In-hole cavity monitoring device and method based on multi-frequency ultrasonic scanning

A multi-frequency ultrasonic and detection device technology, which is applied in measurement devices, processing response signals of detection, and material analysis using sonic/ultrasonic/infrasonic waves, which can solve problems such as poor detection accuracy and limited detection range.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0062] Below in conjunction with accompanying drawing and implementation example the present invention is further described:

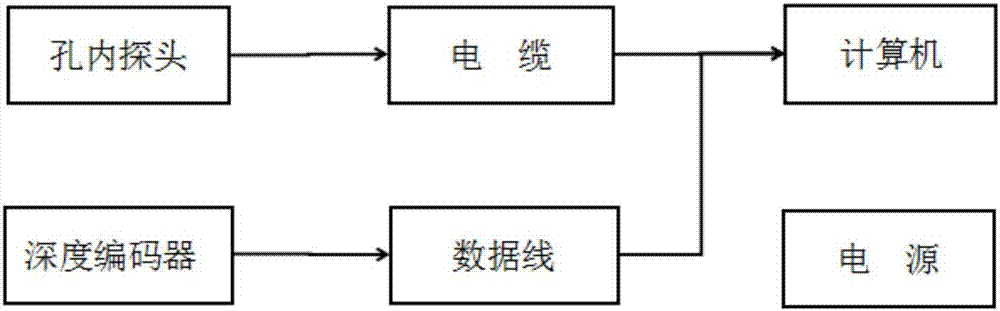

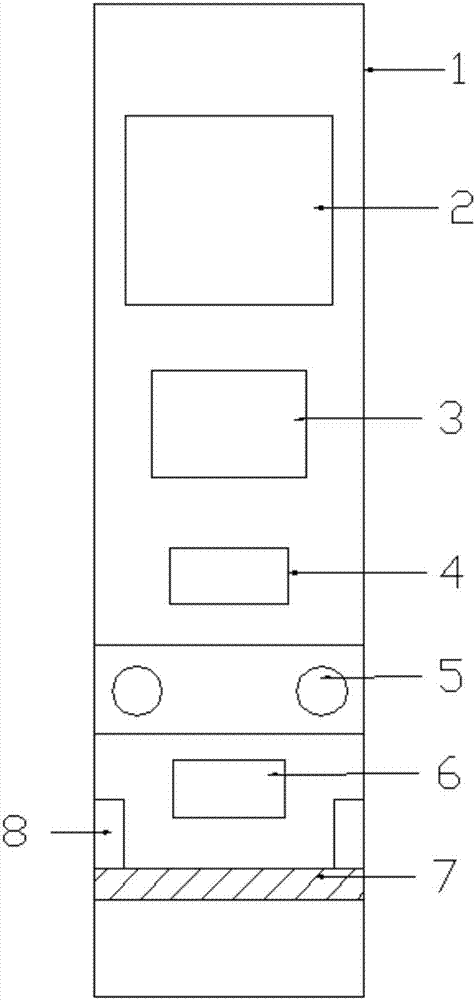

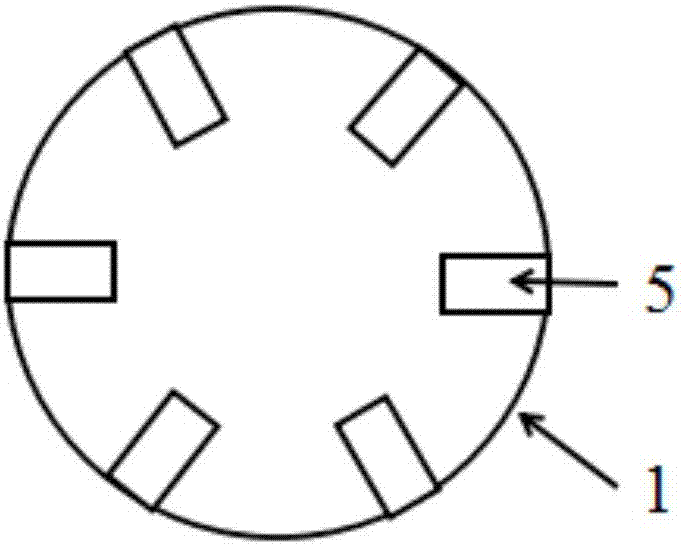

[0063] Such as figure 1 As shown, a multi-frequency ultrasonic scan-based detection device for hollow space in a hole includes a probe in the hole, a cable, a depth encoder, a data line, a computer and a power supply. The probe in the hole is used to accurately detect the scan on the rock wall of the hollow Points and the orientation and length of the scanning line where the ultrasonic transducer is located, the probe in the hole is placed in the empty space in the hole, the probe in the hole is lowered into the hole through the cable, and the collected data is uploaded to the computer on the ground through the cable, When the probe in the hole is lowered from the hole, the depth encoder at the hole starts to work, which is used to record the depth of the probe in the hole, so as to calculate the depth information of the scanning point on the rock wall...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com