Patents

Literature

44results about How to "Mixed comprehensive" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Process for preparing instant powdered naked oats beverage

An instant naked oats powder as solid beverage for the patients of hyperlipomia and diabetes is prepared from naked oats through removing impurities and fine fibres, soaking in hot water, grinding, adding alpha-amylase, auxiliary materials and emulsifier, homogenizing, emulsifying, and spray drying. Its advantages are high dissolving speed and solubility (more than 89.44%), and rich gamma-linolenic acid.

Owner:SHANXI UNIV

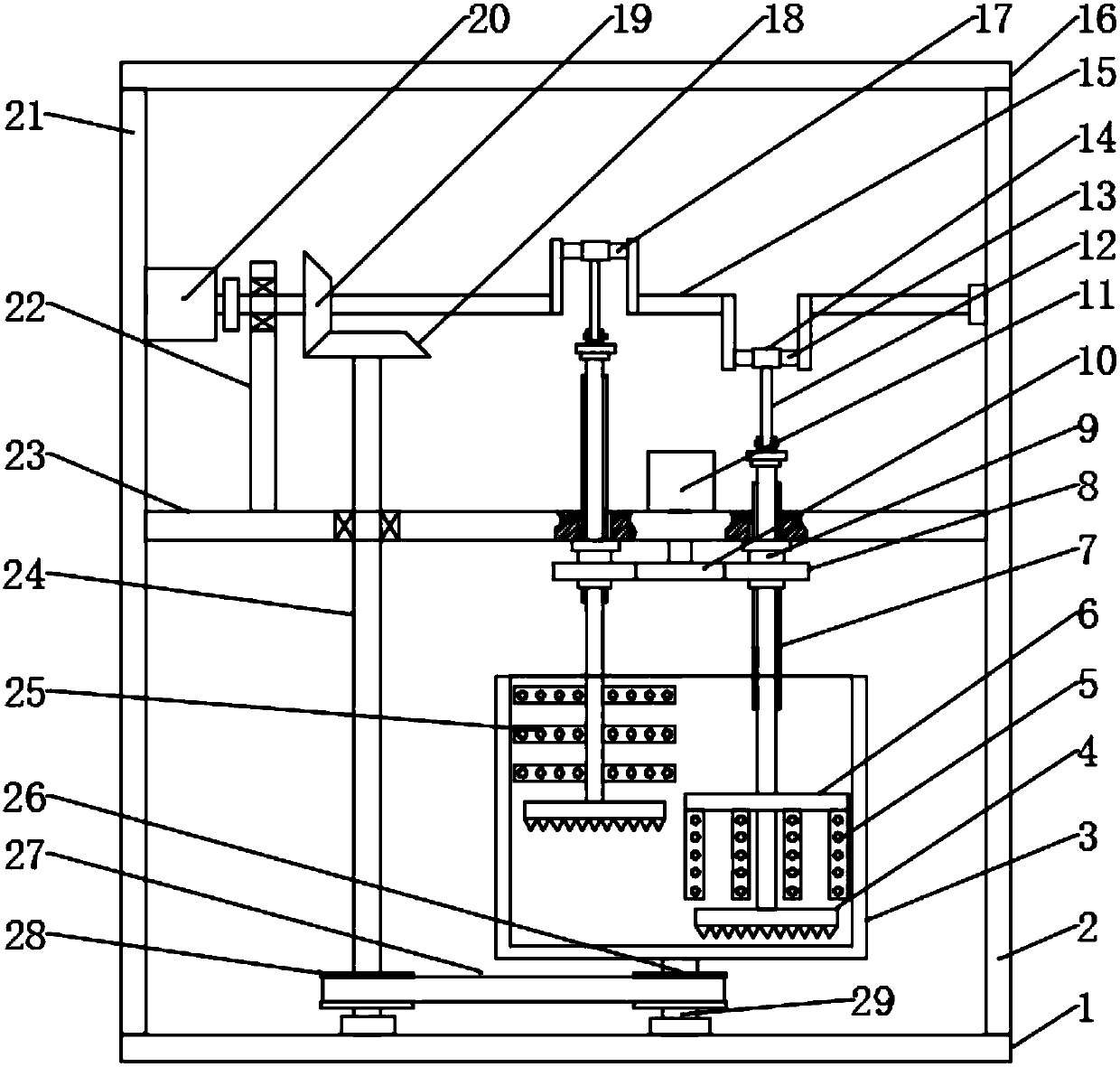

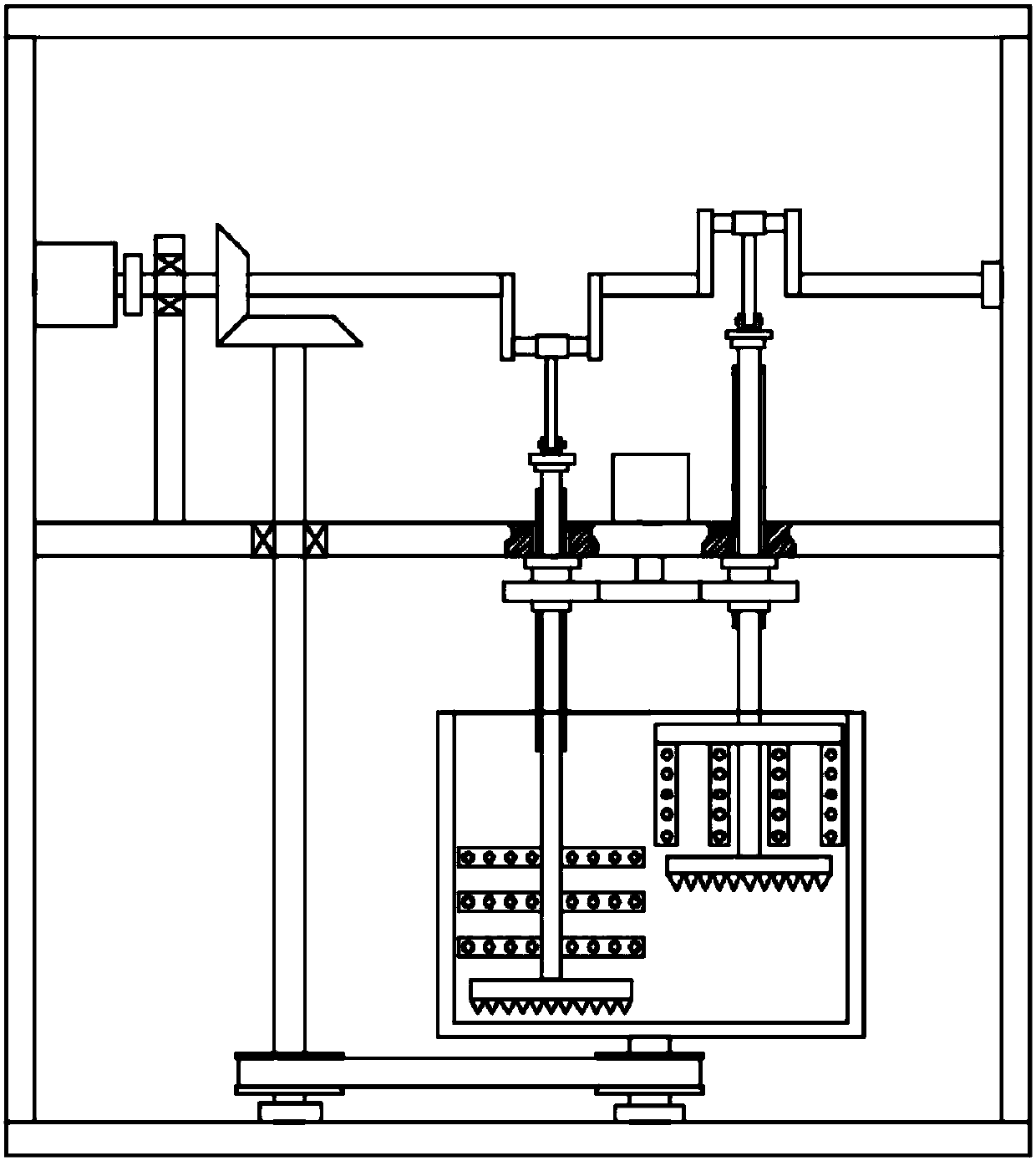

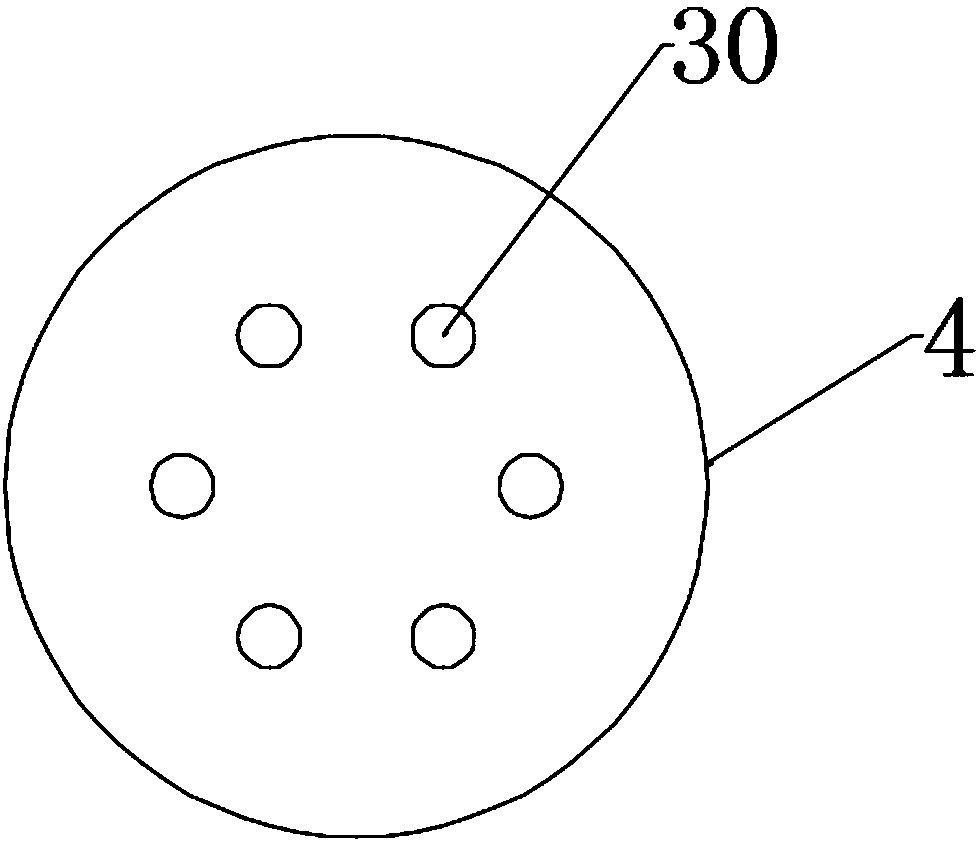

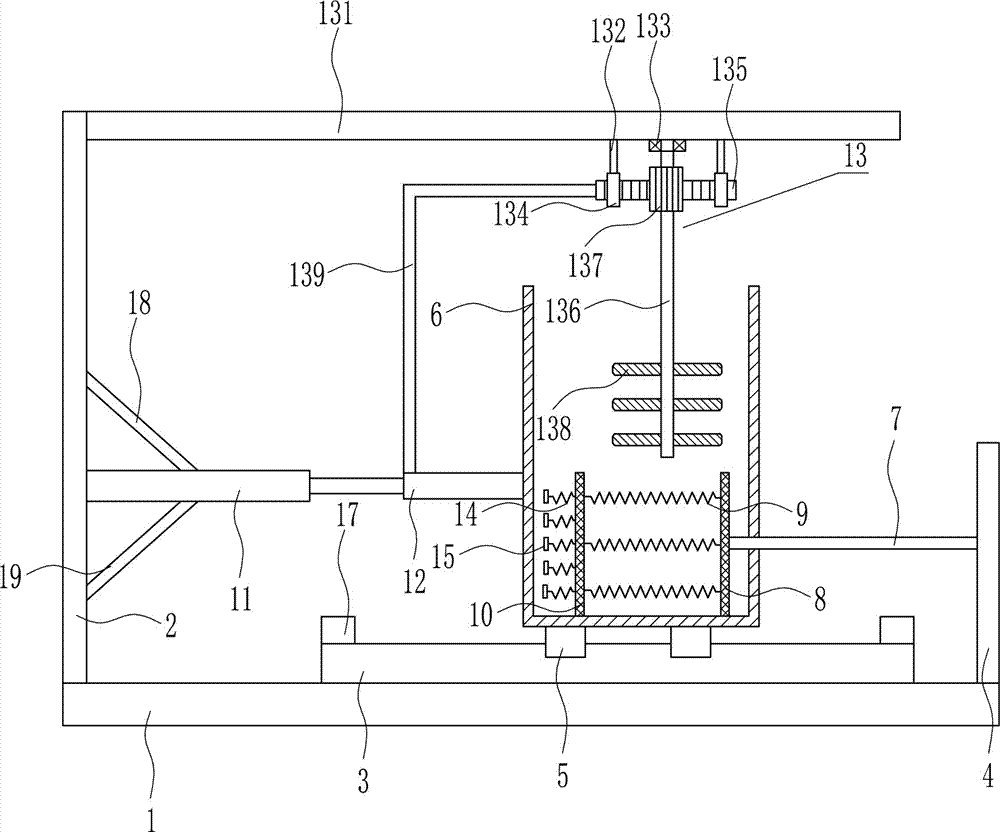

