Phase conjugate reflection bi-pass lighting confocal microscopic device

A phase conjugation and confocal microscopy technology, which is applied in the direction of measuring devices, optical devices, instruments, etc., can solve the problems that the measurement of large curvature surfaces cannot be realized, and it is difficult to improve the axial resolution, so as to improve point scanning resolution and improve Measuring the effect of resolution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] Embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

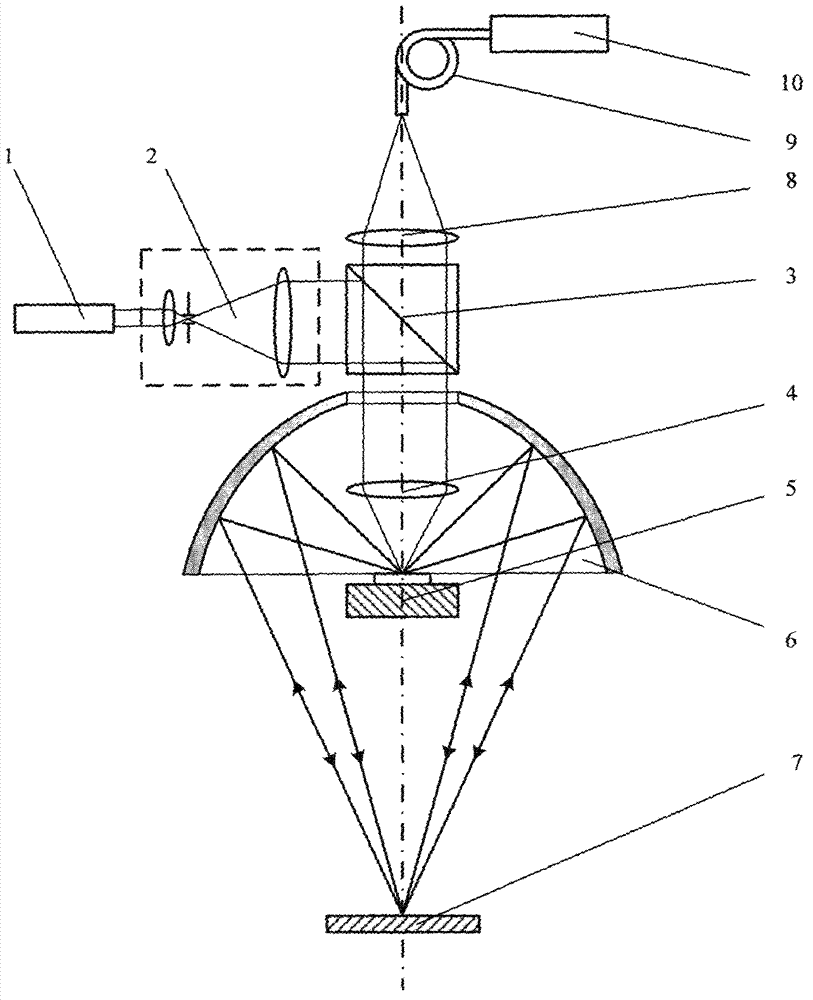

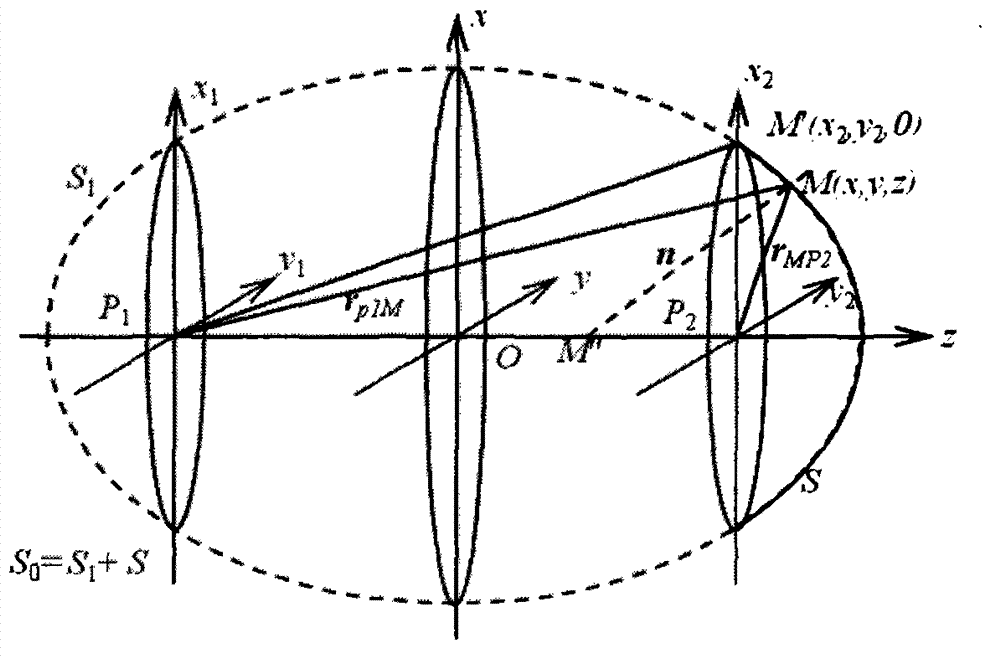

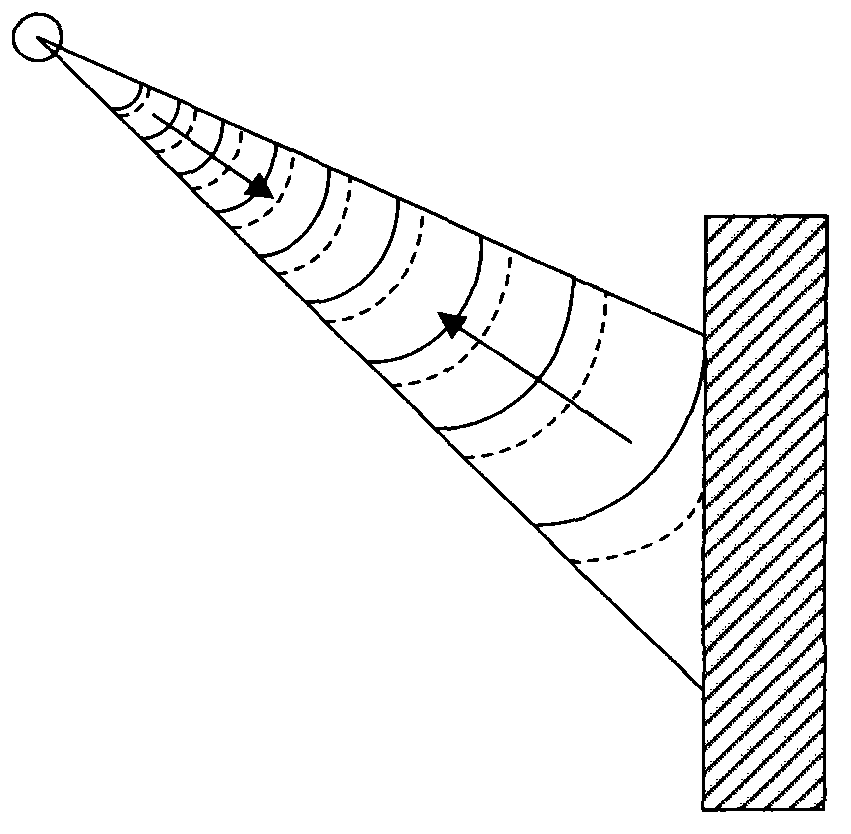

[0022] The phase conjugate reflective double-pass illumination confocal microscope device includes: laser 1, collimator beam expander 2, beam splitter 3, focusing objective lens 4, three-dimensional micro-displacement stage 5, collecting objective lens 8, conducting optical fiber 9, photodetector 10 wherein the collimating beam expander 2 and the beam splitter 3 are sequentially arranged on the direct light path of the laser 1, the focusing objective lens 4 and the three-dimensional micro-displacement stage 5 are arranged on the reflected light path of the beam splitter 3, and the collecting objective lens 8 is arranged on the transmission path of the beam splitter 3 On the optical path, the conducting optical fiber 9 conducts the light collected by the objective lens 8 to the photodetector 10, and an ellipsoidal reflector 6 is arranged on the reflectiv...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com