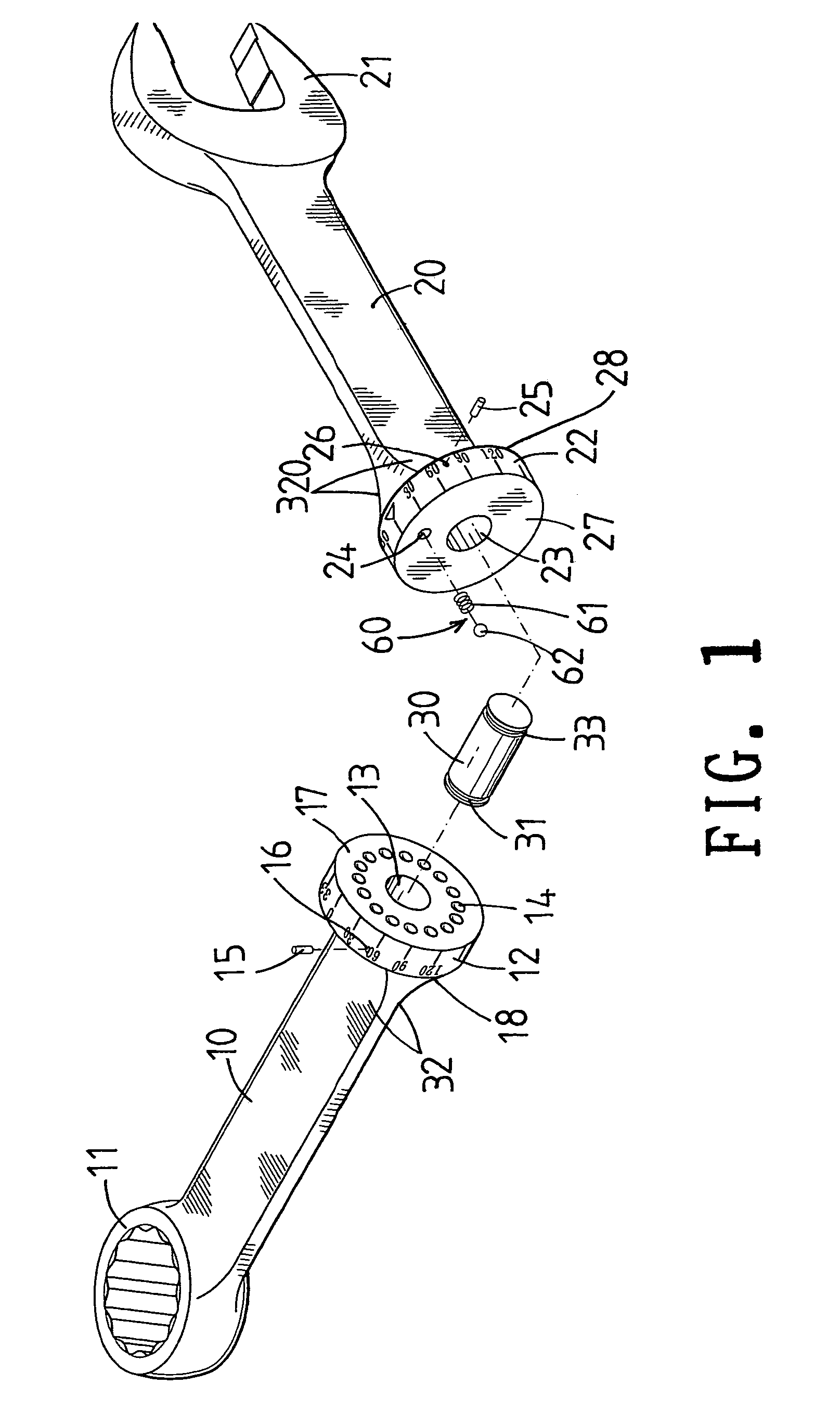

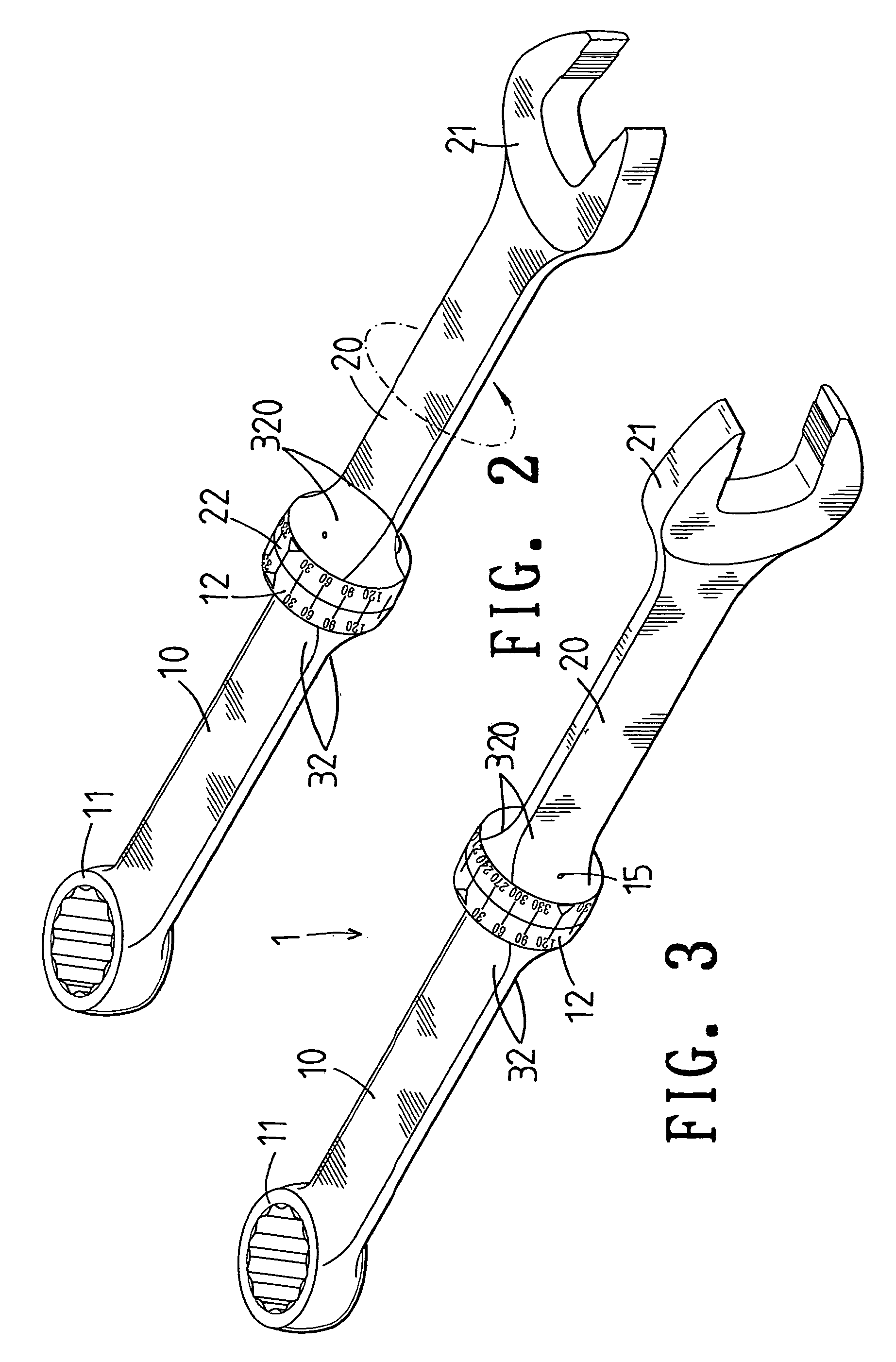

Wrench having rotation adjustment effect

A wrench includes a first handle provided with a first rotation seat, and a second handle provided with a second rotation seat rotatably mounted on the first rotation seat of the first handle. Thus, the first rotation seat of the first handle can be rotated relative to the second rotation seat of the second handle, so that the first handle has a driving face inclined with that of the second handle, thereby facilitating the user operating the first handle or the second handle to rotate the workpiece.

