Method for improving programming speed and precision of soldering robot by using Gerber file

A soldering robot, programming speed technology, applied in metal processing and other directions, can solve the problems of low position accuracy, low programming efficiency, limited programmer proficiency, etc., to achieve the effect of improving welding accuracy and reducing programming time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

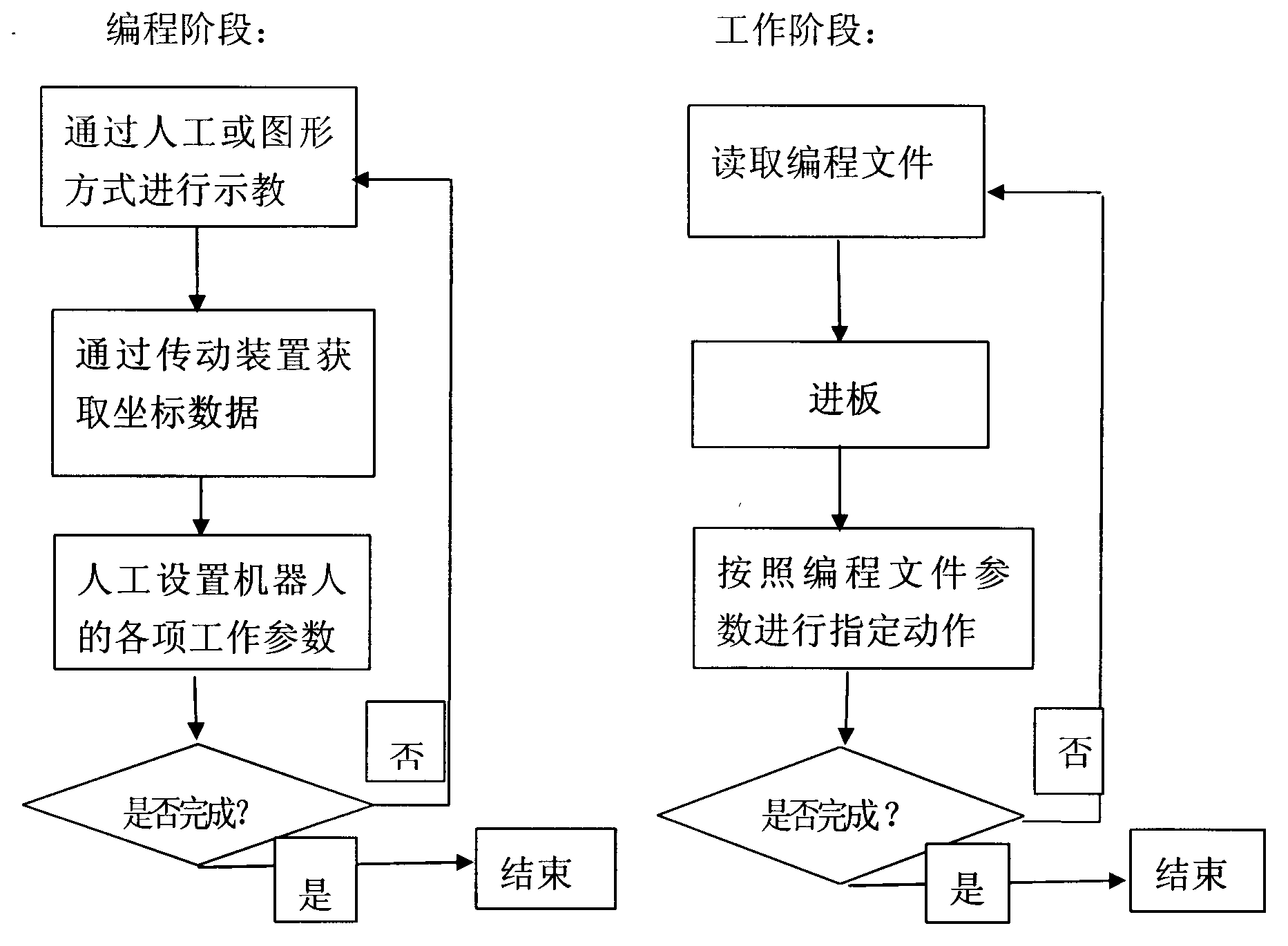

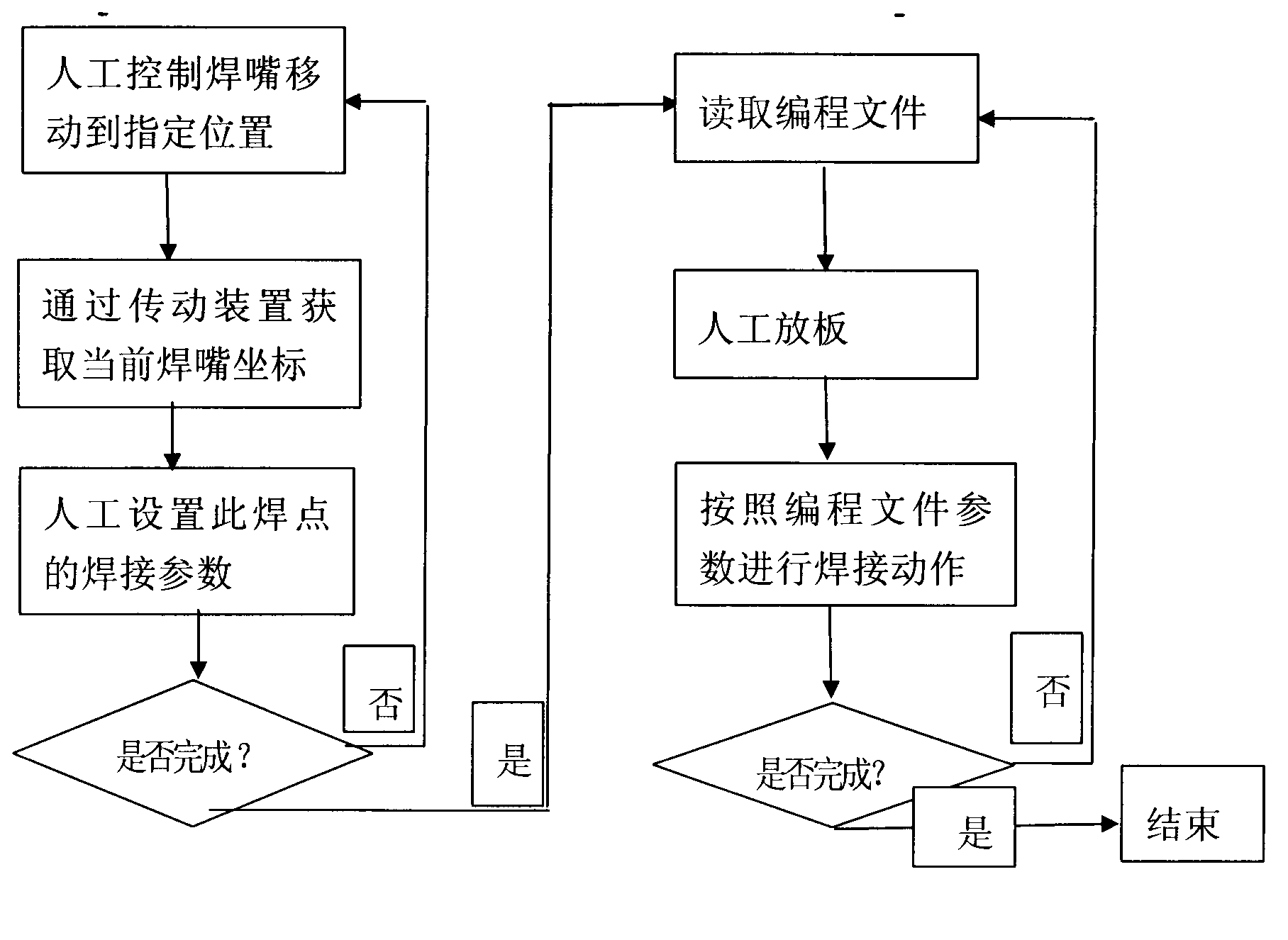

