Hot press

A hot press and laminated board technology, applied in lamination, lamination devices, layered products, etc., can solve the problems of fabric dislocation deformation, easy peeling, deformation, etc., and achieve the effect of adhesion, firmness and order

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

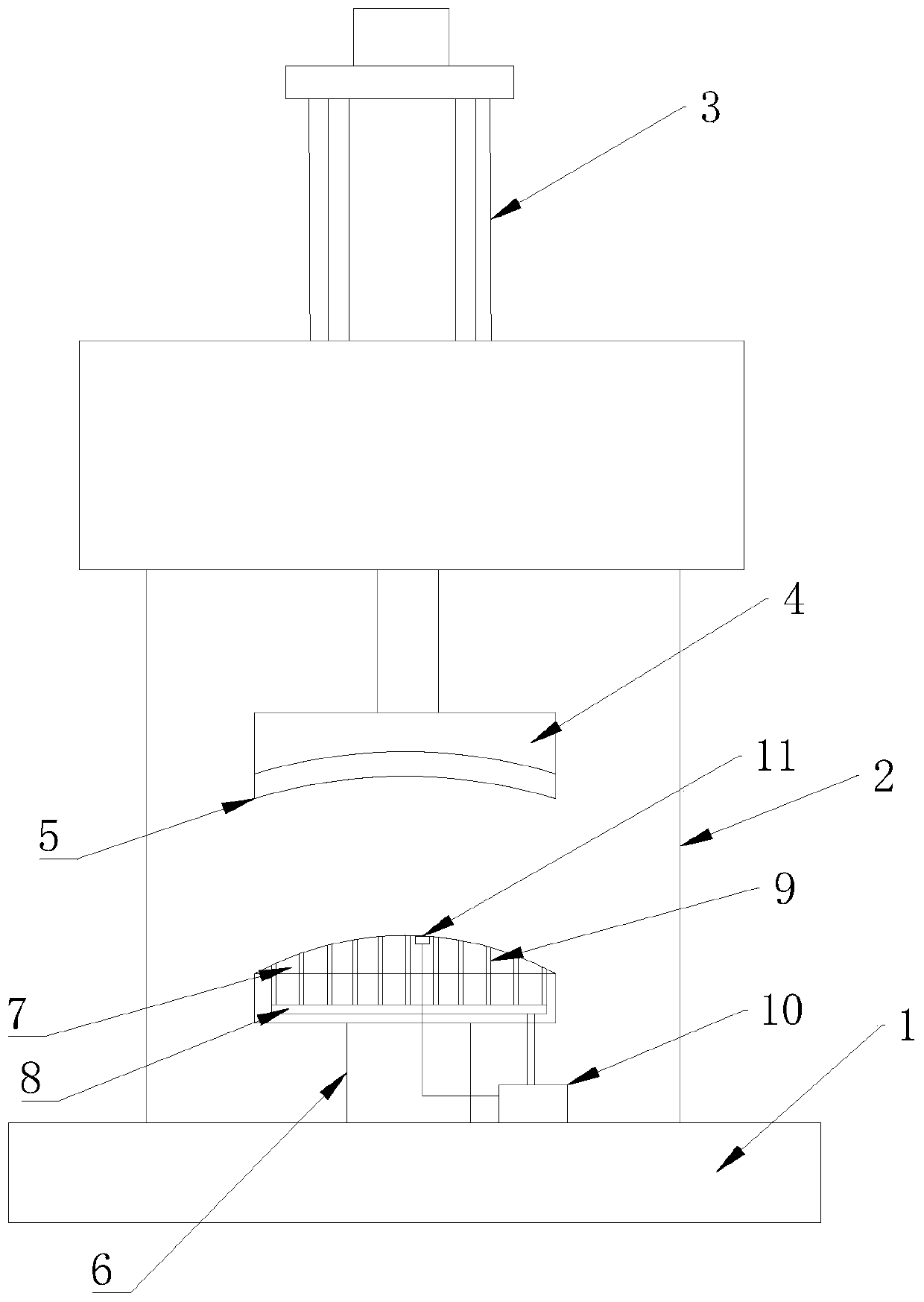

[0012] The present invention will be further described below in conjunction with accompanying drawing.

[0013] Such as figure 1 As shown, a heat press machine includes a base 1, the base 1 is connected with a support frame 2, the support frame 2 is provided with an upper mold base and a lifting mechanism 3 that drives the upper mold base to move up and down, and the base 1 A lower mold base is arranged on the top, the upper mold base includes a heating plate 4 and a pressing plate 5 connected with the heating plate 4, the lower mold base includes a support block 6 and a placement plate 7 corresponding to the pressing plate 5, the A cavity 8 is provided inside the placing plate 7 , and the cavity 8 is connected with several vent holes 9 communicating with the surface of the placing plate 7 , and the cavity 8 is connected with a negative pressure device 10 .

[0014] A kind of hot press machine of this scheme, when it is used, puts two fabrics that need to be hot-pressed on th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com