PVC pipe production equipment and process thereof

A technology for production equipment and PVC pipes, applied in cleaning methods and appliances, chemical instruments and methods, cleaning hollow objects, etc., can solve the problems of unclean washing, raw materials sticking to the inner wall of the shell, etc., so that it is not easy to clean and avoid waste of raw materials , the effect of improving the utilization rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

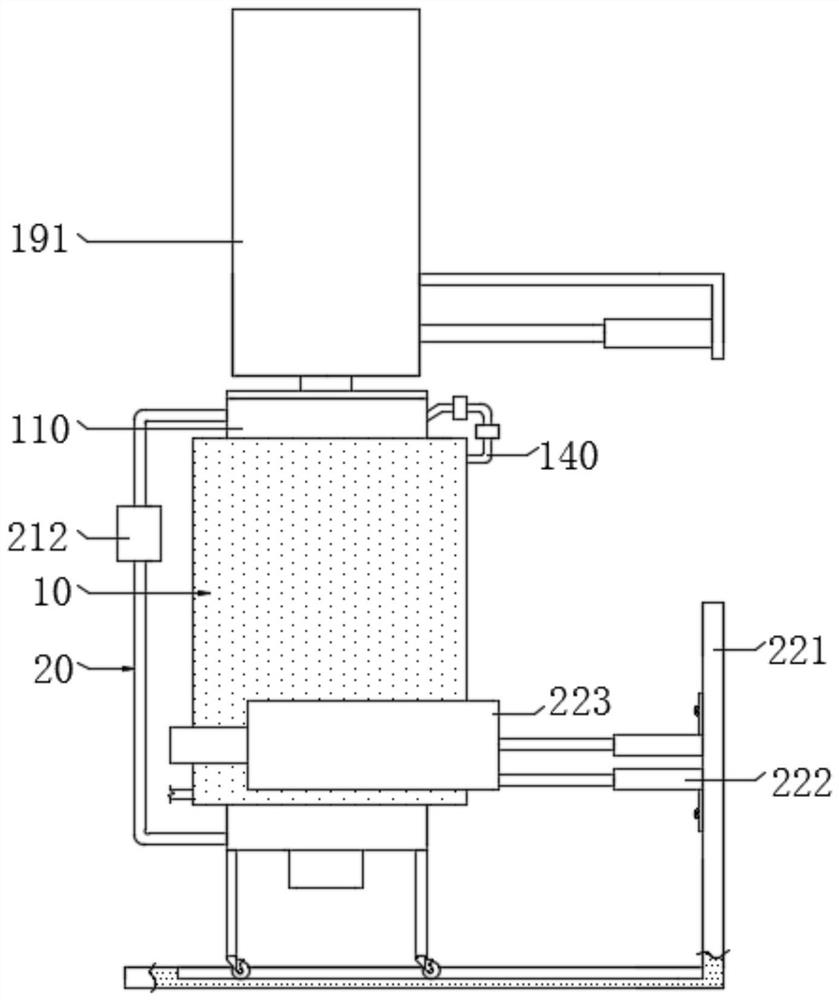

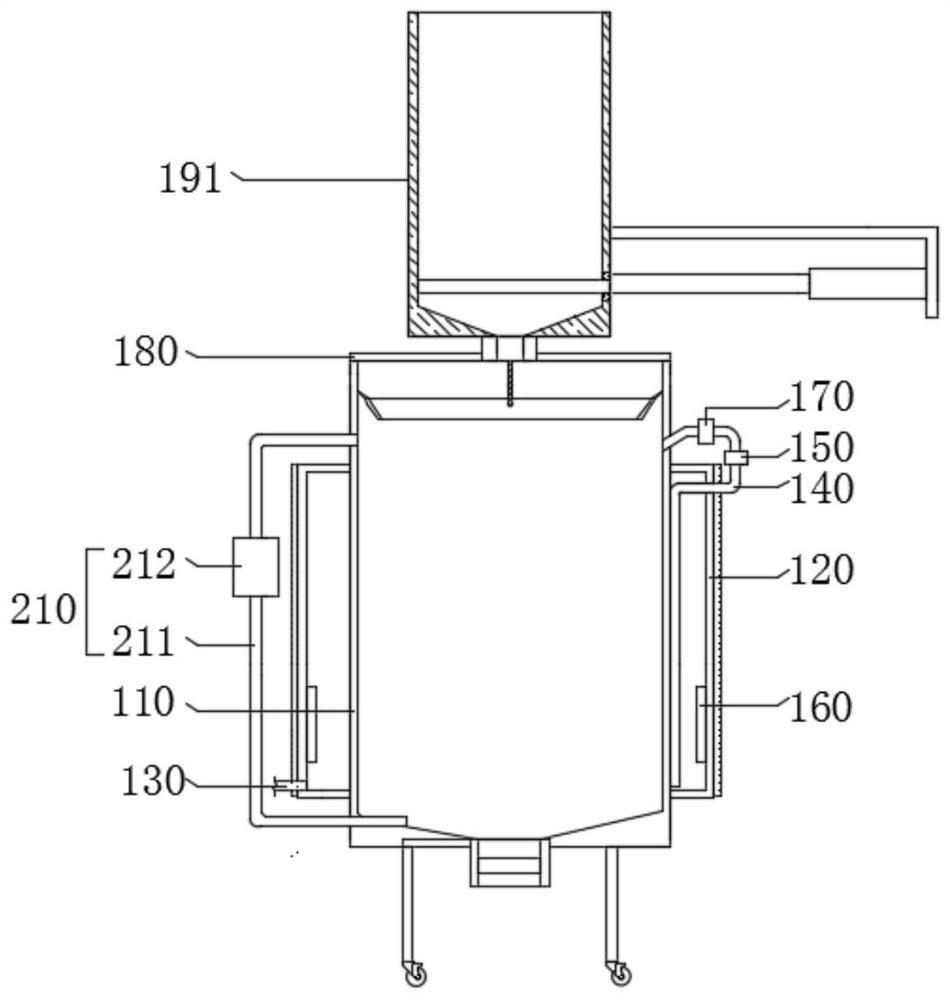

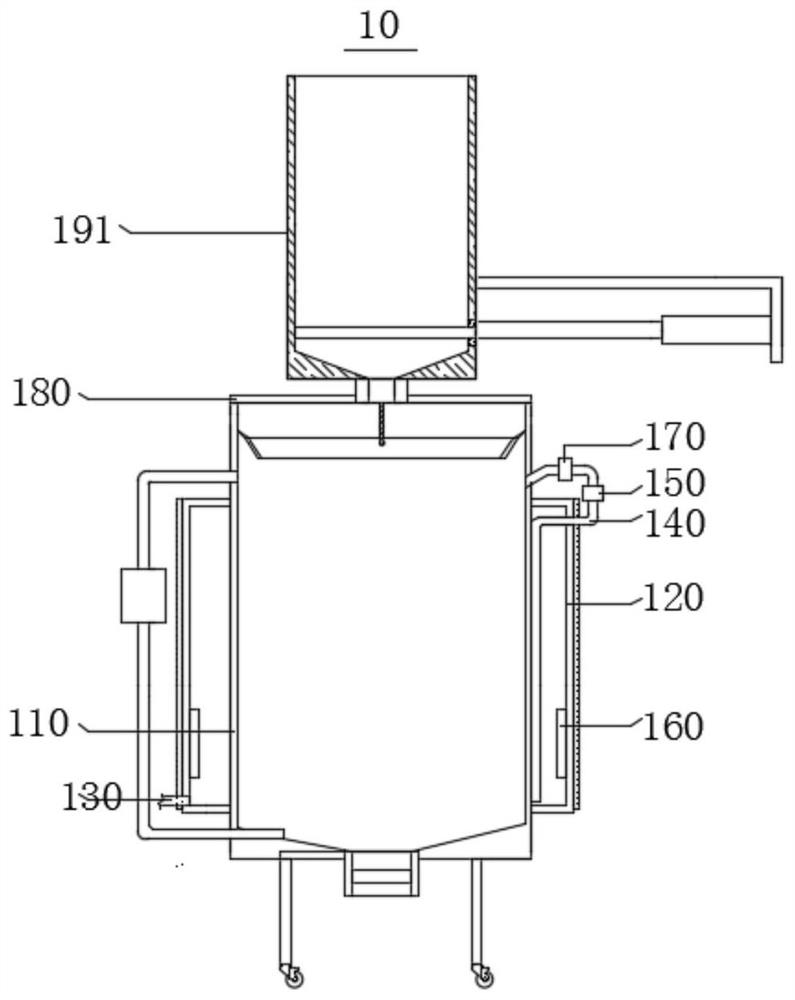

[0051] see figure 1 , shown in 7-9, the invention provides a kind of PVC pipe production equipment, comprising:

[0052] The heating casing assembly 10, the heating casing assembly 10 includes an inner casing 110 and an outer casing 120, the bottom and the upper part of the outer casing 120 are communicated with a water inlet pipe 130 and a drainage pipe 140 respectively, and the end of the drainage pipe 140 runs through communicated with the upper part of the inner casing 110;

[0053] a mixing assembly 20, which is arranged outside the outer casing 120;

[0054] Batching weighing part 190, which is arranged above the inner casing 110, said batching weighing part 190 includes a placement shell 191, a weighing plate 194, and said weighing plate 194 is arranged in the placement shell 191;

[0055] The scraper assembly, the outer lower end of the scraper assembly housing 191 is fixedly provided with a support ring plate 340, and the upper end of the support ring plate 340 is s...

Embodiment 2