Owner:HSIEN CHIH CHING

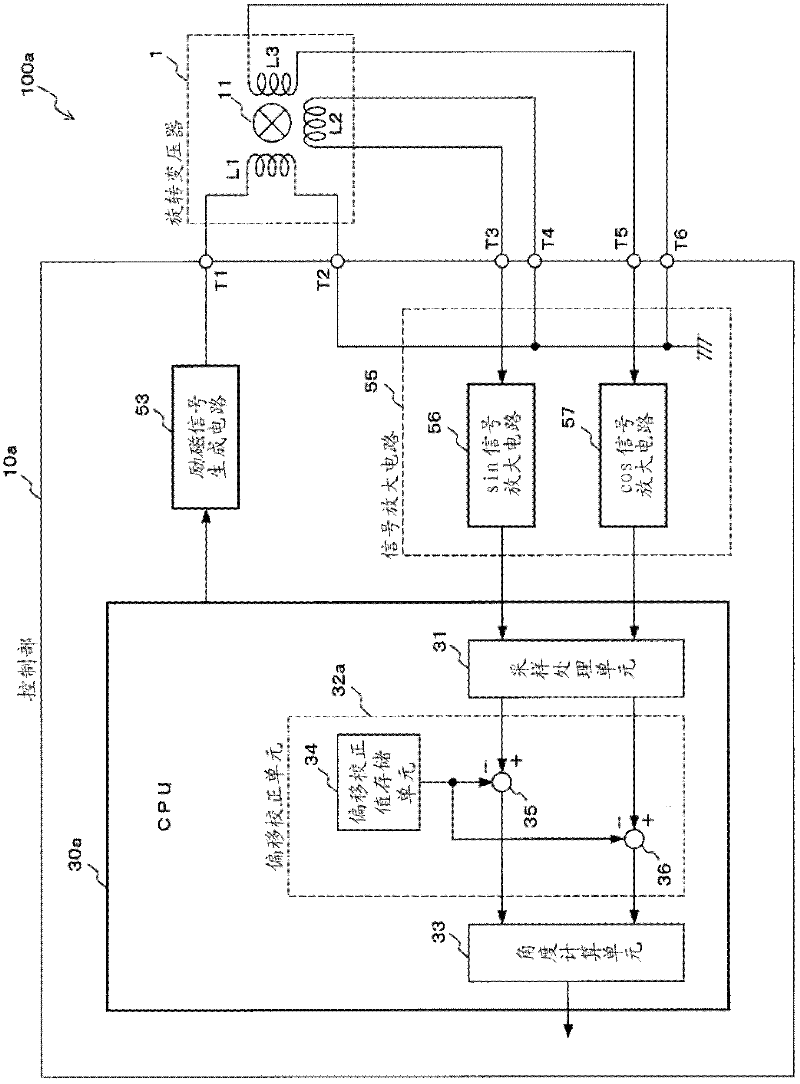

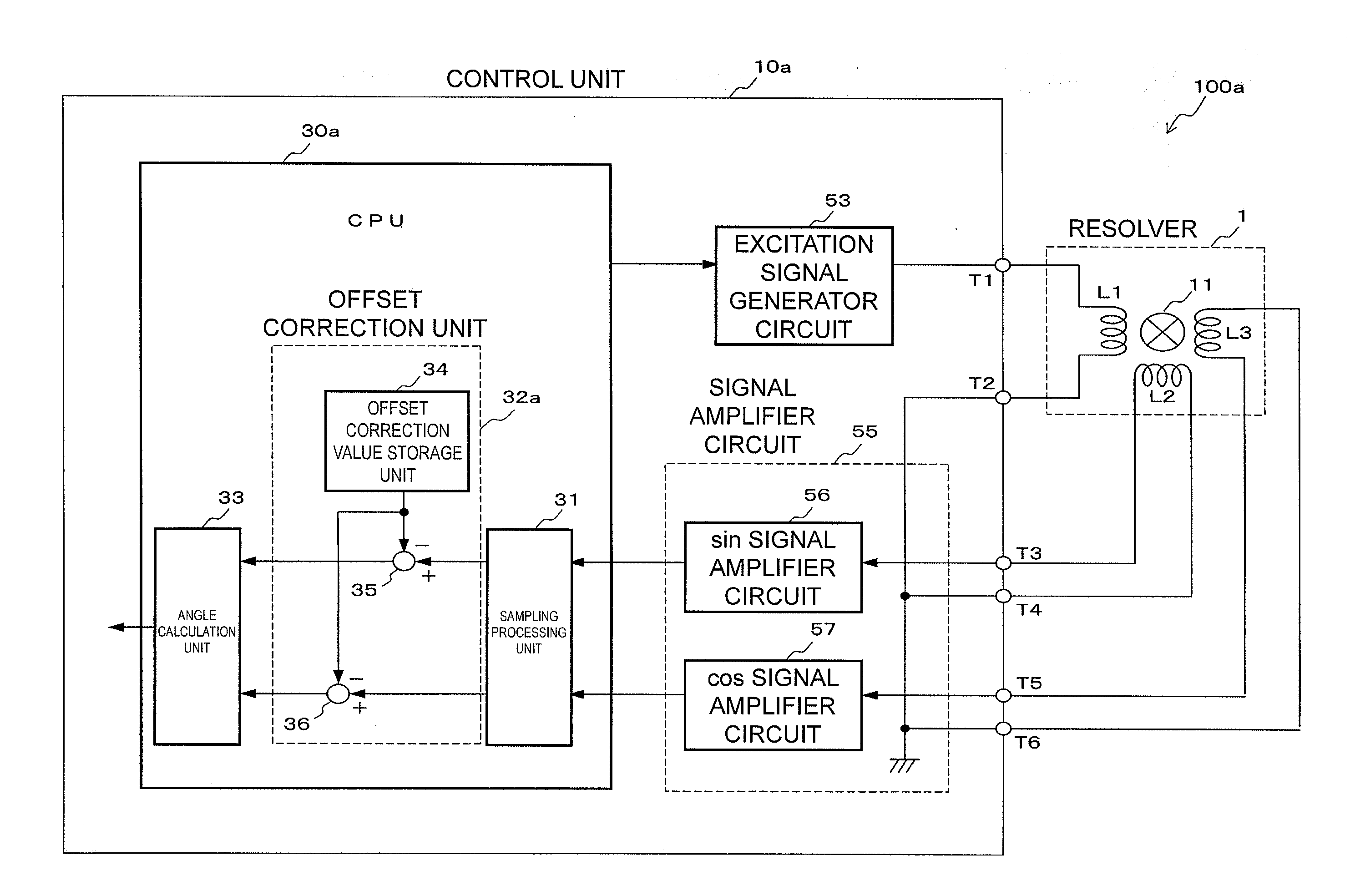

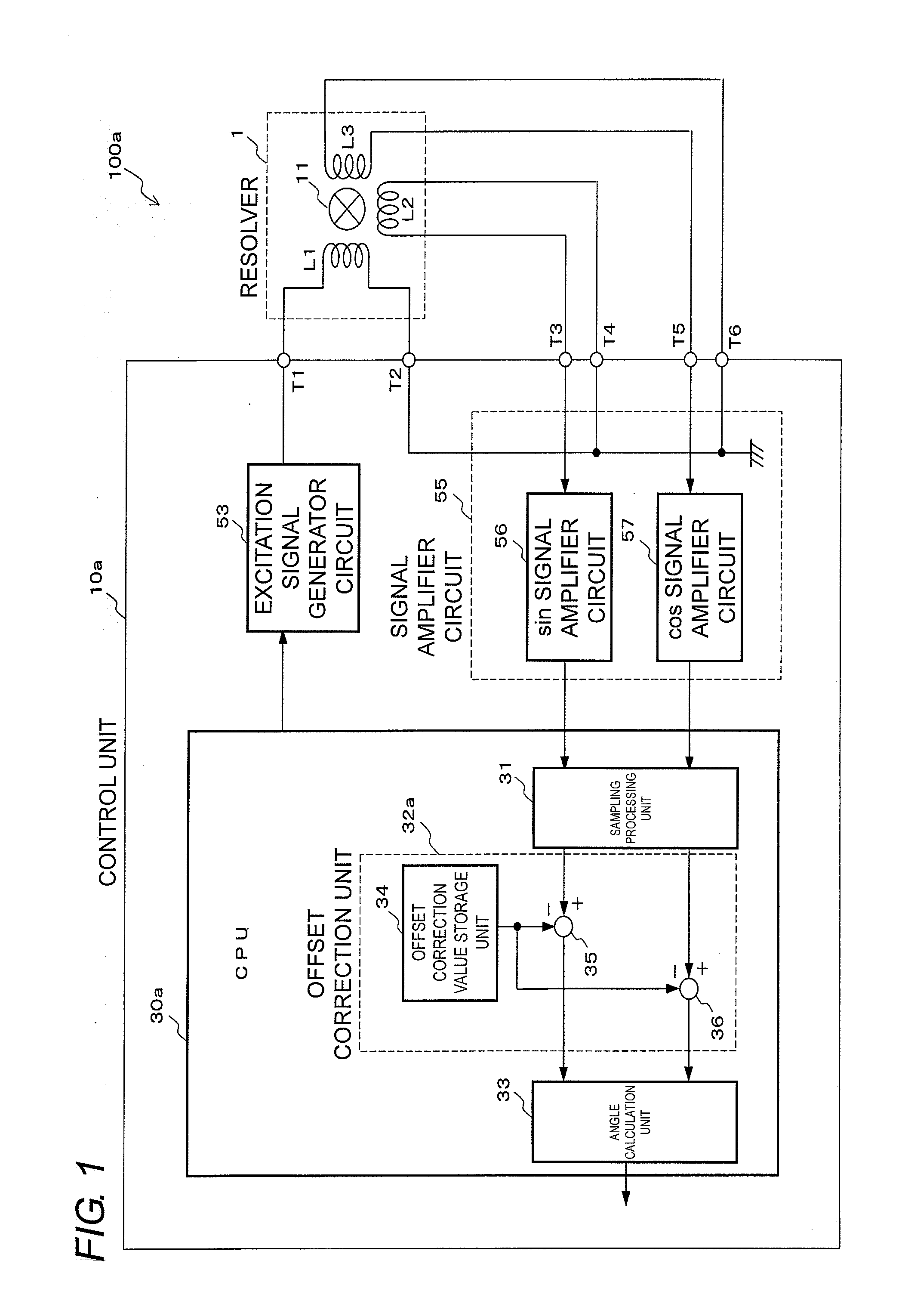

Rotational angle detection device

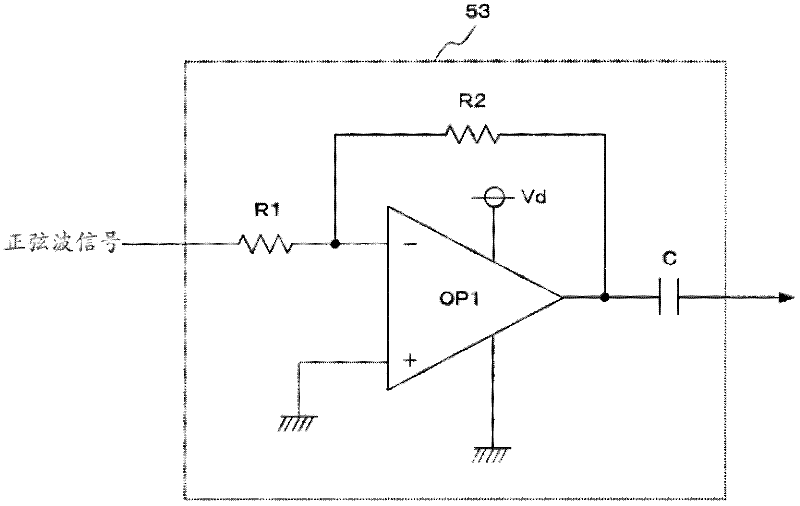

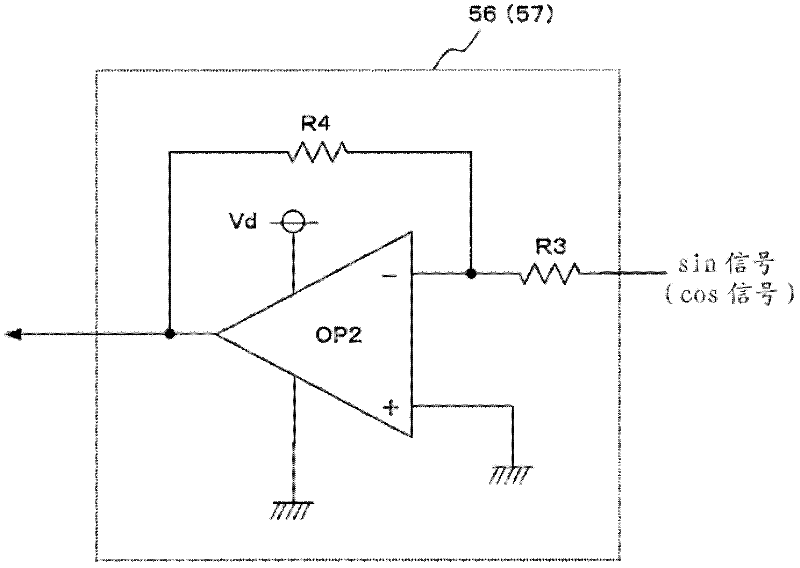

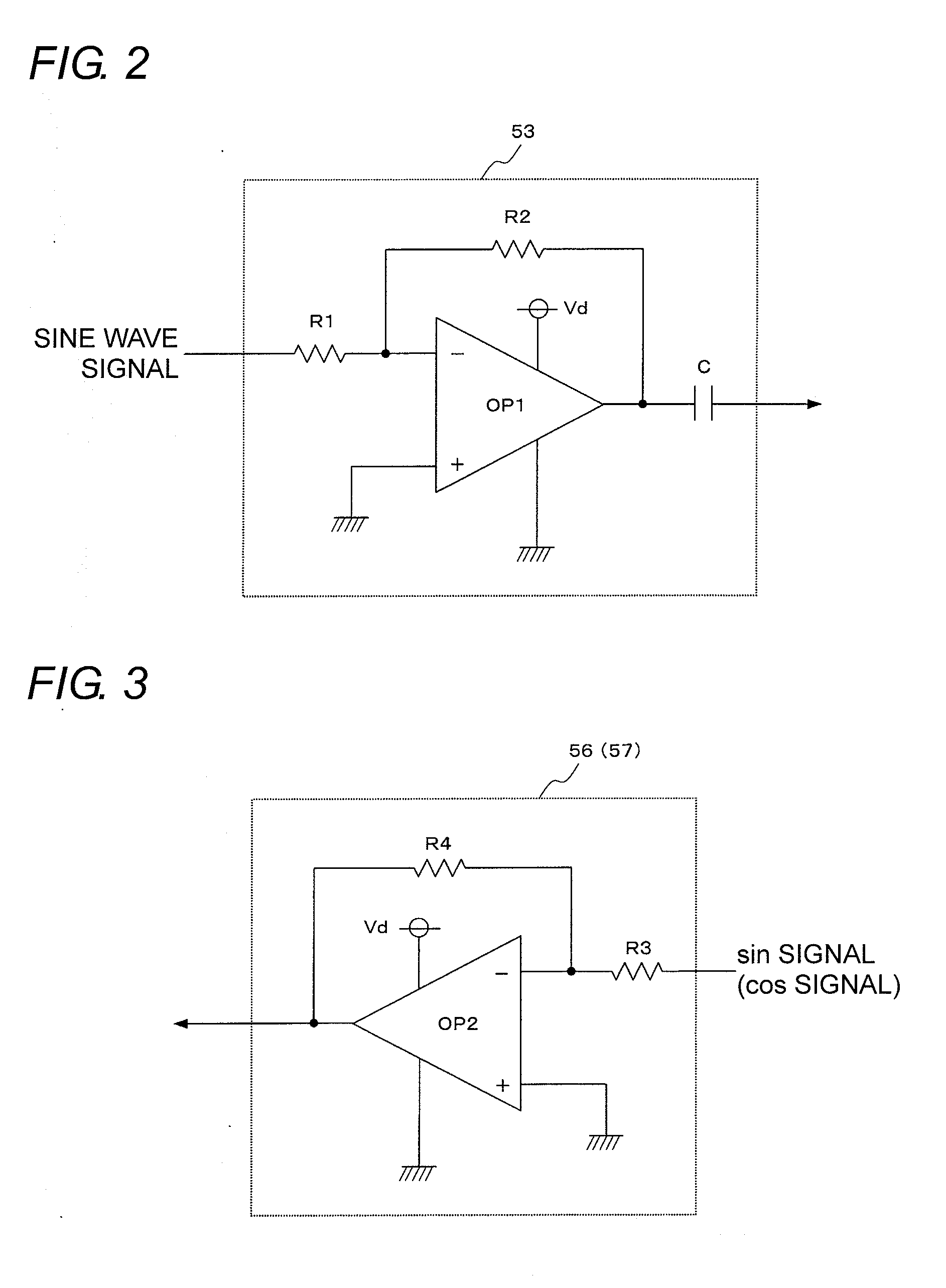

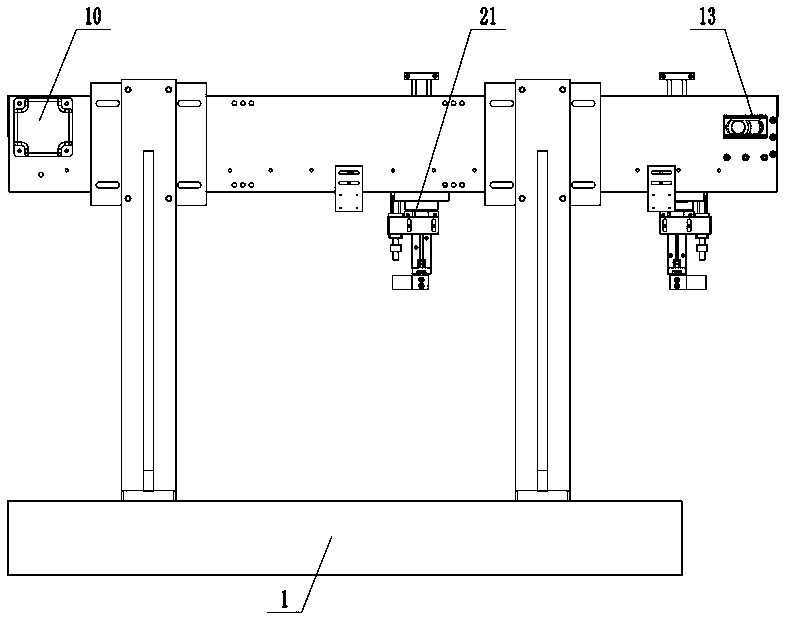

InactiveCN102564294ASimple structureLow costUsing electrical meansDynamo-electric machinesExcitation signalAtomic physics

The present invention provides a rotational angle detection device that reduces cost thereof by simplifying an excitation circuit and is capable of detecting an angle accurately even in the case where offsets occur in output signals. The rotational angle detection device (100a) has a resolver (1) in which an excitation coil (L1) and a output coil (L2, L3) are provided , an excitation signal generator circuit (53) that generates an excitation signal and sends the excitation signal to the excitation coil (L1), and CPU (30a) which detects the amplitudes of the output signals of the output coils (L2, L3) in a predetermined cycle and calculates the rotational value with the value detected. CPU (30a) comprises an offset correction value storage unit (34) that stores offset correction value for correcting the offsets of the two sampling signals obtained from the respective output signal of the output coil (L2, L3). An angle calcualtion unit (33) calculates the rotational angle based on the respective sampling unit with offsets removed.

Owner:OMRON AUTOMOTIVE ELECTRONICS CO LTD

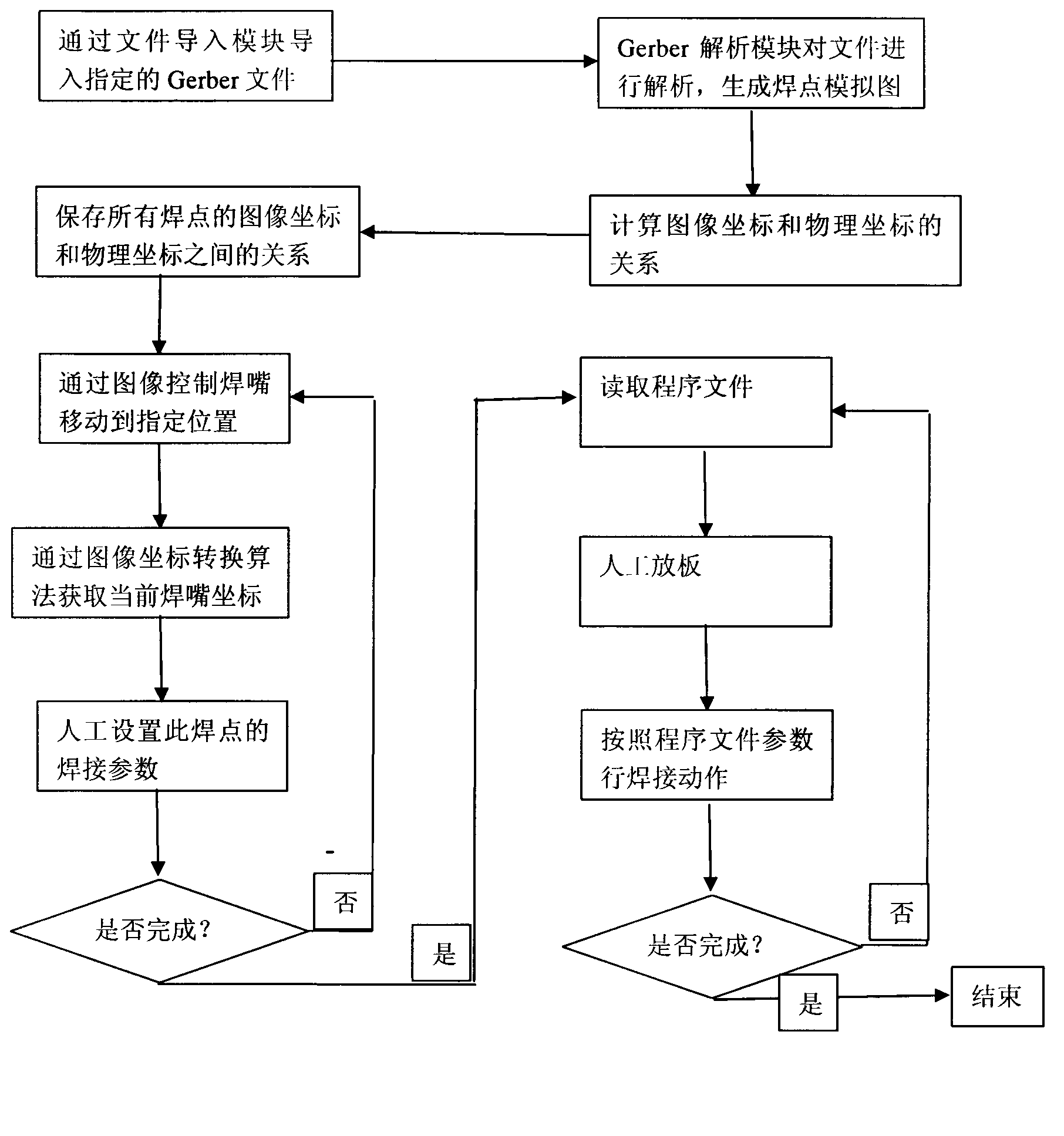

Method for improving programming speed and precision of soldering robot by using Gerber file

ActiveCN102990178AShorten programming timeImprove welding precisionMetal working apparatusSolderingPrinted circuit board

The invention discloses a method for improving programming speed and precision of a soldering robot by using a Gerber file. The method comprises the following steps of: (1) introducing the Gerber file into a programming file; (2) setting Gerber parameters; (3) analyzing the Gerber file, and obtaining a welding layer in a Gerber graph; (4) processing a Gerber welding graph, and constructing a relation between graph coordinates and object coordinates; (5) selecting a welding point to be welded on the processed Gerber welding graph, calculating actual physical coordinates corresponding to the graph coordinates according to the coordinate conversion relation obtained in step (4), and moving a welding nozzle to a position with the actual physical coordinates; and (6) finding actual physical coordinates of other welding points by the method in step (5), and welding. By adopting the method, a camera is not required to shoot a thumbnail, and the programming time is shortened; the rotating angle of a printed circuit board (PCB) can be accurately calculated and can be accurately compensated; the welding precision is improved; and during welding, a phenomenon of inaccurate welding caused by deflection of the position of the PCB can be avoided.

