Meta-aramid paper containing nanometer diamondene, and making method thereof

A nanodiamondene and aramid paper technology, applied in special paper, paper, papermaking and other directions, can solve the problems of affecting paper performance, uneven distribution, easy to agglomerate, etc., achieve good dielectric strength, easy dispersion, preparation method simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

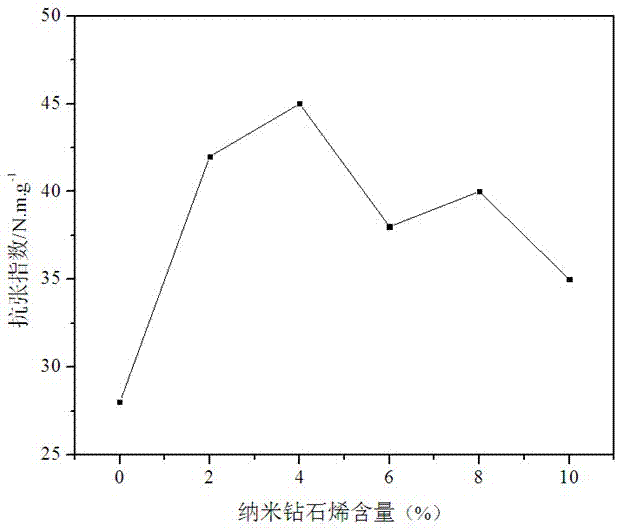

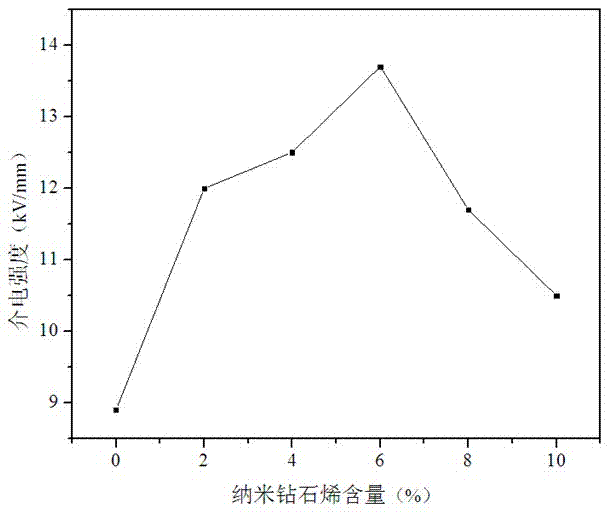

[0028] A meta-aramid paper containing nanodiamondene, mainly made of basic raw materials, polyethylene oxide and nanodiamondene, the basic raw materials are made of the following raw materials in parts by weight: 30 parts of meta-aramid chopped fibers, 70 parts of meta-aramid pulp, the amount of polyethylene oxide is 0.3% of the basic raw material, and the amount of nanodiamondene is 2%. The length of the meta-aramid chopped fibers is 4mm, and the denier (fiber thickness) is 1D; the average length of the meta-aramid pulp is 1mm, the aspect ratio is 60, and the beating degree is 30°SR.

[0029] The nano-diamantene is prepared by mixing nano-diamantene with three different particle sizes of 200 nm, 300 nm, and 400 nm in a mass ratio of 3:4:2 through activation treatment and surface modification, wherein,

[0030] The specific operations of the activation treatment are: ①Ultrasonic alkali cleaning: put the mixed nanodiamondene in the alkali washing liquid for ultrasonic alkali wa...

Embodiment 2

[0039] A meta-aramid paper containing nanodiamondene, mainly made of basic raw materials, polyethylene oxide and nanodiamondene, the basic raw materials are made of the following raw materials in parts by weight: 60 parts of meta-aramid chopped fibers, Meta-aramid pulp 40, the amount of polyethylene oxide is 0.6% of the basic raw material, and the amount of nano-diamondene is 10%. The length of the meta-aramid chopped fibers is 8mm, and the denier (fiber thickness) is 2D; the average length of the meta-aramid pulp is 3mm, the aspect ratio is 100, and the beating degree is 50°SR.

[0040] The nano-diamantene is prepared by mixing nano-diamantene with three different particle sizes of 200nm, 300nm, and 400nm in a mass ratio of 4:5:3 through activation treatment and surface modification. The specific operation of the activation treatment is: ① ultrasonic Alkali washing: Put the mixed nanodiamondene in the alkaline washing solution for ultrasonic alkaline washing and stirring. The...

Embodiment 3

[0049] A meta-aramid paper containing nanodiamondene, mainly made of basic raw materials, polyethylene oxide and nanodiamondene, the basic raw materials are made of the following raw materials in parts by weight: 50 parts of meta-aramid chopped fibers, Meta-aramid pulp 50, the amount of polyethylene oxide is 0.4% of the basic raw material, and the amount of nanodiamondene is 4%. The length of the meta-aramid chopped fibers is 6mm, and the denier (fiber thickness) is 2D; the average length of the meta-aramid pulp is 3mm, the aspect ratio is 80, and the beating degree is 40°SR.

[0050] The nanodiamantene is prepared by mixing nanodiamantene with three different particle sizes of 200, 300nm and 400nm in a mass ratio of 4:5:2, after activation treatment and surface modification, wherein,

[0051] The specific operations of the activation treatment and surface modification of nano-diamantene are the same as in Example 1.

[0052] The preparation method of the meta-aramid paper co...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com