Method for detecting surface defects of aluminum-silicon plated products

A technology of defect detection and aluminum-silicon plating, which is applied in the direction of measuring devices, instruments, scientific instruments, etc., can solve the problems of difficult surface defect detection and classification, heavy surface texture, missed detection, etc., to reduce repeated detection of defects, relieve storage pressure, The effect of improving accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

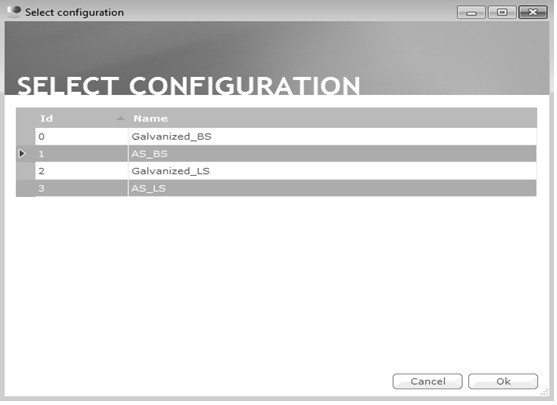

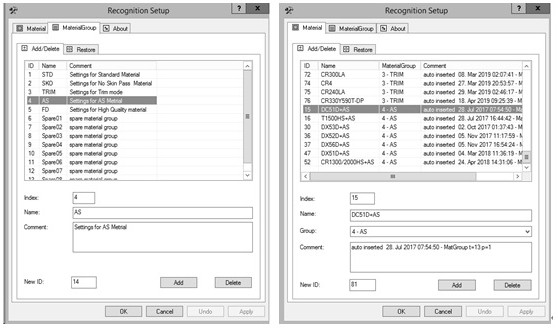

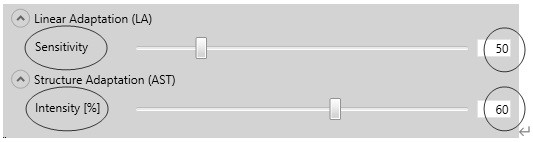

[0058] In the detection mode of aluminum-silicon products, set the detection parameters as follows image 3 set up.

[0059] After the detection sensitivity and texture adaptation are set, the detection of surface texture (false defects) is suppressed, and scratches are detected. Such as Figure 4 As shown, the red box indicates that the substrate texture-like false defect is suppressed and detected, and the green box indicates that the scratch defect is detected.

Embodiment 2

[0061] through as Figure 5 In the typical defect images shown, it can be intuitively observed that the area array image has a better ability to restore two-dimensional defects, while the line array image has a better ability to restore three-dimensional defects.

[0062] According to the respective detection advantages of line array and area array cameras, the defect subclassification and program compilation shown in Table 2 below are established.

[0063] Table 2 Establishment of defect subcategories

[0064]

[0065] If (class in [111,314,464]) class = -1;

[0066] The line-scan camera automatically filters the detected two-dimensional defects (line-array spots), and the area-scan camera automatically filters the detected three-dimensional defects (area array scratches, area array edge wrinkles), and realizes the directional optimization of defect detection in different dimensions.

[0067] By adopting the present invention, there are following beneficial effects:

[...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com