Owner:廖怀宝

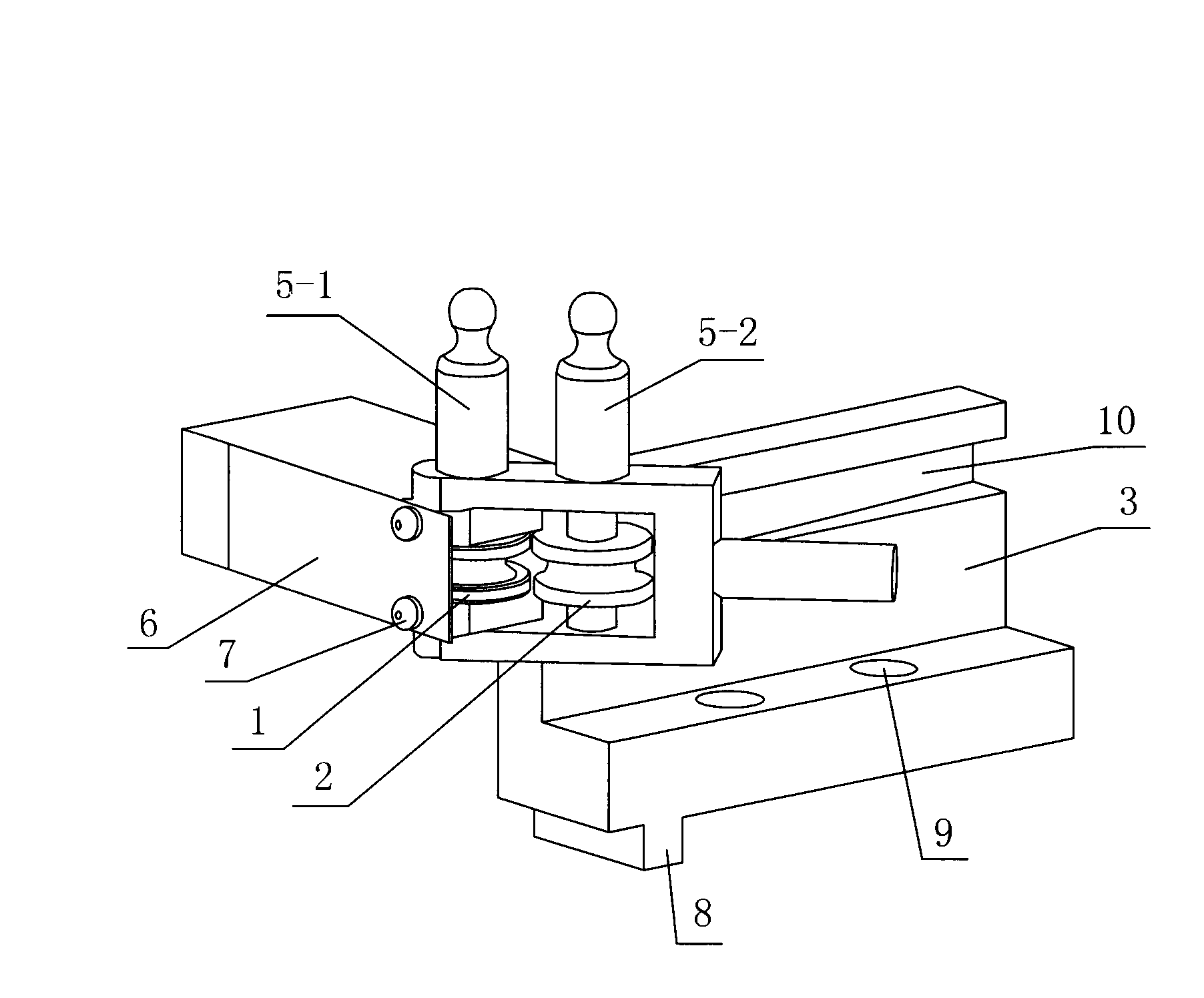

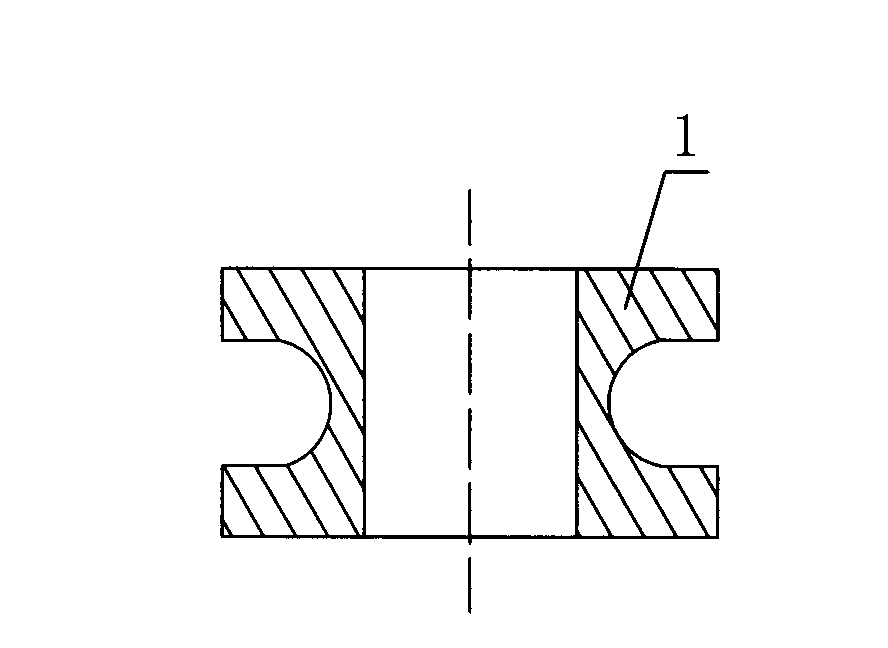

Processing device of thin-diameter thin-wall metal elbow

The invention discloses a processing device of a thin-diameter thin-wall metal elbow. The thin-diameter thin-wall metal elbow comprises a base, a guide wheel I, a handle, a guide wheel II and a separation blade, wherein the base is fixedly mounted on a worktable; the guide wheel I is movably mounted on the base and can rotate around the central axis of the base; the handle is mounted on the base by a movable connecting piece and can rotate left and right around the movable connecting piece; the guide wheel II is mounted in a slot arranged in the middle of the handle; the separation blade is fixed on the base and prevents a bent tubular product from radially moving in an elbow-bending process; and molded arc grooves with the same diameter as the bent tubular product are arranged on the guide wheel I and the guide wheel II along the circumferential direction and arranged on the same horizontal line. The processing device has simple structure, convenient mounting, simple and convenient use and operation and good use effect and can process various thin-diameter thin-wall metal elbows with different strength levels; and an elbow-processing process has little influence on the performance of tubular products and has convenient and flexible operation, high efficiency and low cost.

Owner:NORTHWEST INSTITUTE FOR NON-FERROUS METAL RESEARCH

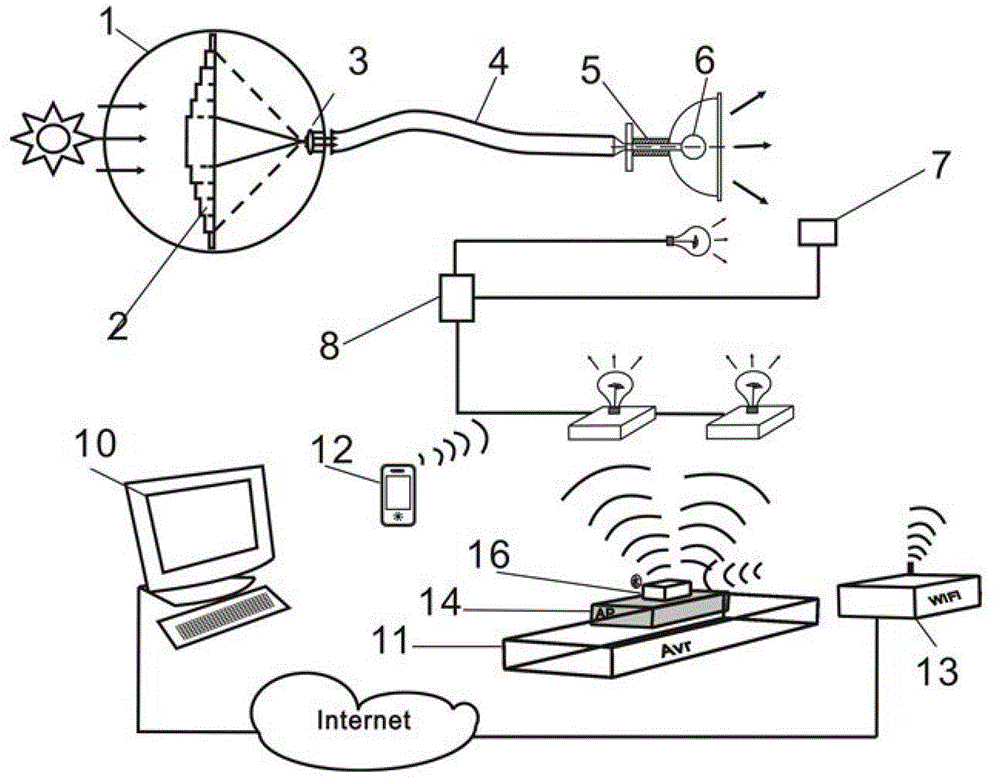

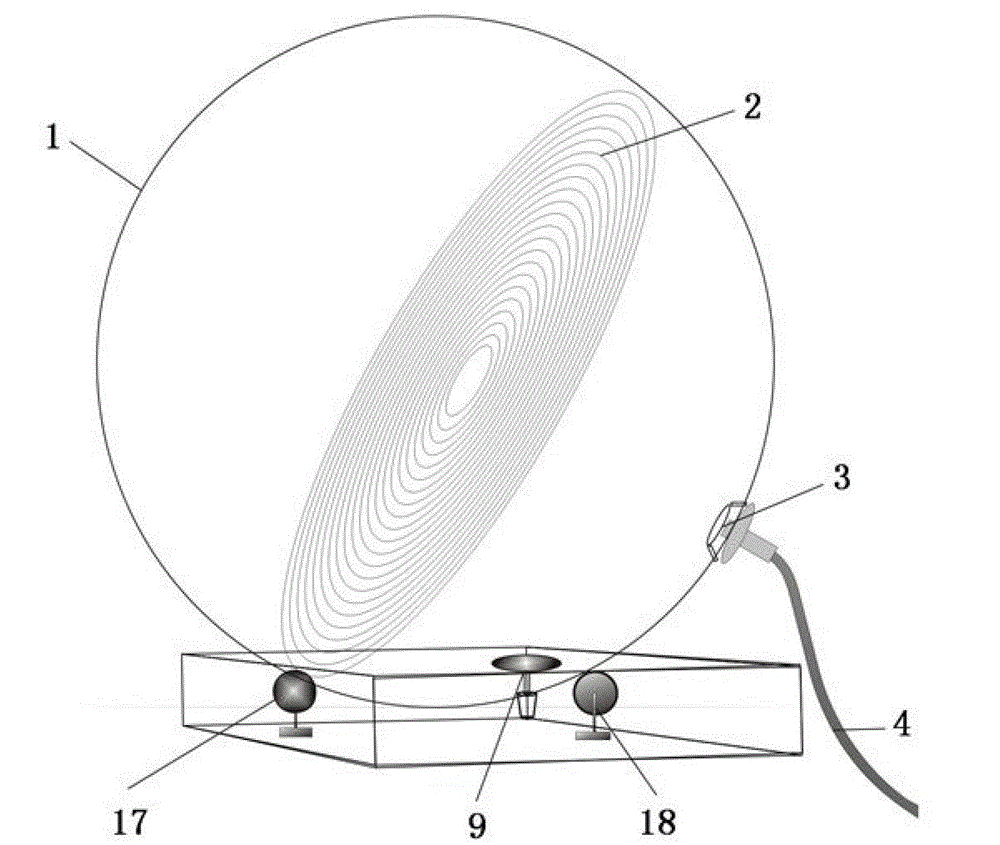

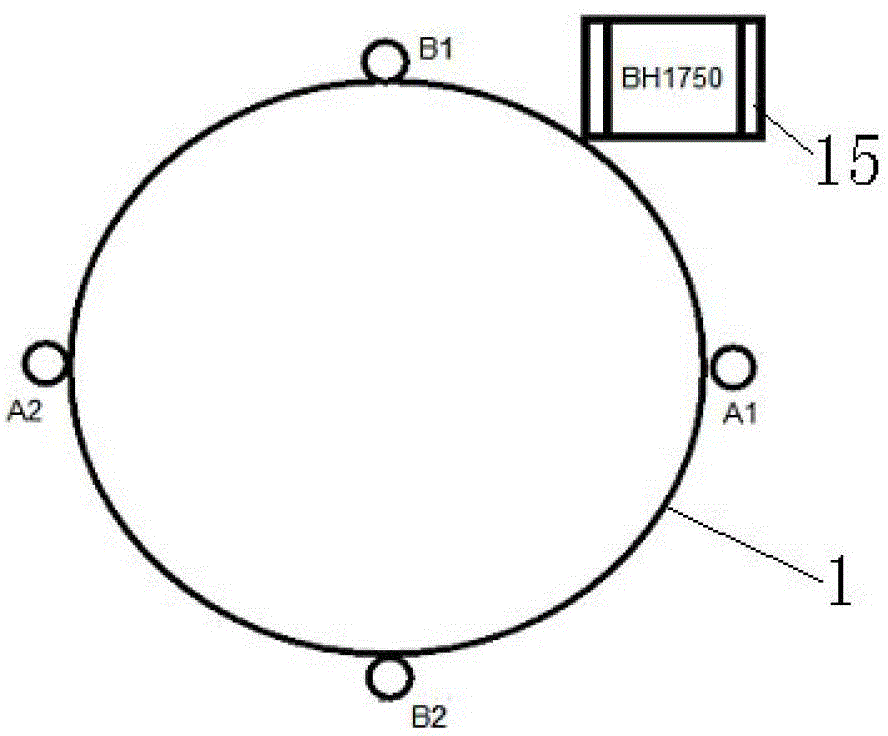

Natural light and electric power mixed illuminating system based on internet of things

InactiveCN103148436AIn line with daily habitsEasy to install and maintainLighting applicationsElectric circuit arrangementsMicrocontrollerWireless control

The invention discloses a natural light and electric power mixed illuminating system based on the internet of things, which comprises a sunlight collector, a tracking mechanism, an indoor mixed illumination unit and a control mechanism, wherein according to the structure of the sunlight collector, a Fresnel lens is mounted on an inner equatorial plane of a light-filtering spherical shell, a secondary convergent lens is arranged at the back of the Fresnel lens, a light-emitting port of the secondary convergent lens is communicated with an optical fiber, and the light-filtering spherical shell is arranged in a drive frame of the tracking mechanism; in the tracking mechanism, four photoelectric sensors and one fine tracking sensor are uniformly mounted on an outer equatorial plane of the light-filtering spherical shell in a direction facing the sun; two omnidirectional wheels in the drive frame are in transmission connection with respective reducing motors respectively; and in the control mechanism, a computer is connected with a wireless router and an AP (access point) module of an Ethernet interface, the AP module is connected with a singlechip, and a lamp carrying a Wifi module is connected with an electric power illumination converter. The mixed illuminating system achieves manually controlled lighting, and remote range and close range wireless control.

Owner:XIAN UNIV OF TECH

Motor control device and electric steering system

InactiveUS8670904B2Precise angle of rotationAvoid discomfortVehicle testingCommutation monitoringMotor controlEngineering

A motor control device includes: a rotation angle detection portion that detects a rotation angle of a motor and outputs a rotation angle signal; an abnormal condition detection portion that detects the presence or absence of an abnormal condition of the rotation angle detection portion; a rotation angle estimation portion that estimates the rotation angle of the motor and outputs an estimate rotation angle signal; and a driving control portion that controls driving of the motor on the basis of the rotation angle signal, which is output from the rotation angle detection portion, when the abnormal condition detection portion does not detect an abnormal condition of the rotation angle detection portion, and controls driving of the motor on the basis of the estimate rotation angle signal, which is output from the rotation angle estimation portion, when the abnormal condition detection portion detects an abnormal condition of the rotation angle detection portion.