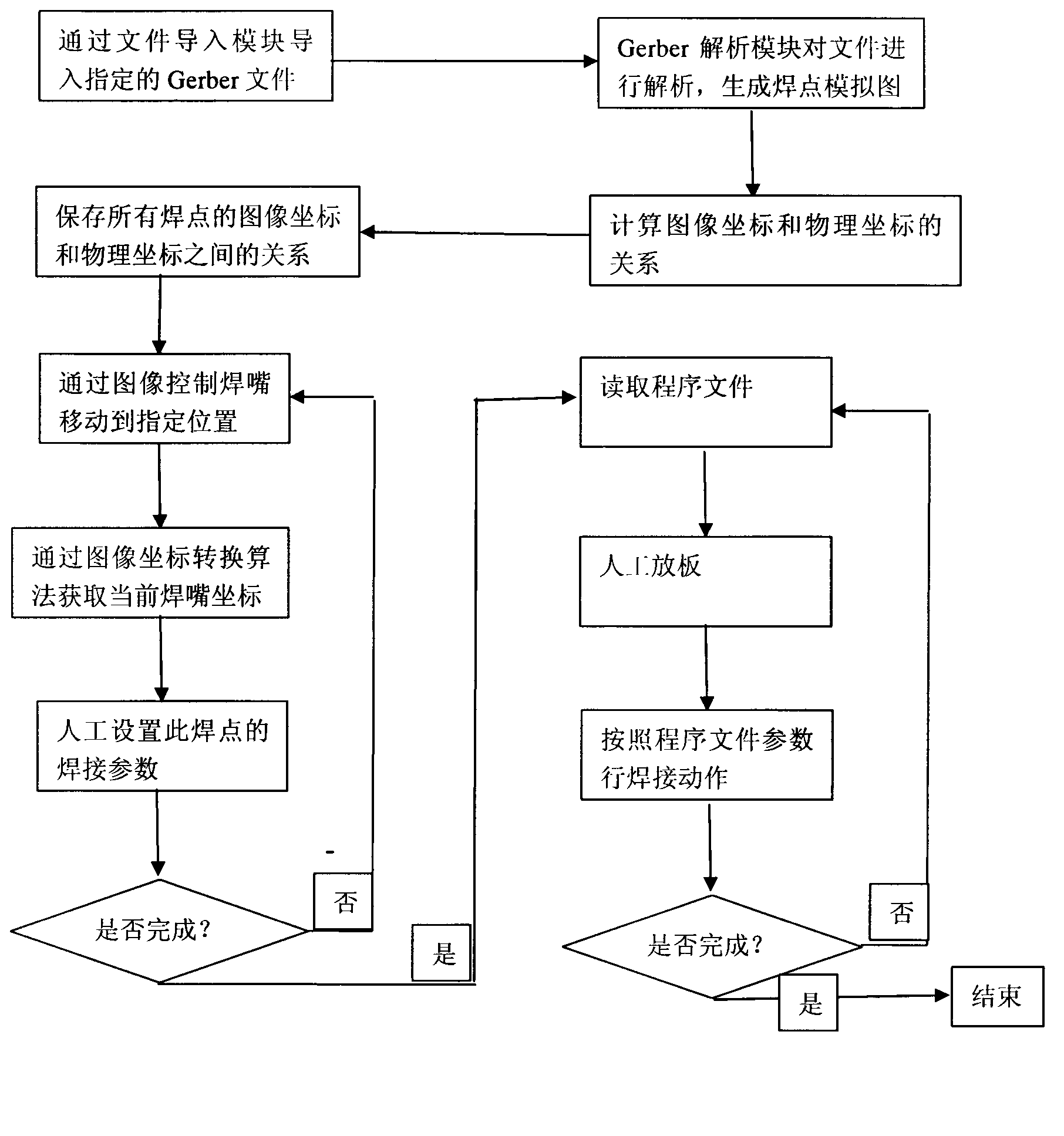

[0035] The technical solutions of the present invention will be described in detail below in conjunction with the accompanying drawings.

[0036] The design concept of the present invention is as follows: use the processing function of graphics and images that the robot has (this belongs to the conventional technology in the field of robot programming), and in the programming process, the Gerber file is imported into the programming file. The Gerber file contains Gerber graphics information, which is converted into a file format that the programming file can support after being processed by the code in the software, and then imported.

[0037] Gerber file is an international standard photo-painting format file, which is widely used in PCB board manufacturing and electronic assembly industry. It contains two formats, RS-274-D and RS-274-X, among which RS-274-D is called the basic GERBER format, and a D code file must be attached at the same time to fully describe a graphic; RS-...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com