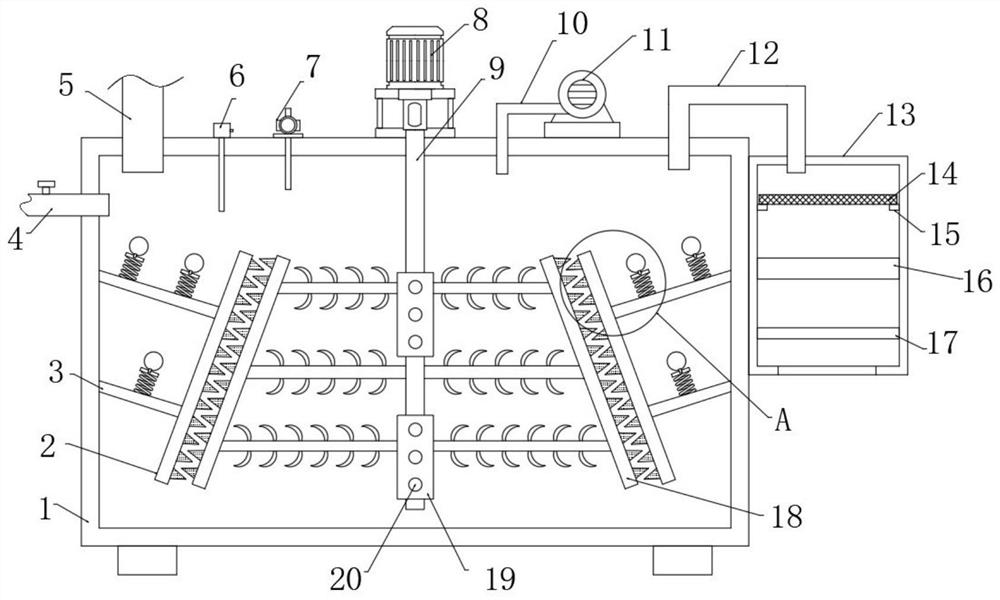

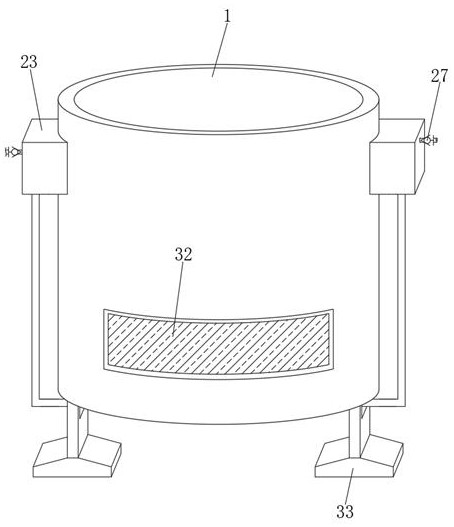

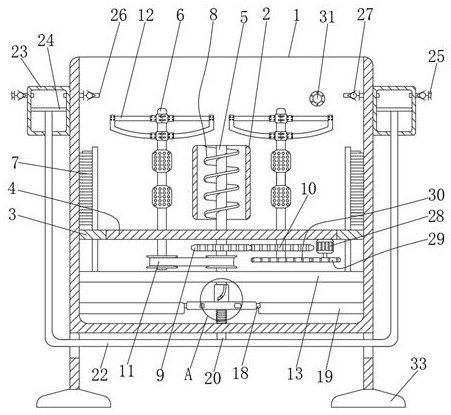

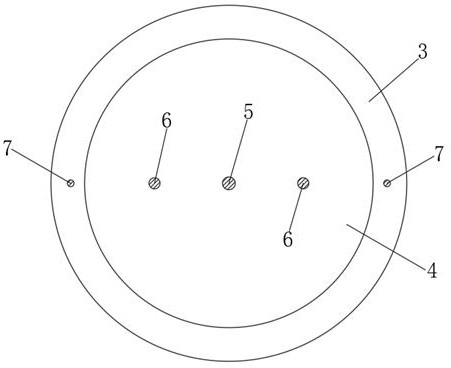

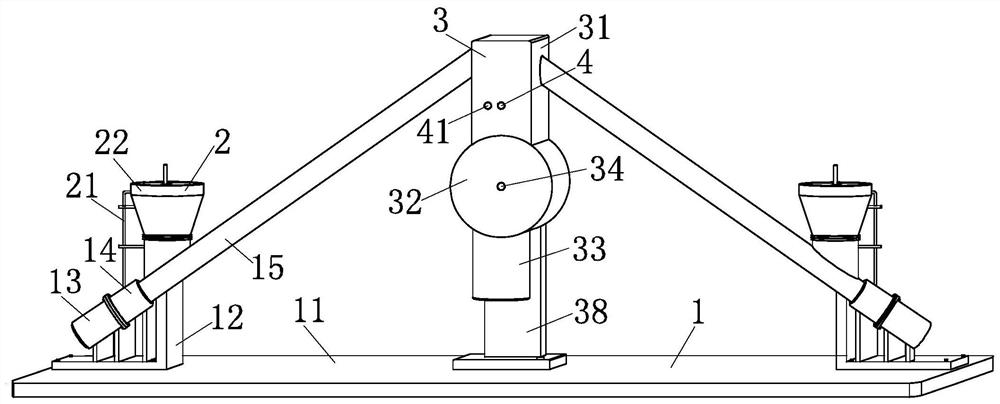

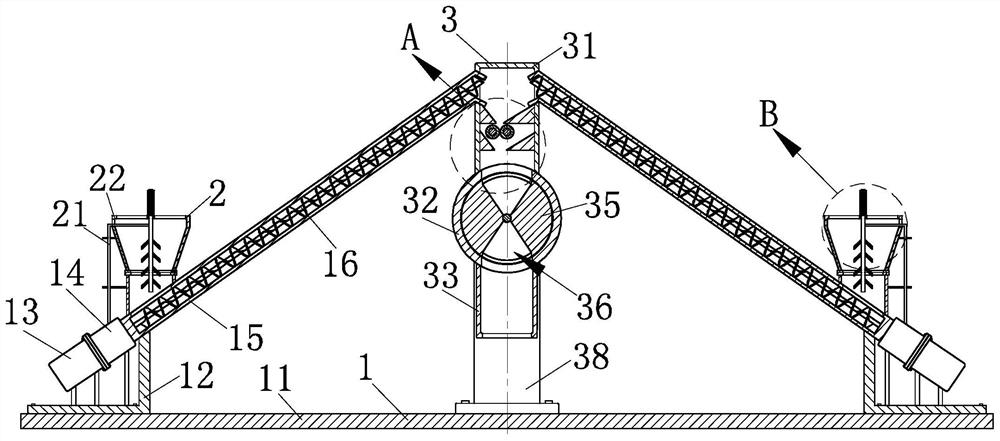

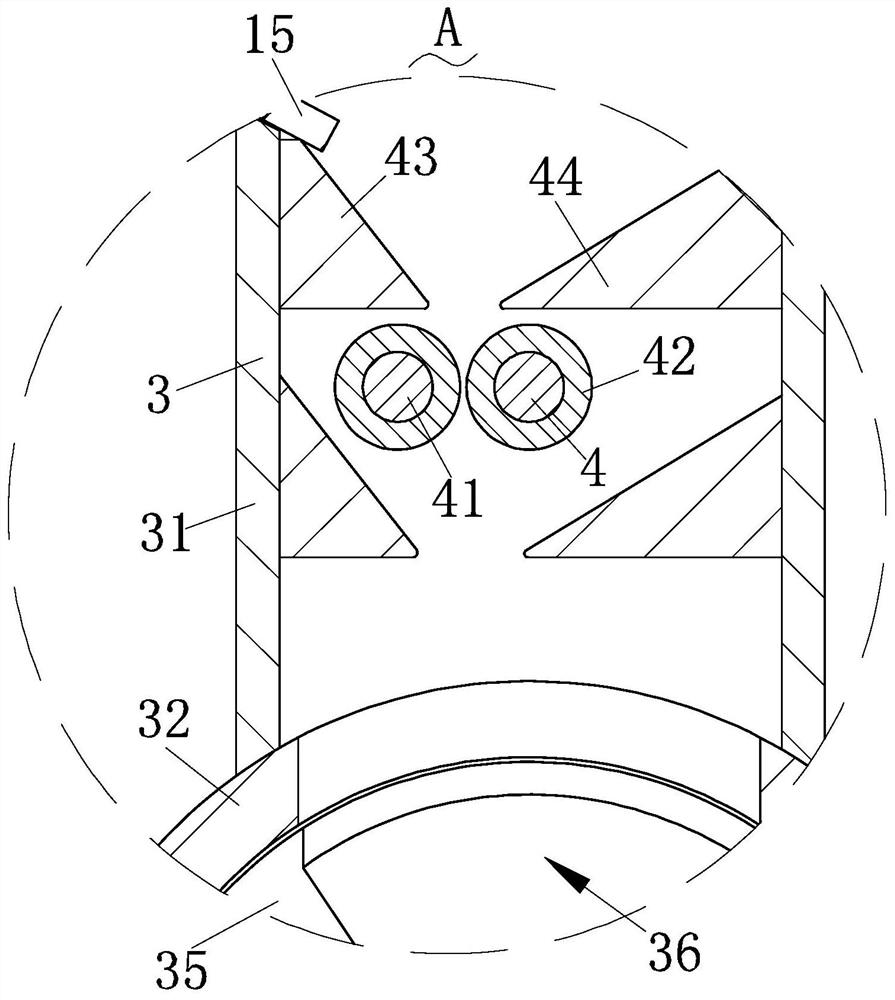

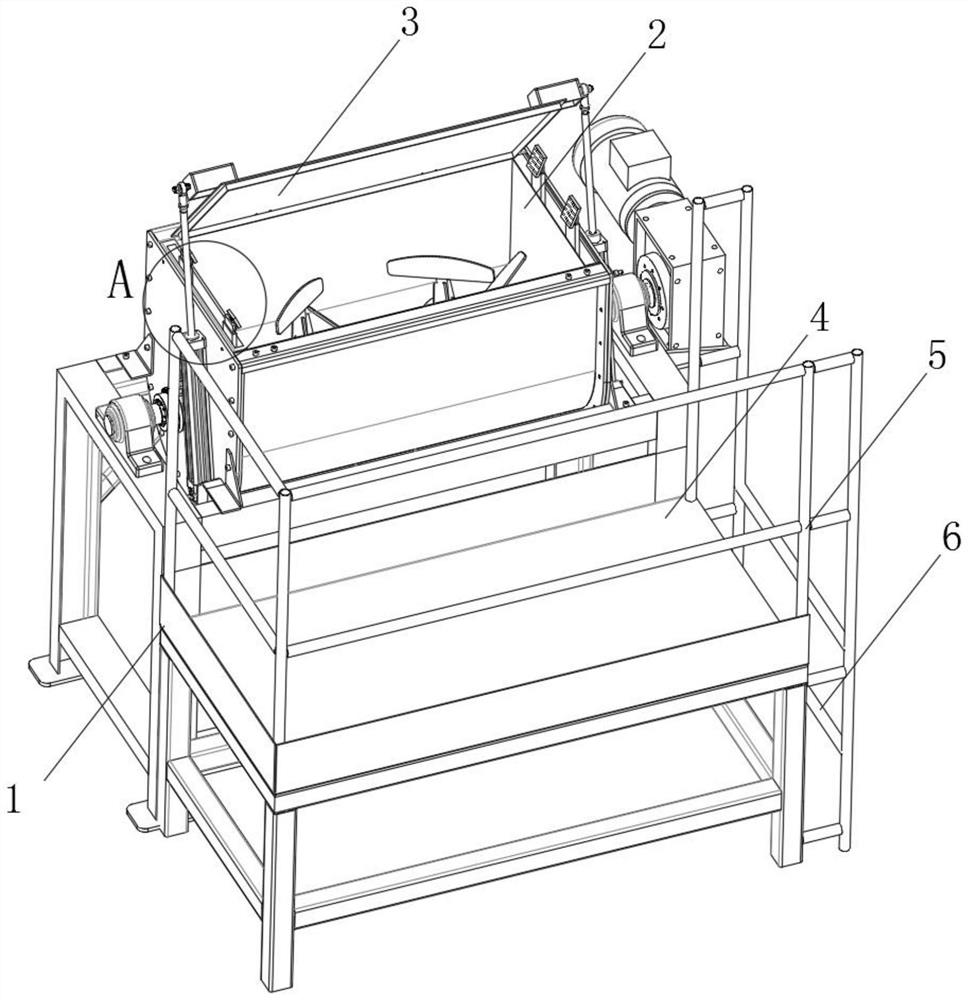

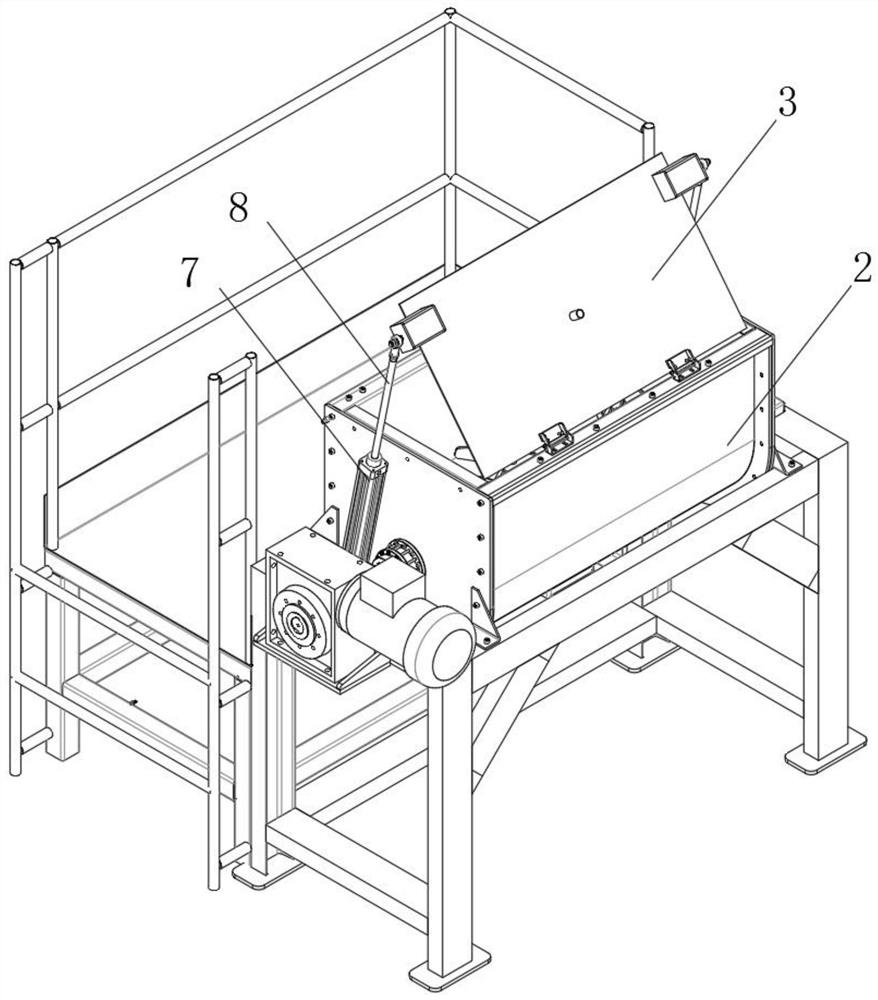

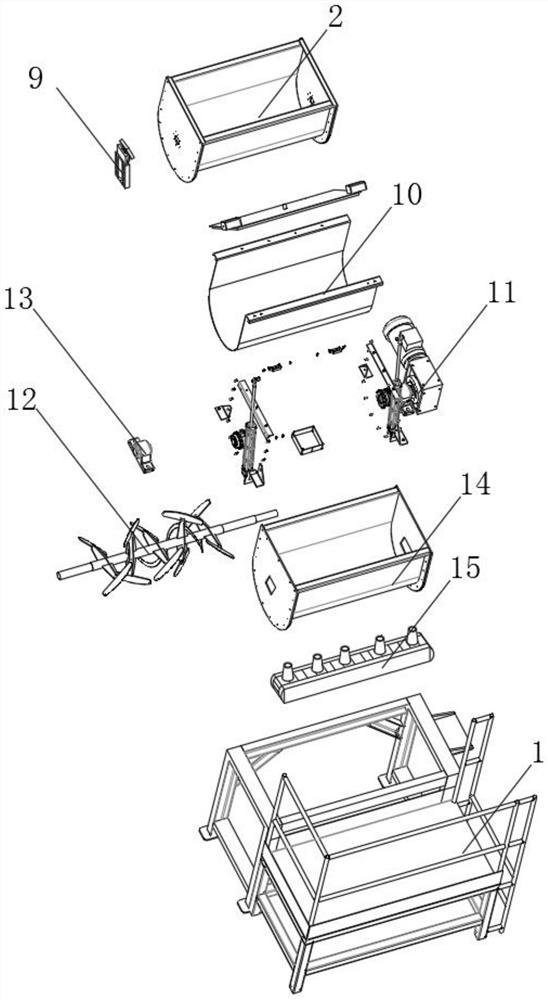

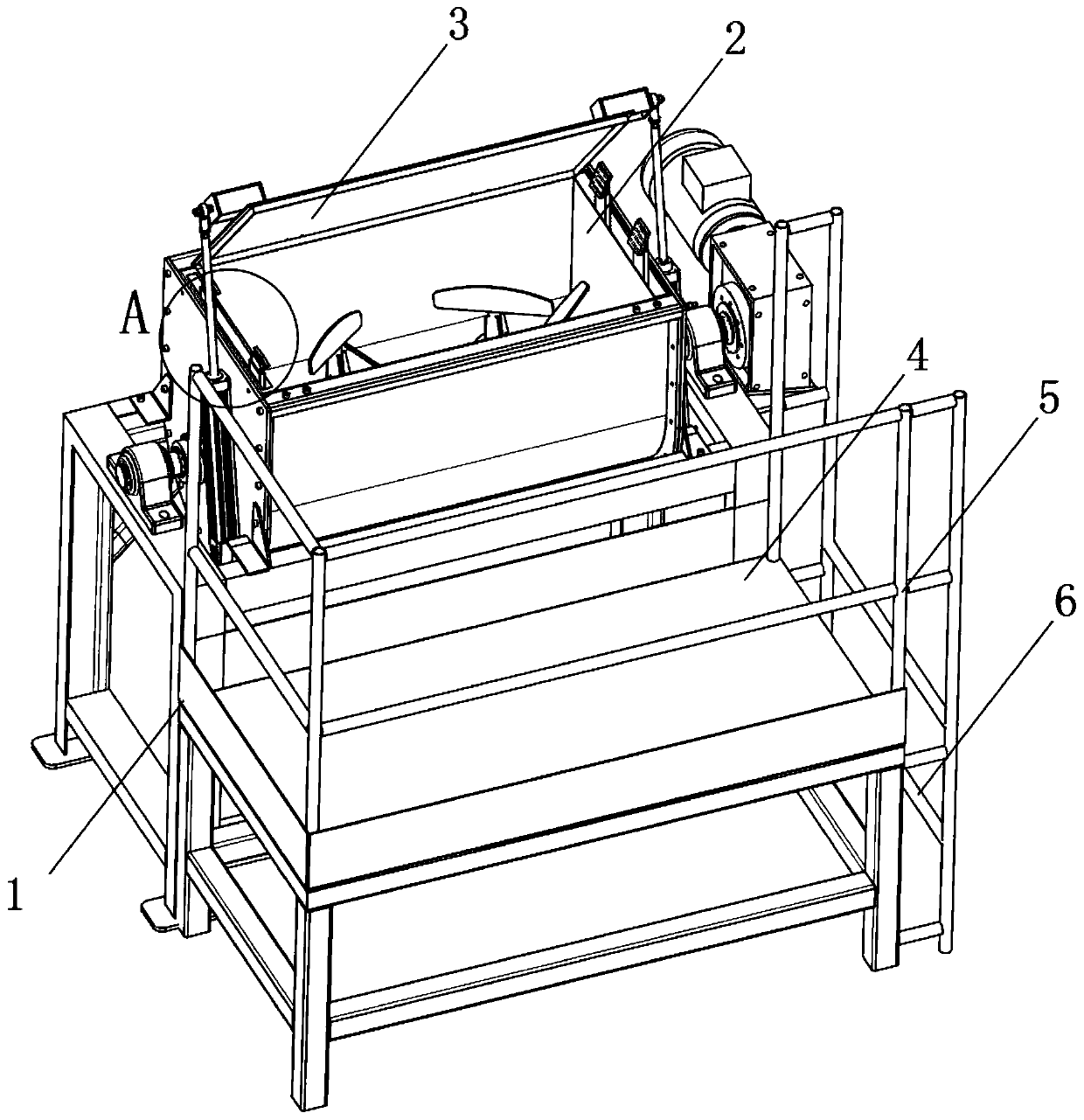

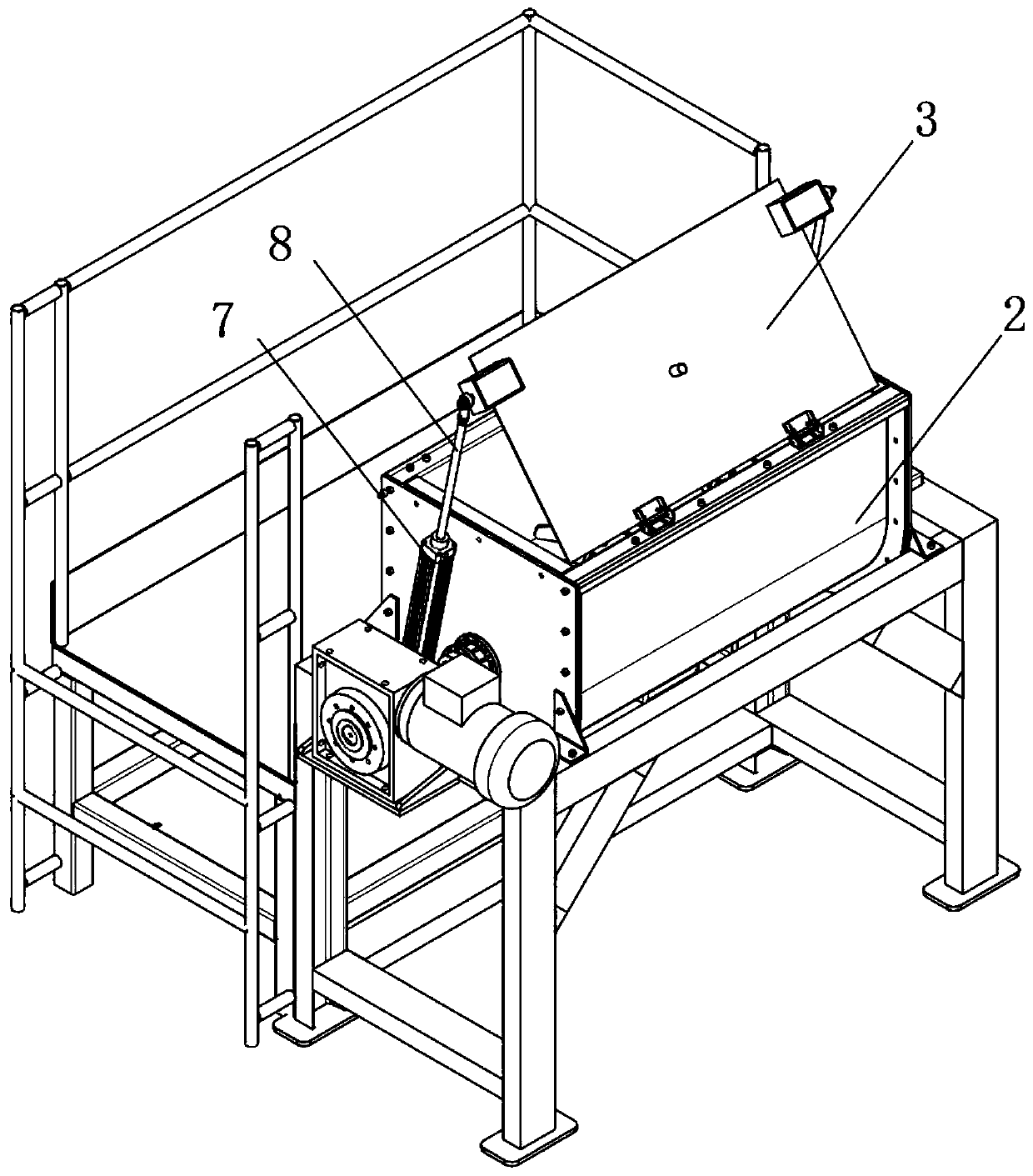

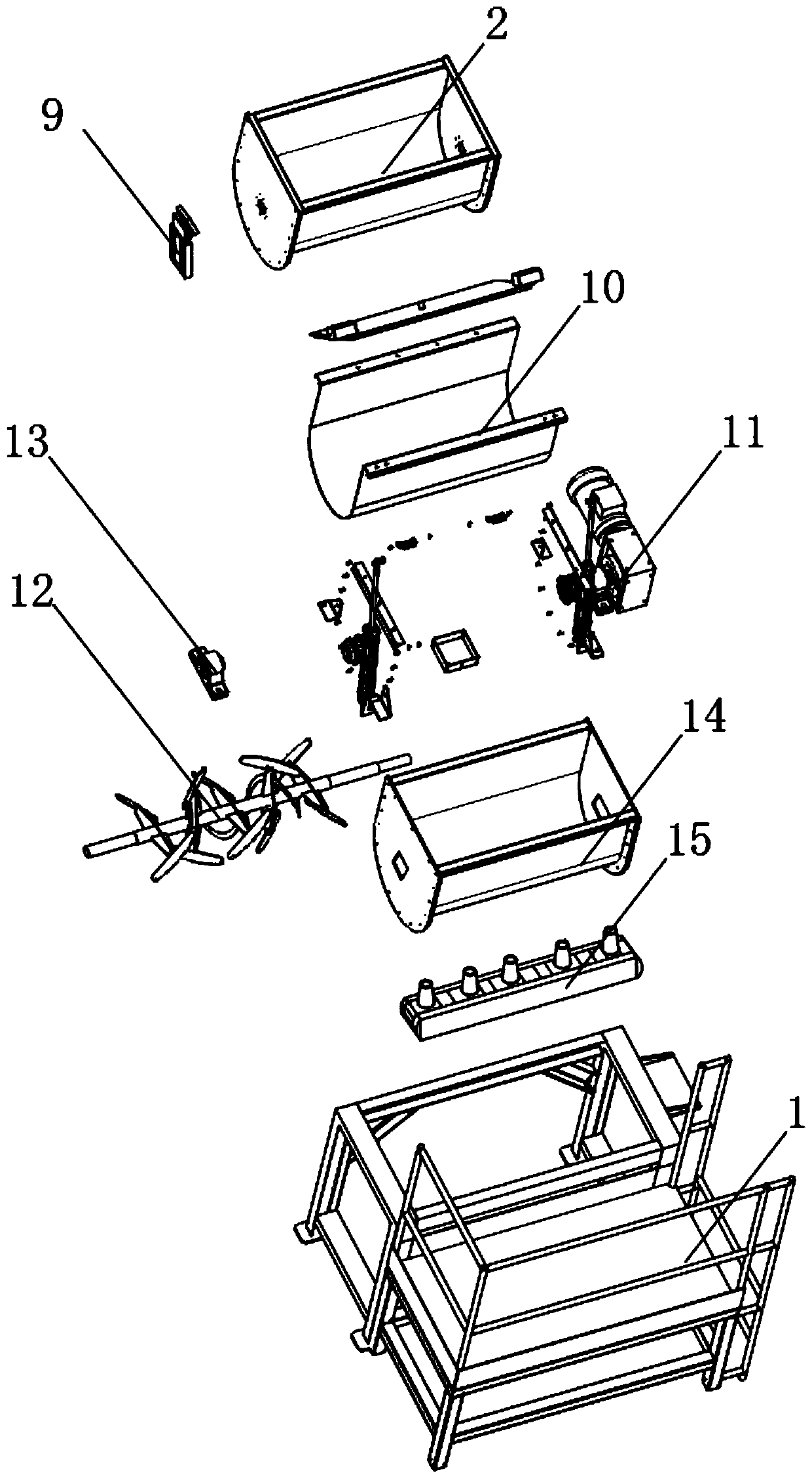

Raw material mixing device for road bridge construction

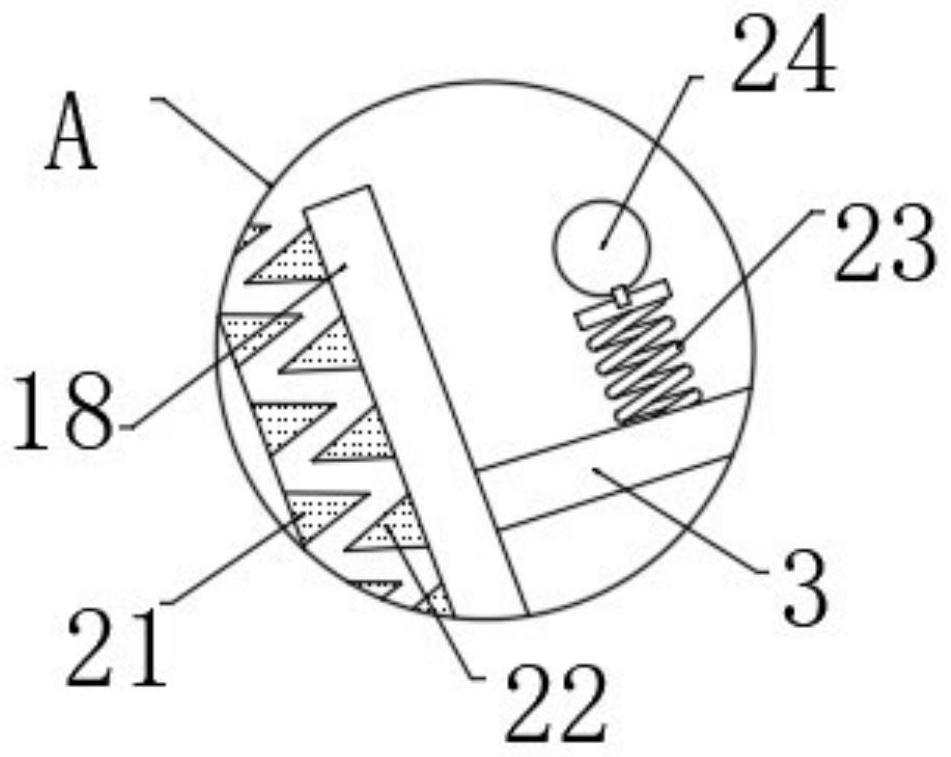

ActiveCN107740347AWell mixedMixed comprehensiveBridge erection/assemblyRoads maintainenceArchitectural engineeringBevel gear