Owner:HONDA MOTOR CO LTD

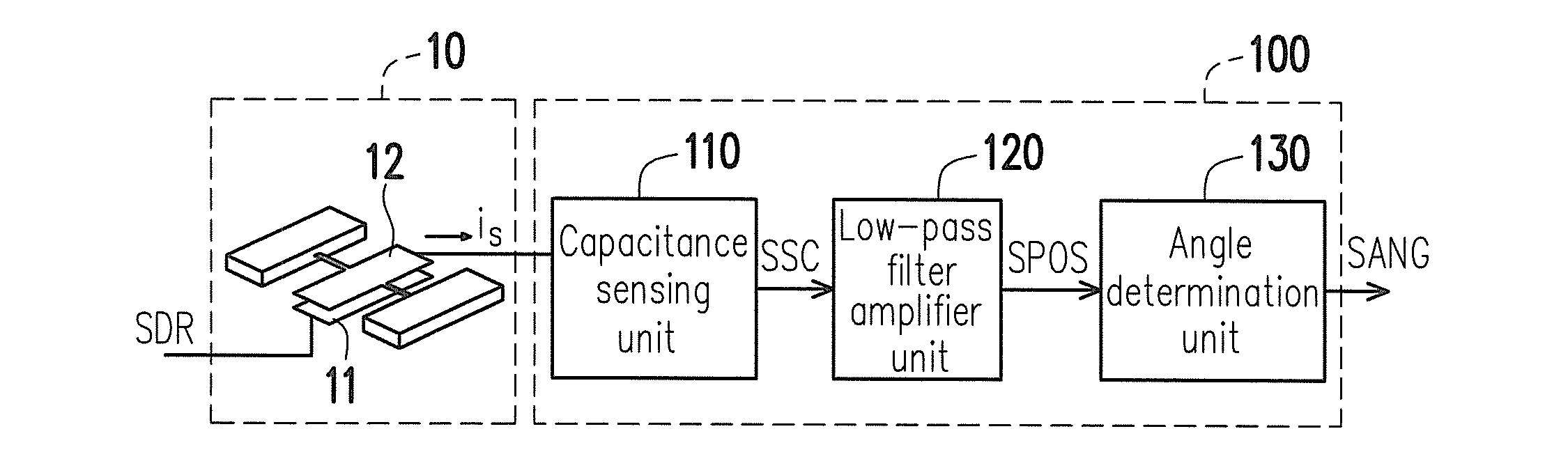

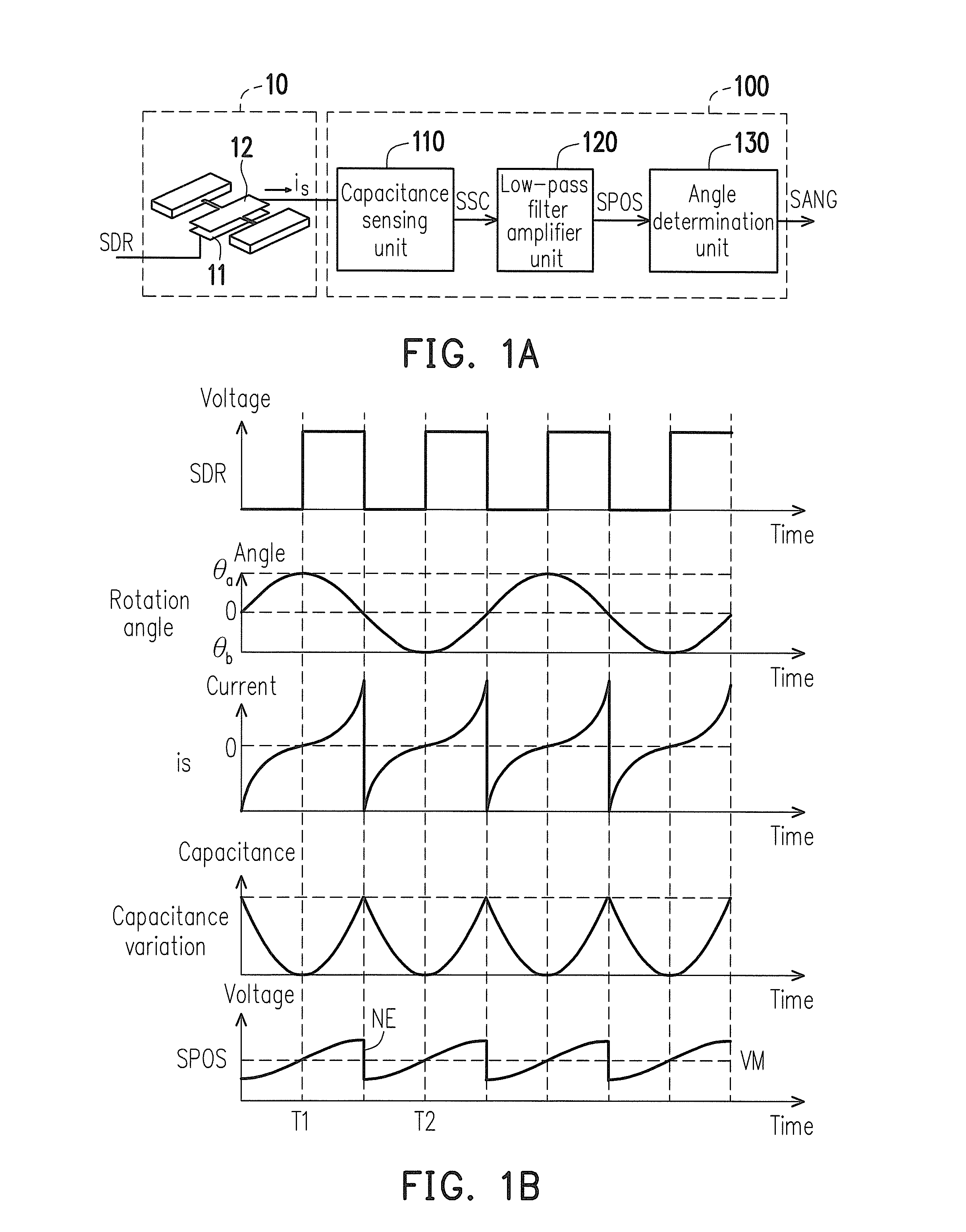

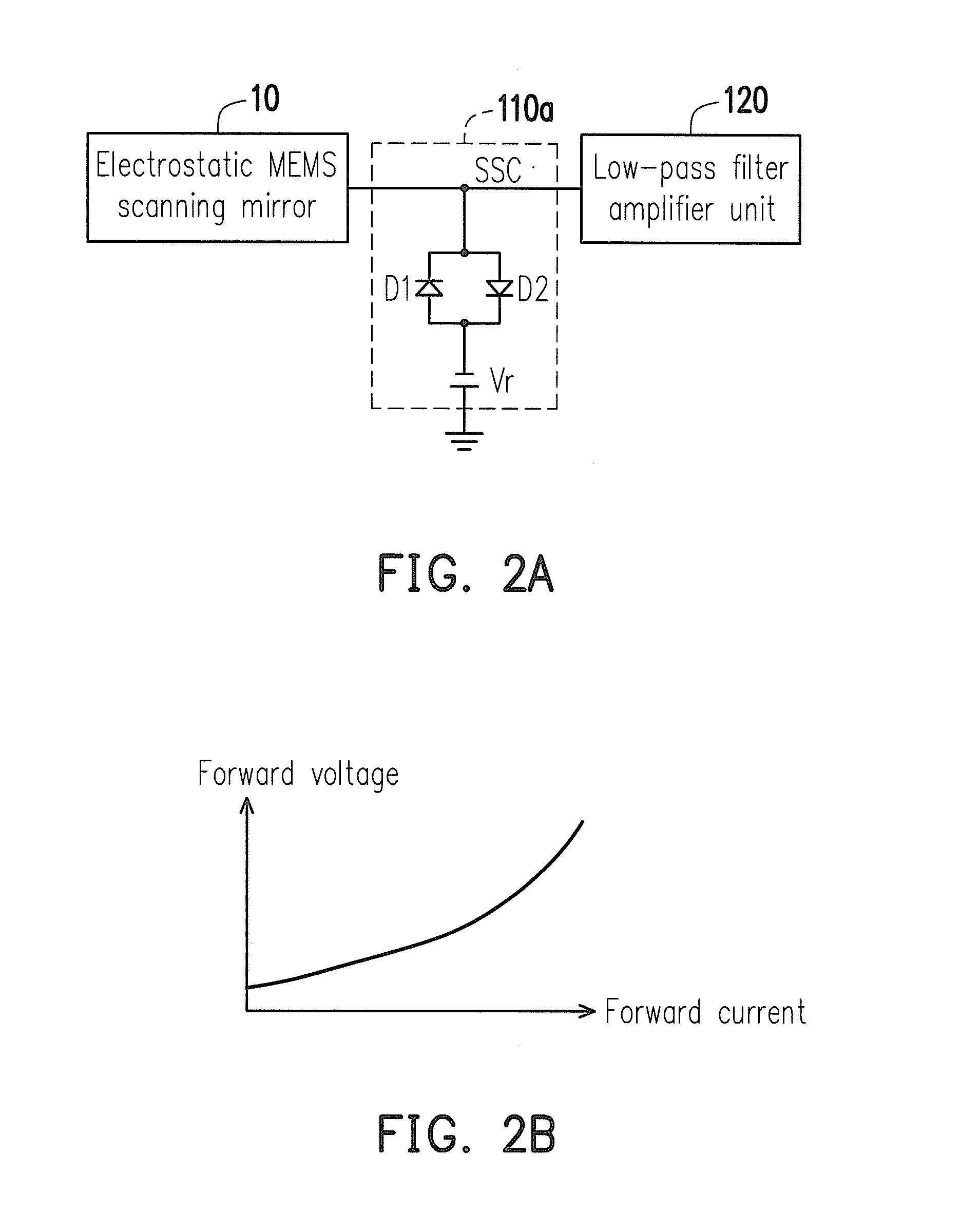

Angle detection circuit of electrostatic MEMS scanning mirror

InactiveUS20150185051A1Precise angle of rotationAccurate inductionResistance/reactance/impedenceConverting sensor output electrically/magneticallyPhysicsCapacitance

An angle detection circuit of an electrostatic MEMS scanning mirror is provided. The angle detection circuit includes a capacitance sensing unit, a low-pass filter amplifier unit and an angle determination unit. The capacitance sensing unit is coupled to a mirror electrode of the electrostatic MEMS scanning minor for sensing an equivalent capacitance of the electrostatic MEMS scanning mirror and providing a capacitance sensing signal. The low-pass filter amplifier unit is coupled to the capacitance sensing unit for receiving the capacitance sensing signal and providing a position signal. The angle determination unit is coupled to the low-pass filter amplifier unit for receiving the position signal, and determines a rotation angle of the mirror electrode of the electrostatic MEMS scanning mirror to provide an angle signal.

Owner:LITE ON TECH CORP

Rotary oil coating mechanism driven by servo motor

InactiveCN107930930AUniversal adjustment position is preciseAccurate rotation speedSpraying apparatusElectric machineDrive shaft

The invention relates to a rotary oil coating mechanism driven by a servo motor, and belongs to the technical field of oil coating. The rotary oil coating mechanism comprises a motor, a speed reducer,a mechanism fixing plate, a rotary plate and oil coating mechanisms. The motor is connected with the speed reducer, the speed reducer is fixed to the mechanism fixing plate, a driving shaft of the speed reducer is connected with the rotary plate, and the two sides of the rotary plate are each provided with one oil coating mechanism. The servo motor is rotated so as to drive two oil coating guns to carry out circumferential spraying operation at specified positions at specified angles, universal position adjusting is precise, the speed and angle of rotation driven by the servo motor are precise, and multithreading control part coating can be achieved.

Owner:WUXI TEHENG TECH CO LTD

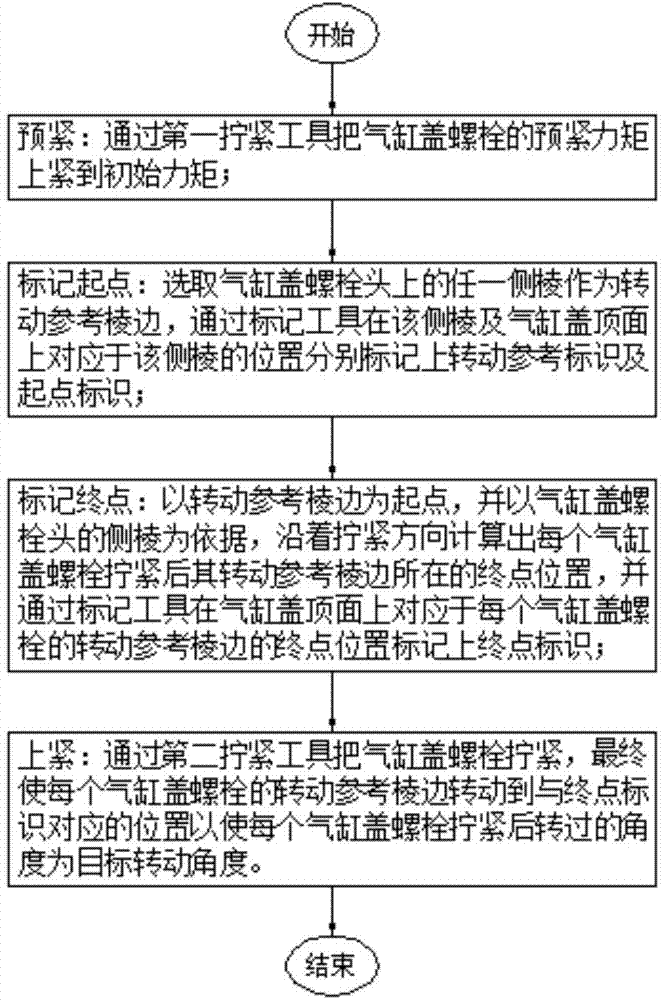

Air cylinder cover bolt screwing process

ActiveCN103921242APrecise angle of rotationMeet the technical requirements of the processSpannersWrenchesEngineering

