Down-adjustment type high-speed thin sheet longitudinal shearing machine

A slitting machine and thin plate technology, applied in the direction of shearing machine equipment, shearing devices, shearing machine accessories, etc., can solve the problems of affecting the quality of metal strips, unstable tension of metal plates, difficult metal narrow strips, etc., to achieve The process of movement is stable, the adjustment is convenient and quick, and the moving distance is precise

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

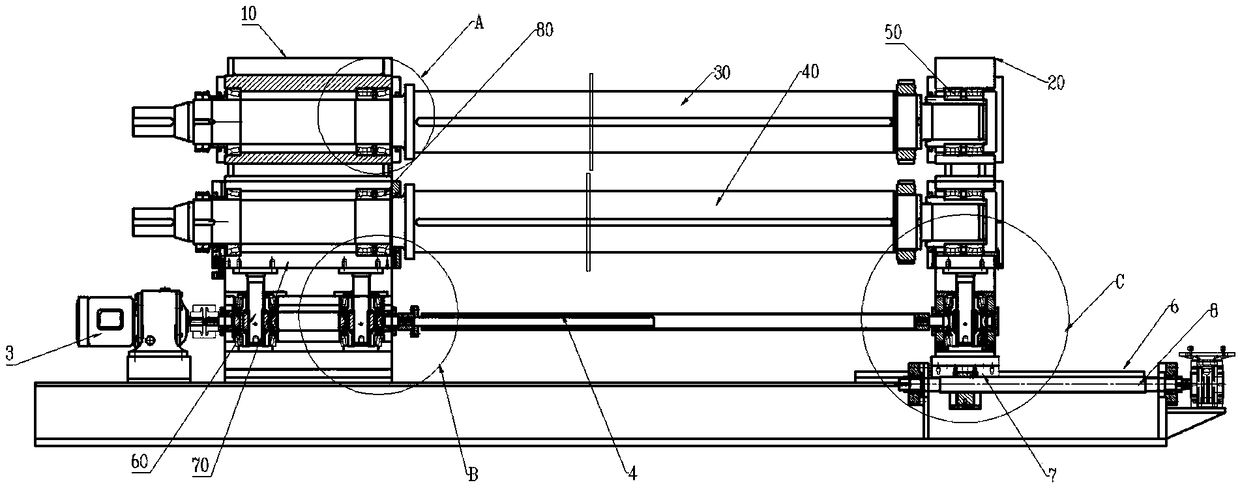

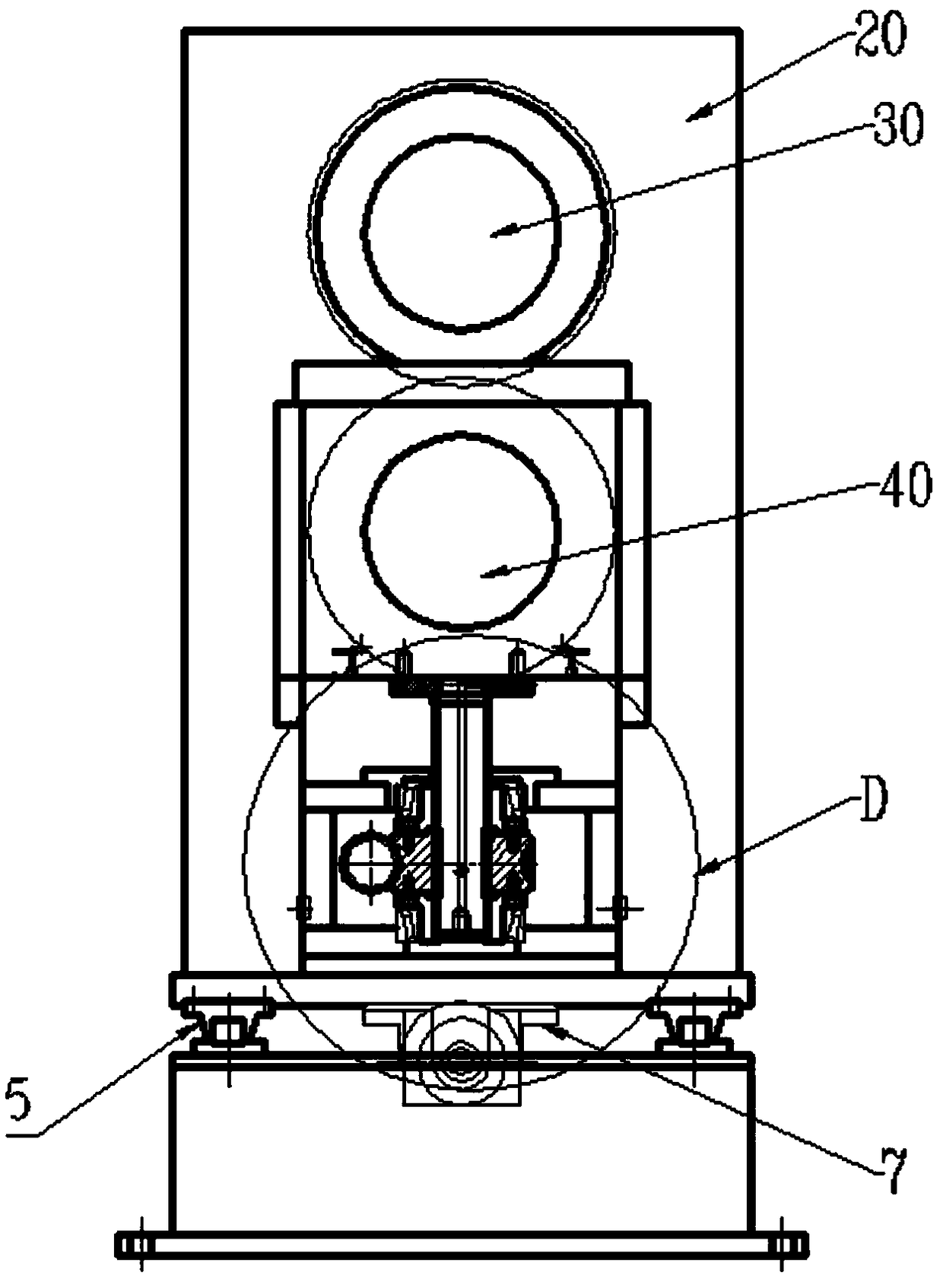

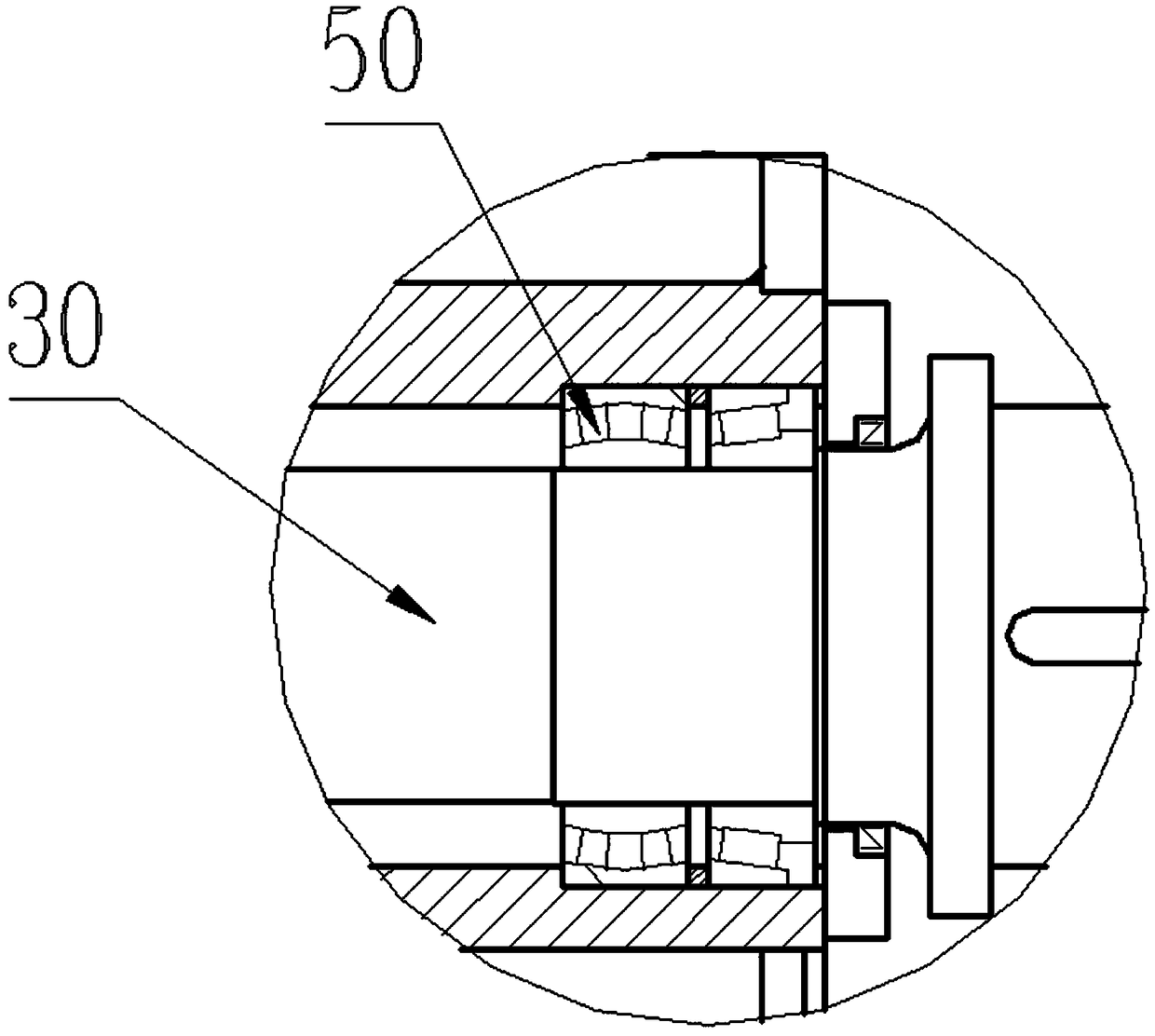

[0023] combine Figure 1 to Figure 6 The lower-adjustment high-speed sheet slitting machine shown in this embodiment includes a left frame 10, a right frame 20, and an upper knife arranged between the left frame 10 and the right frame 20. The shaft 30 and the lower cutter shaft 40, the left side frame 10 and the right side frame 20 are fixed with upper side bearings 50, and the upper side bearings 50 are sleeved on the two ends of the upper cutter shaft 30, and the upper cutter shaft 30 passes through the upper side The side bearing 50 is fixed between the left side bracket 10 and the right side bracket 20, and the ball screw 60 arranged vertically is movably supported in the left side frame 10 and the right side frame 20, and the leading screw 60 is sleeved and connected with The screw nut, the screw nut is fixed with the lower tool holder 70, the lower tool holder 70 is provided with a lower side bearing 80, and the lower knife shaft 40 is arranged between the left side fram...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com