A double-sided stamping high-precision positioning edge banding machine

一种高精度、封边机的技术,应用在其他胶合板/胶合板器具、不规则去除装置、制造工具等方向,能够解决封边尺寸无法调节、封边胶条卡在装置内部、局限性大等问题,达到提高封边质量、提高封边的效果、节约成本的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The following will clearly and completely describe the technical solutions in the embodiments of the present invention with reference to the accompanying drawings in the embodiments of the present invention. Obviously, the described embodiments are only some, not all, embodiments of the present invention. Based on the embodiments of the present invention, all other embodiments obtained by persons of ordinary skill in the art without making creative efforts belong to the protection scope of the present invention.

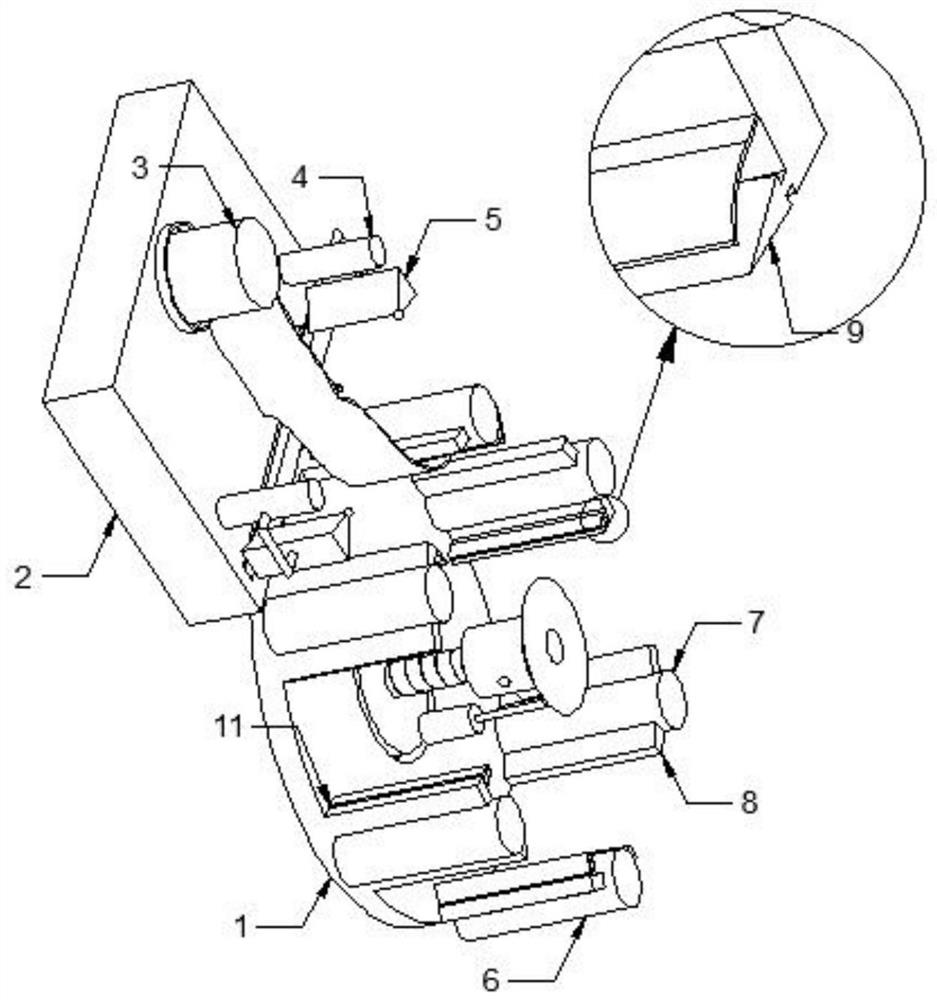

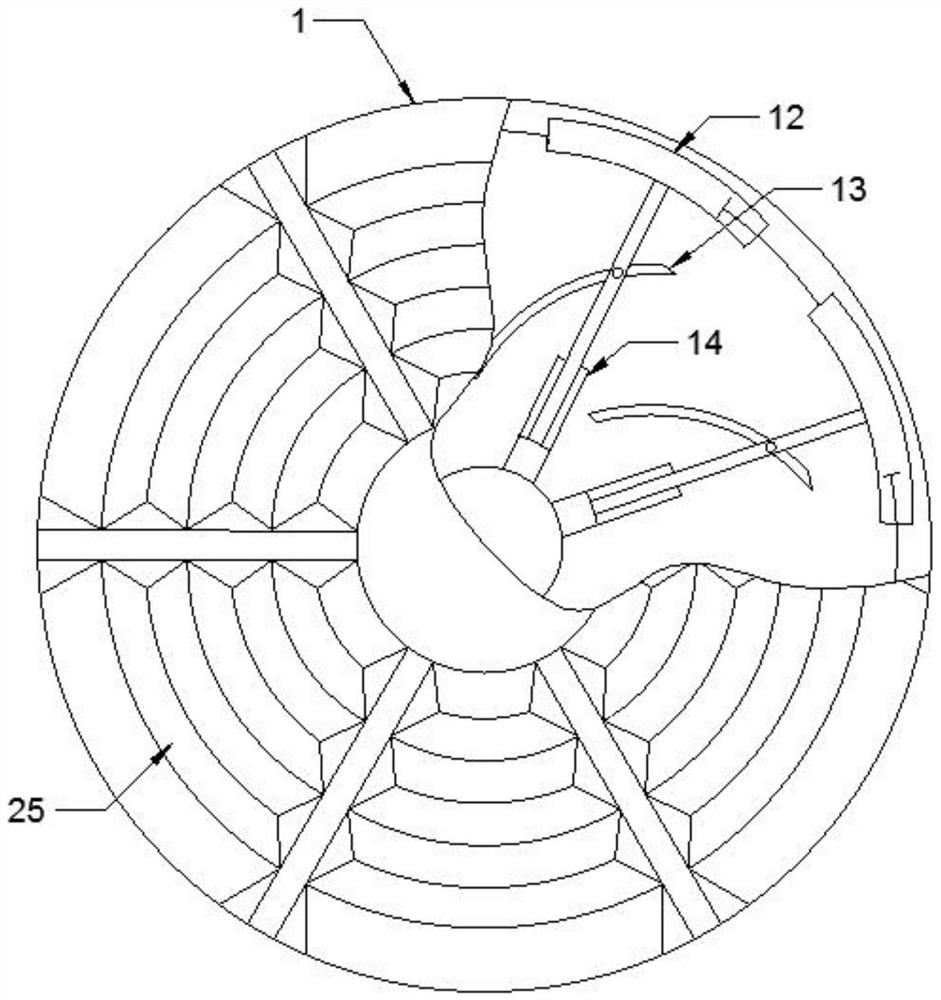

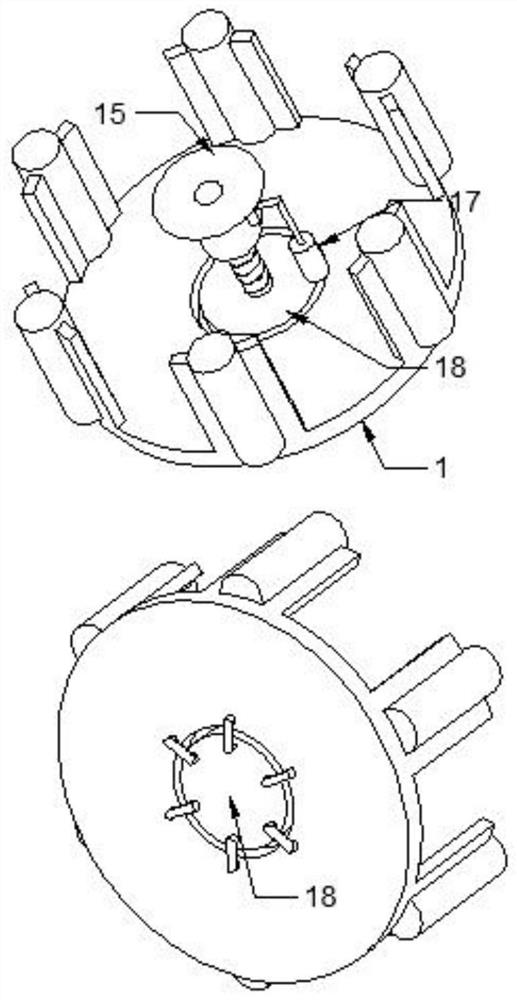

[0028] see Figure 1-5 , the present invention provides a technical solution: a double-sided stamping high-precision positioning edge banding machine, including a main frame 1, a fixing mechanism 15 is arranged inside the main frame 1, a trimming mechanism 11 is arranged on the periphery of the main frame 1, and one side of the main frame 1 runs through The auxiliary machine 2 is connected, and the upper end of the auxiliary machine 2 is provided with an edge ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com