Owner:GUANGXI YUCHAI MASCH CO LTD

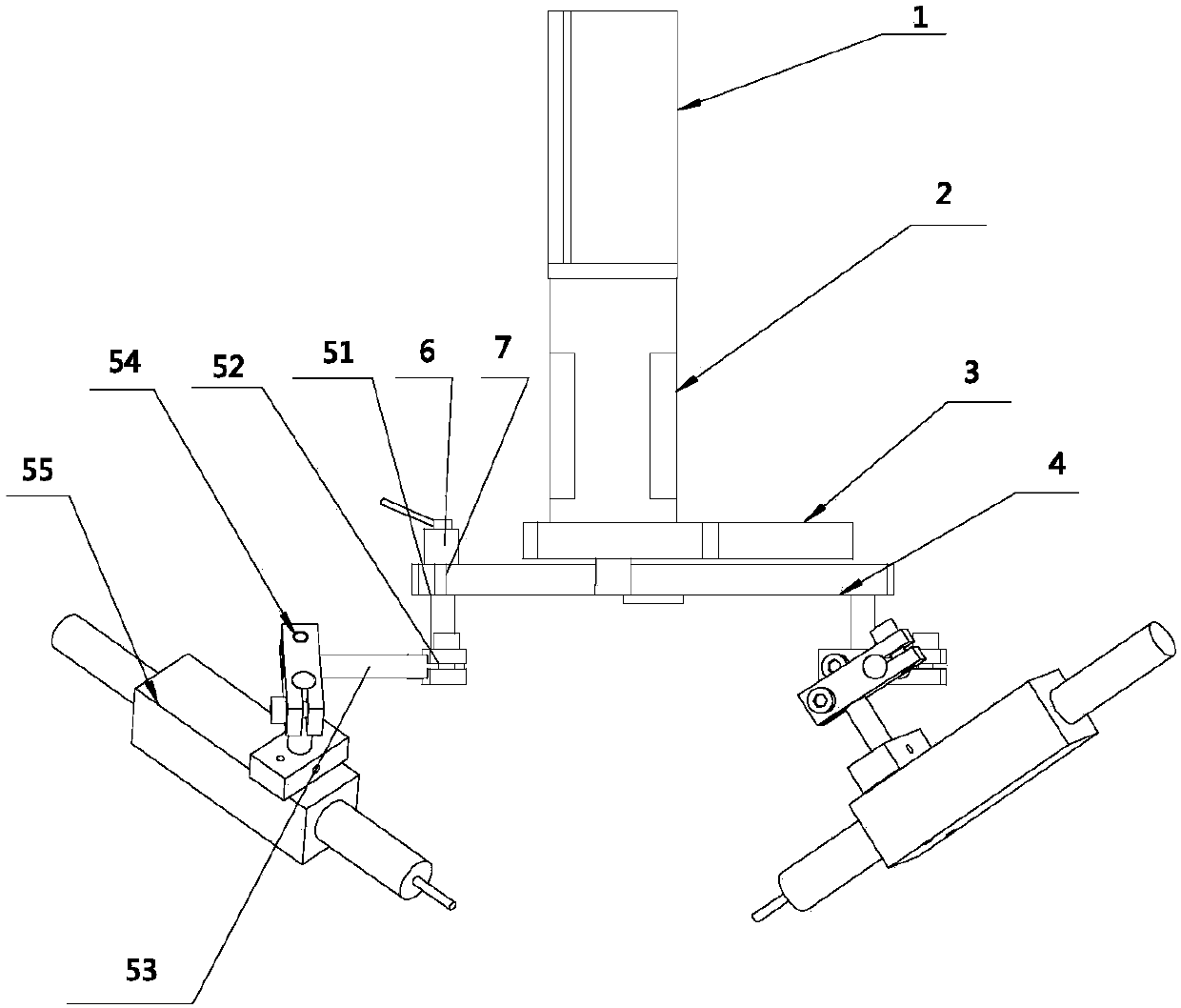

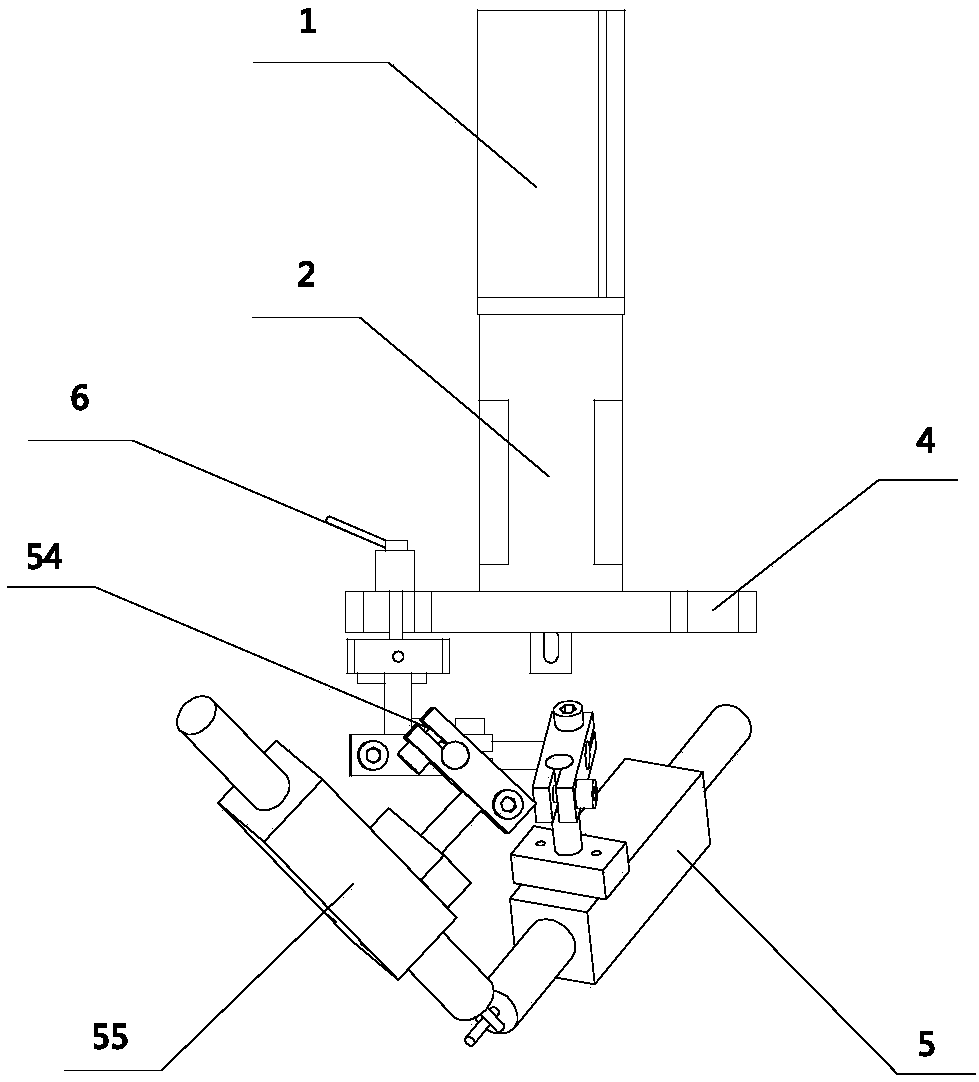

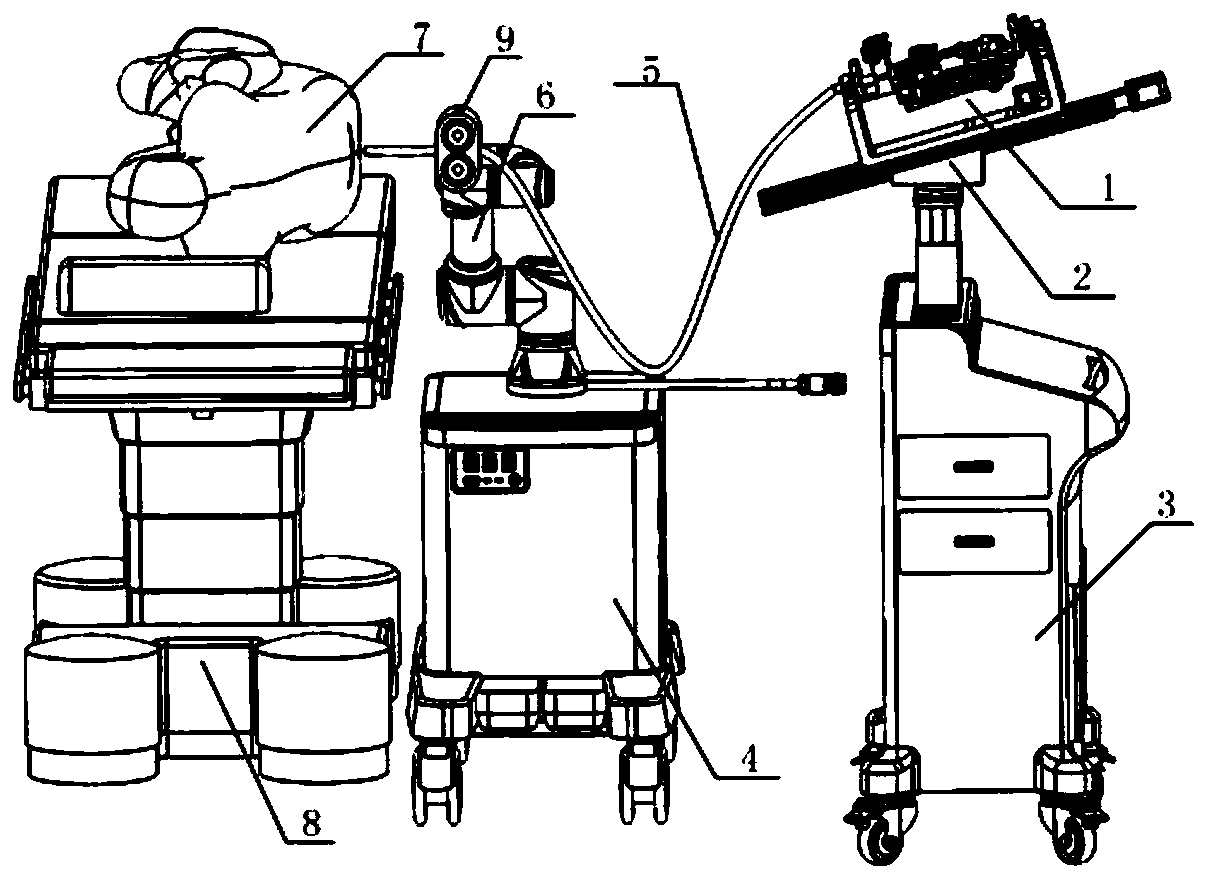

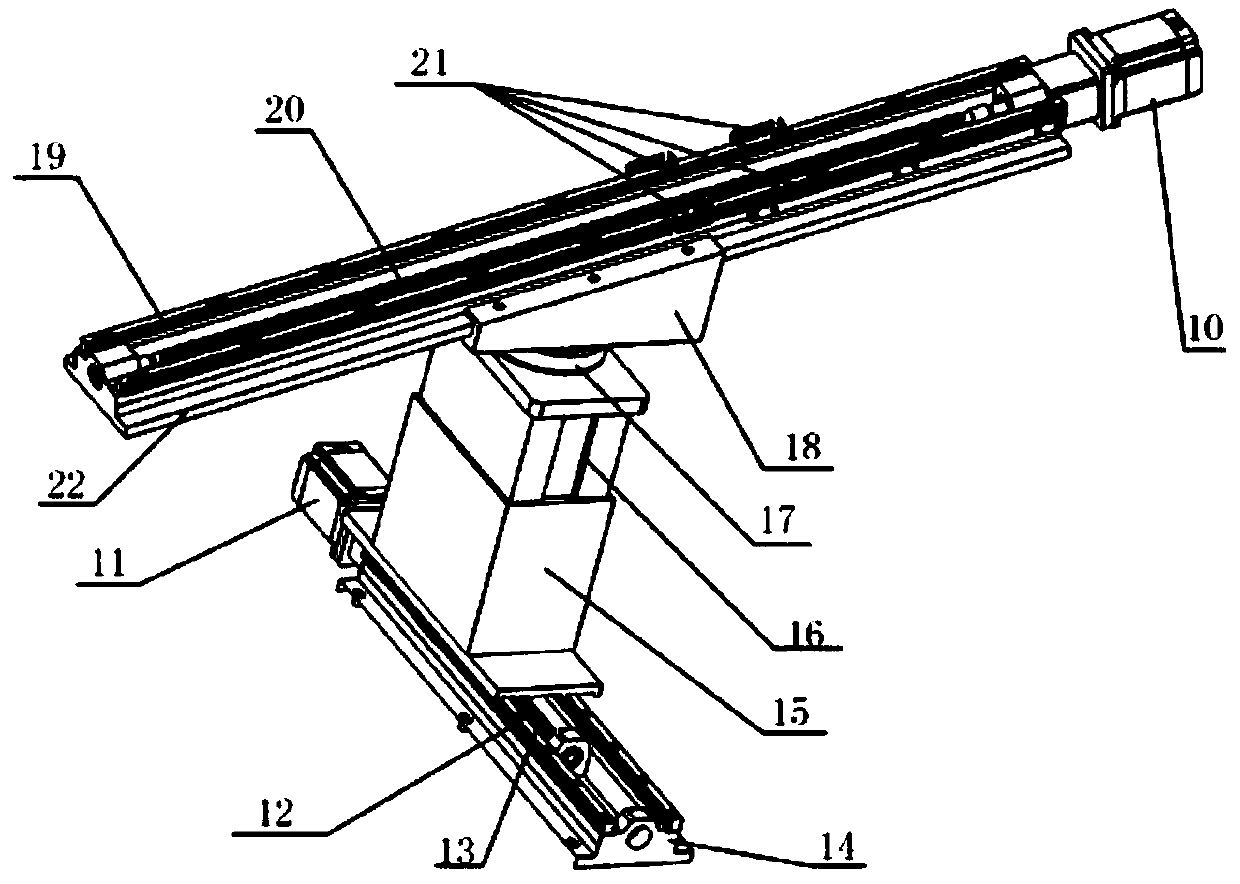

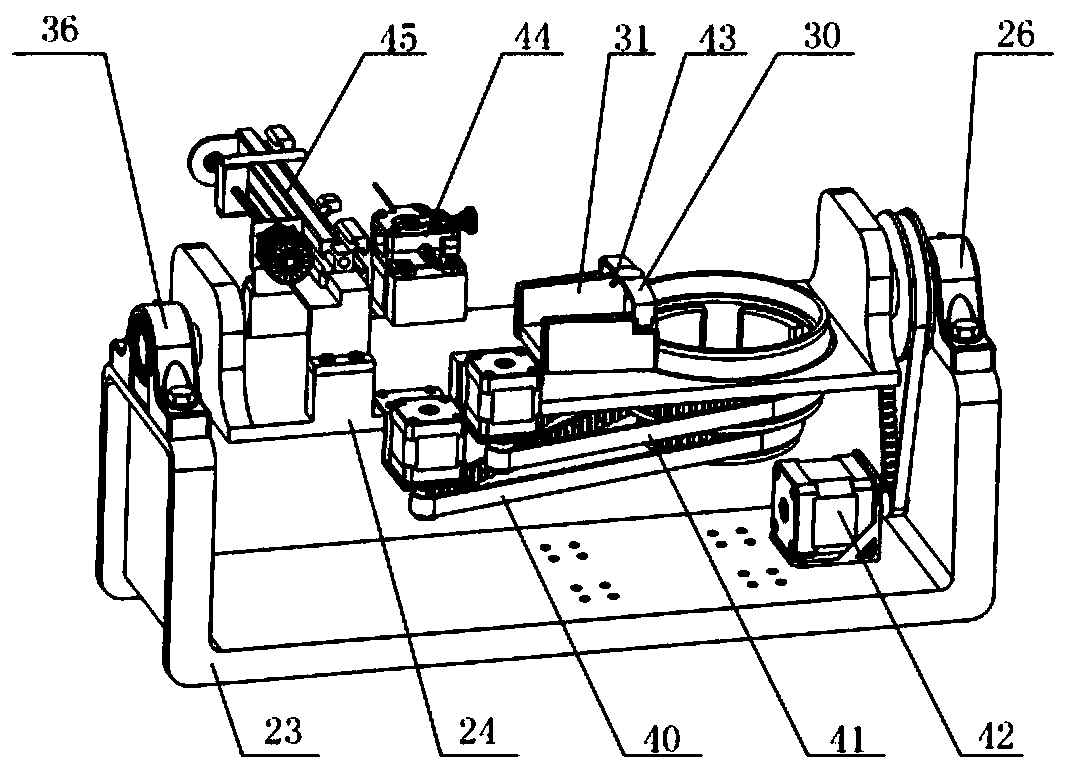

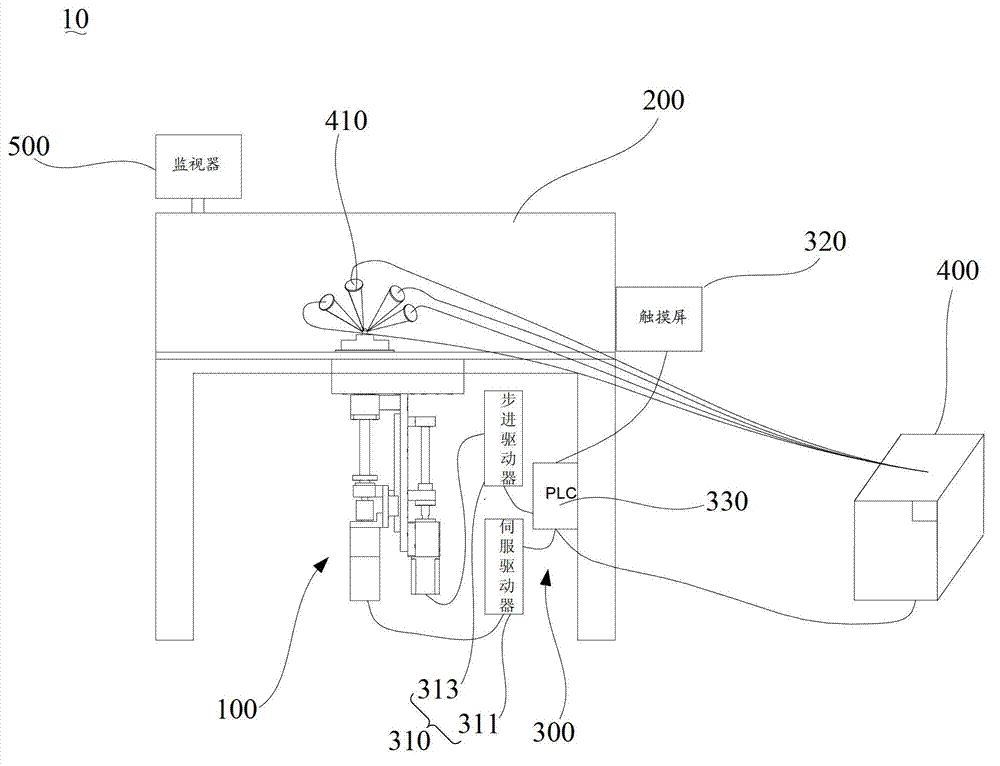

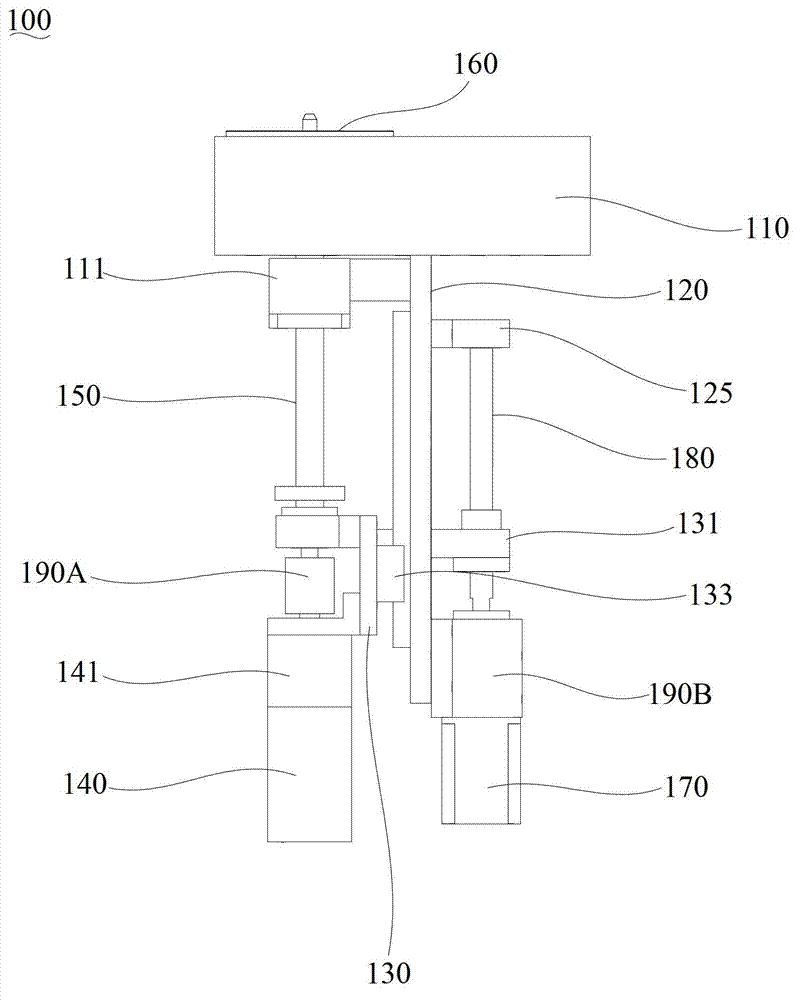

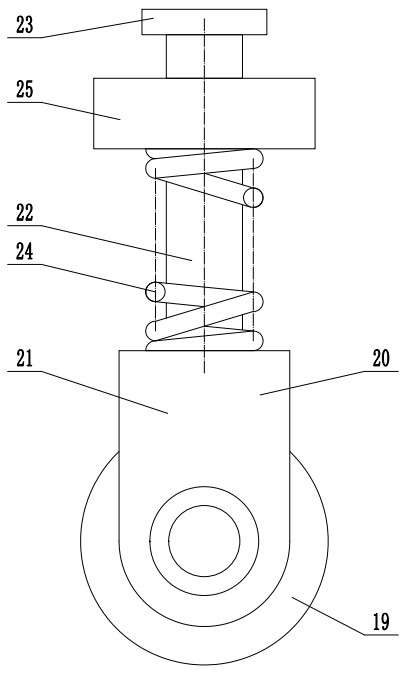

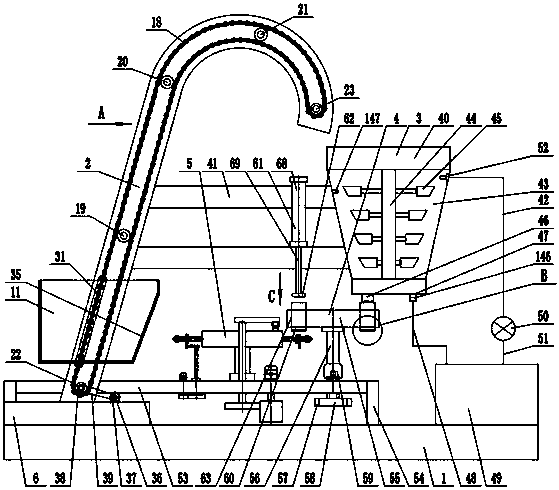

Robotic system for assisting doctor in operating colonoscope

PendingCN111494012AAvoid harmPrecise angle of rotationVaccination/ovulation diagnosticsRectum colonoscopesRobotic systemsPhysical medicine and rehabilitation

The invention discloses a robot system for assisting a doctor in operating a colonoscope. The robot system comprises a handle driving mechanism, a colonoscope feeding mechanism, a handle controller pose adjusting mechanism and a pose adjusting driven arm. The handle driving mechanism can replace a traditional mode that a doctor manually pokes an impeller; the rotation angle of the colonoscope tipis adjusted; the colonoscope feeding mechanism can replace a doctor to convey a colonoscope into the intestinal tract of a patient; the handle controller pose adjusting mechanism can adjust the angleand the position of the handle operator to realize convenient colonoscope delivery; the pose adjusting driven arm can adjust the colonoscope to the anus of a patient to realize convenient conveying ofthe colonoscope. The device can replace a traditional mode of manual impeller operation of doctors, a problem that the fingers and the shoulders of the doctors are injured by long-time impeller stirring is solved; meanwhile, the traditional mode of assisting the doctors in operating conveying and opening and closing of biopsy forceps by assistants is replaced, and the purpose that the doctors independently complete colon examination and polyp extirpating work is achieved.

