Full-automatic punching flanging device

A fully automatic punching technology, applied in the field of mechanical processing, can solve the problems of high production cost, poor hole pitch accuracy, and low work efficiency, and achieve the effects of low production cost, high work efficiency, and high hole pitch accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

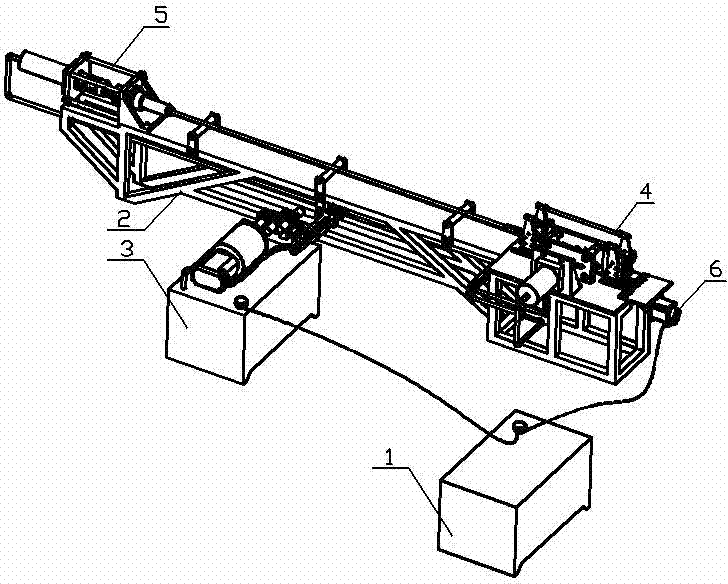

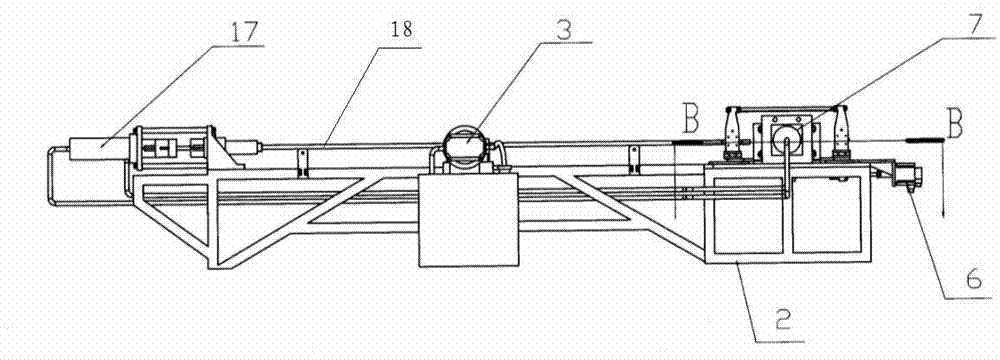

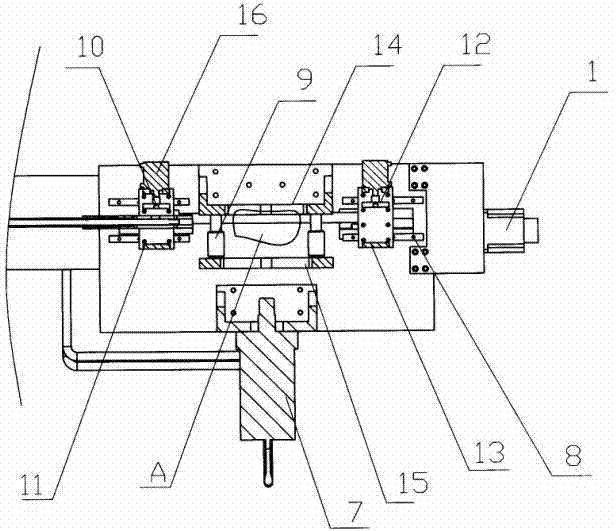

[0021] The fully automatic punching and flanging device is composed of a console 1, a frame body 2, a fuel tank 3, a front cylinder group 4, a rear cylinder group 5 and a motor 6, and the front cylinder group 4 and the rear cylinder group 5 are respectively installed on two sides of the frame body 2. The oil tank 3 is installed outside the frame body 2 to provide power for the front oil cylinder group 4 and the rear oil cylinder group 5 respectively. The motor 6 is installed outside the frame body 2 at the end of the front oil cylinder group 4. The console 1 is connected with the oil tank 3 and the motor 6 respectively. connect. The front oil cylinder group 4 is composed of front oil cylinder 7, guide rail 8, pipe frame 9, left upper clamping die 10, left lower clamping die 11, right upper clamping die 12, right lower clamping die 13, upper female die 14, lower female die Die 15, switch 16 is formed, and described guide rail 8 is fixed on the frame body 2, and upper left clamp...

Embodiment 2

[0024] The section of the flanging punch 23 is stepped, and other structures are the same as those in the first embodiment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com