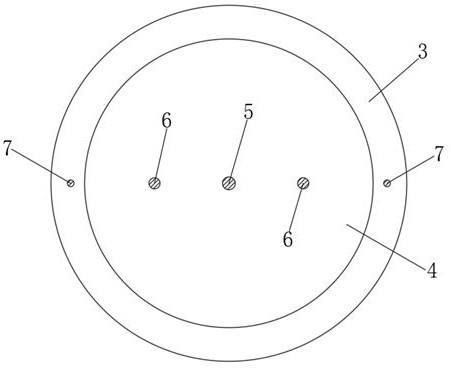

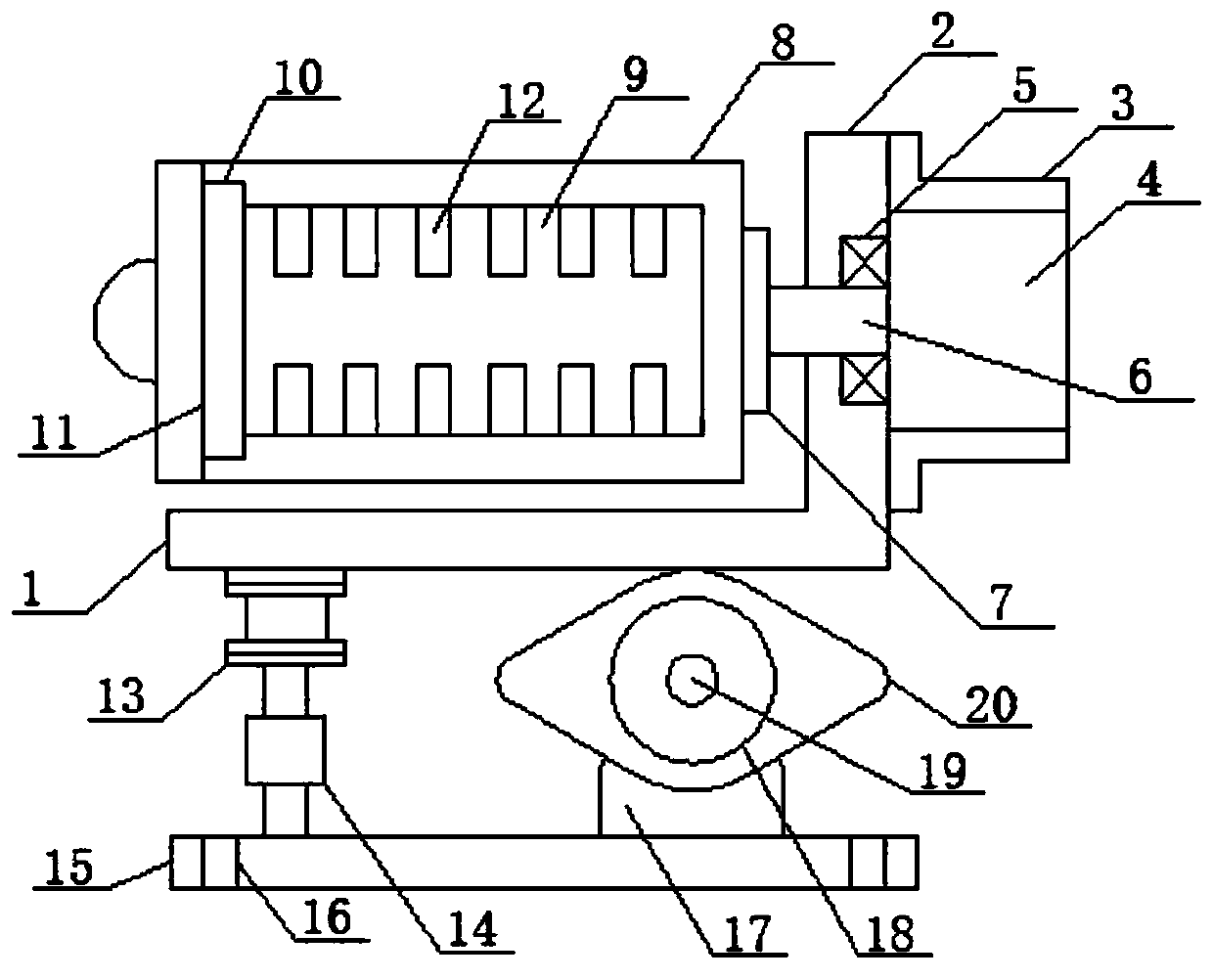

The invention discloses a raw material mixing device for road bridge construction. The raw material mixing device comprises a baseboard, a mixing bucket, a supporting shaft, a crank shaft, a first motor, a connecting rod, a spline shaft, a first gear, a second gear, a second motor, a round disc, a first stirring rod and a second stirring rod. The second motor, the first gear, the second gear, thespline shaft, the first stirring rod and the second stirring rod are arranged, by cooperatively driving the first stirring rod and the second stirring rod to rotate, two stirring modes exist simultaneously, the stirring and mixing efficiency is improved, the first motor, the crank shaft and the connecting rod are arranged, by cooperatively driving the first stirring rod, the second stirring rod and the round disc to move longitudinally, raw materials can be fully and comprehensively mixed, a first bevel gear, a second bevel gear and a rotary shaft are arranged, through the parts, the mixing bucket is cooperatively driven to rotate, the rotation direction of the mixing bucket is opposite to those of the first stirring rod and the second stirring rod, and the mixing efficiency is further improved.

