Rotary oil coating mechanism driven by servo motor

A technology of servo motor and rotary coating, applied in the direction of spraying device, etc., can solve the problems of uneven oil coating and inconvenient cleaning of parts, achieve precise adjustment of universal position, and realize multi-threaded control of parts coating, rotation speed and precise angle effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

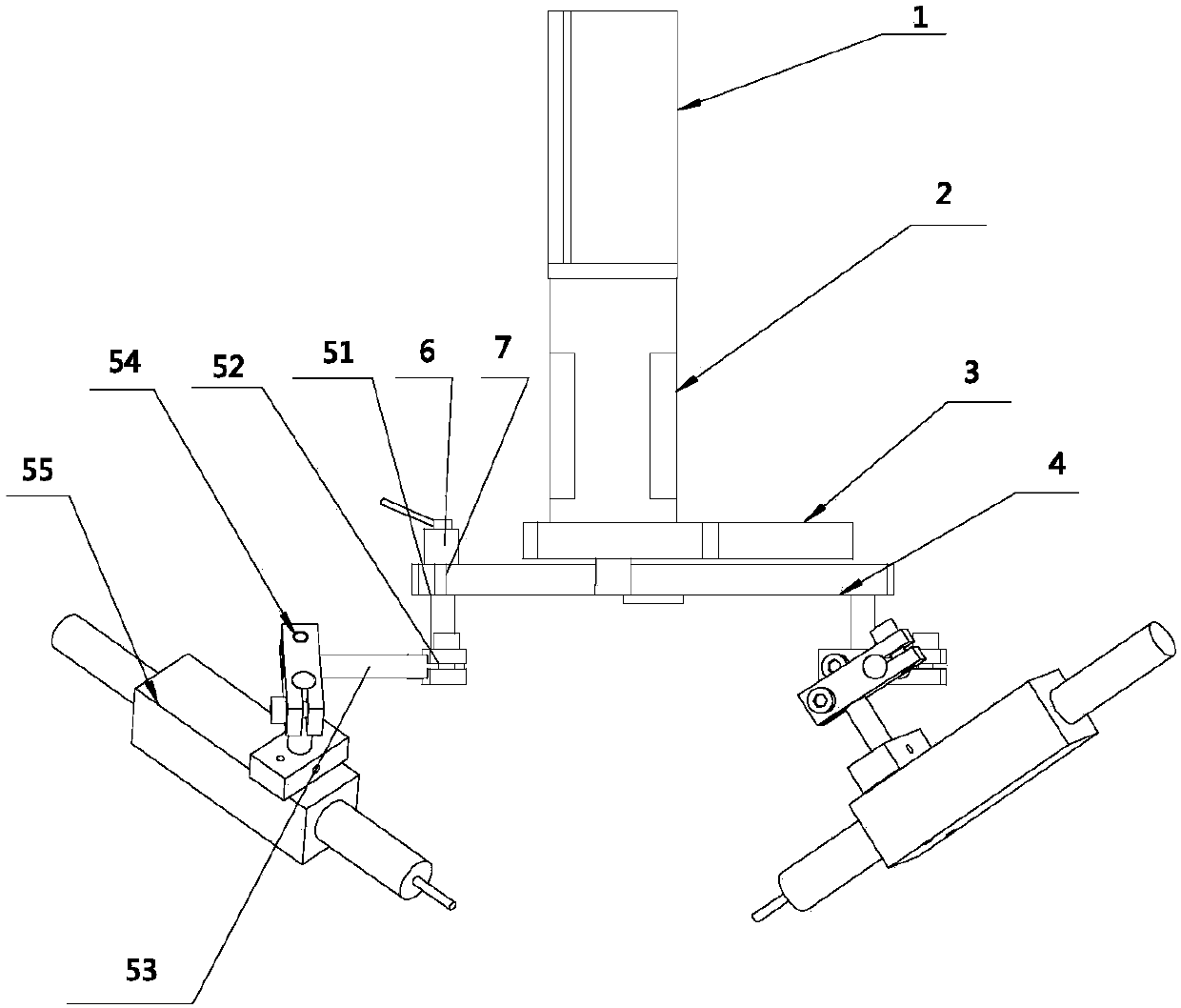

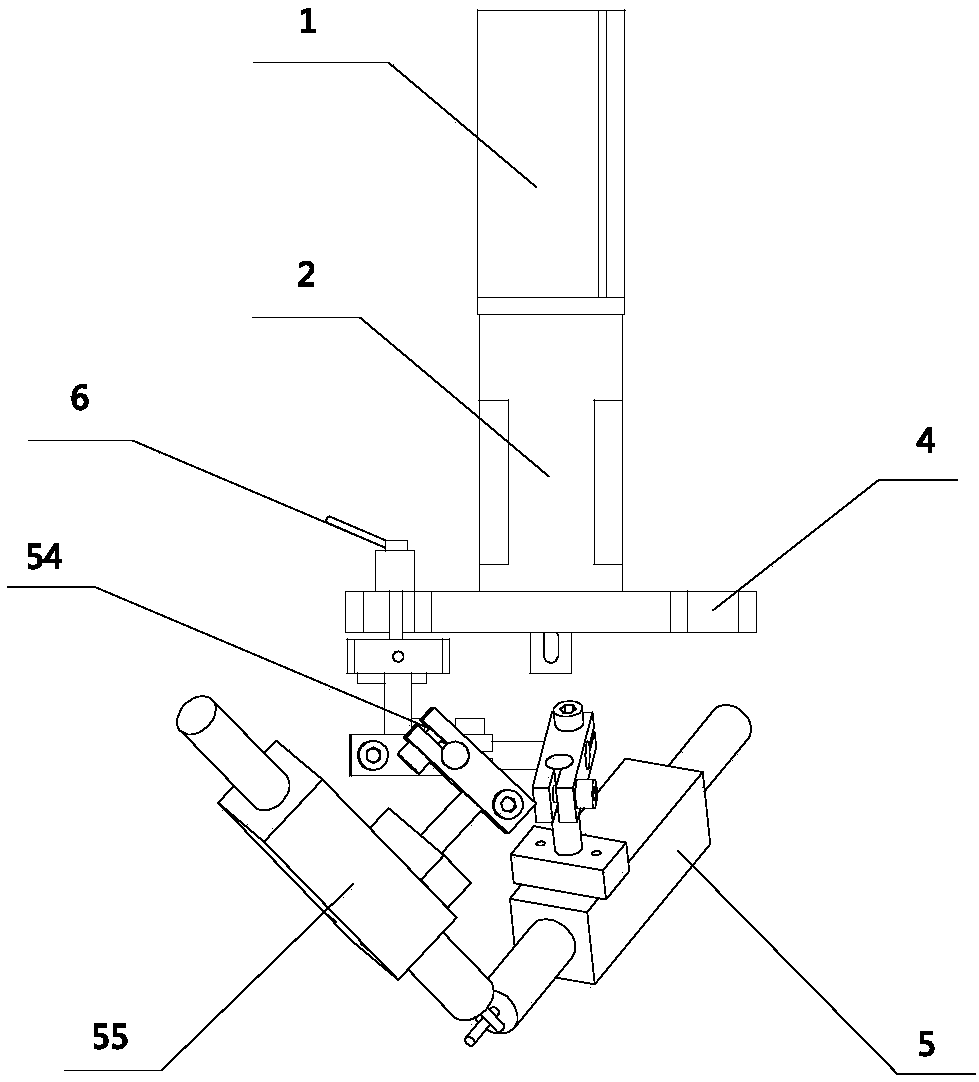

[0014] Such as Figure 1-2 Shown: a rotary oiling mechanism driven by a servo motor, including a motor 1, a reducer 2, a mechanism fixing plate 3, a rotating plate 4 and an oiling mechanism 5; the motor 1 is connected to a reducer 2, and the reducer 2 Fixed on the mechanism fixing plate 3, the drive shaft of the reducer 2 is connected with the rotating plate 4; two sides of the rotating plate 4 are respectively connected with a group of oiling mechanisms 5.

[0015] The oiling mechanism 5 includes a first connecting rod 51, a connecting block 52, a second connecting rod 53, a universal adjustment block 54 and an oiling gun 55; the first connecting rod 51 is connected with the connecting block 52, and the connecting block 52 It is connected with the second connecting rod 53 , the second connecting rod 53 is connected with the universal adjustment block 54 , and the universal adjustment block 54 is connected with the grease gun 55 .

[0016] The upper end of the first connectin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com