Heating module mounting device

An installation device and accommodating space technology, applied in the field of heating module installation devices, can solve problems such as troublesome keel installation and ground damage, and achieve the effects of low cost, reasonable structure and uniform force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

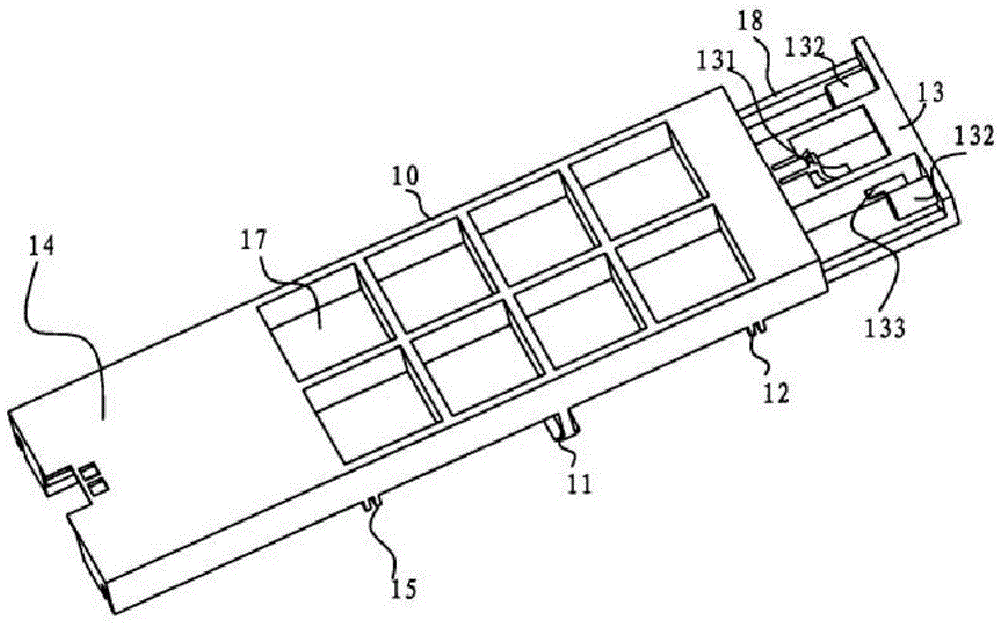

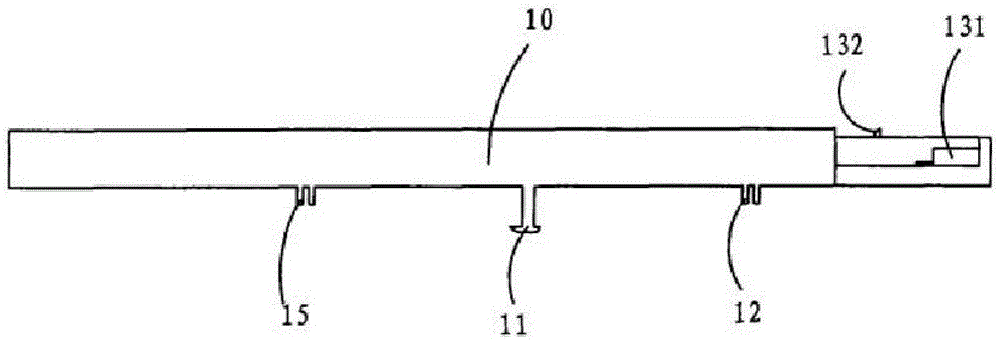

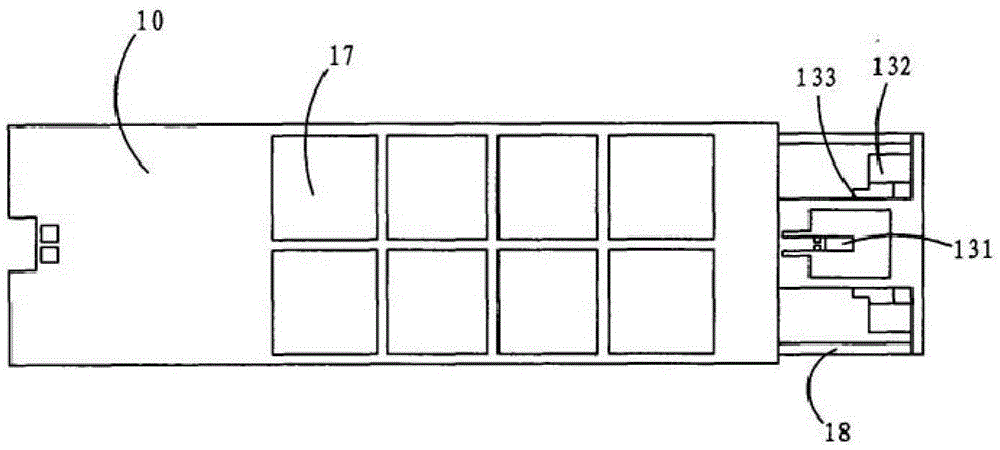

[0017] In order to describe the present invention further, illustrate with specific implementation below in conjunction with accompanying drawing:

[0018] See attached Figure 1~4 , including at least two brackets 10, the top surface of the bracket 10 protrudes upwards with a hook body 11 and an embedding groove 12, one side of the bracket 10 is extended with a guide frame 13, and the other side of the bracket 10 is provided with another snap-fit An accommodating space 14 of the sliding guide frame 13 of the bracket, and a spring 141 connected to the sliding guide frame 13 is arranged in the accommodating space 14 . When in use, the heating module 20 is a rectangular block plate 20. An embedding flange 21 is protruded at the central part of one side edge of the block plate 20, and an embedding groove 23 is recessed at the central part of the other side edge, so that Two adjacent heating modules 20 are correspondingly embedded into one body, and the bottom side edge of the em...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com