Owner:ZHEJIANG GUOYUAN CONSTR

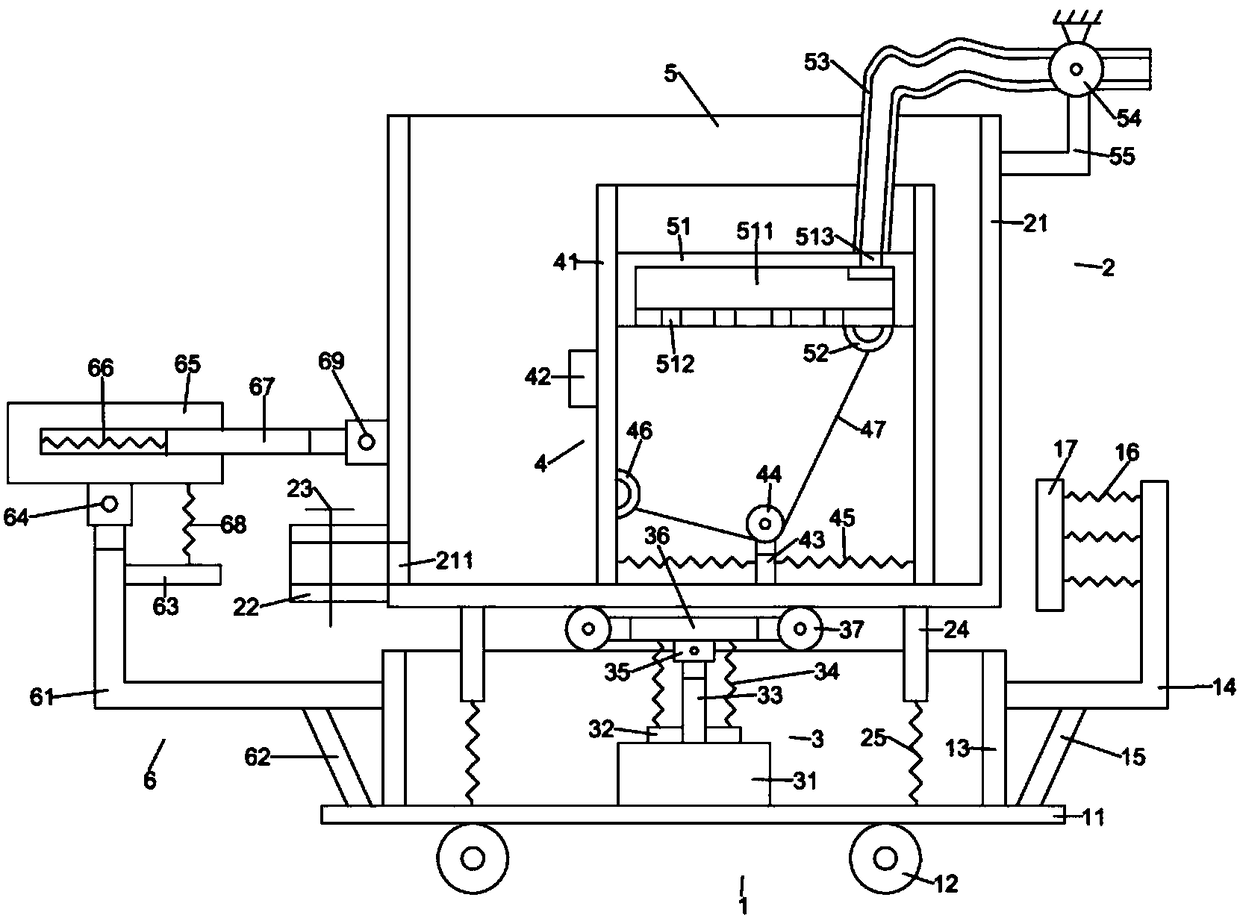

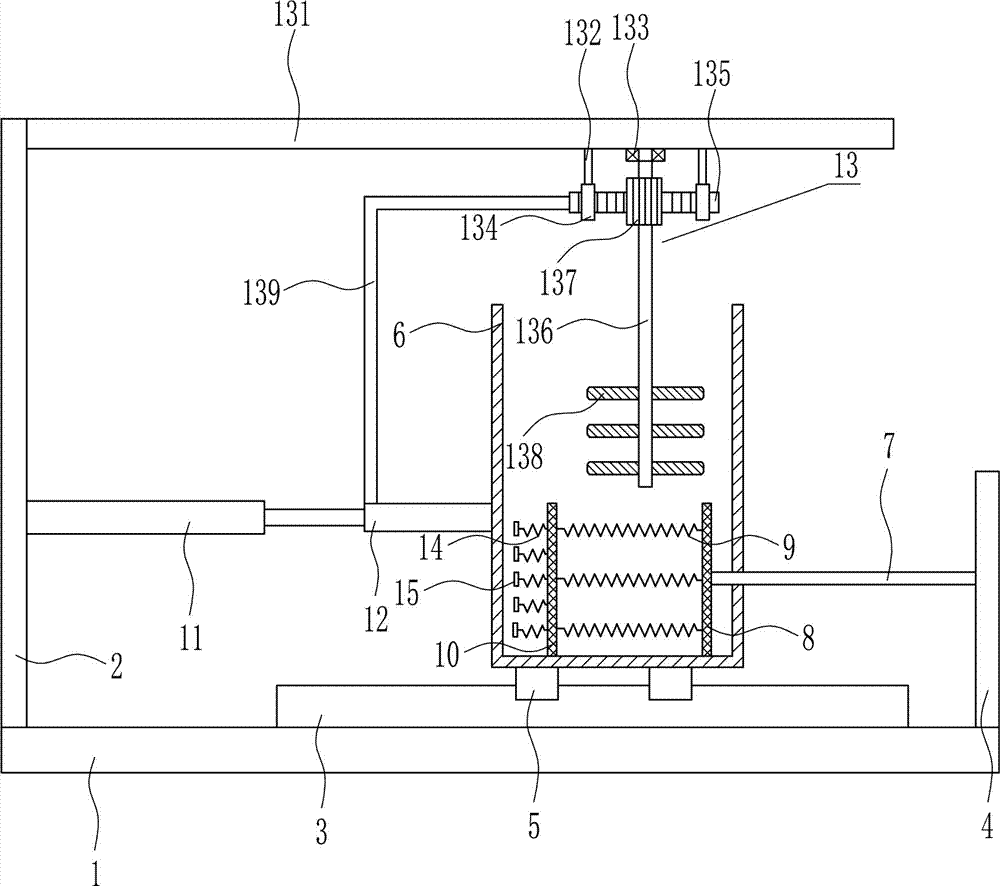

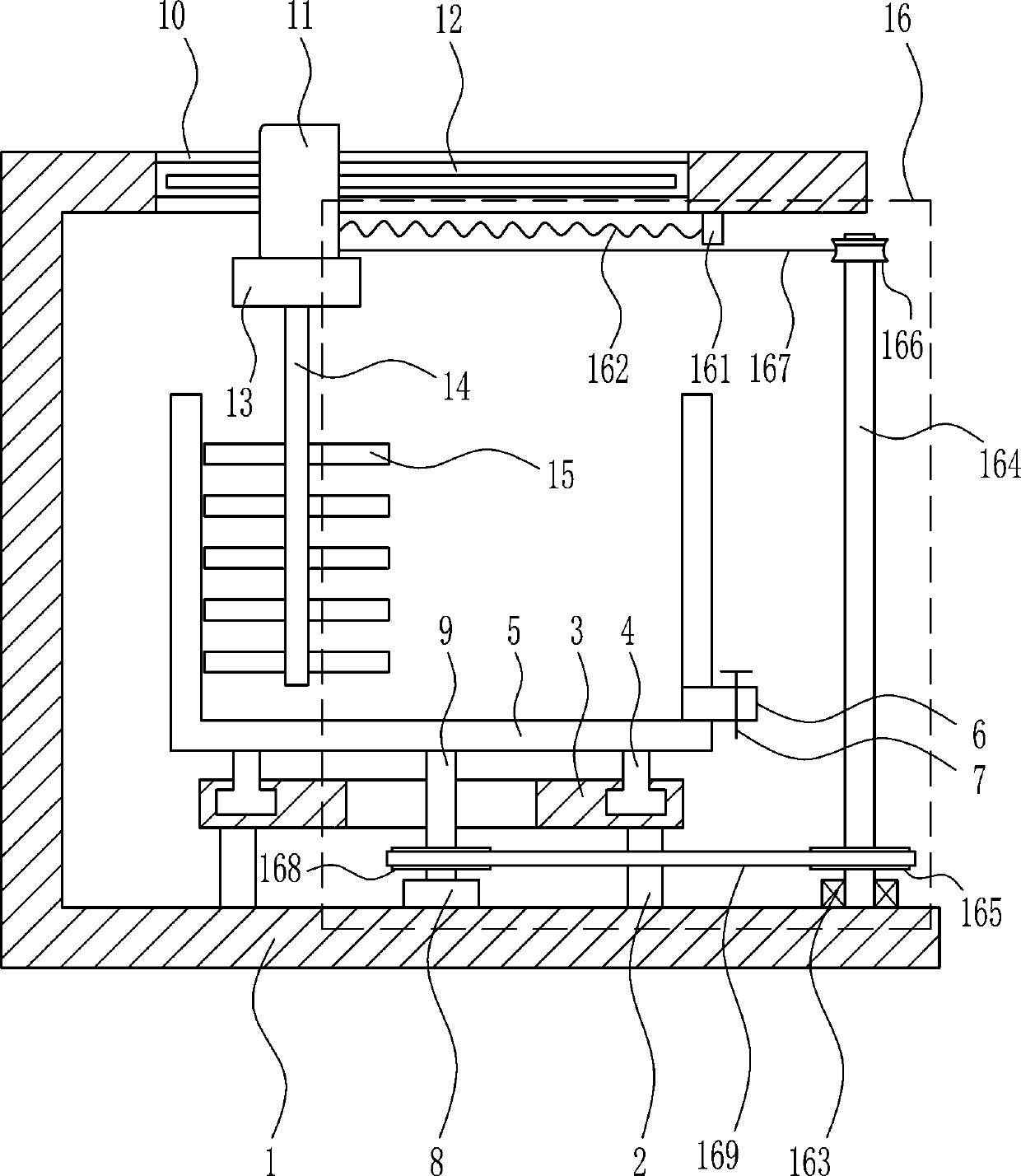

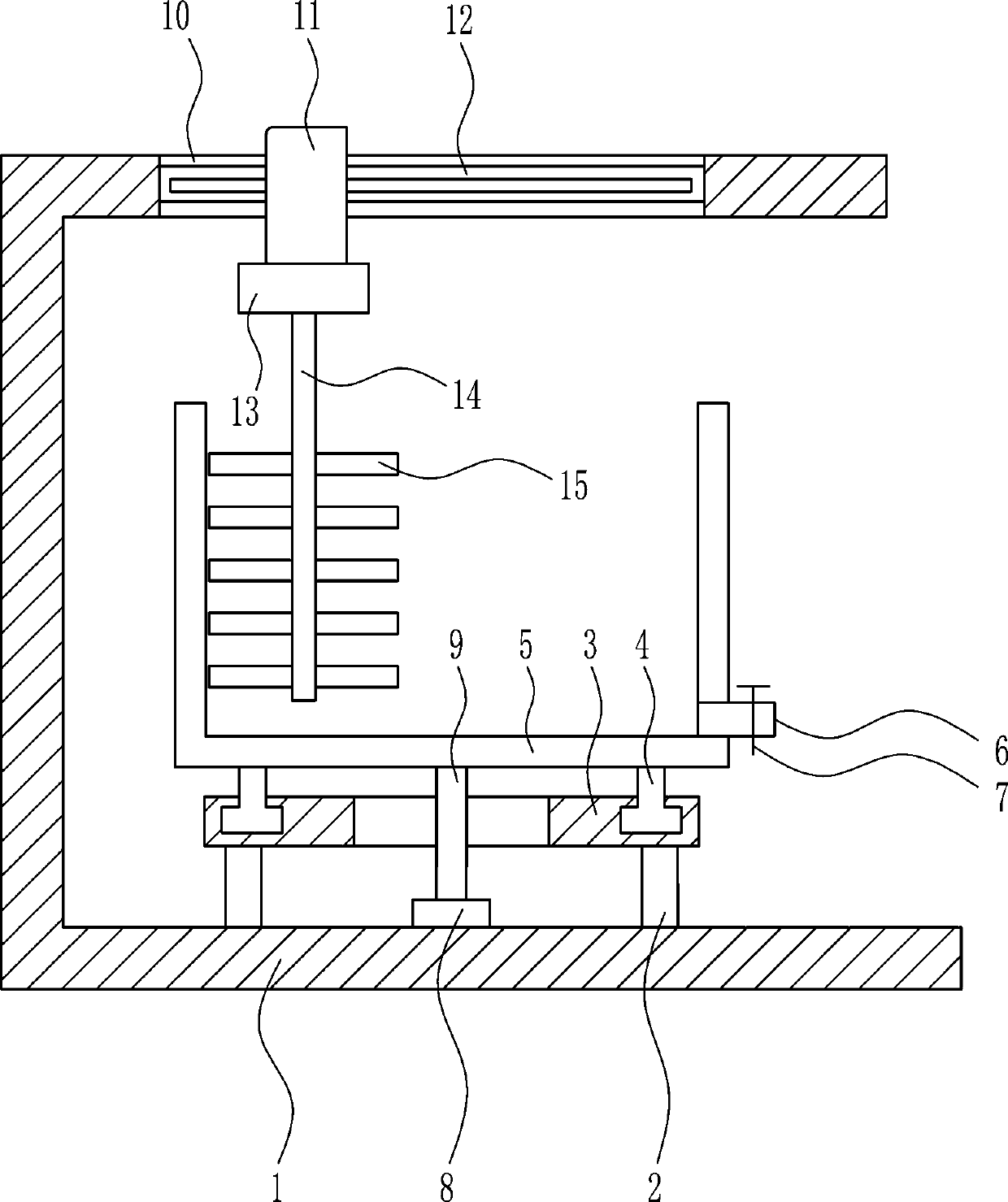

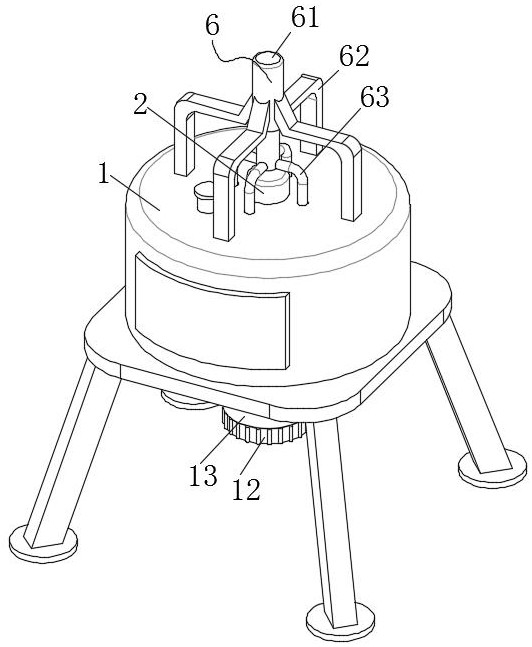

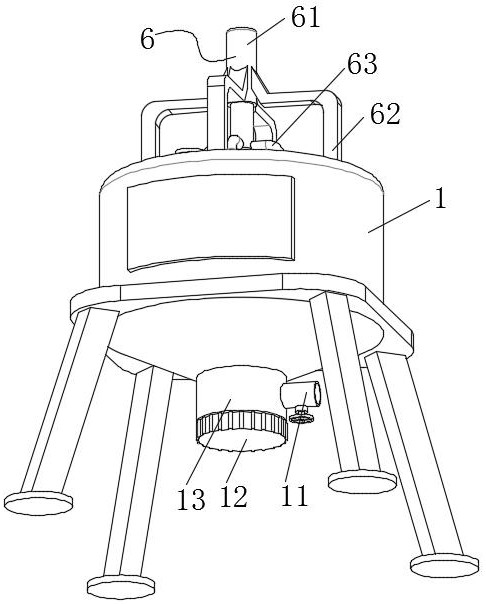

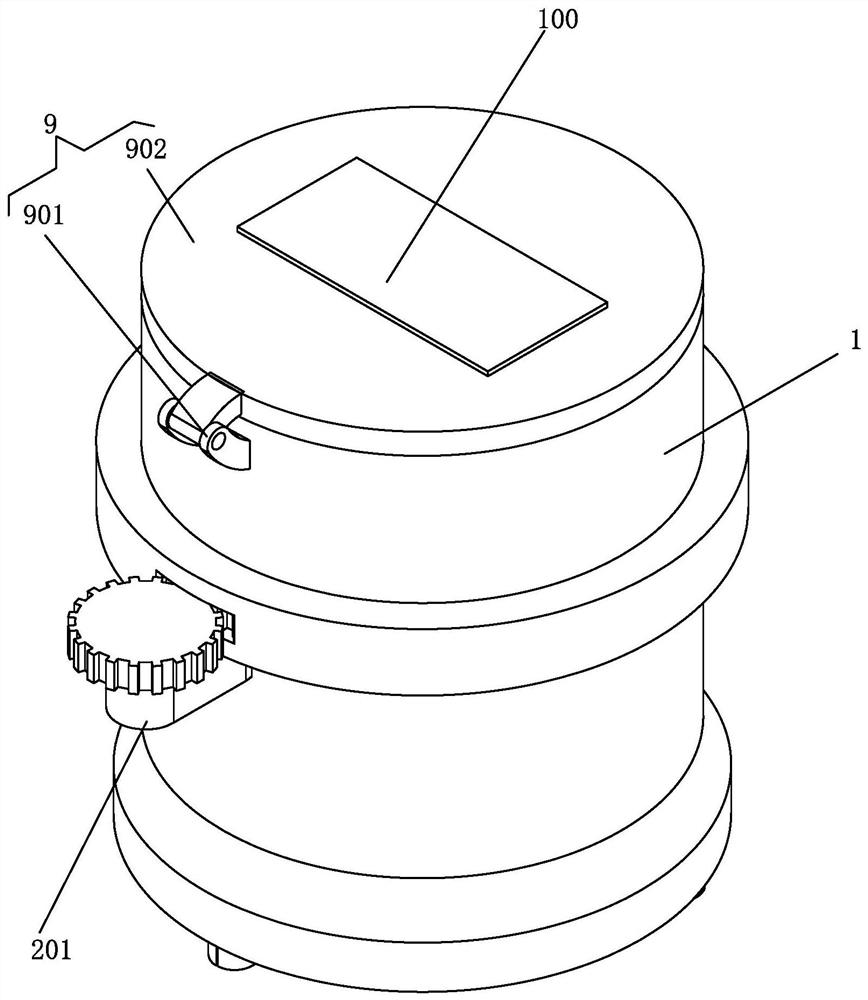

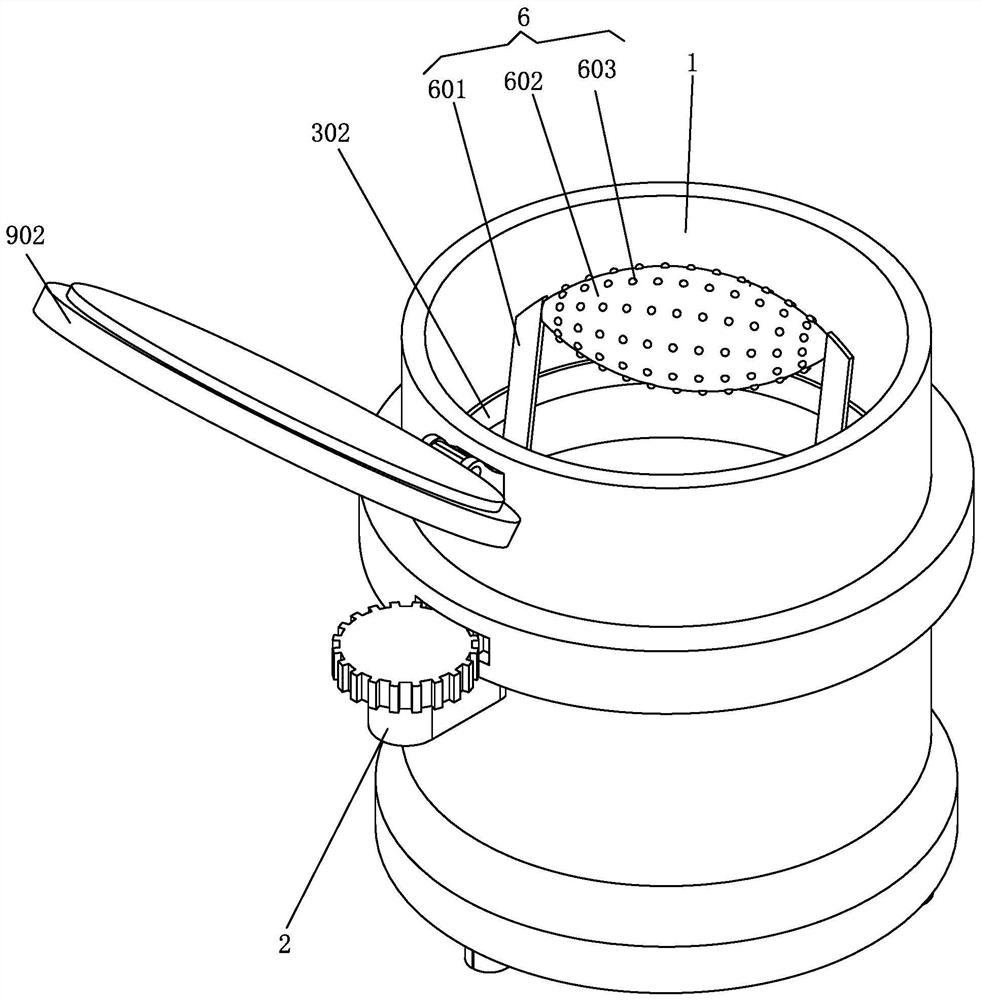

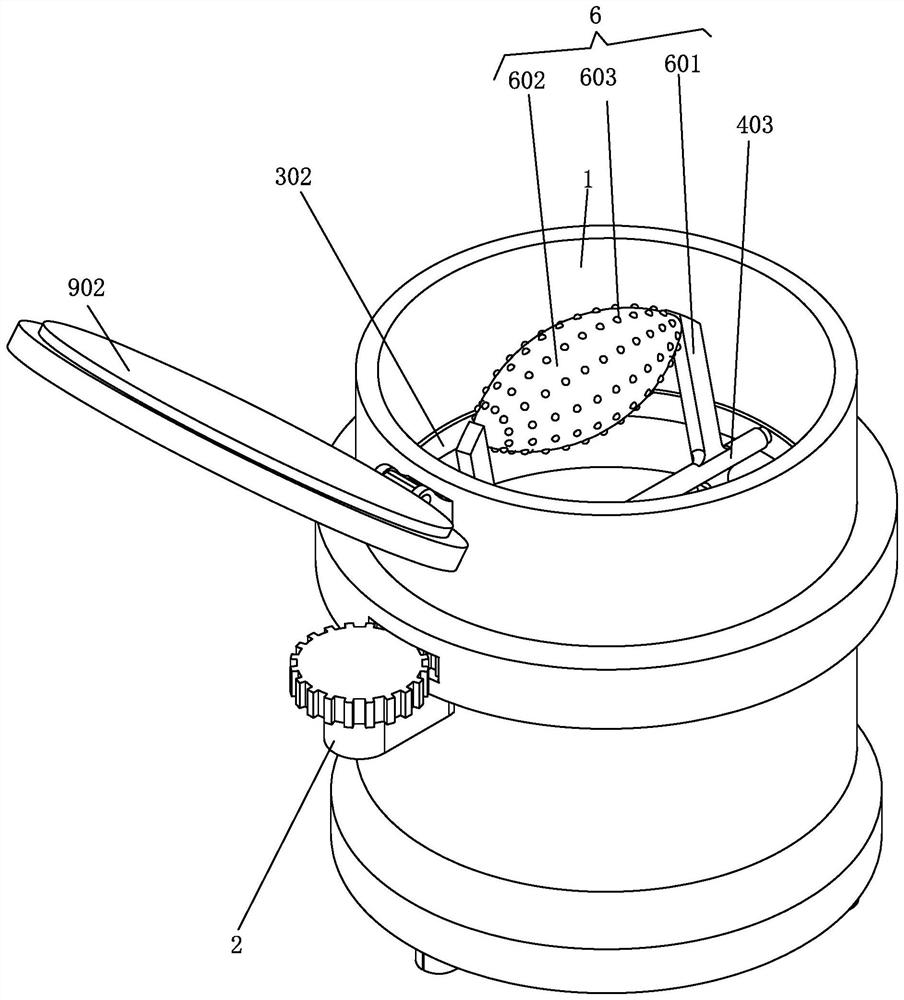

Mixing processing device for biological agents in field of bioengineering

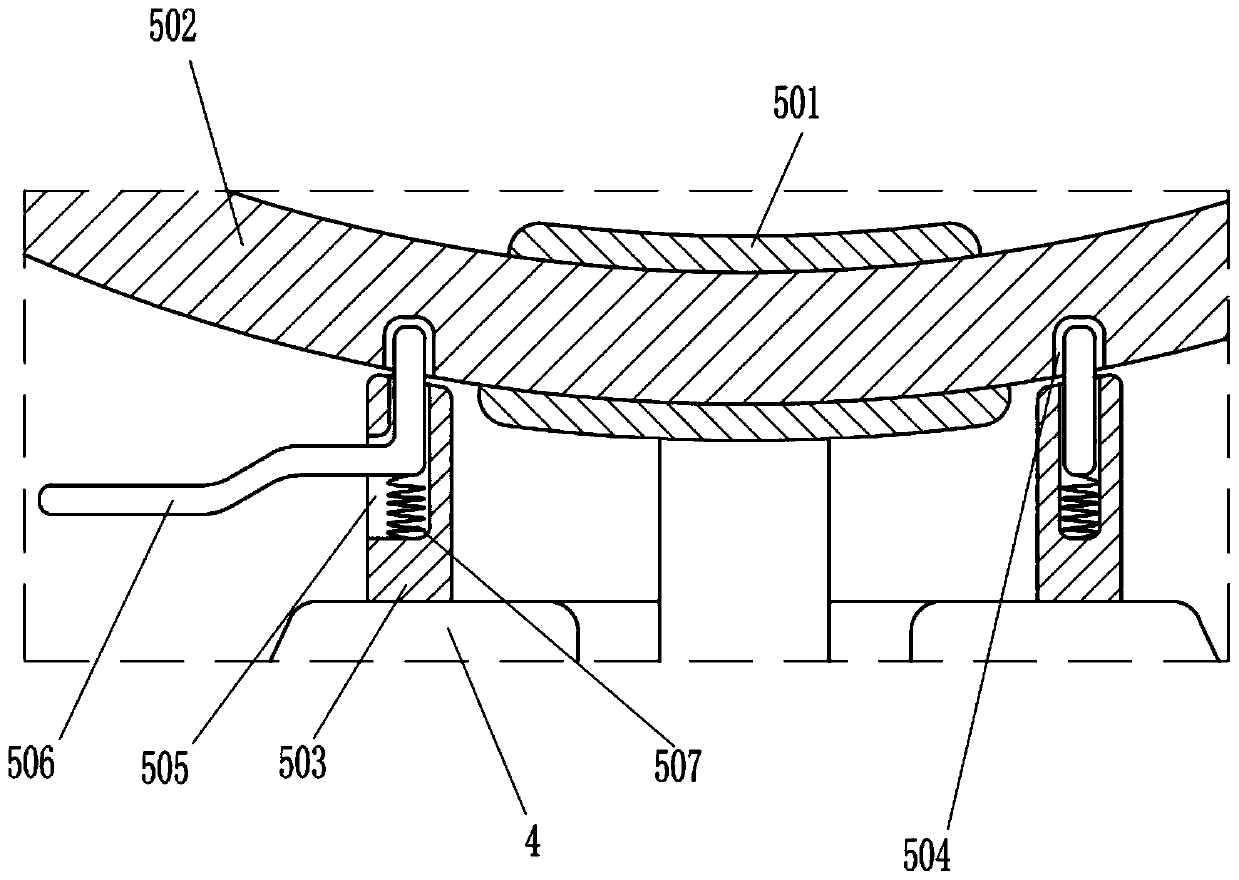

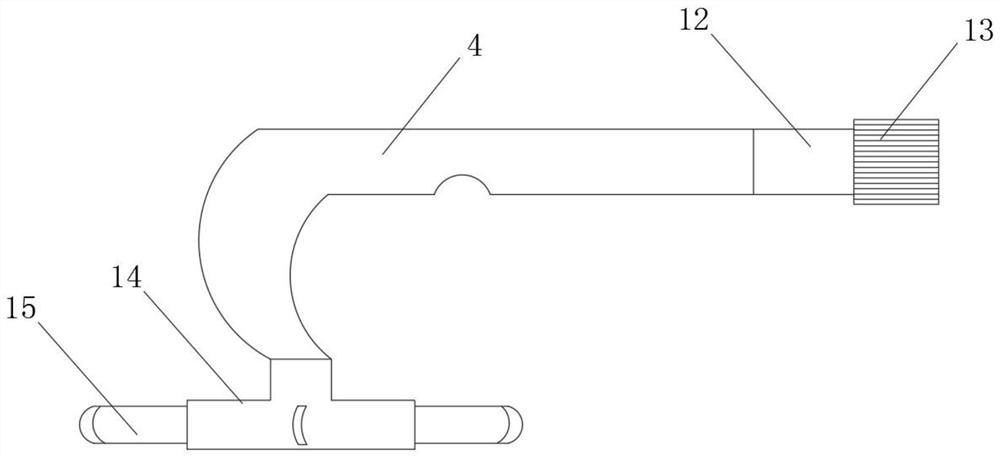

InactiveCN108543481AWell mixedMixed comprehensiveShaking/oscillating/vibrating mixersTransportation and packagingBiochemical engineeringBiological agent

Provided is a mixing processing device for biological agents in the field of bioengineering. The mixing processing device comprises a bottom plate device, a frame device which is arranged on the bottom plate device, an electric cylinder device which is disposed on the bottom plate device, a filter frame device which is accommodated in the frame device, a blowing device which is disposed on the filter frame device and a positioning device which is arranged on the left side of the frame device. Through the mixing processing device, the biological agents can be mixed fully, the mixing processingdevice has comprehensive mixing, diversified stirring modes and an ideal stirring effect, and full mixing for a reaction can be realized between the agents, so that needs of bioengineering are met.

Owner:张雪媚

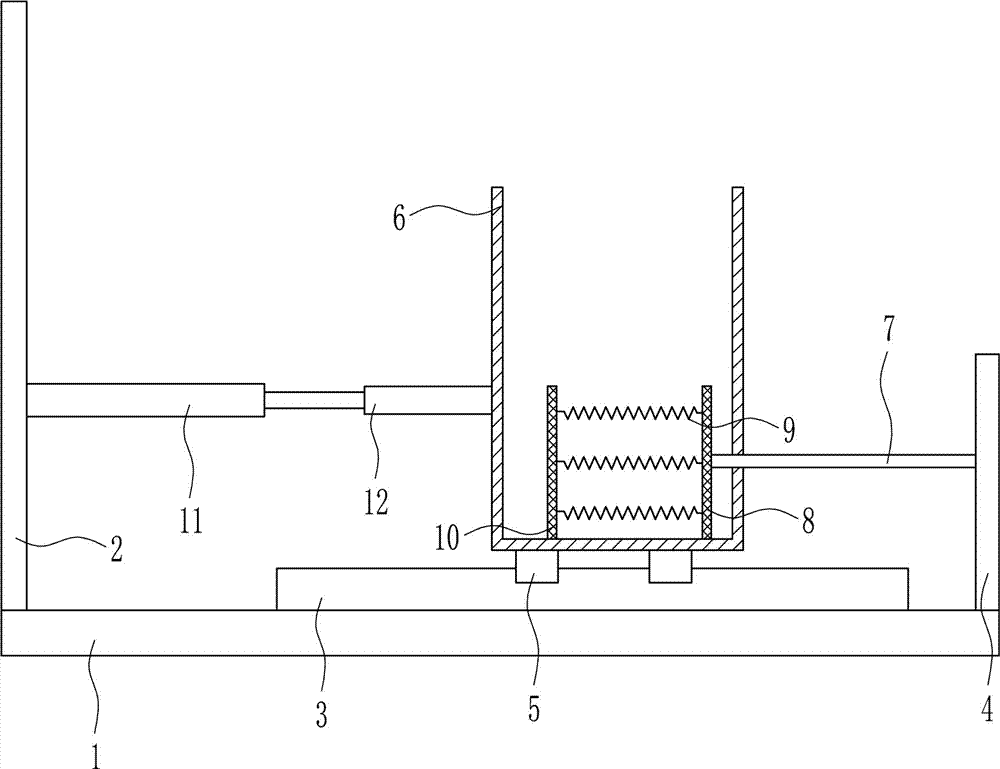

High-efficiency mixing apparatus for drugs used for medical treatment

InactiveCN106902685AMixed comprehensiveFully absorbedShaking/oscillating/vibrating mixersTransportation and packagingMixing effectPediatrics

The invention relates to a mixing apparatus for drugs used for medical treatment, especially to a high-efficiency mixing apparatus for drugs used for medical treatment. The objective of the invention is to provide the high-efficiency drug mixing apparatus which is low in manufacturing cost, simple to operate, good in mixing effect and capable of assisting people in adequate absorption of drugs. The high-efficiency mixing apparatus for drugs used for medical treatment comprises a base plate, a left side plate, a slide rail, a fixed baffle plate, slide blocks, a barrel, a first connecting rod, etc., wherein the top of the base plate is successively provided with the left side plate, the slide rail and the fixed baffle plate from left to right; the left side plate and the fixed baffle plate are vertically arranged; and the slide rail is horizontally arranged. According to the invention, a cylinder is used as a drive to allow the barrel to move leftward and rightward, so drugs for medical treatment are shaken in the barrel; meanwhile, a movable web plate and a movable block move leftward and rightward under the action of a first spring and a second spring.

Owner:张传波

An experiment device used for preparing environment-friendly spray coating

InactiveCN107913638AQuality improvementGood control over mixing speedRotating receptacle mixersTransportation and packagingSpray coatingEngineering

The invention relates to an experiment device, particularly an experiment device used for preparing environment-friendly spray coating. A technical problem to be solved is to provide an experiment device which is used for preparing environment-friendly spray coating and which is capable of controlling a raw material ratio well and slowly adding raw materials. To solve the problem, the experiment device is provided and includes a mounting rack, supporting bars, an annular slide rail, first slide blocks, a frame, a first material discharging pipe, and the like. The supporting bars are disposed at the inner bottom of the mounting rack in a bilaterally symmetrical manner. Tops of the supporting bars are connected to the annular slide rail. The inside of the annular slide rail is provided withthe first slide blocks in a slide connection manner. Tops of the first slide blocks are connected to the frame. The device achieves effects of controlling a raw material ratio well and slowly adding raw materials. A first motor rotates clockwise to drive the frame to rotate clockwise, and a second motor rotates anticlockwise to drive stirring bars to rotate anticlockwise, thus making a raw material mixing speed higher.