Owner:HARBIN UNIV OF SCI & TECH

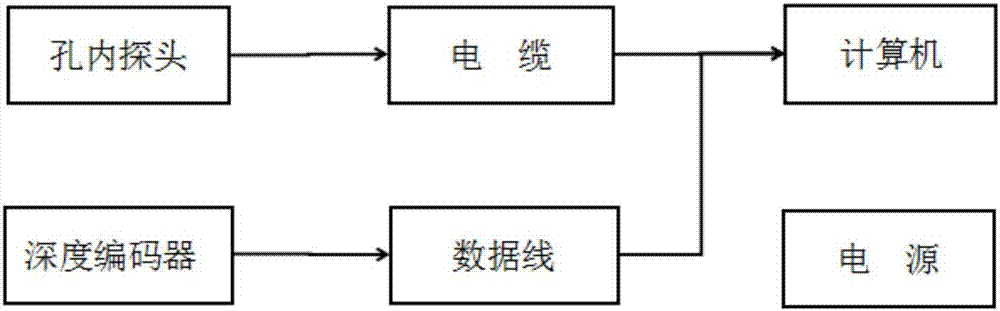

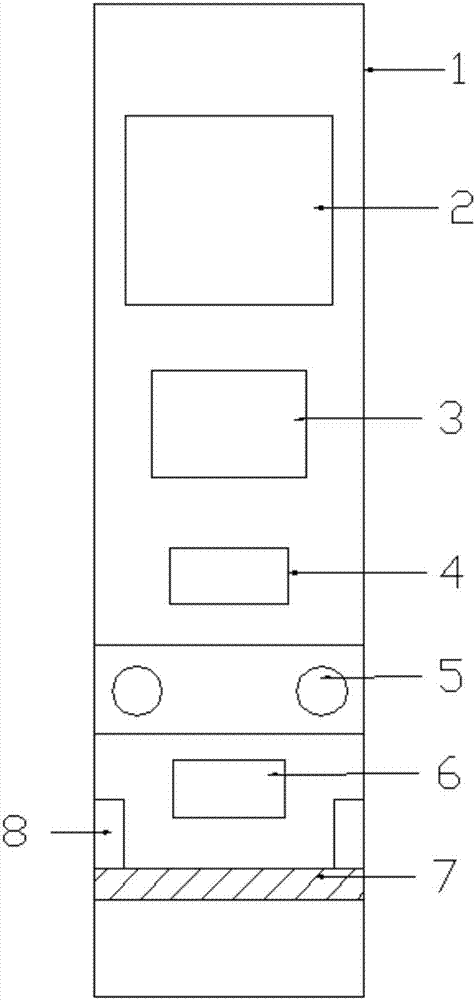

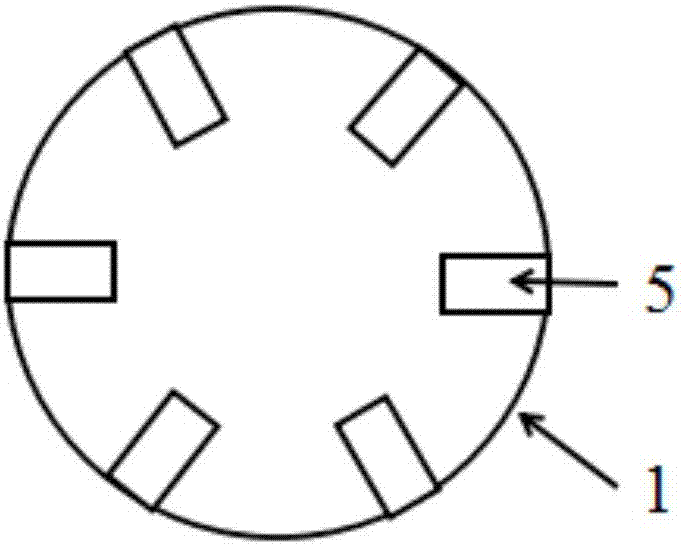

In-hole cavity monitoring device and method based on multi-frequency ultrasonic scanning

ActiveCN106950288ASolve the problem of limited detection rangeImplement detectionProcessing detected response signalSonificationLeak detection

The invention discloses an in-hole cavity monitoring device and method based on multi-frequency ultrasonic scanning. The in-hole cavity monitoring device comprises a rotary driving component, an orientation component, a scanning component, a calibrating component and a reflection component. The invention further discloses an in-hole cavity monitoring method based on multi-frequency ultrasonic scanning, and aims to solve the problems of limit and low accuracy in a single-frequency ultrasonic detection range. Clear waveforms generated by selecting ultrasonic energy converters of two frequencies are comparatively analyzed in order to calculate the number of periods of ultrasonic pulse leak detection respectively, so that the transmission time detection accuracy is increased; meanwhile, the calibrating component and the reflection component are adopted in order to measure a sound speed in an environmental medium to realize high-accuracy measurement of a wave speed; lastly, distance values measured by the ultrasonic energy converters of two frequencies are averaged to obtain an accurate distance. The in-hole cavity monitoring device and method have the advantages of skillful design, strict concept, simple structural system, and easiness in implementation.

Owner:INST OF ROCK AND SOIL MECHANICS - CHINESE ACAD OF SCI

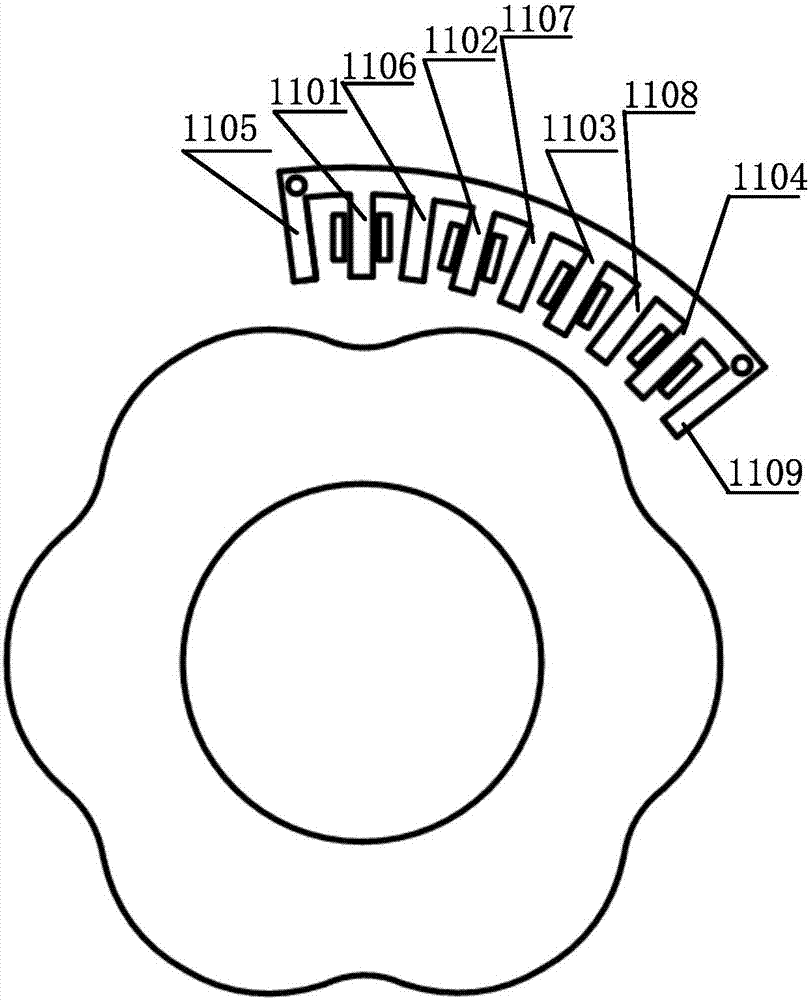

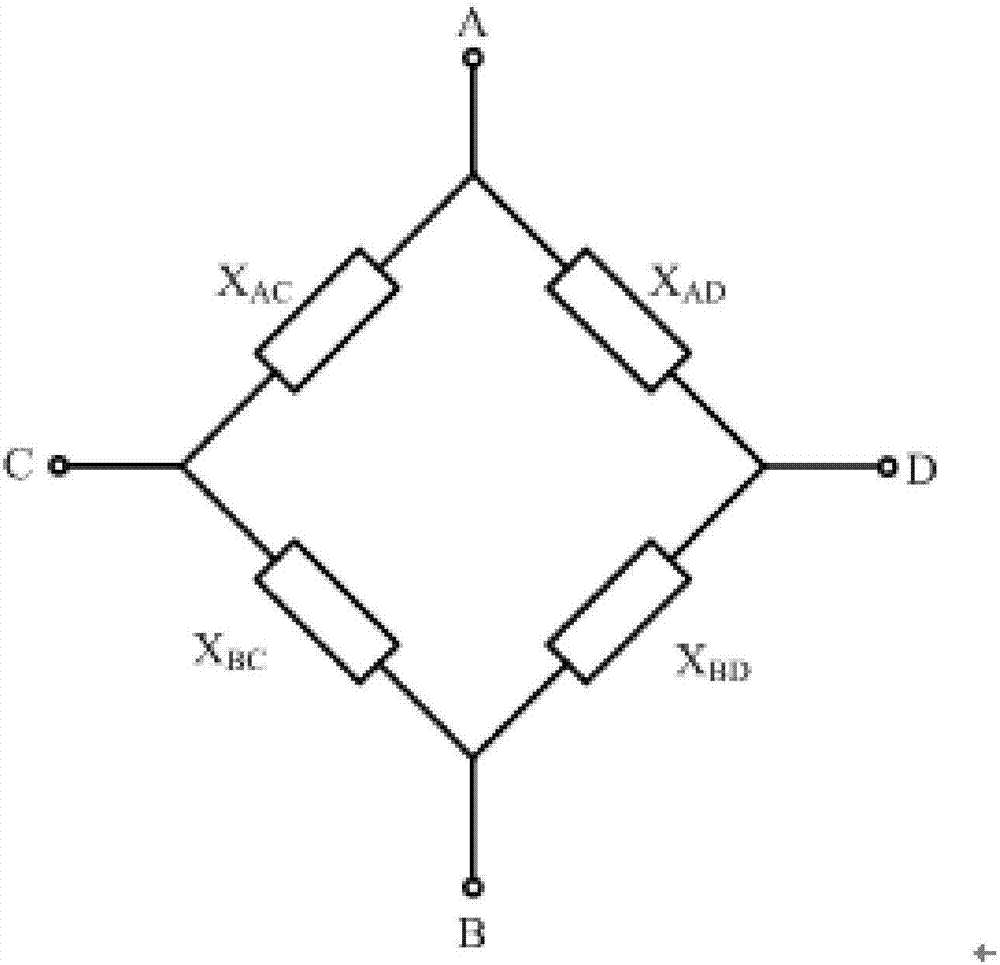

Angle detection device

ActiveCN107063075AEfficient samplingPrecise angle of rotationElectric machinesUsing electrical meansSoftware engineeringMechanical engineering

The present invention belongs to an angle detection device, belonging to the detection technology field. The angle detection device comprises a rotary transformer and a signal processing device. The rotary transformer comprises at least four leads, where at least two of the leads are excitation leads, and at least two of the leads are signal leads. The signal processing device comprises: an excitation circuit configured to connect with the excitation leads and provide excitation signals for the excitation leads; a signal collection circuit configured to control the signal leads and collect position signals of the rotary transformer from the signal leads; and an angle calculation circuit configured to connect the signal collection circuit and calculate the rotation angle of the rotary transformer according to the position signals emitted by the signal collection circuit. The angle detection device can provide an efficient signal processing technology for an inductance rotary transformer, especially to an inductance rotary transformer having four leads consisting of two excitation leads and two signal leads to obtain accurate rotation angle of the rotary transformer.

