Cylinder cover valve seat ring valve wire grinding and flapping machine

A valve seat ring and cylinder head technology, which is applied in the directions of grinding machine parts, grinding feed motion, grinding/polishing equipment, etc. Problems such as poor processing effect of seat ring finish

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

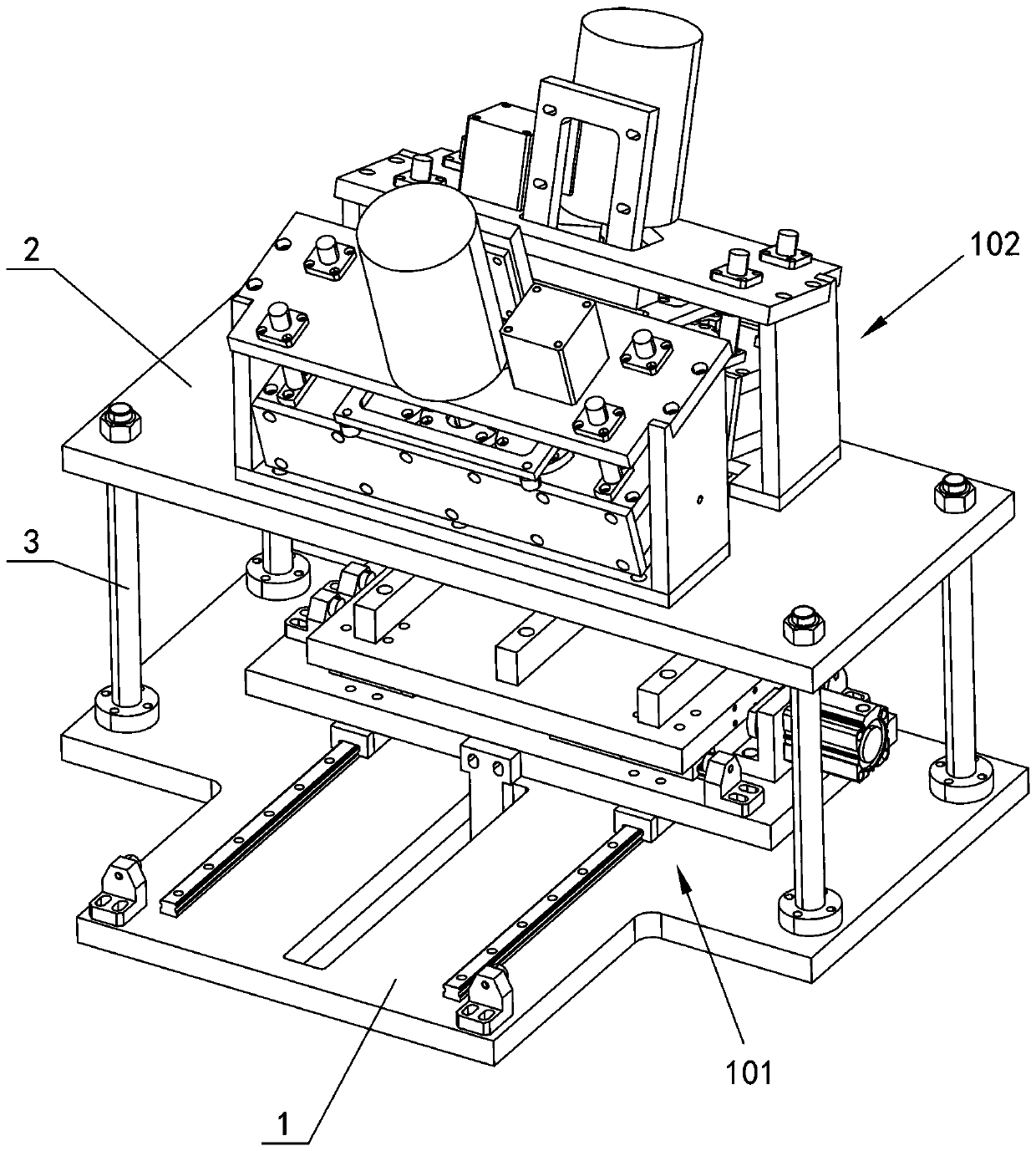

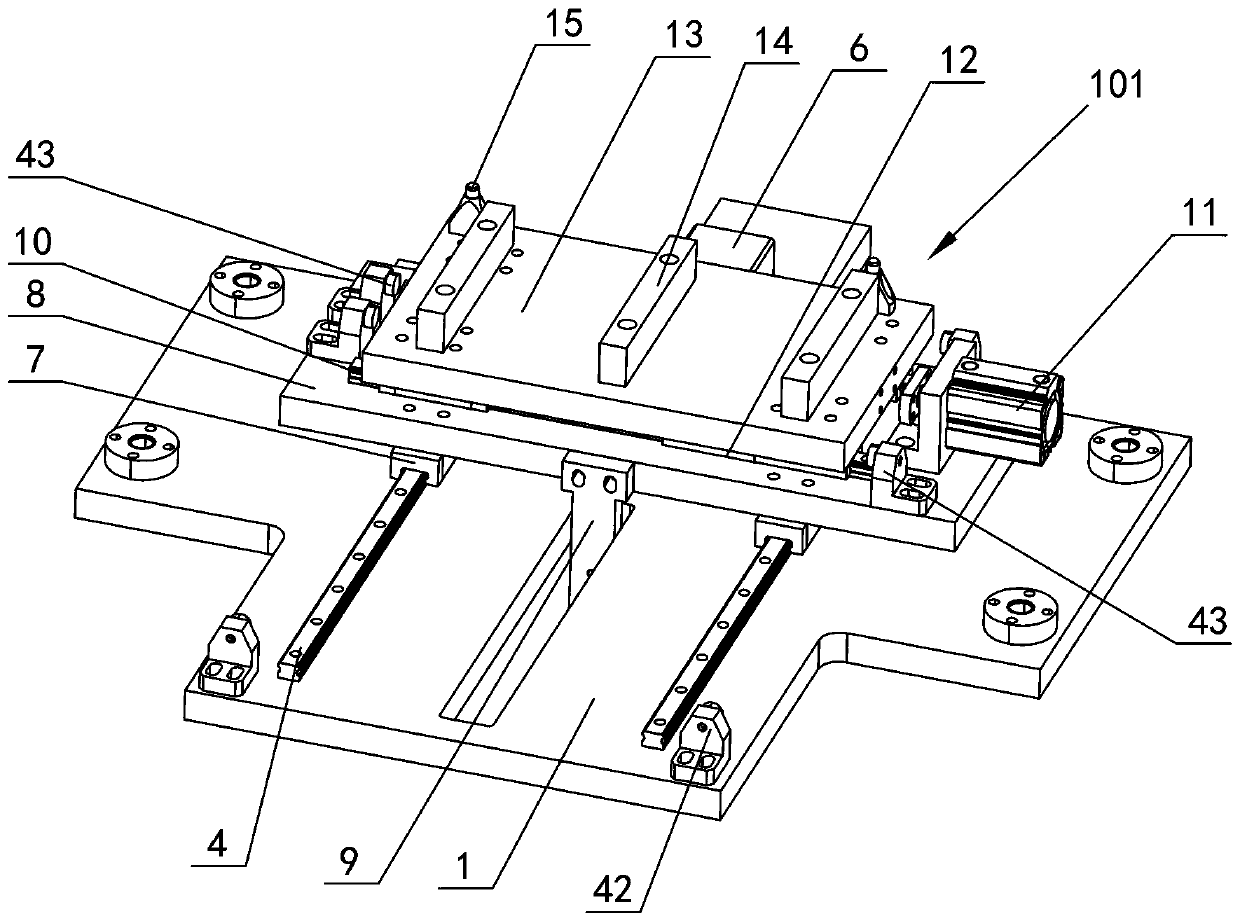

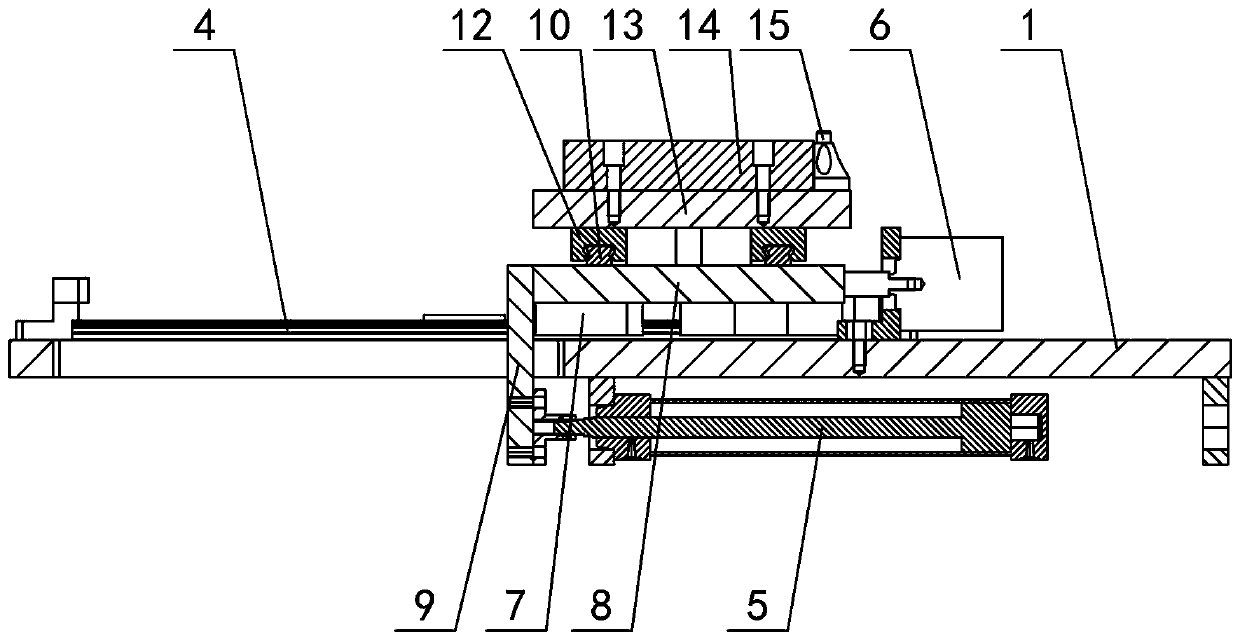

[0018] The invention relates to a cylinder head valve seat ring grinding and beating machine, such as figure 1 — Figure 11As shown, it includes a lower fixed plate 1 and an upper fixed plate 2, a support rod 3 is connected between the upper and lower fixed plates, a cylinder head positioning and moving device 101 is arranged on the lower fixed plate, and two groups of front and rear rotating lifting devices 102 are arranged on the upper fixed plate , the cylinder head positioning and moving device 101 includes front and rear slide rails 4, long distance front and rear movement cylinders 5 and short distance front and rear movement cylinders 6, the front and rear slide rails, long distance front and rear movement cylinders and short distance front and rear movement cylinders are connected with the lower fixed plate Fixed, the front and rear sliders 7 are set on the front and rear slide rails, and the front and rear slide plates 8 are set on the front and rear sliders. The pist...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com