Owner:李四英

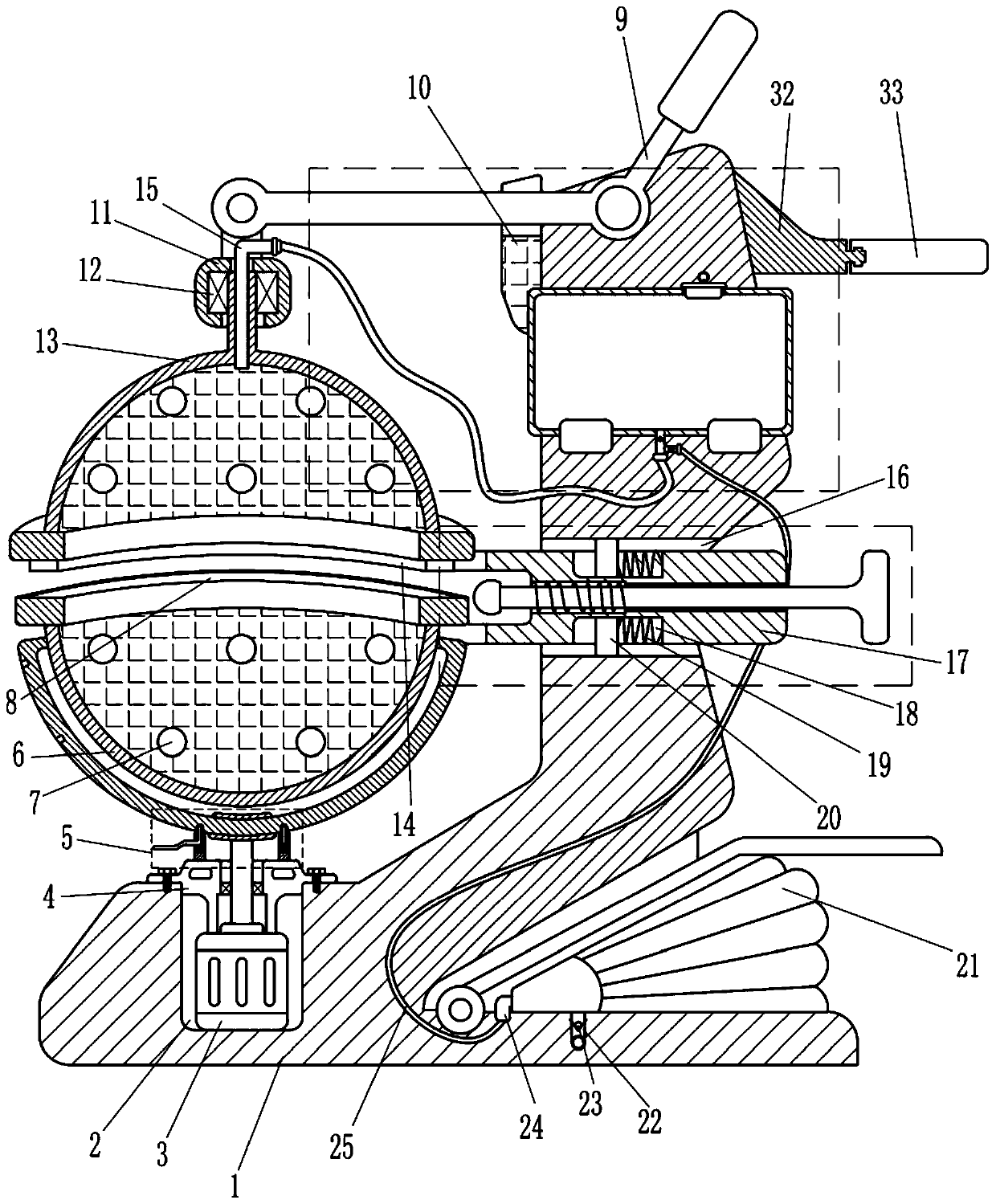

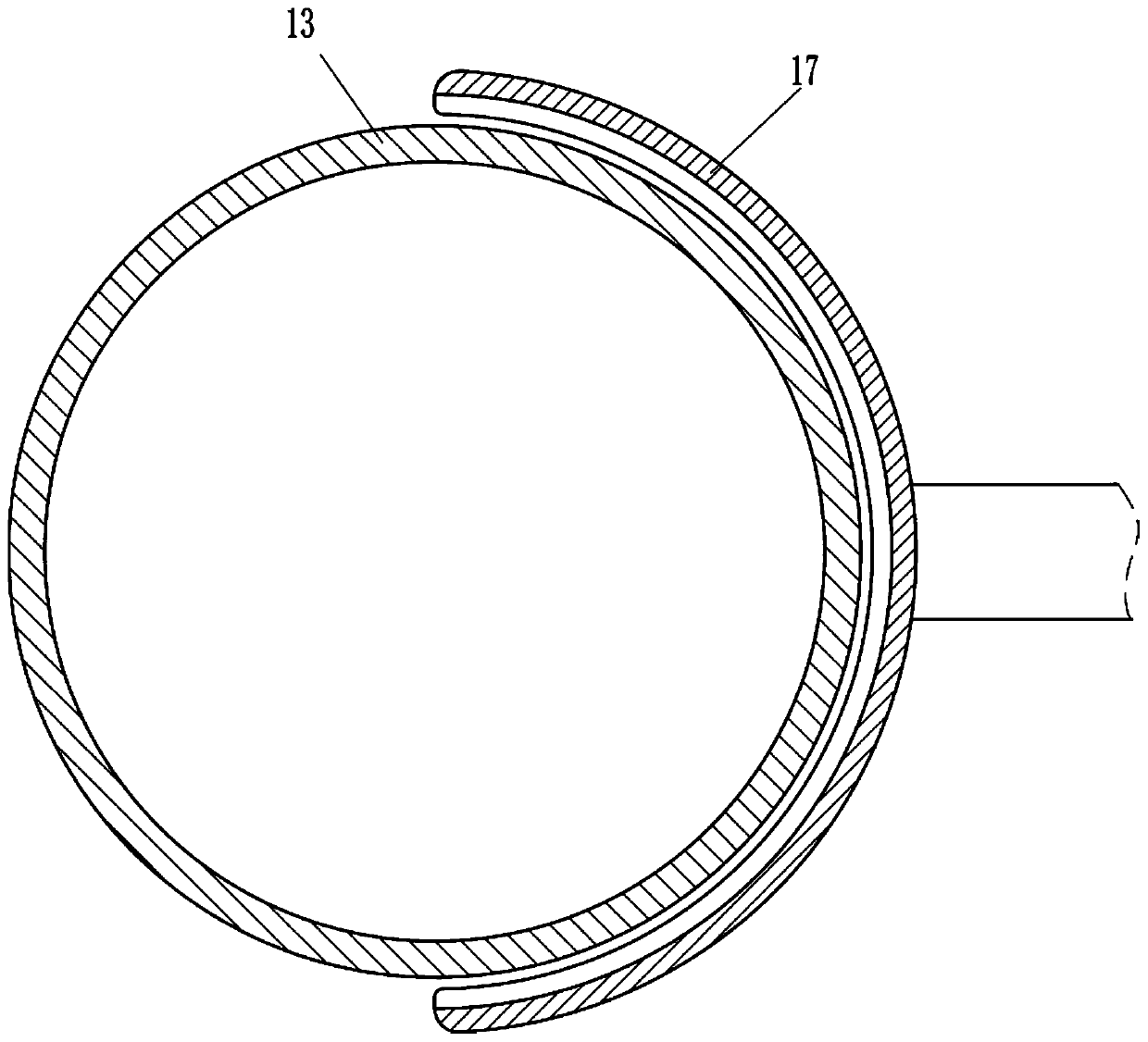

Nd-Fe-B magnetic powder material-mixing machine

InactiveCN110215877AQuick take outMixed comprehensiveRotating receptacle mixersTransportation and packagingLubricantMaterials science

The invention relates to a material-mixing machine, in particular to a Nd-Fe-B magnetic powder material-mixing machine. The technical problem is to provide a Nd-Fe-B magnetic powder material-mixing machine which can quickly and uniformly mix a Nd-Fe-B powder material and an additive, and conveniently treats the Nd-Fe-B powder material attached to a mixing tool. The technical scheme is that: the Nd-Fe-B magnetic powder material-mixing machine comprises a mounting frame, a geared motor and the like, wherein a first concave groove is formed on the left side of the top of the mounting frame. By cooperation of a sliding sleeve and an arc-shaped rod, when the magnetic powder is taken out, since a lower material-mixing ball is in an inclined state, the magnetic powder can slide down to the lowerside, and the magnetic powder can be taken out better and faster. A lubricant is sprayed on the magnetic powder by a gas, the magnetic powder can be more fully mixed with the lubricant, a rotating rodis stuck above a pry rod, the rotating rod is stuck, and the rotating rod and apparatuses on the rotating rod do not swing downwards due to gravity, so that holding the pry rod all the time is not necessary while feeding, and the equipment is more convenient to use.

Owner:XINFENG BAOGANG XINLI RARE EARTH

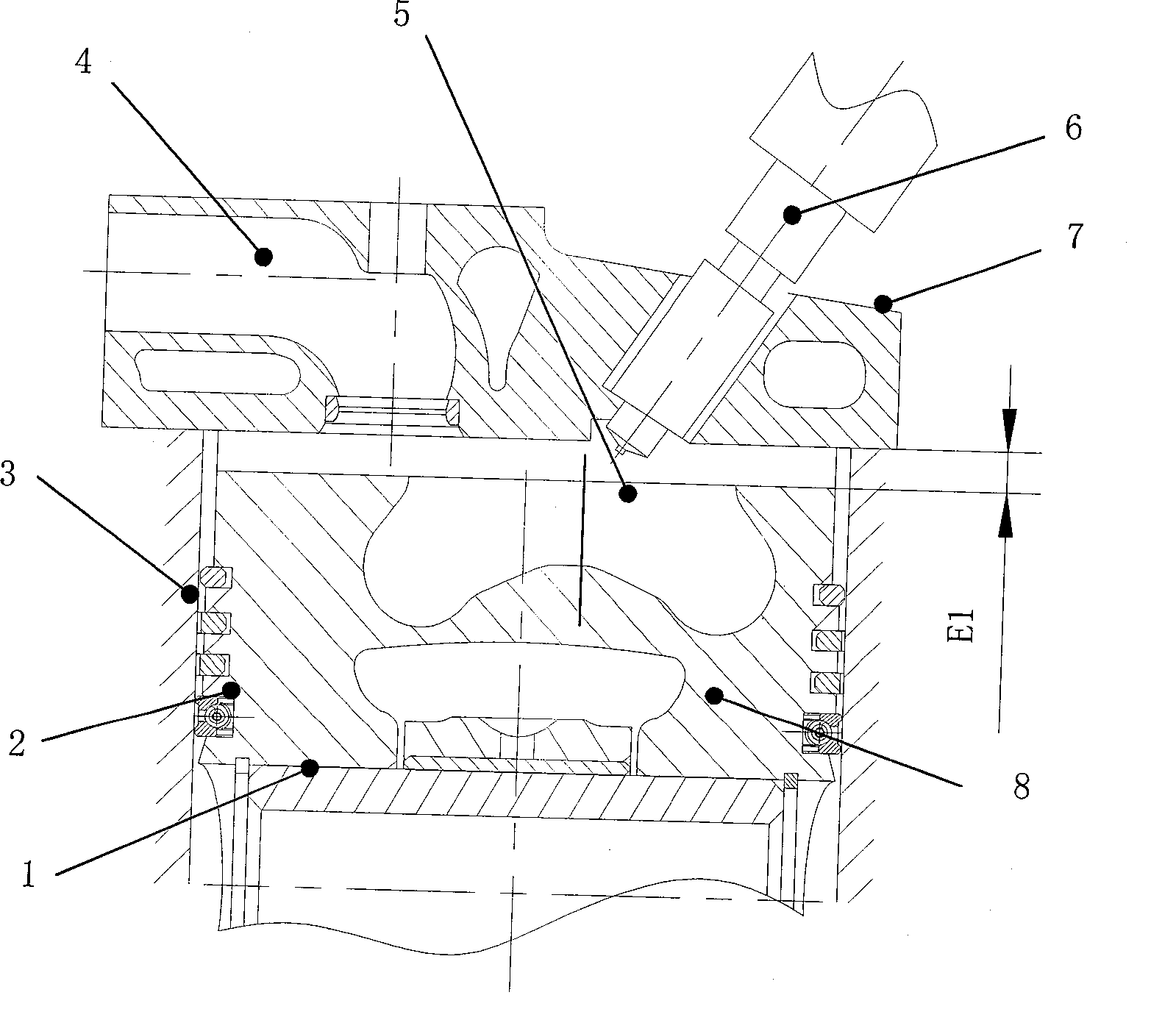

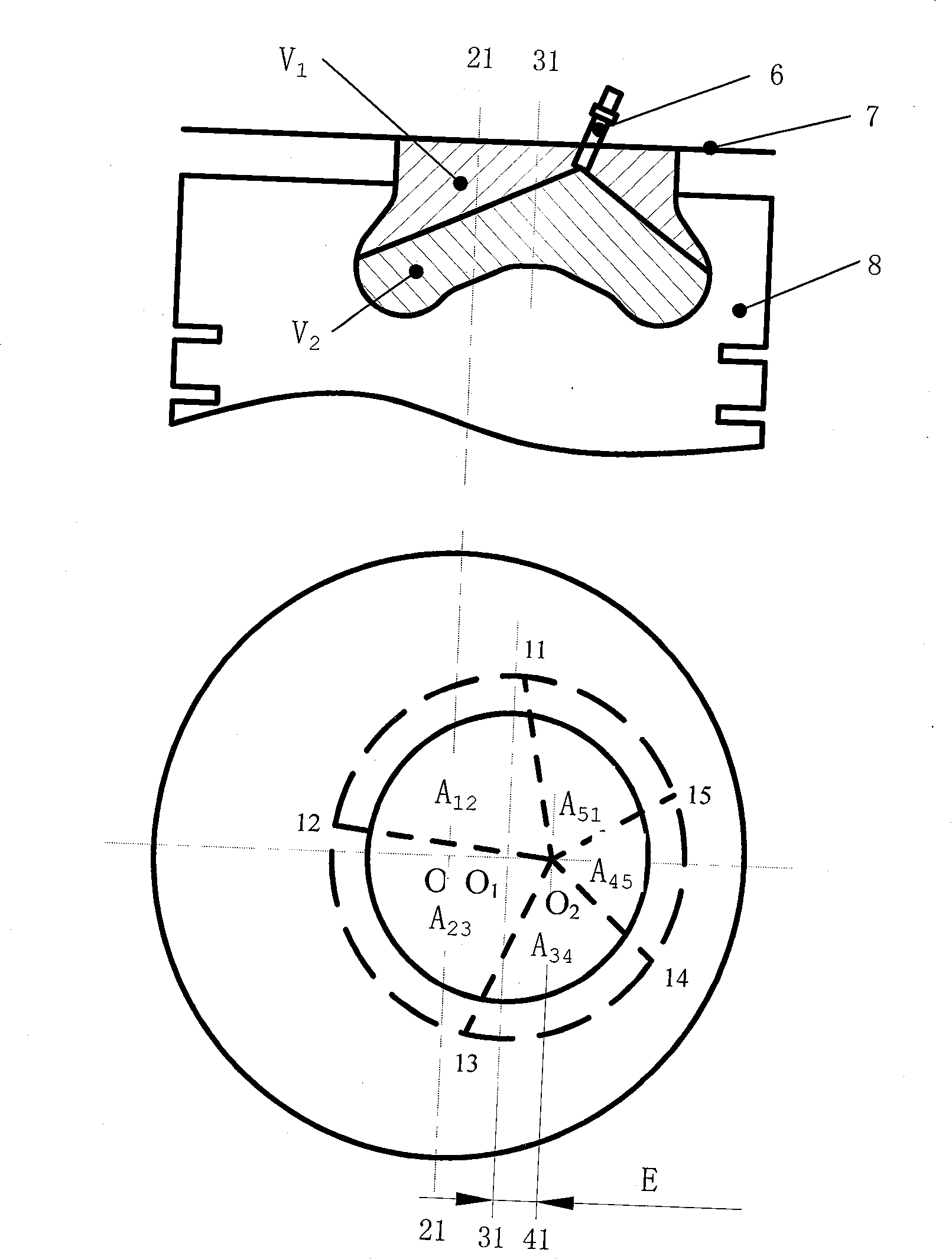

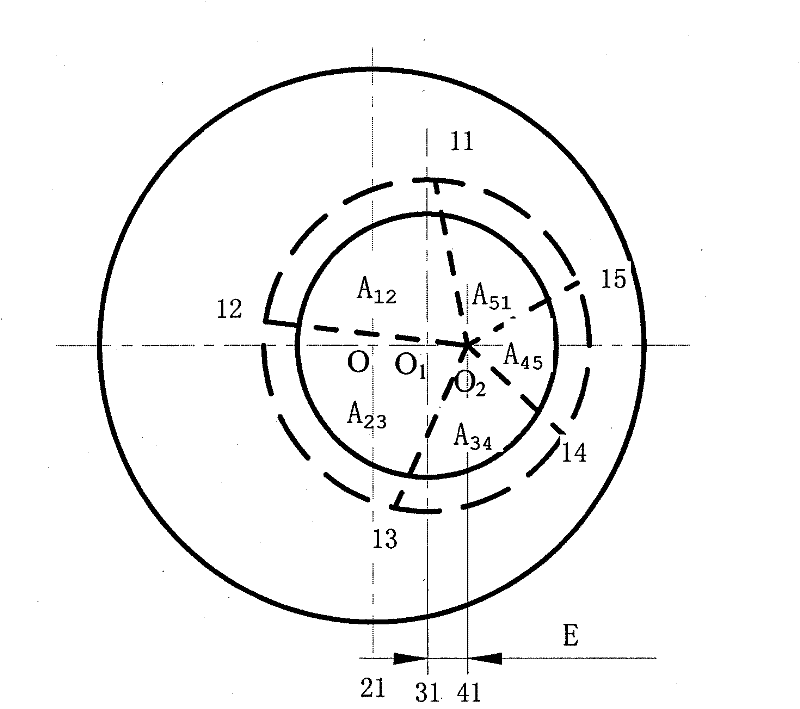

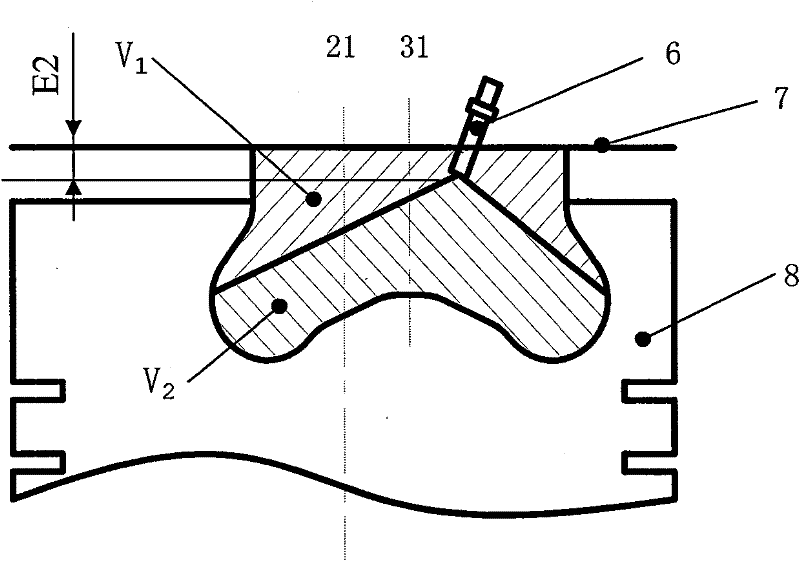

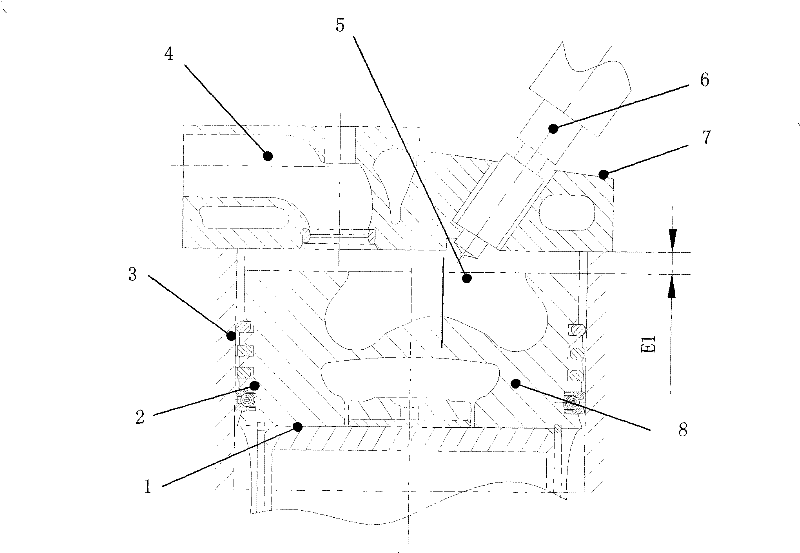

Fuel oil uniform mixing and burning system of double air ports diesel engine

InactiveCN101451463AImprove performanceReduce angleInternal combustion piston enginesFuel injection apparatusCombustion systemCombustion chamber

The present invention relates to a fuel equipartition mixture and combustion device design proposal of two valve diesel. A fuel injector set on the cylinder cap and an inlet channel; a burning compartment is below the fuel injector and inlet channel; the inlet channel is eddy flow type inlet channel; a drop pit shape shrunk burning compartment in the shape of letter W is set above the valve; head section of the fuel injector stretches out of the bottom of the cylinder cap and against the burning compartment. Parameter design of cylinder cap, fuel injector and burning compartment make fuel and air adequate distribution in certain rules on axial and circumferential direction within effective combustion space, and realize oil gas mixing design of equal excess air factor within effective combustion space. Under effect of high jet pressure and air-intake transverse currents of fuel injection system, oil gas inside the cylinder mixes uniformly, velocity of combustion quicker, duration short, oil spout can be postponed, and high-efficiency quick burning of low discharge can be realized. Engine synthetic performance can be optimized through the invention, and engine power can be improved while nocuousness discharged object can be reduced.