Owner:苏州昱泽智能科技有限公司

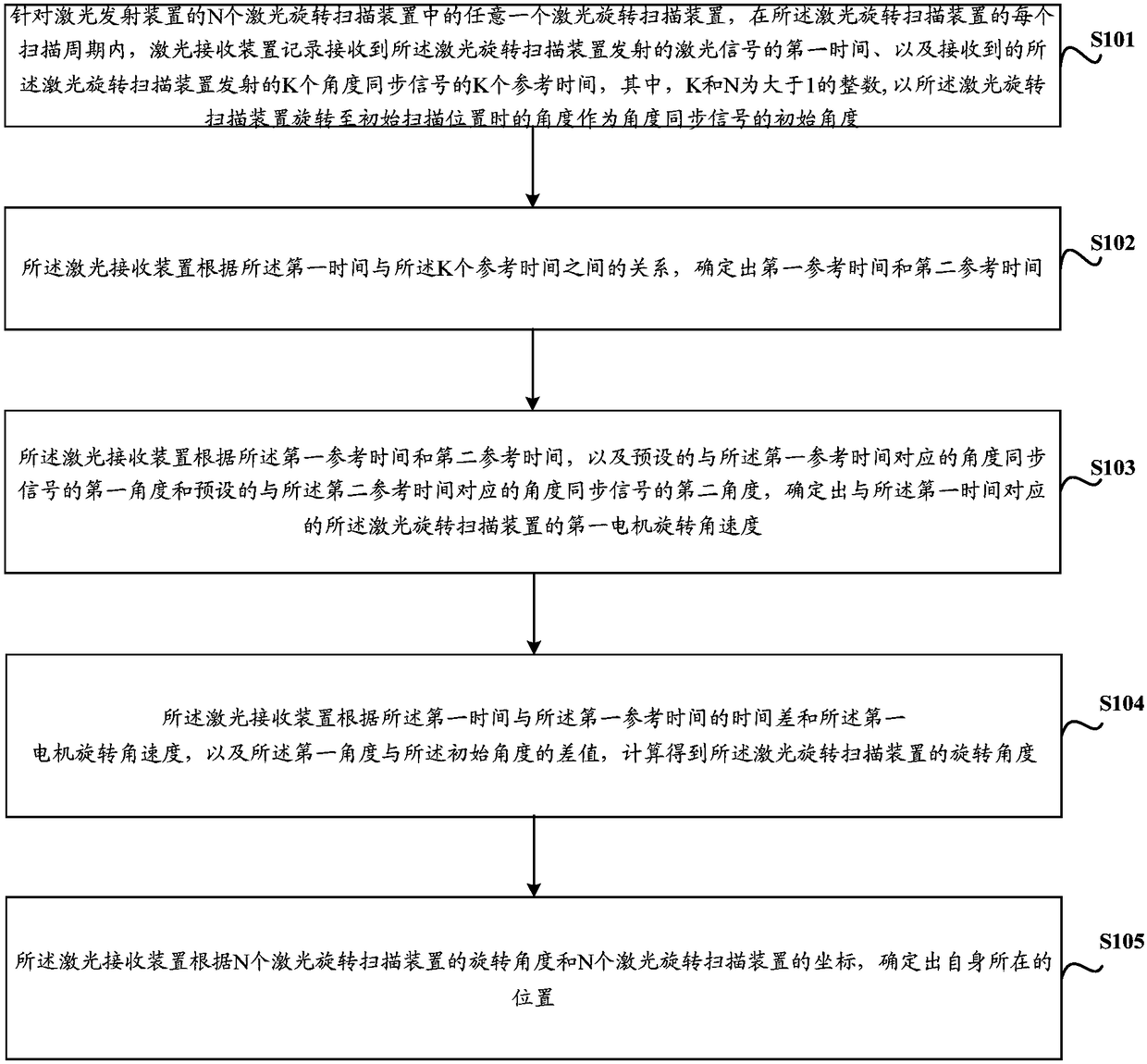

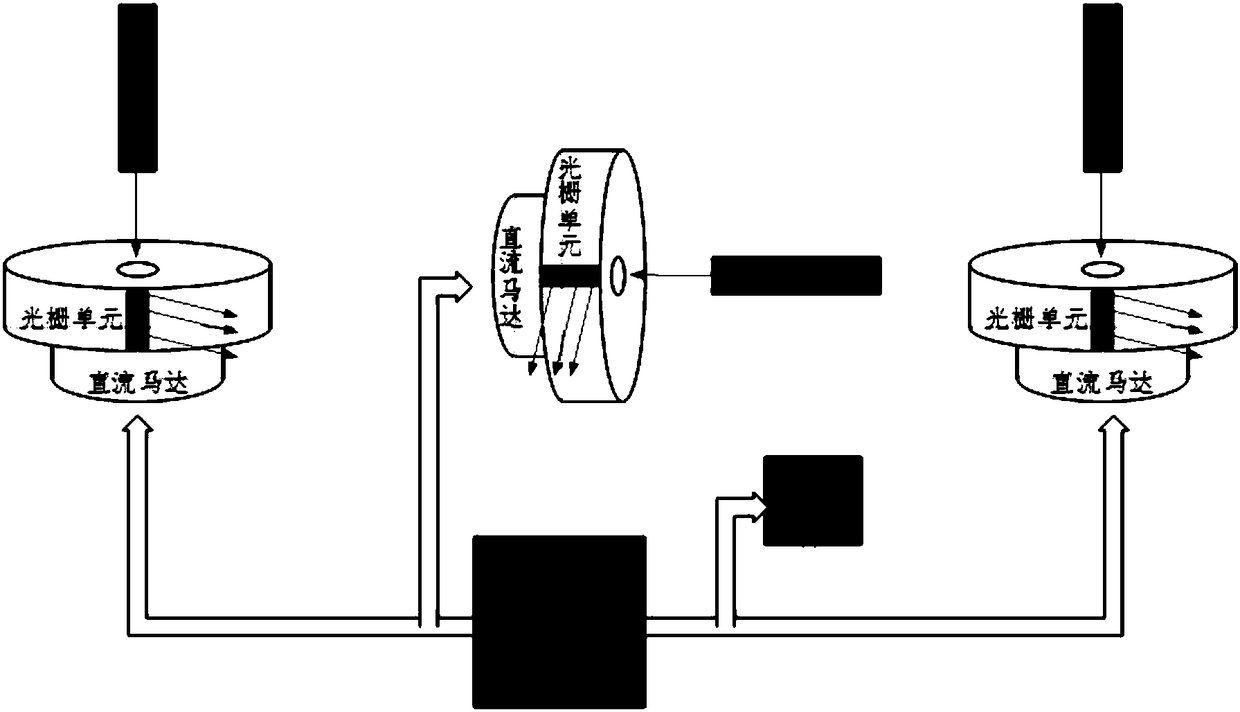

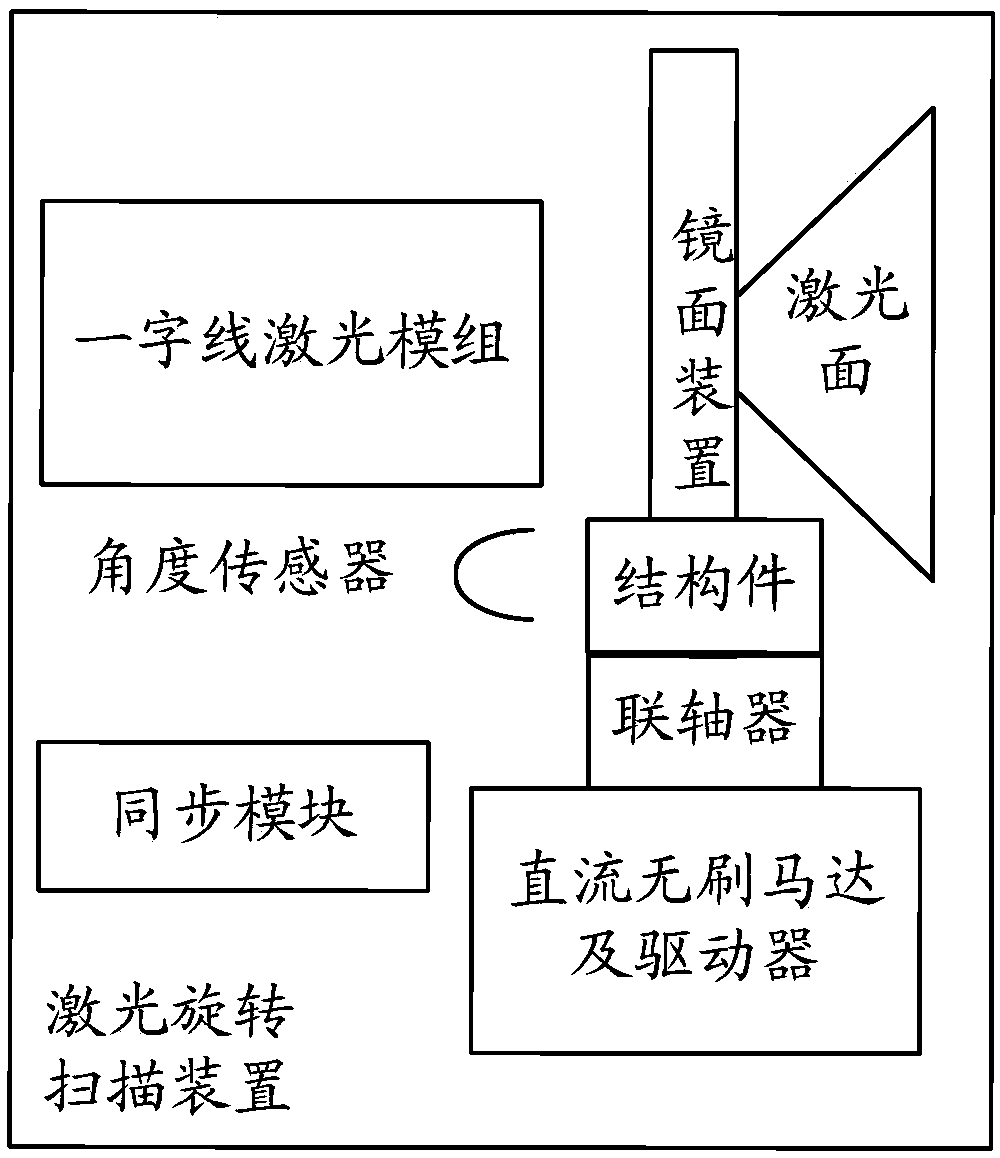

Target positioning method using laser scanning and devices

InactiveCN108226865AImprove accuracyRefined Rotational Angular VelocityPosition fixationLaser scanningAngular velocity

The invention discloses a target positioning method using laser scanning. The method includes the following steps that: as for any one of the N laser rotational scanning devices of a laser emitting device, first reference time and second reference time are determined from each scanning period of the laser rotational scanning device; a laser receiving device determines the first motor rotation angular velocity of the laser rotational scanning device corresponding to first time according to the first reference time, the second reference time, the first angle of preset angle synchronization signals corresponding to the first reference time, and the second angle of preset angle synchronization signals corresponding to the second reference time; the rotation angle of each laser rotational scanning device is obtained through calculation; and the laser receiving device determines a position where the laser receiving device is located according to the rotation angles of the N laser rotationalscanning devices and the coordinates of the N laser rotational scanning devices.

Owner:SHANGHAI LEXIANG TECHNOLOGY CO LTD

Rotational angle detection device

InactiveUS20120109562A1Calculate with easeSimplify circuit configurationElectrical measurementsTesting/calibration of speed/acceleration/shock measurement devicesRotary transformerSingle excitation

A rotational angle detection device has a resolver in which an excitation coil, a first output coil and a second output coil are provided on a periphery of a rotor coupled to a rotation shaft, an excitation signal generator circuit that generates an excitation signal and sends the excitation signal to the excitation coil, and a rotational angle calculation unit that performs sampling for respective output signals of the first output coil and the second output coil in a predetermined cycle, and calculates a rotational angle of the rotation shaft based on two sampling signals obtained as a result of the sampling. The excitation signal generator circuit is of a single excitation mode and generates a single excitation signal.

Owner:OMRON AUTOMOTIVE ELECTRONICS CO LTD

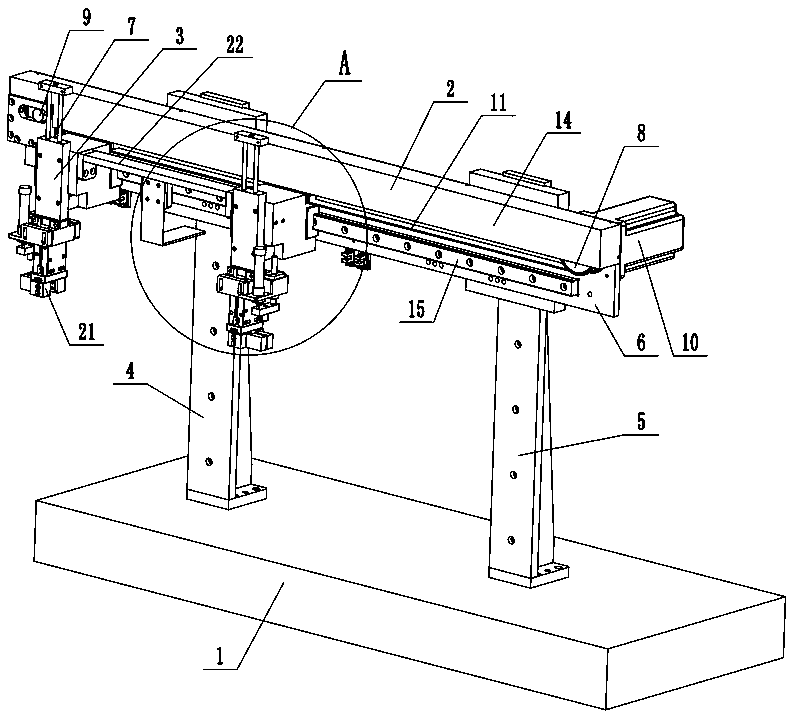

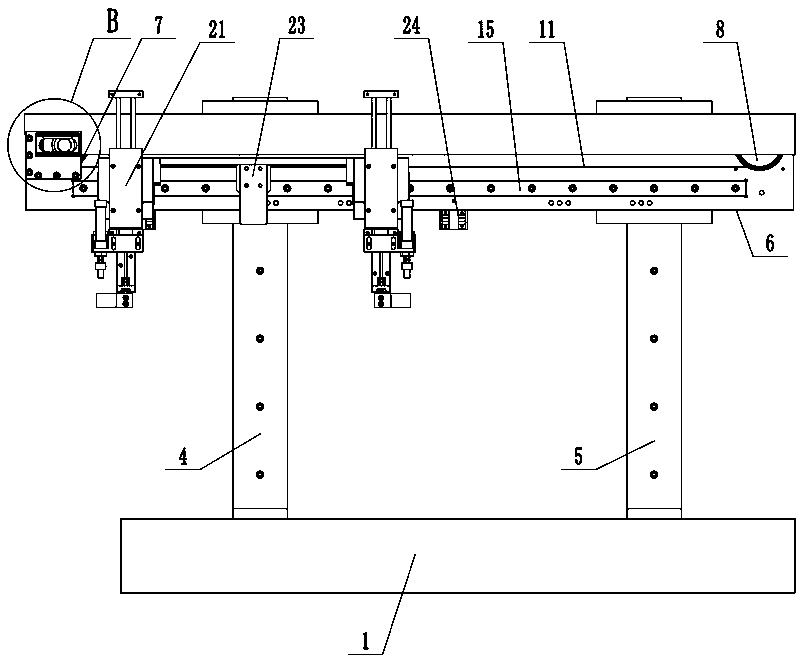

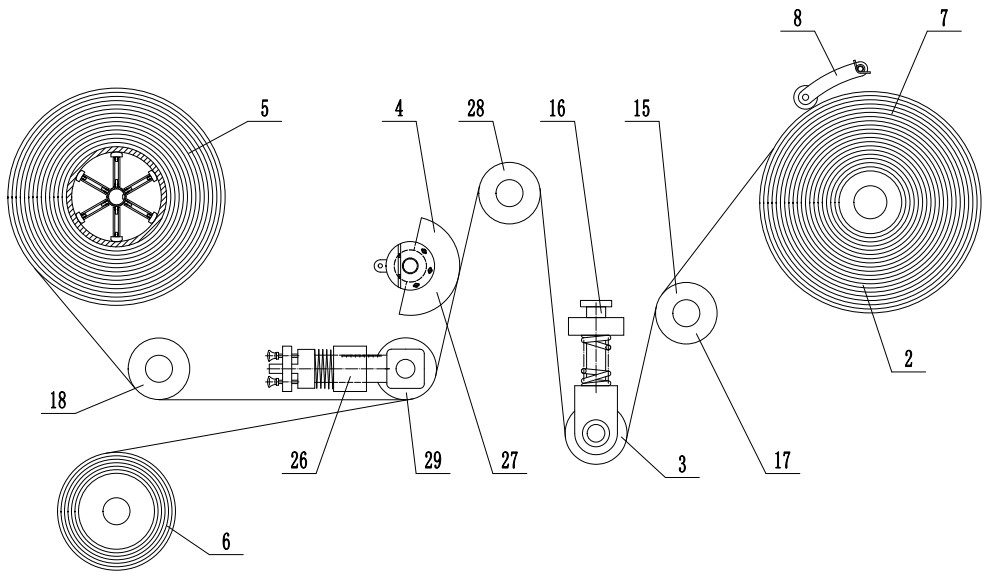

Automatic bobbin feeding and discharging equipment for weaving machine

ActiveCN108674968AGuaranteed synchronicityGuaranteed positioning accuracyConveyorsFilament handlingBobbinEngineering

The invention provides automatic bobbin feeding and discharging equipment for a weaving machine, and belongs to the technical field of textile machines. The automatic bobbin feeding and discharging equipment comprises a horizontal operation mechanism and a feeding and discharging mechanism. An operation belt of the horizontal operation mechanism is arranged on a first belt wheel and a second beltwheel in a surrounding mode. Two feeding and discharging assemblies of the feeding and discharging mechanism are installed on the operation belt and are connected through a synchronous frame. Operation sliding blocks of the feeding and discharging assemblies are arranged on an operation guide rail in a sliding mode. A first clamping sliding block and a second clamping sliding block of a clamping manipulator are arranged in a clamping sliding groove of a clamping air cylinder supporting plate in a sliding mode. A first clamping claw is arranged at the lower end of the first clamping sliding block, and a second clamping claw is arranged at the lower end of the second clamping sliding block. The lower end of a pressing piston rod of a pressing assembly is connected with a pressing plate. A pressing guide rod is arranged on a pressing guide block in a vertical sliding mode. The operation position of the feeding and discharging mechanism is very accurate, automatic feeding and discharging of bobbins can be automatically realized, and the structure is reasonable and compact.

Owner:江西绣丽织带有限公司

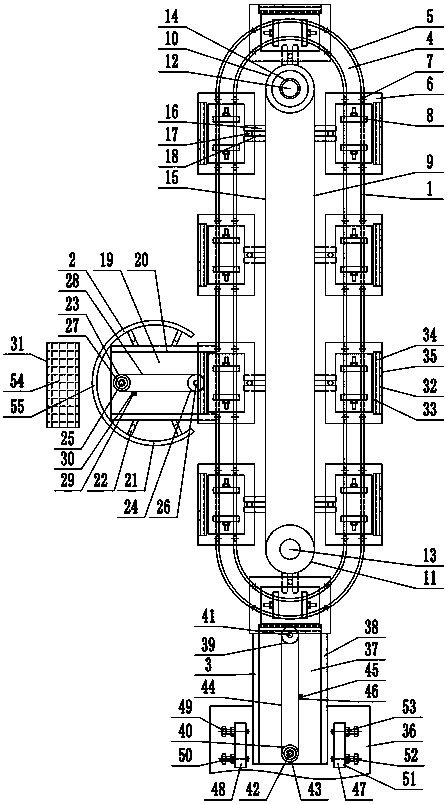

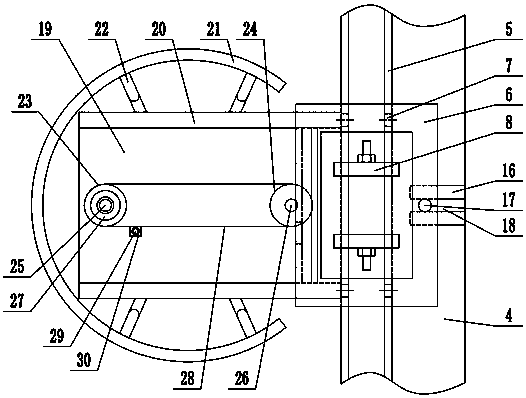

Ring type worktable transfer device with loading and unloading station

ActiveCN108555620AImprove the protective effectAvoid accidentsLarge fixed membersMetal working apparatusSprocketEngineering

The invention provides a ring type worktable transfer device with a loading and unloading station and belongs to the technical field of machining. The ring type worktable transfer device with the loading and unloading station comprises a worktable ring mechanism, a workpeice loading and unloading mechanism and a worktable transfer mechanism, wherein a worktable of the worktable transfer mechanismis slidably arranged on a ring track through a worktable roller; locking blocks of a ring driving assembly are uniformly arranged on a first chain; bayonet locks are locked into the slots in the locking blocks; a second chain of the workpeice loading and unloading mechanism is arranged around a third chain wheel and a fourth chain wheel; a first driving pin is mounted on a first pin supporting plate; and a second driving pin of the worktable transfer mechanism is mounted on a second pin supporting plate. The ring type worktable transfer device with the loading and unloading station not only transfers the worktable continuously to feed the worktable into a machine tool and shift the worktable out to shorten the dry running time of the machine tool and improve the production capacity of themachine tool, but also has the loading and unloading station to load and unload workpieces; and the ring type worktable transfer device is reasonable in structure and continuous production of the machine tool is facilitated.

