Detection device and detection method for metal corrosion of power transformation equipment

A technology of power transformation equipment and detection method, which is applied in the field of target detection, can solve the problems of low recall rate and corrosion detection accuracy, and achieve the effect of simple training method, low cost, and improved detection rate and recall rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further described in detail below in conjunction with specific implementation methods and accompanying drawings.

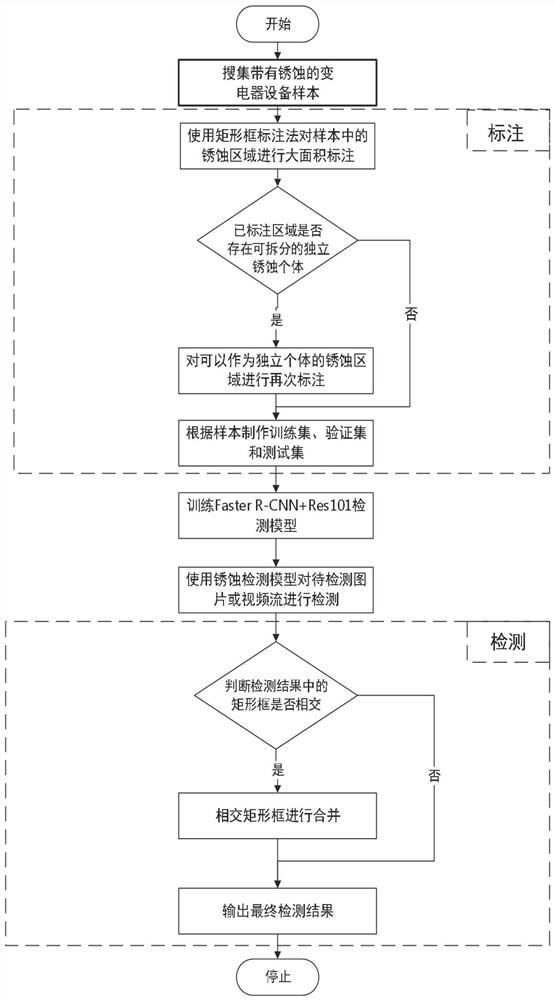

[0020] Such as figure 1 As shown, the detection method for metal corrosion of substation equipment of the present invention can be applied to any inspection robot and unmanned aerial vehicle with a camera, including the following steps:

[0021] (1) Collect samples of substation equipment with rust defects; and, collect samples of substation equipment with corrosion defects should cover all substation equipment in actual operation and the number of samples should be as large as possible;

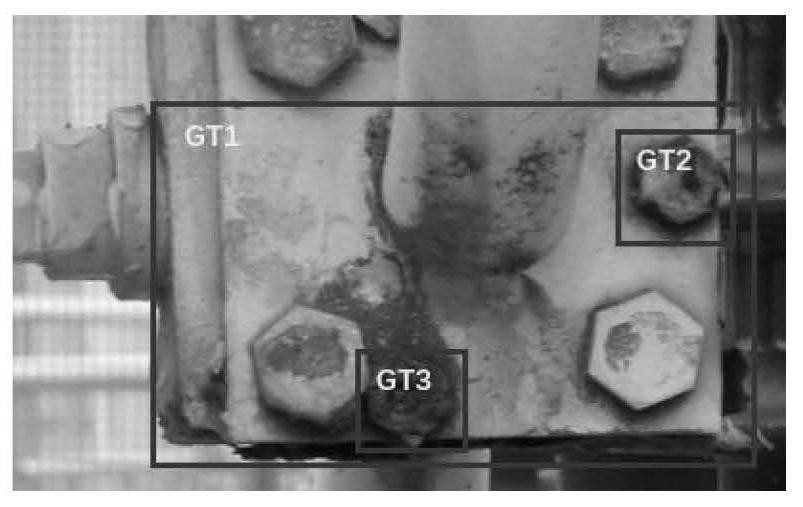

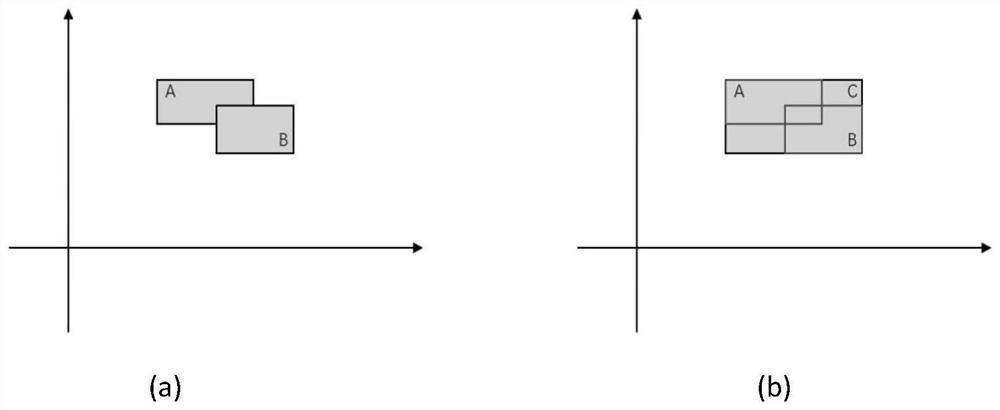

[0022] Due to the different sizes of substation equipment and the spread of corrosion, the size of the corrosion area is irregular. At the same time, metal corrosion is also detachable, that is, it can be used as an integral part of a whole piece of corrosion, or it can be seen as individual corrosion areas. Therefore, if figure 2 As show...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com