Owner:JIANGSU UNIV

Fermentation device for animal husbandry excrement treatment

InactiveCN111762987AEfficient crushingFully brokenWaste water treatment from animal husbandryBiological sludge treatmentAnimal scienceElectric machinery

The invention belongs to the technical field of animal husbandry, and particularly relates to a fermentation device for animal husbandry excrement treatment. In view of the problem of incomplete fermentation, presented is the following scheme, namely, the fermentation device comprises a fermentation box, a motor is arranged on the outer wall of the top of the fermentation box, a rotating rod is arranged on an output shaft of the motor, cross rods distributed at equal intervals are arranged on the outer wall of one side of the rotating rod, crushing and stirring blocks distributed at equal intervals are arranged on the two sides of the outer wall of each cross rod, each crushing and stirring block is of a sickle-shaped structure, the inclination directions of the crushing and stirring blocks located on the two sides of the rotating rod are opposite, and a stirring ring is arranged on the outer wall of one side of each cross rod. The device is provided with the cross rods, the crushing and stirring blocks, the stirring rings, rotating plates, fixed plates, first crushing blocks, second crushing blocks, springs and stirring floating balls, the crushing and stirring blocks are each ofa sickle-shaped structure and can crush excrement, the excrement and fermentation liquor can be mixed more comprehensively, different vortexes can be generated by the stirring rings of different specifications and sizes, and the mixing effect of the excrement is improved.

Owner:GANSU AGRI UNIV

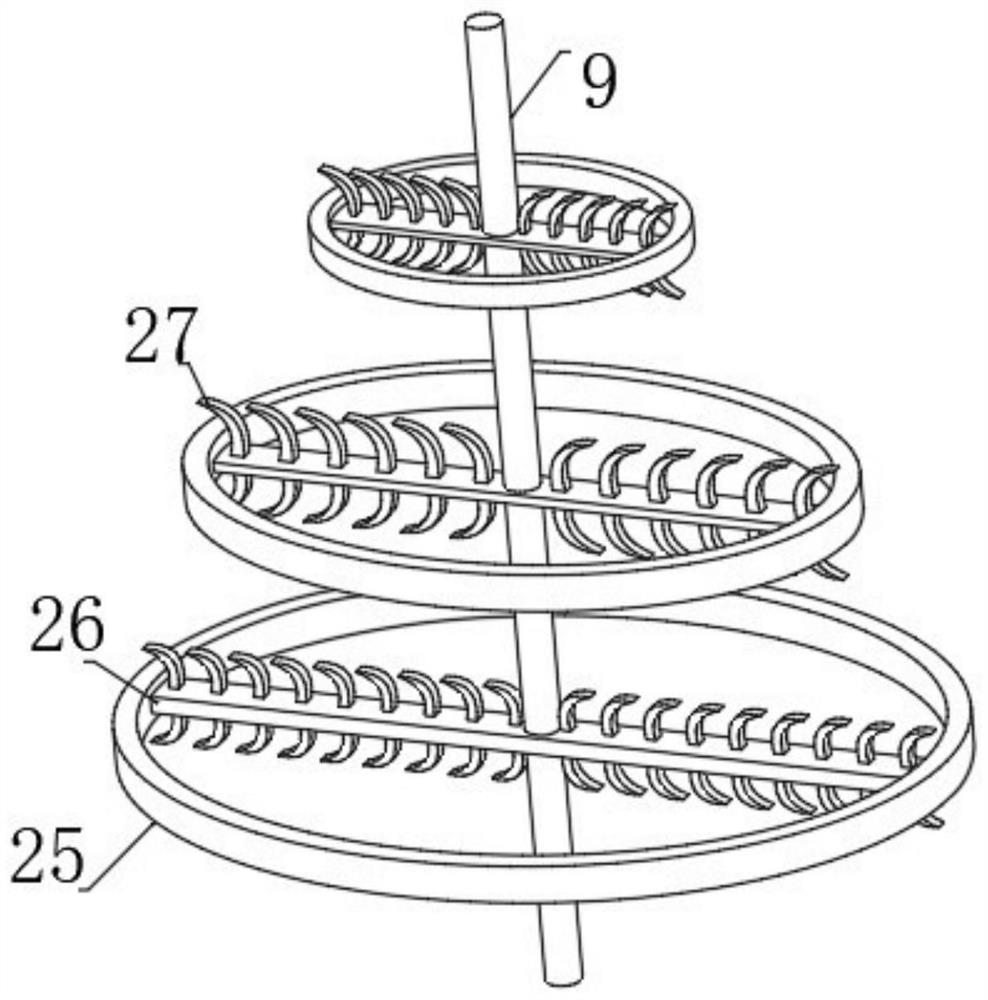

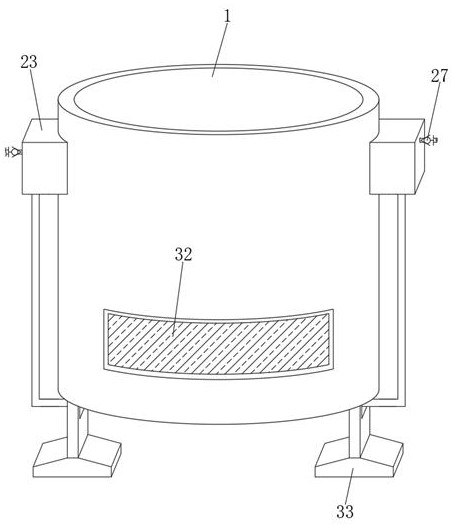

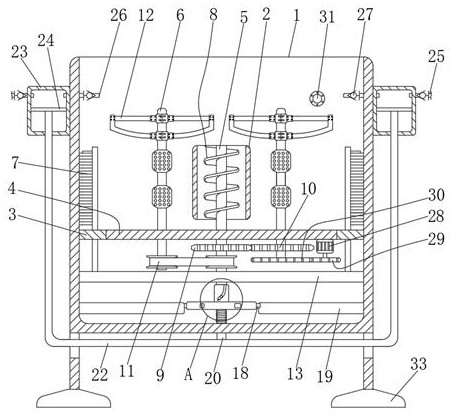

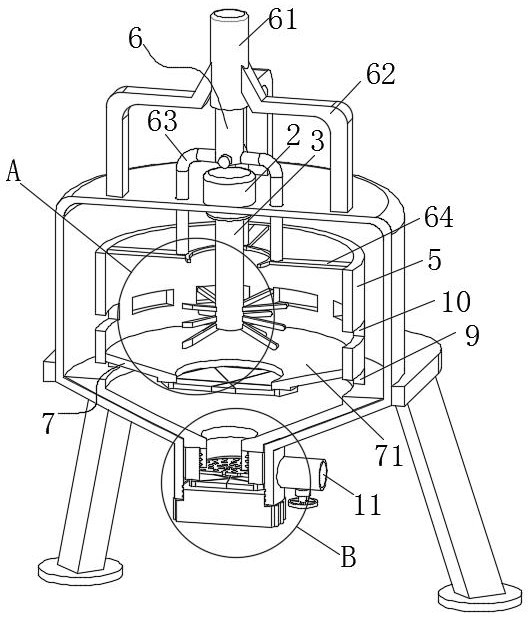

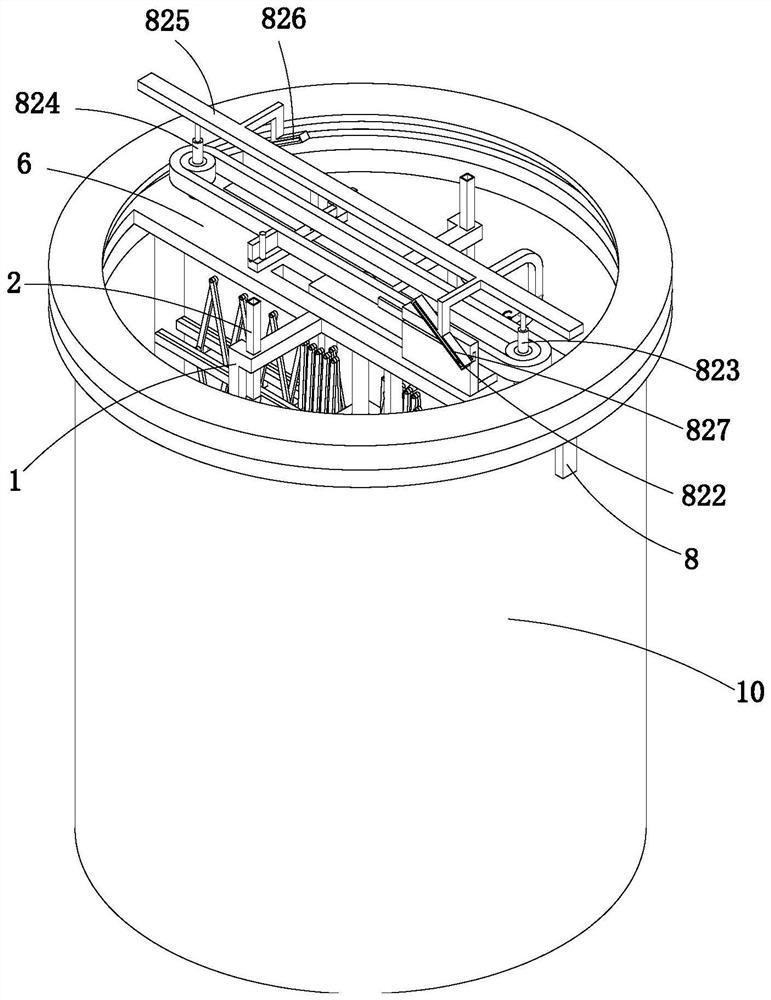

Automatic multi-layer mixing equipment used for dry-mixed mortar production

ActiveCN113478654AWell mixedMixed comprehensiveMixing operation control apparatusHollow article cleaningEngineeringMechanical engineering

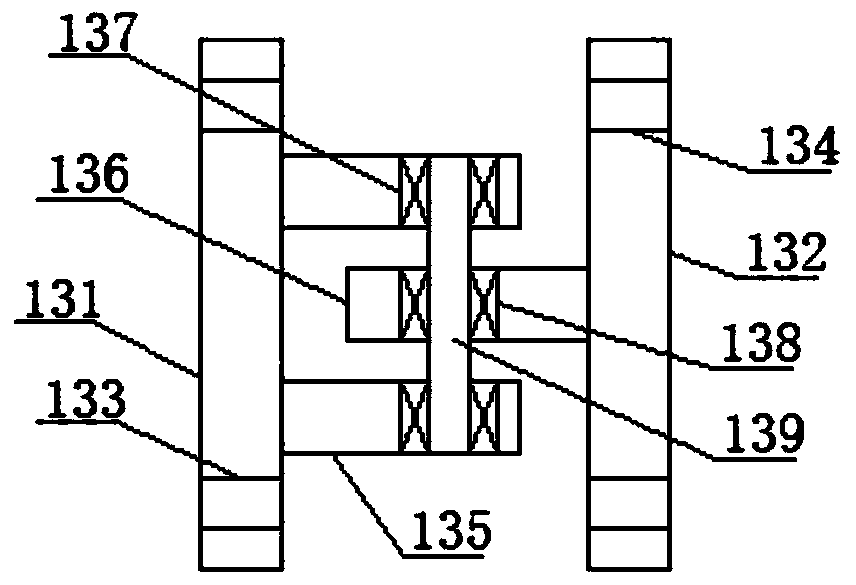

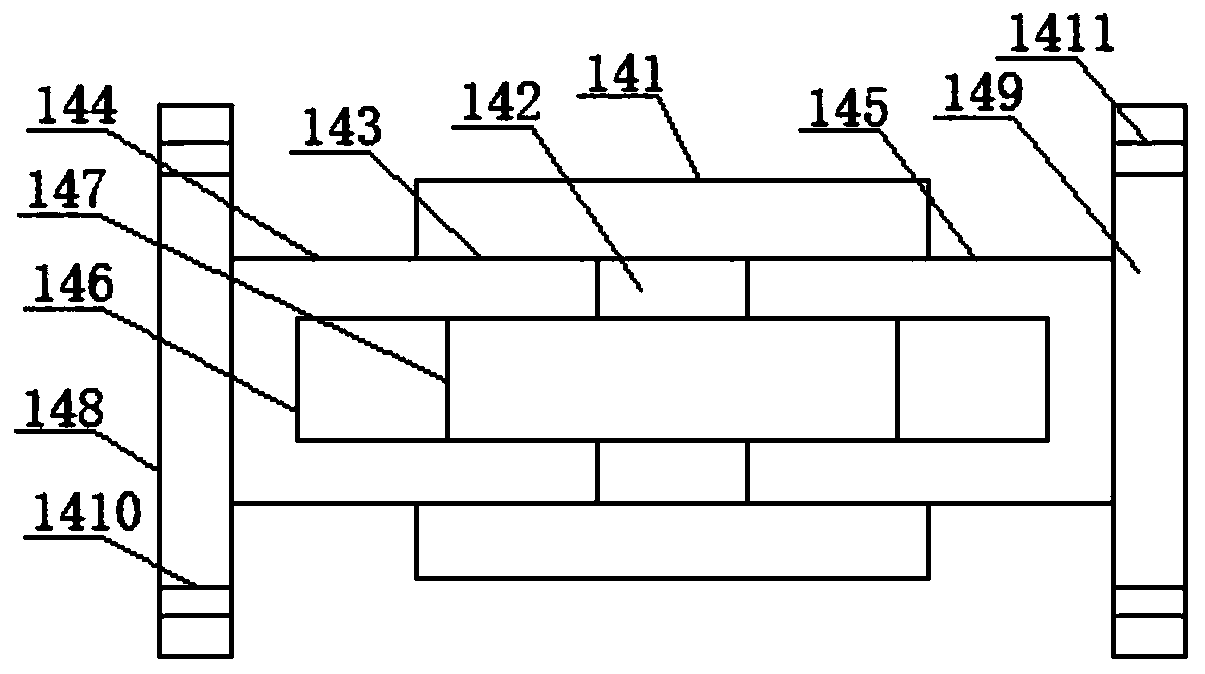

The invention discloses automatic multi-layer mixing equipment used for dry-mixed mortar production, and relates to the technical field of dry-mixed mortar mixing equipment. The automatic multi-layer mixing equipment comprises a mixing barrel, the inner wall of the mixing barrel is fixedly connected with a conveying barrel, the inner wall of the mixing barrel is rotationally connected with a first rotating plate, the inner wall of the first rotating plate is rotationally connected with a second rotating plate, a rotating rod and two stirring rods are rotationally connected to the inner wall of the second rotating plate, two brush plates are rotationally connected to the inner wall of the first rotating plate, a conveying packing auger is arranged on a rod arm of the rotating rod, and a transmission component used for enabling the two stirring rods to oppositely and reversely rotate and meanwhile driving the conveying packing auger to synchronously operate is arranged below the first rotating plate. Through mutual cooperation of the above structures, the equipment has the effects of comprehensively mixing mortar and preventing mortar from being bonded to the inner wall of a device in the mixing process, and the problems that raw materials with small specifications are prone to being accumulated at the bottom of the device in the mixing process, and mortar is prone to being bonded to the inner wall of the device in the mixing process are solved.

Owner:南通晶德盈节能环保科技有限公司

Foodstuff mixing device for animal husbandry

InactiveCN110585968AQuality improvementStirring effect and efficiency are obviousShaking/oscillating/vibrating mixersFeeding-stuffEngineeringCam

The invention discloses a foodstuff mixing device for animal husbandry. The foodstuff mixing device comprises a bottom mounting base plate. With drum-type raw material mixing, raw materials can be comprehensively mixed; the phenomenon of low raw material mixing degree caused by mixing dead angles is avoided, so the quality of a mixed finished product is improved; moreover, the device can enable adrum shell to repeatedly move up and down; therefore, the internally mixed raw materials can achieve a transverse moving effect, and the stirring effect and efficiency are more obvious; moreover, thedevice is provided with a bolt mounting type part rotary connecting mechanism, two parts can be connected, and meanwhile, relative rotation between the two connecting parts is not affected; in addition, the device is provided with a reverse thread structure rotary type longitudinal height adjusting mechanism capable of adjusting the height of one end of the roller shell; in addition, the device isprovided with a bidirectional cam type rotary distance adjusting mechanism capable of enabling a roller to transversely move.