Owner:南通通途机电制造有限公司

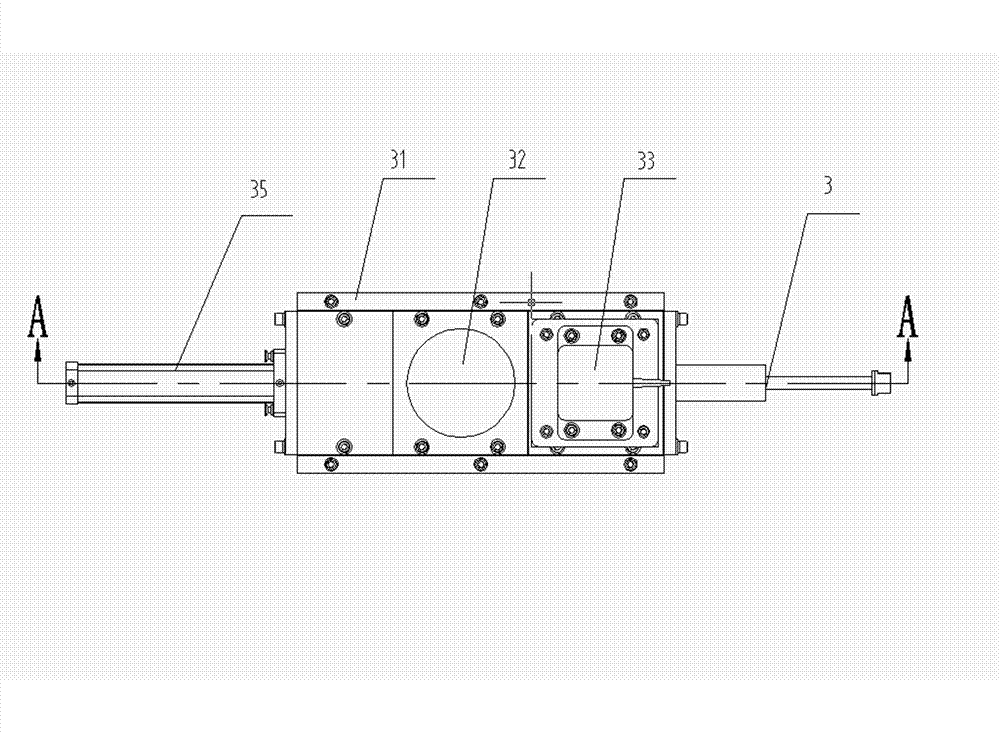

Laser welding device

ActiveCN103170745APrecise angle of rotationEffectively control the rotation angleWelding/cutting auxillary devicesAuxillary welding devicesLinear motionSpot welding

The invention relates to a laser welding device comprising a worktable, a weld fixing device and a control device, wherein the weld fixing device comprises a fixing plate, a vertical plate, a connecting plate, a first motor, a rotating shaft, a workpiece fixing structure, a second motor and a lead screw; the rotation motion of the workpiece fixing structure is controlled through the first motor; and the rotating speed of the workpiece fixing structure is determined by the rotating speed of an output shaft of the first motor. According to the invention, the rotating speed of the first motor can be set to a preset value, so that the accurate rotation angle of the workpiece fixing structure is guaranteed; in addition, the lifting motion of the workpiece fixing structure is realized through driving the lead screw by using the second motor and cooperating with a lead screw nut; the circular motion of the second motor can be transformed into accurate linear motion through the cooperation of the lead screw and the lead screw nut, so that the control of the lifting height can be realized through controlling the rotating speed of the second motor; and therefore, the weld fixing device is capable of effectively controlling the rotation angle and the lifting height of the workpiece fixing structure and welding spots are uniformly distributed during multiple-spot welding.

Owner:HANS LASER TECH IND GRP CO LTD

Adjustable cutting equipment for melt-blown cloth

ActiveCN111910418AAdjustable cutting widthGood width adjustment accuracySevering textilesWebs handlingEngineeringMechanical engineering

Owner:桐乡市中瑞环保科技有限公司

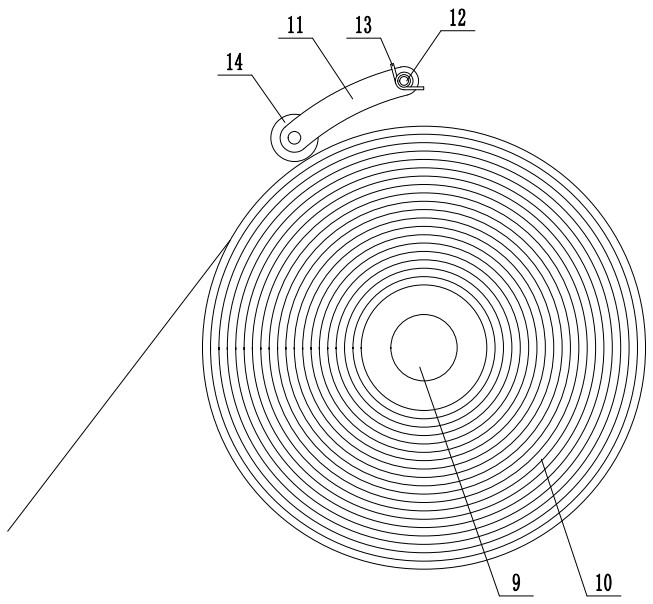

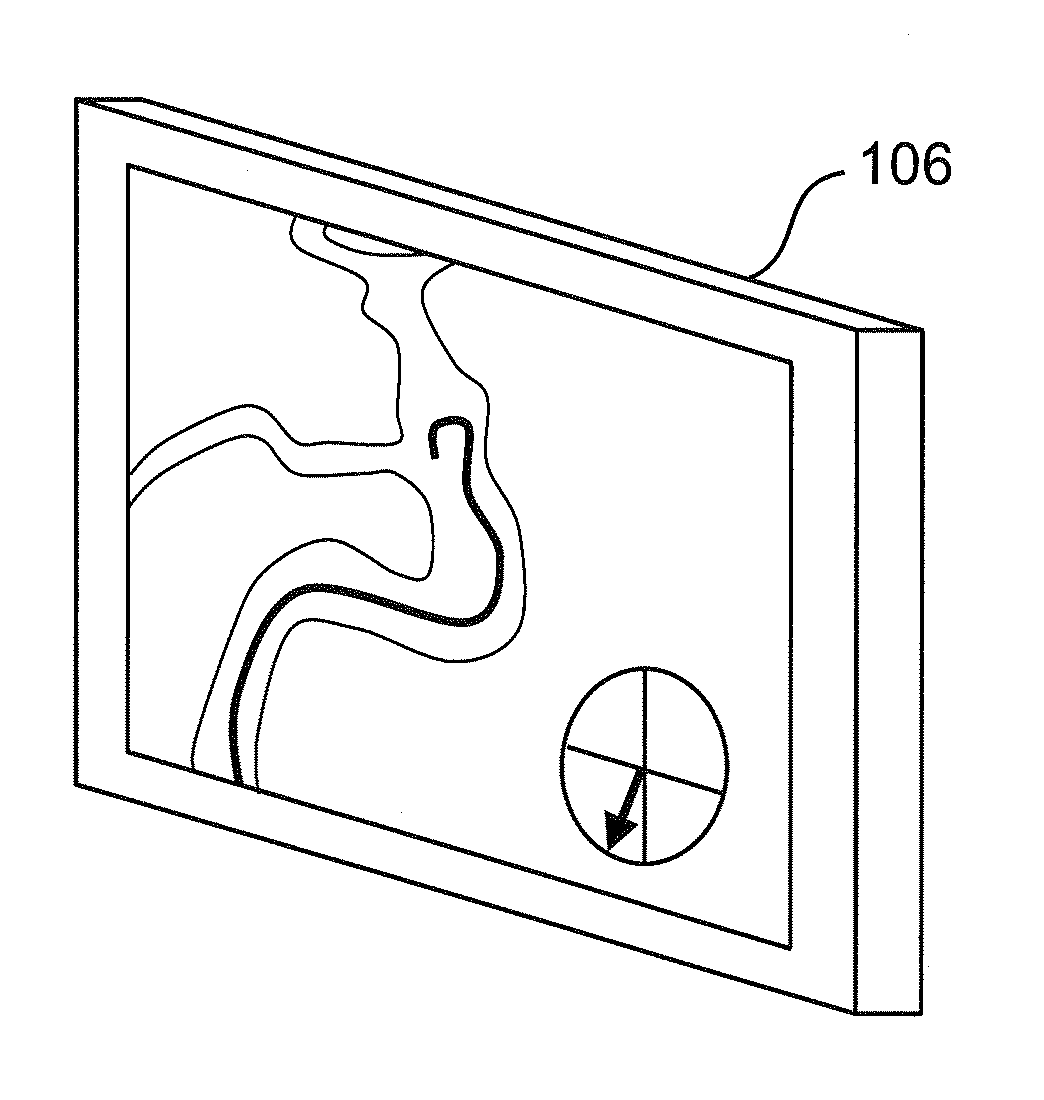

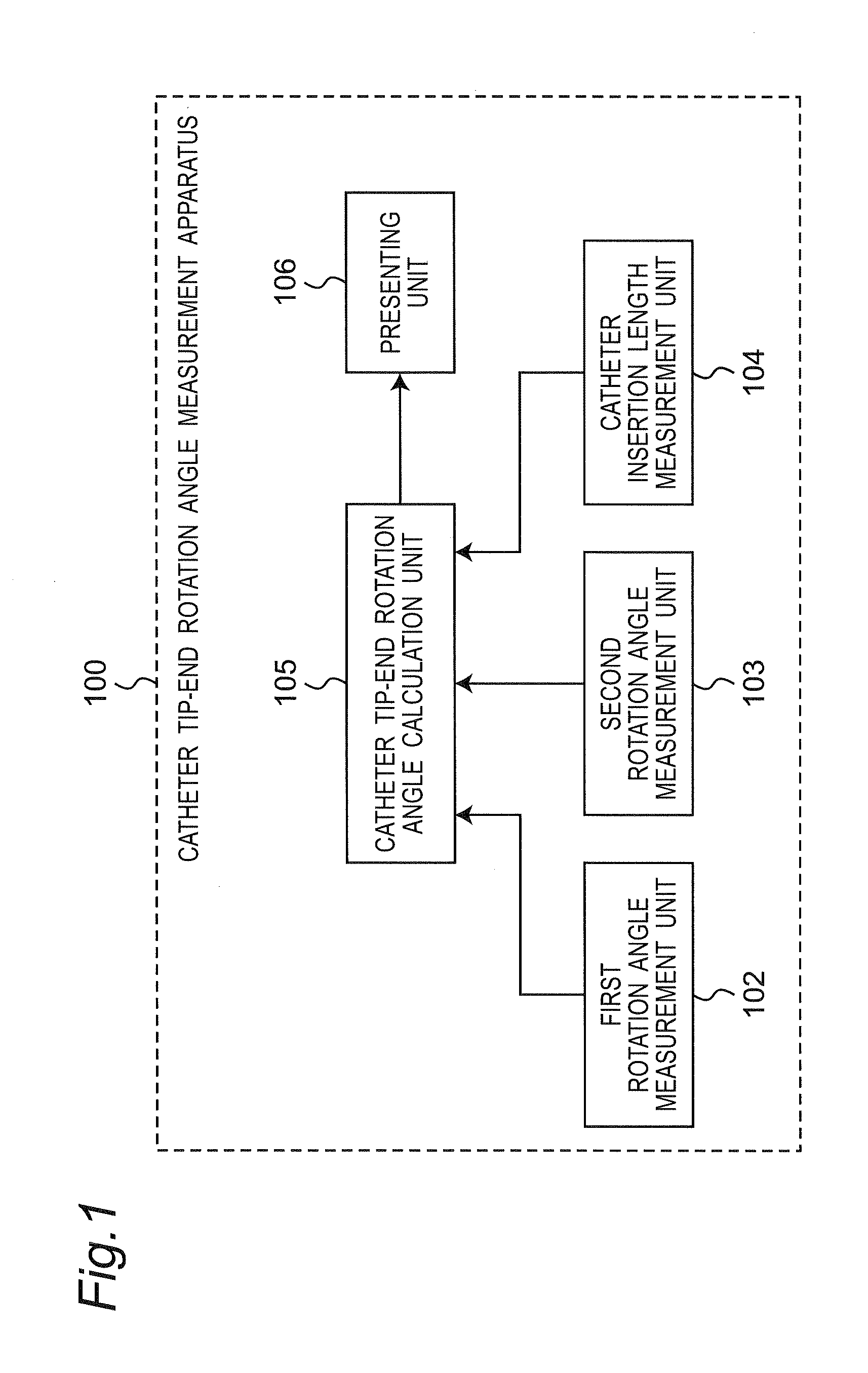

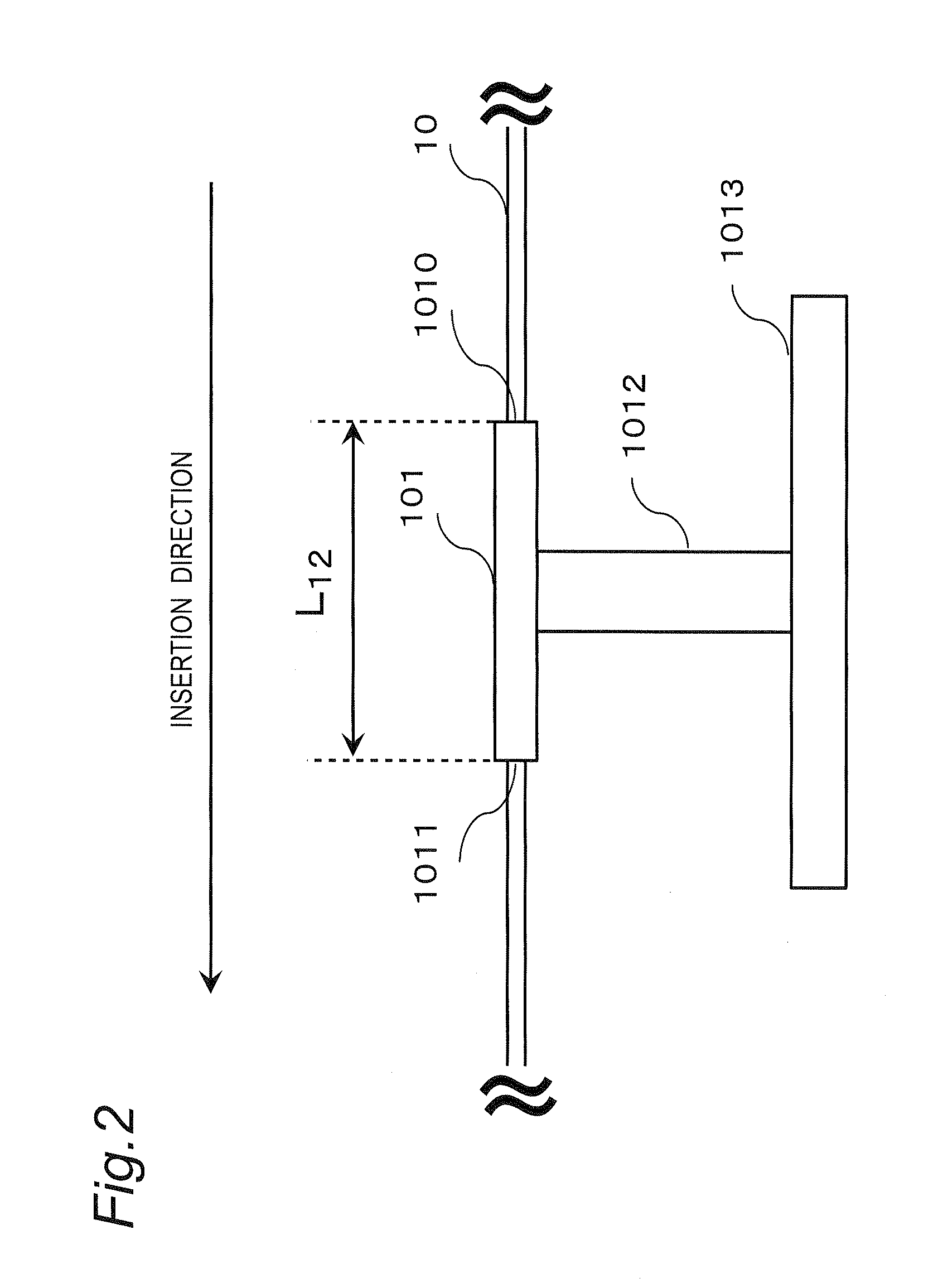

Catheter tip-end rotation angle measurement apparatus, catheter tip-end rotation angle measurement method, and catheter tip-end rotation angle measurement program

ActiveUS20140187921A1Accurate measurementPrecise angle of rotationCatheterDiagnostic recording/measuringLength measurementMOTION LIMITATION

A catheter tip-end rotation angle measurement apparatus includes a motion restriction unit, of a tube shape penetrated from a first hole to a second hole of a catheter on tip end and opposite sides, that restricts the catheter motion to an insertion direction by causing the catheter to pass through from the first to second holes, first and second rotation angle measurement units that measure first and second rotation angles that are rotation angles of the catheter at the first and second holes, a catheter insertion length measurement unit that measures a catheter insertion length, and a catheter tip-end rotation angle calculation unit that calculates the rotation angle of the catheter tip end by using an angle difference between the first and second rotation angles, the catheter insertion length, and a distance between the first and second holes.

Owner:PANASONIC CORP

Rotary preserved szechuan pickle filling equipment

The invention provides rotary preserved szechuan pickle filling equipment, and belongs to the technical field of preserved szechuan pickle processing. The rotary preserved szechuan pickle filling equipment comprises a carrying and dumping mechanism device, a stirring and seasoning device, an automatic feed divider and a rotary filling device. The stirring and seasoning device is arranged on one side of the carrying and dumping mechanism device, and the automatic feed divider is arranged below a stirrer. The rotary filling device is arranged on the left side of the automatic feed divider, and the rotary filling device comprises a filling rotary disc mechanism, a bag supply mechanism and a bag taking mechanism. The filling rotary disc mechanism comprises a rotary disc conveying assembly, a rotary disc driving assembly and a bag receiving driving assembly. The bag receiving driving assembly is arranged on the left side of the filling rotary disc, and the bag supply mechanism is arranged on the left side of the filling rotary disc mechanism. The bag taking mechanism is arranged between the bag supply mechanism and the filling rotary disc mechanism, and a bag opening mechanism is arranged on the front side of the filling rotary disc. The rotary preserved szechuan pickle filling equipment achieves continuous rotary filling of preserved szechuan pickle, and is high in filling automation degree.

Owner:桐乡市大周商贸有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com