[0060] see figure 1 with 2 , the heating casing assembly 10 can indirectly heat the materials put into the inner casing 110 through water heating, and at the same time, the inner casing 110 is equipped with a temperature controller for controlling the heating of the heating rod 160; the mixing assembly 20 can be used at different times On the basis of occupying the inner space of the inner shell 110, the materials inside are efficiently mixed from the outside, so that more raw materials for making PVC pipes can be mixed at one time.

[0061] see figure 1 , 2 , 3, 4, 5, the heating shell assembly 10 includes an inner shell 110 and an outer shell 120, the four corners of the bottom of the inner shell 110 are all equipped with legs through screws, and the bottom of the legs are connected with rollers through screws, The outer casing 120 is connected to the outer side of the inner casing 110 , and a water storage cavity is formed between the outer casing 120 and the inner casin...

Embodiment 3

[0064] see figure 1 with 2 , the heating casing assembly 10 can indirectly heat the materials put into the inner casing 110 by means of water heating, and at the same time, the inner casing 110 is equipped with a temperature controller for controlling the heating of the heating rod 160; the mixing assembly 20 can On the basis of not occupying the inner space of the inner shell 110, the materials inside are efficiently mixed from the outside, so that more raw materials for making PVC pipes can be mixed at one time, and the production efficiency of PVC pipes can be improved.

[0065] see Figures 1 to 5 , the heating casing assembly 10 includes an inner casing 110 and an outer casing 120. The four corners of the bottom of the inner casing 110 are all equipped with legs through screws, and the bottom of the legs are connected with rollers through screws, and the outer casing 120 is connected to the inner casing 110. Outside the casing 110 , a water storage chamber is formed bet...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com