Owner:华琳琳

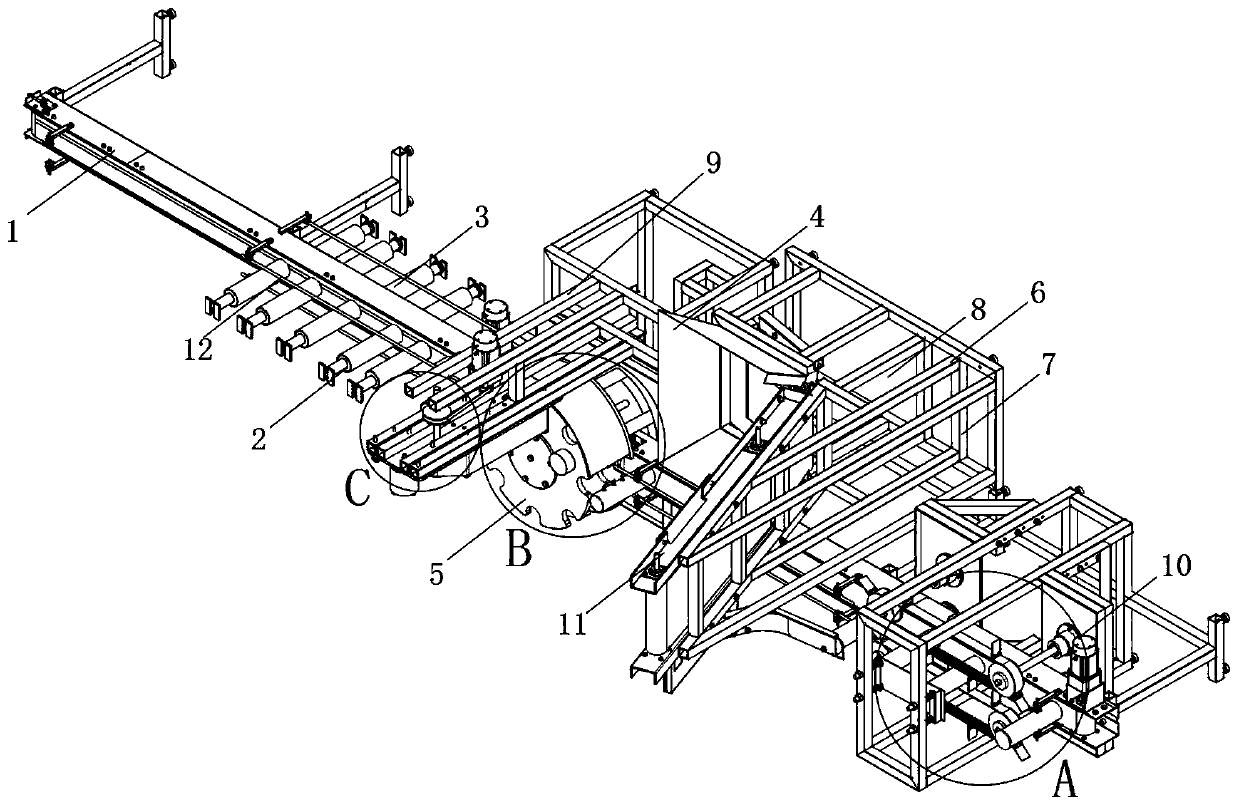

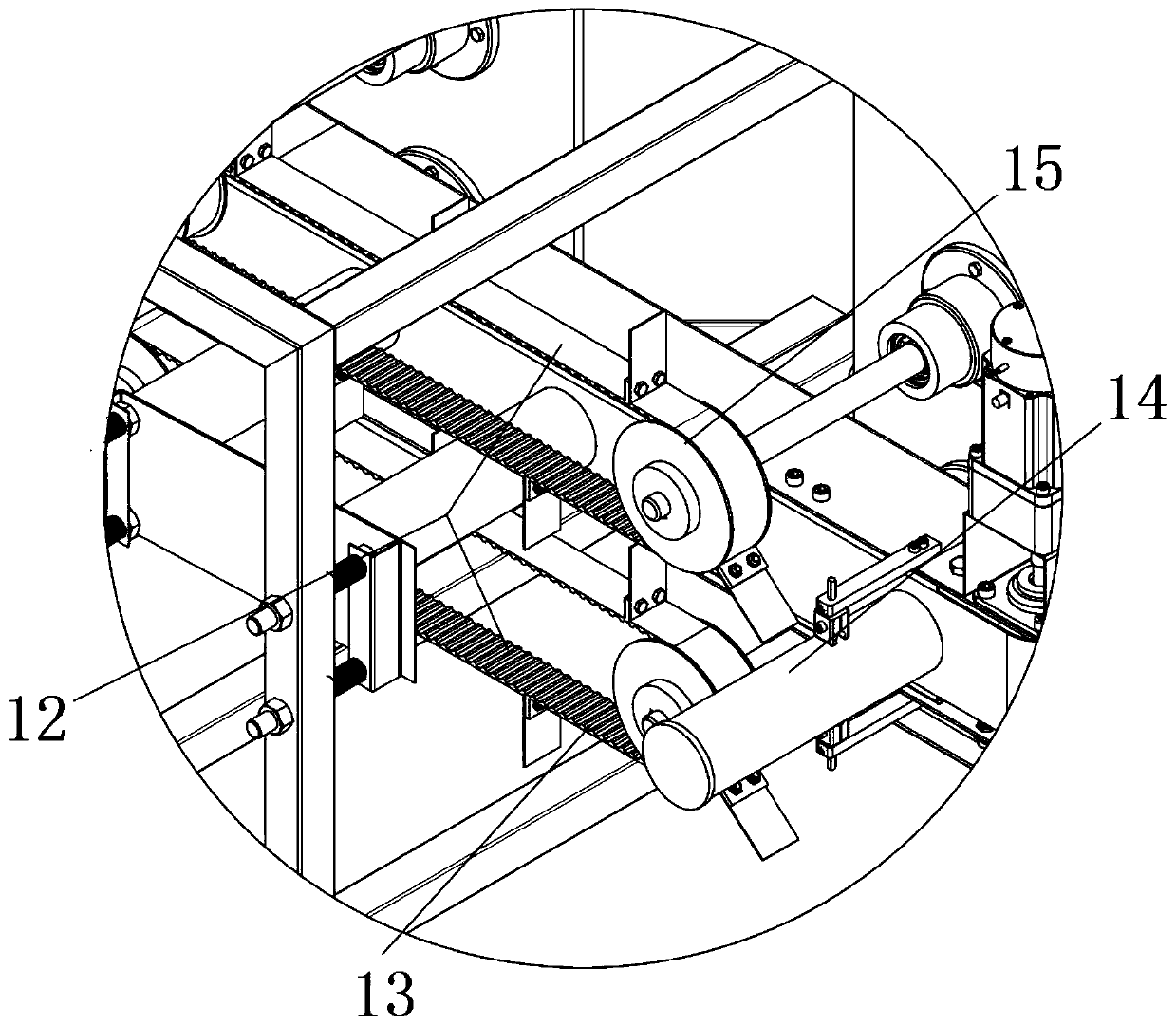

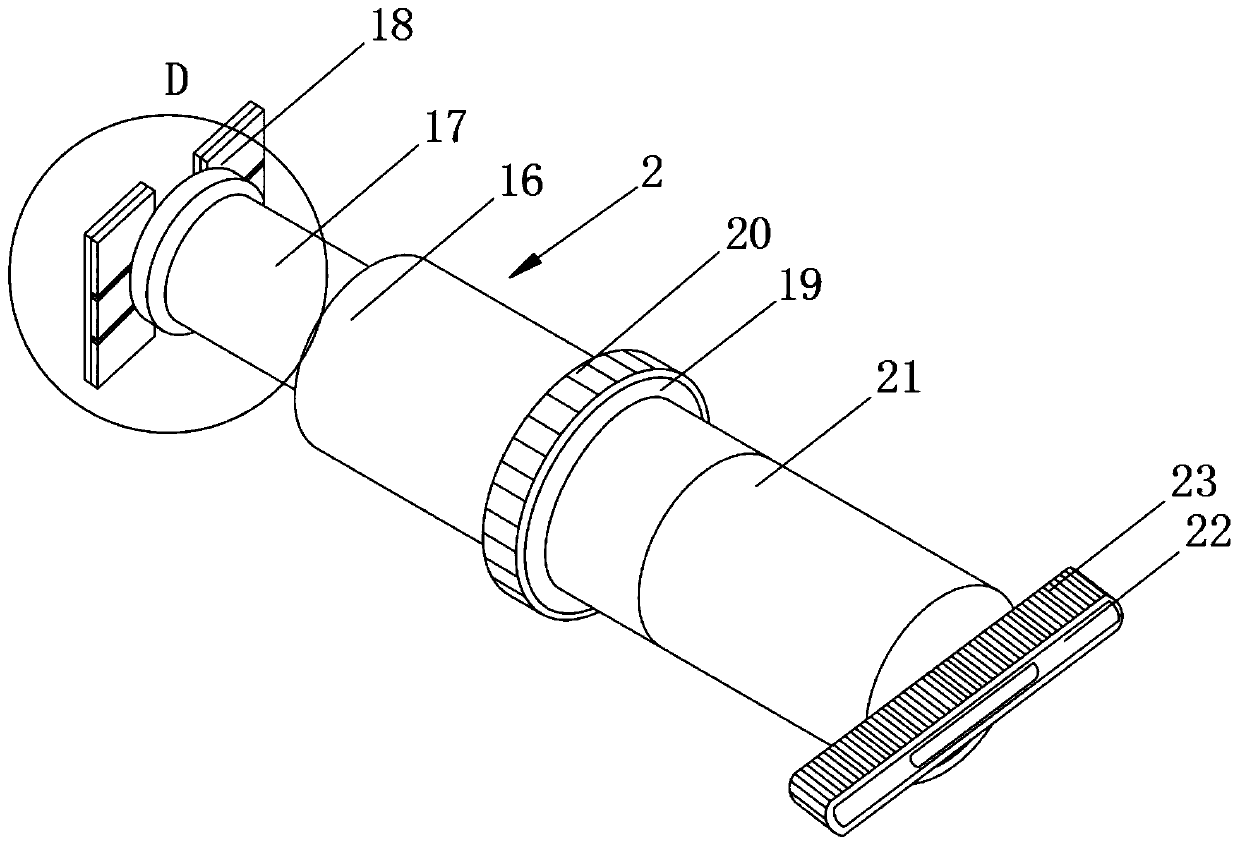

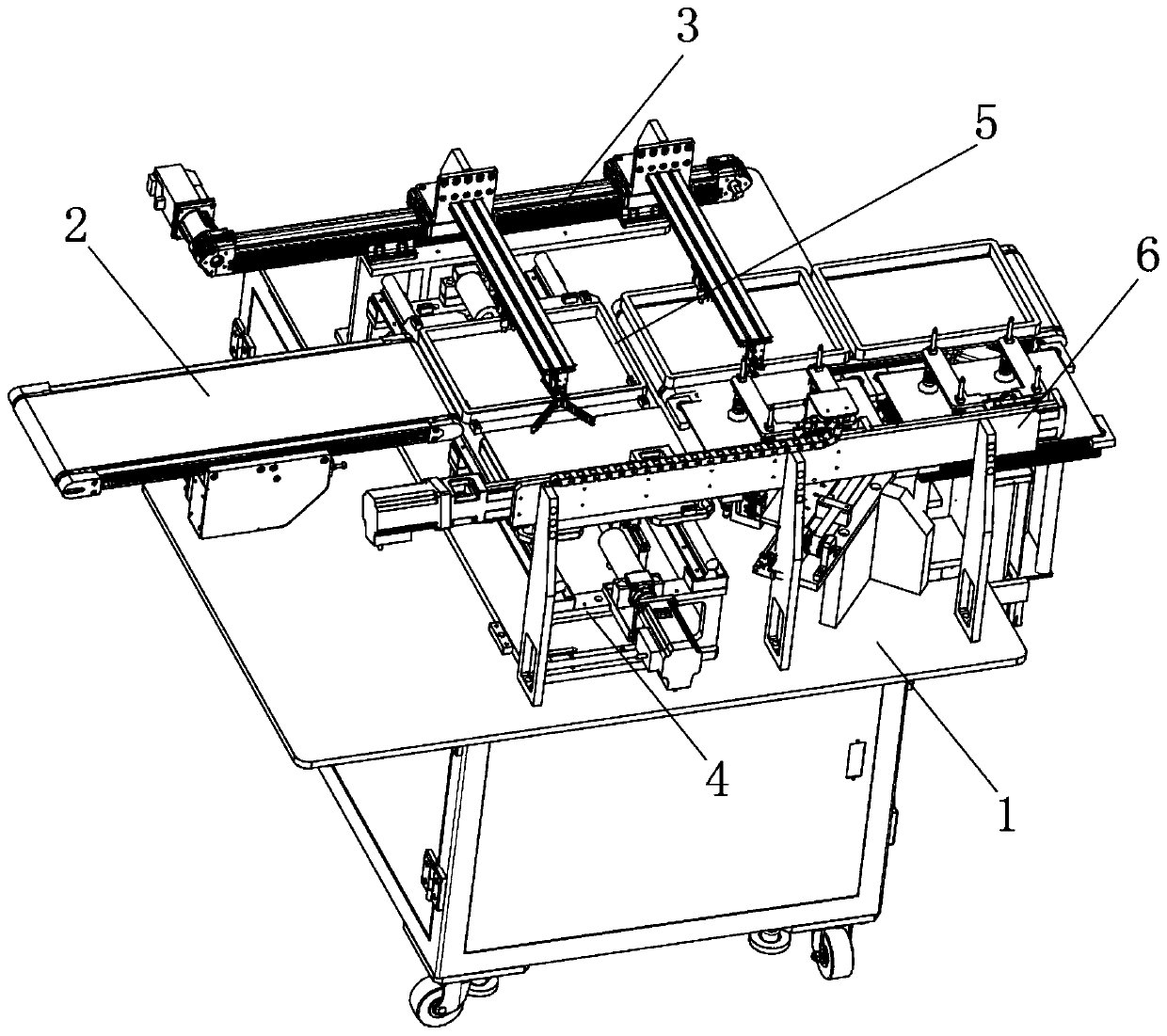

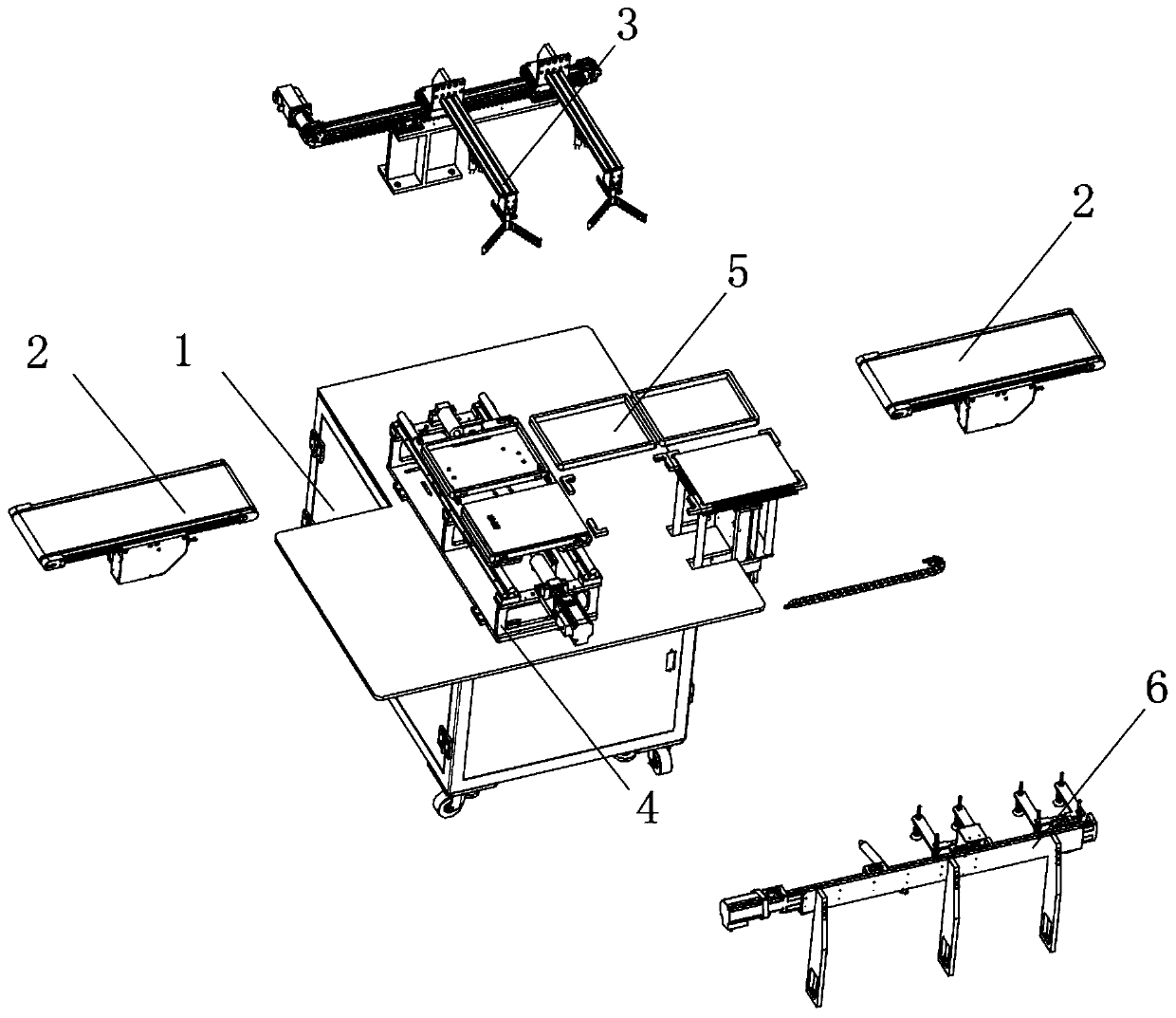

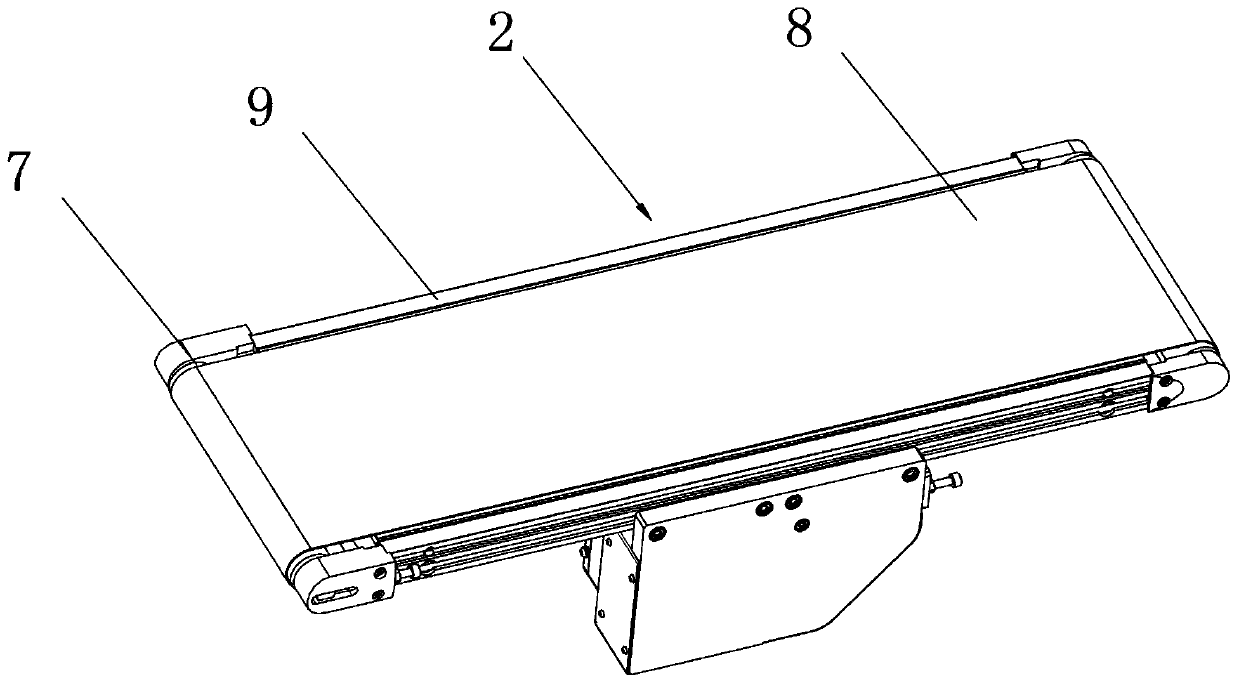

Quantitative feeding and discharging device for anaerobic fermentation biogas production pond and control method of device

InactiveCN110218636AHigh degree of automationImprove matchBioreactor/fermenter combinationsBiological substance pretreatmentsMotor driveTransmission belt

The invention discloses a quantitative feeding and discharging device for an anaerobic fermentation biogas production pond and a control method of the device. The device comprises a clamping and connecting cabinet, multiple feeding rollers, multiple discharging rollers, an assembling and connecting frame, a material box and a transmission frame, wherein the clamping and connecting cabinet penetrates through the assembling and connecting frame, and the feeding rollers all penetrate through the side wall of one end of the clamping and connecting cabinet. The device has the advantages that fourthmotors drive clamping teeth on the inner walls of toothed slots to move through a fourth transmission belt, correspondingly sealing plates are driven to move forward and backward stably, and the whole feeding area of a feeding opening is adjusted, so that the feeding and discharging speed and feeding capacity of the device for the anaerobic fermentation biogas production pond are quantitativelycontrolled, and it is ensured that the matching degree of the control over the feeding and discharging speed and feeding capacity of the device for biogas production ponds different in size and volumeis higher and more appropriate. Scrapers are matched with stirring teeth to extrude materials reciprocatively, and meanwhile, fifth motors drive the scrapers and the stirring teeth to continuously mix and stir the materials, so that the diversified organic materials are mixed more uniformly and comprehensively while the materials become finer.

Owner:吴小微

Mixed material oxidation reaction device

InactiveCN108636333AImprove efficiencyImprove the effectChemical/physical/physico-chemical stationary reactorsPolymer chemistryReaction chamber

The invention discloses a mixed material oxidation reaction device. The device comprises a mixed material oxidation reaction device body, an air outlet is formed in the top of the mixed material oxidation reaction device body, a main feed port is formed in the side surface of the upper end of the mixed material oxidation reaction device body, an air inlet is formed in the side surface of the lowerportion of the mixed material oxidation reaction device body, an oxygenation pump is connected to the air inlet, an oxygen tank for supplying oxygen to the oxygenation pump is connected with the oxygenation pump, a reaction chamber is arranged inside the mixed material oxidation reaction device body, the reaction chamber is internally provided with at least a partition plate, at least one spray device is arranged on the inner wall of the reaction chamber, and a discharge port is further formed in the bottom of the reaction device body; a plurality of through holes are formed in the partitionplate; the spray device is provided with a spray head. The invention provides the mixed material oxidation reaction device capable of rapidly and uniformly mixing materials and integrating mixing withoxidation.

