Turbine blade infrared radiation light collection device

A technology of turbine blades and collection devices, applied in the field of mechanical structure, can solve the problem that the focusing collimator cannot be adjusted.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be further introduced below in conjunction with the drawings and embodiments.

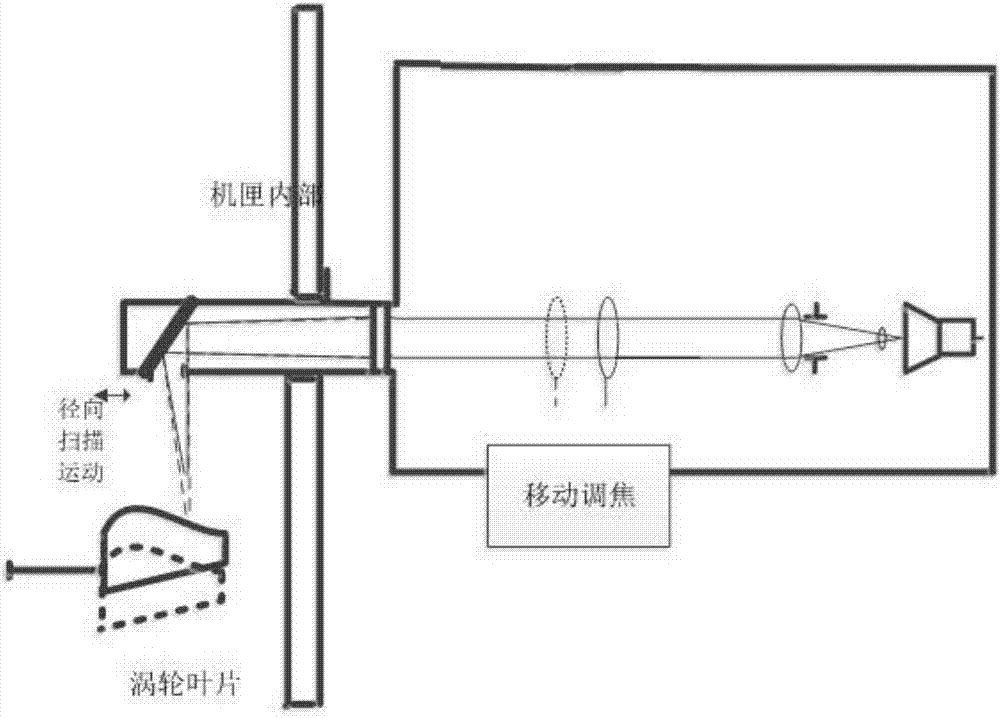

[0017] The reflecting mirror is made of quartz, the reflecting surface is plated with metal platinum, the lens diameter is 10mm, and the deflection angle is adjusted by the main control center to reflect the infrared light radiated by the turbine blades into the temperature measuring light path.

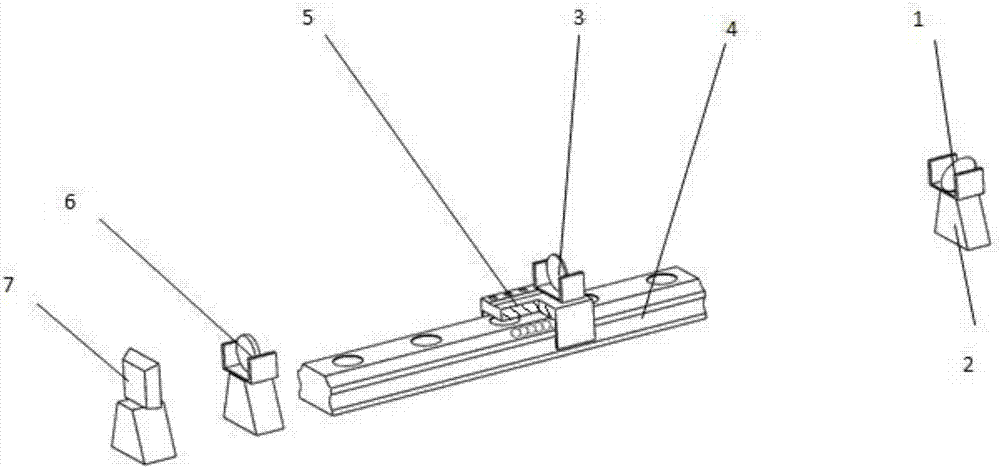

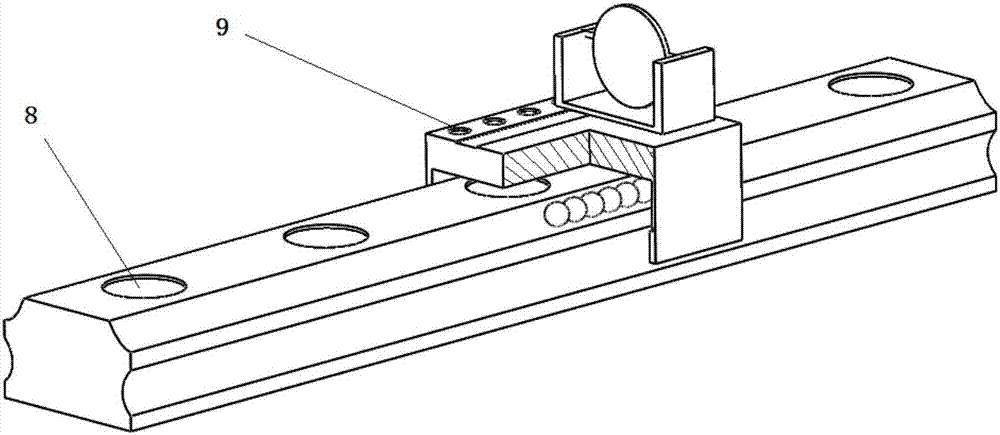

[0018] The measurement base is used for fixing the reflector and the infrared light detector.

[0019] The collimating mirror is made of calcium fluoride material and has a diameter of 30 mm. It is used to turn the infrared light reflected by the reflector into parallel light and accurately focus the infrared light radiated by the turbine blades in the infrared detector. Such as Figure 4 As shown, when the deflection angle of the reflector changes, the radiant energy radiated by points on the turbine blades at different positions is reflected into the light path. Since the poi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com