Method for positioning Mark points of PCB (printed circuit board) by image matching

A PCB board and matching method technology, applied in the field of PCB welding visual inspection, can solve the problems of inability to locate the PCB board, inability to quasi-pad welding, inability to accurately calculate the offset of the PCB board, etc., and achieve the effect of high compensation accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The technical solution of the present invention will be described in detail below in conjunction with the accompanying drawings.

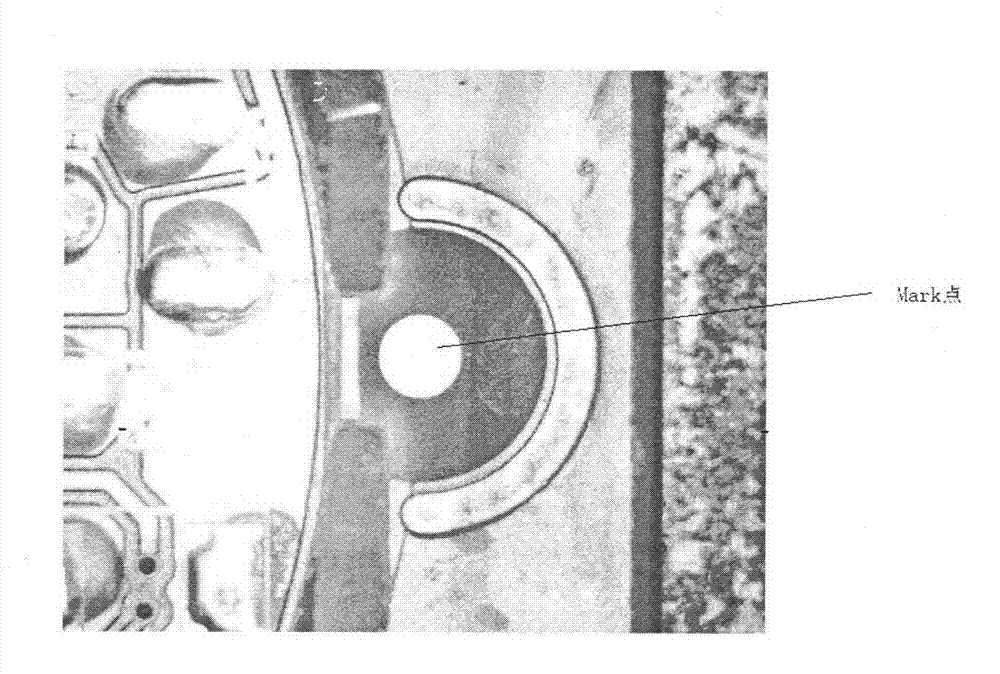

[0018] The image matching method refers to using the Mark point image in the benchmark as a data source. The so-called Mark point image in the benchmark refers to: the Mark point area image cut when doing the program; then when performing automatic detection, Utilize this image to carry out the search of scanning type, when the image size and the shape of finding the image and reference Mark point are all the same, just think that the detected image contains the detection Mark point; The offset between them is used for PCB board compensation.

[0019] The specific operation steps are as follows:

[0020] 1. Use the camera to capture the PCB image containing Mark points, and display it on the computer screen (called FOV field of view, FOV refers to the actual area currently captured by the camera), and then use the screenshot control that co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com