Owner:SUZHOU JINXIANG TITANIUM EQUIP

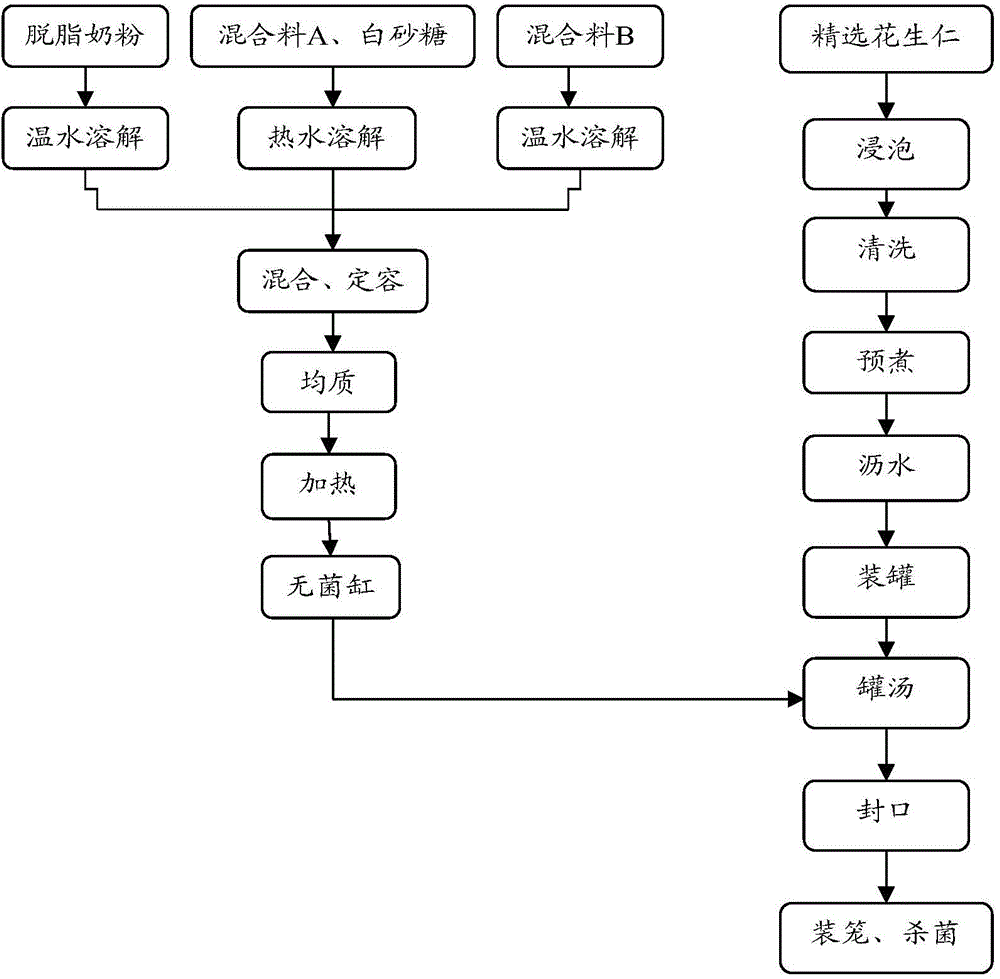

Can containing egg milk and peanuts, and preparation method of can

InactiveCN104643134AImproves absorption, digestion and nutritional valueEasy to absorbFood preparationChemistryProtein content

The invention discloses a can containing egg milk and peanuts, and a preparation method of the can. The can is characterized by comprising 40-50 parts of an egg milk solution and 50-60 parts of peanut kernels in 100 parts by weight, wherein the egg milk solution is prepared by dissolving the following components into 1000L of water: 100-150kg of white granulated sugar, 20-30kg of skim milk powder, 20-50kg of whole egg powder, 200-500g of D-sodium erythorbate, 600-1000g of xanthan gum, 2-5kg of lecithin and 400-800g of phosphate. The preparation method comprises the steps of preparing the egg milk solution, treating the peanut kernels, mixing, canning and sterilizing. According to the method, the raw materials are scientifically matched and treated; the prepared can containing the egg milk and the peanuts has the characteristics of being rich in nutrition, being capable of enabling a person to be full and quenching thirst, and being low in sugar content and fat content and high in protein content and calcium content; therefore, the can containing the egg milk and the peanuts is a convenient food which is good in color, aroma and taste, is suitable both for home and journey and can be eaten when being cold and hot.

Owner:FUJIAN QUANZHOU XIDUODUO FOOD

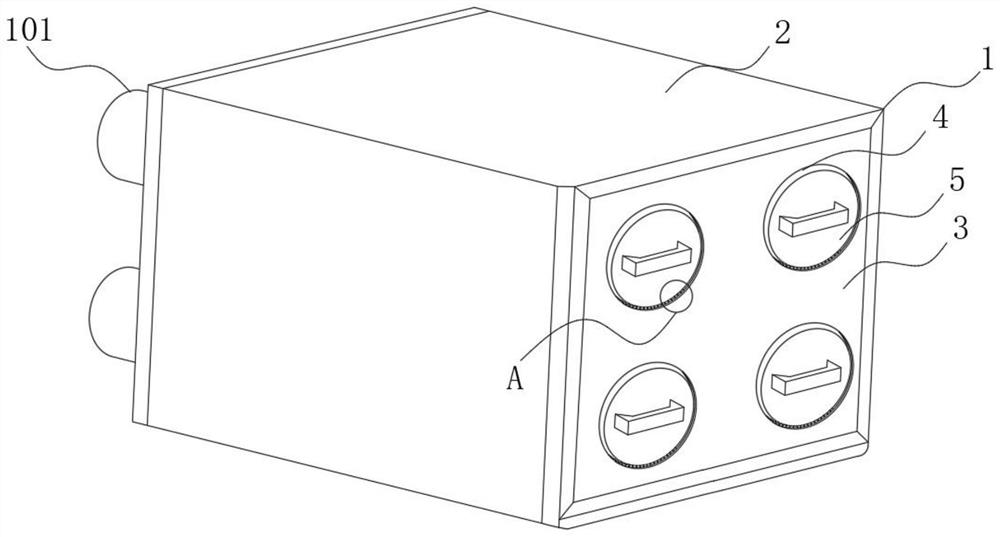

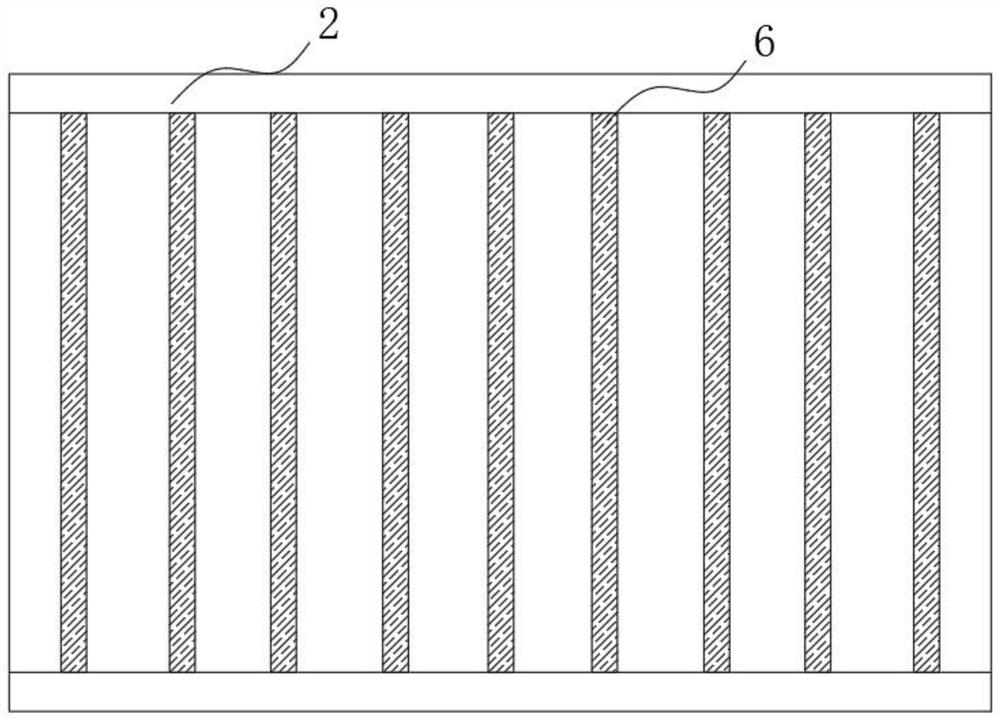

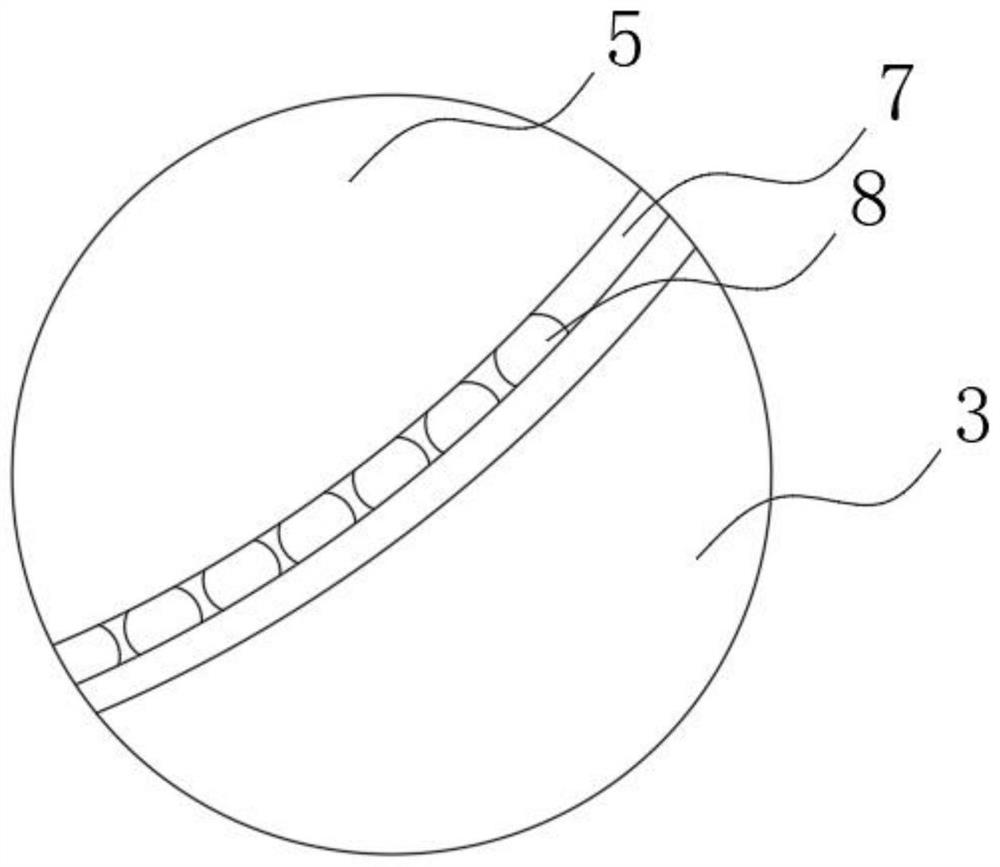

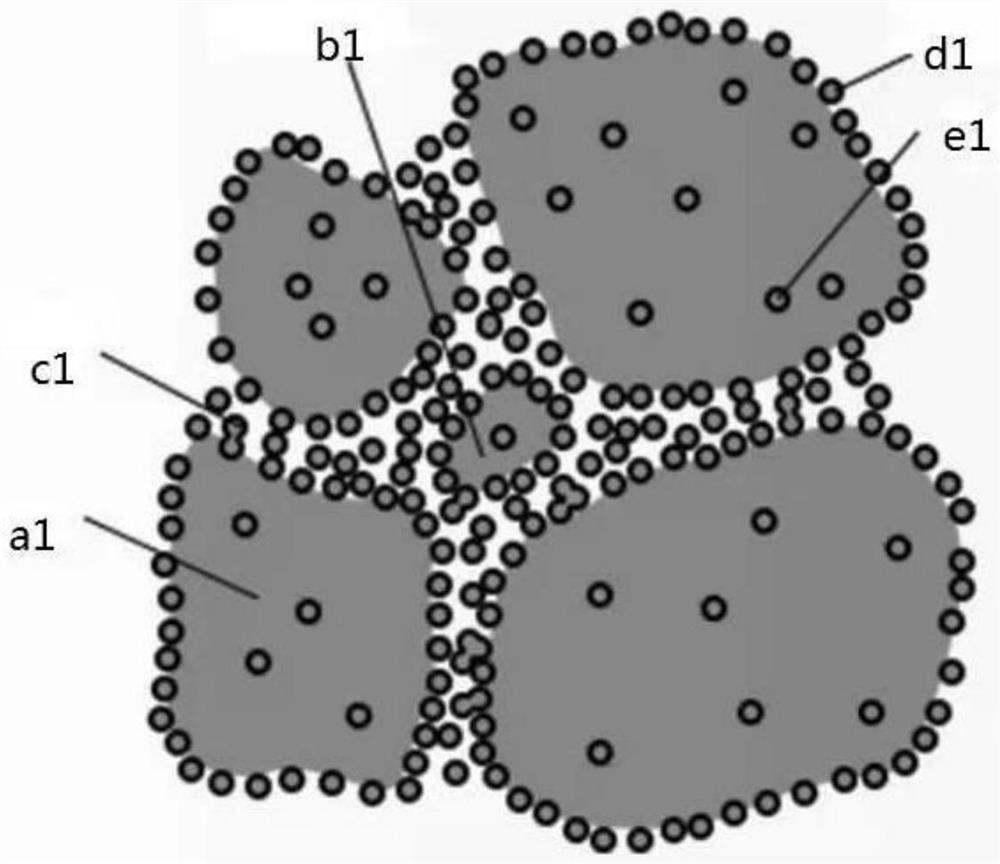

Environment-friendly art pigment for preschool children and preparation method thereof

InactiveCN112724766AImprove water resistanceGood alkali resistanceArtist's paintsPropanoic acidPlant Gums

The invention discloses an environment-friendly art pigment for preschool children and a preparation method thereof. The environment-friendly art pigment for preschool children is prepared from the following raw materials in parts by weight: 6-8 parts of vegetable gum, 7-9 parts of acrylic emulsion, 22-25 parts of pigment powder, 3-6 parts of calcium propionate, 5-8 parts of starch ether, 2-4 parts of glycerol, 20-24 parts of an adhesive, 1.5-2 parts of a bacteriostatic agent, 8-11 parts of chitosan modified talcum powder, 0.8-1 part of xylooligosaccharide and 15-20 parts of distilled water. The adopted raw materials are very environmentally friendly, the vegetable gum, the starch ether and the xylooligosaccharide are extracted from pure natural plants and do not contain harmful substances, by adopting the preparation method, all the components of the pigment can be mixed more uniformly and comprehensively, the color of the prepared pigment is purer, and the slurry drying device adopted in the preparation method disclosed by the invention can be used for simultaneously and respectively drying the flowing slurry in the four drying cylinders, so that the efficiency of preparing the pigment by the preparation method disclosed by the invention is greatly improved.

Owner:王艳妮

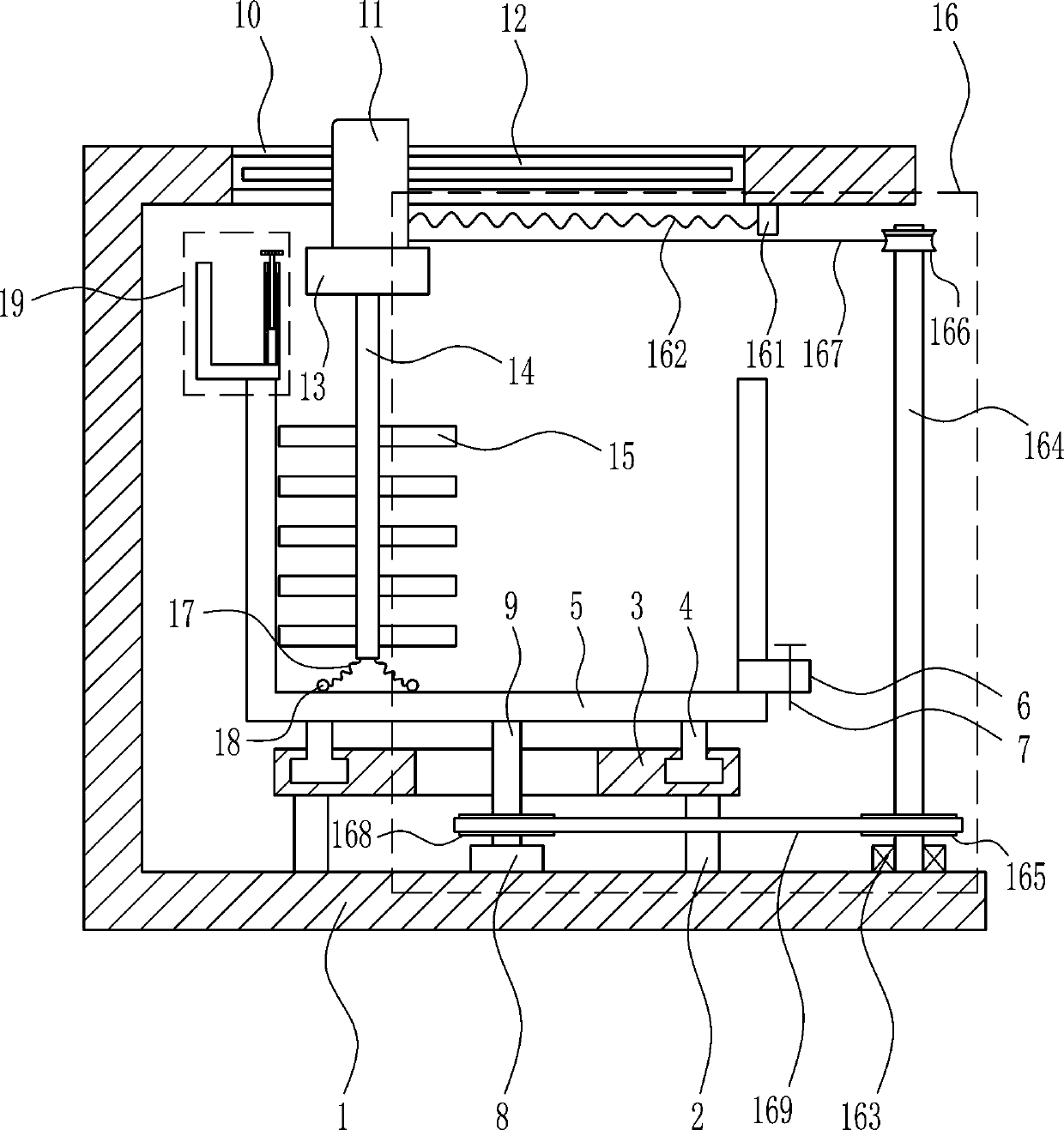

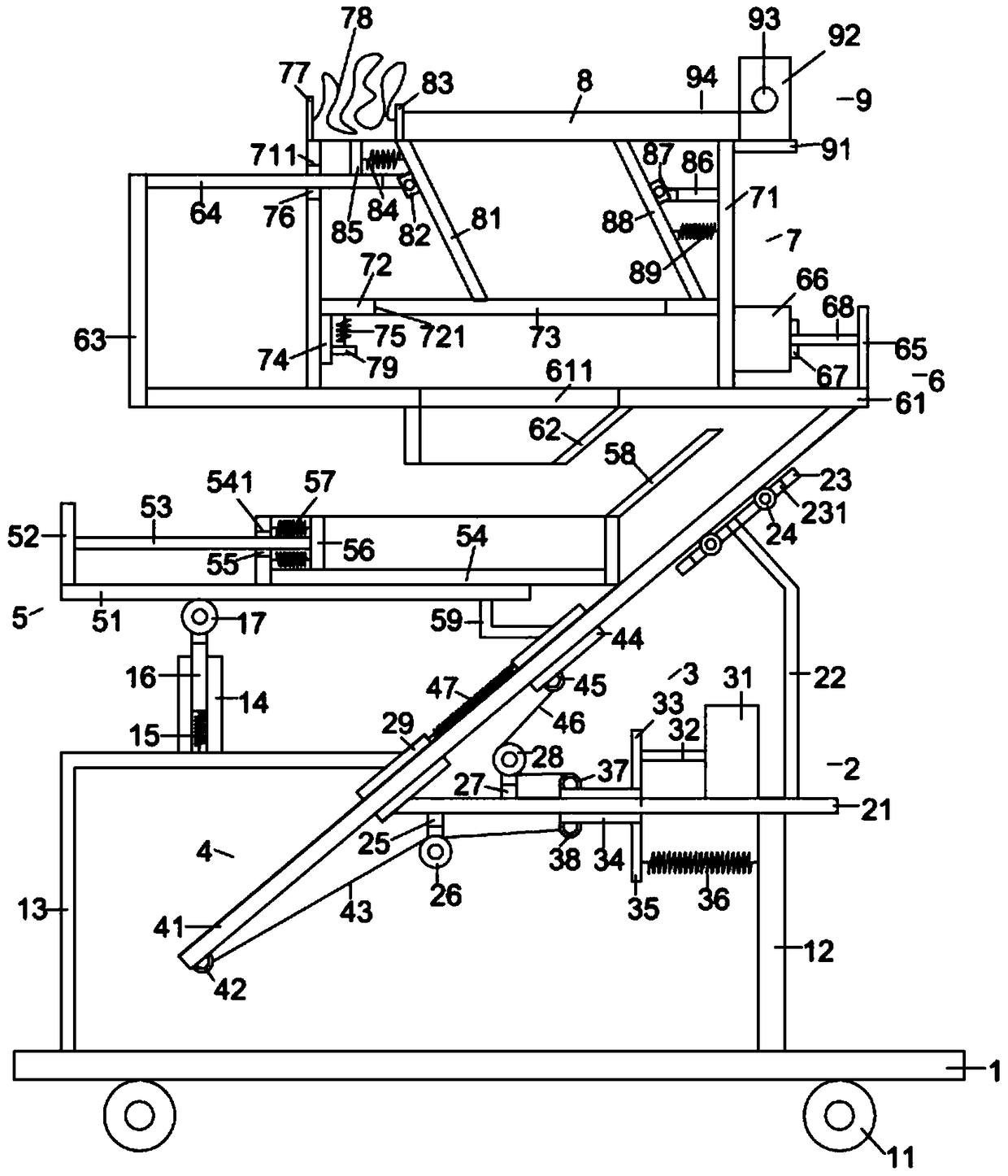

Novel biomass pellet production and processing equipment in field of new energy

InactiveCN109225005AEasy to mix and handleFully and effectively mixed treatmentShaking/oscillating/vibrating mixersTransportation and packagingNew energyEngineering

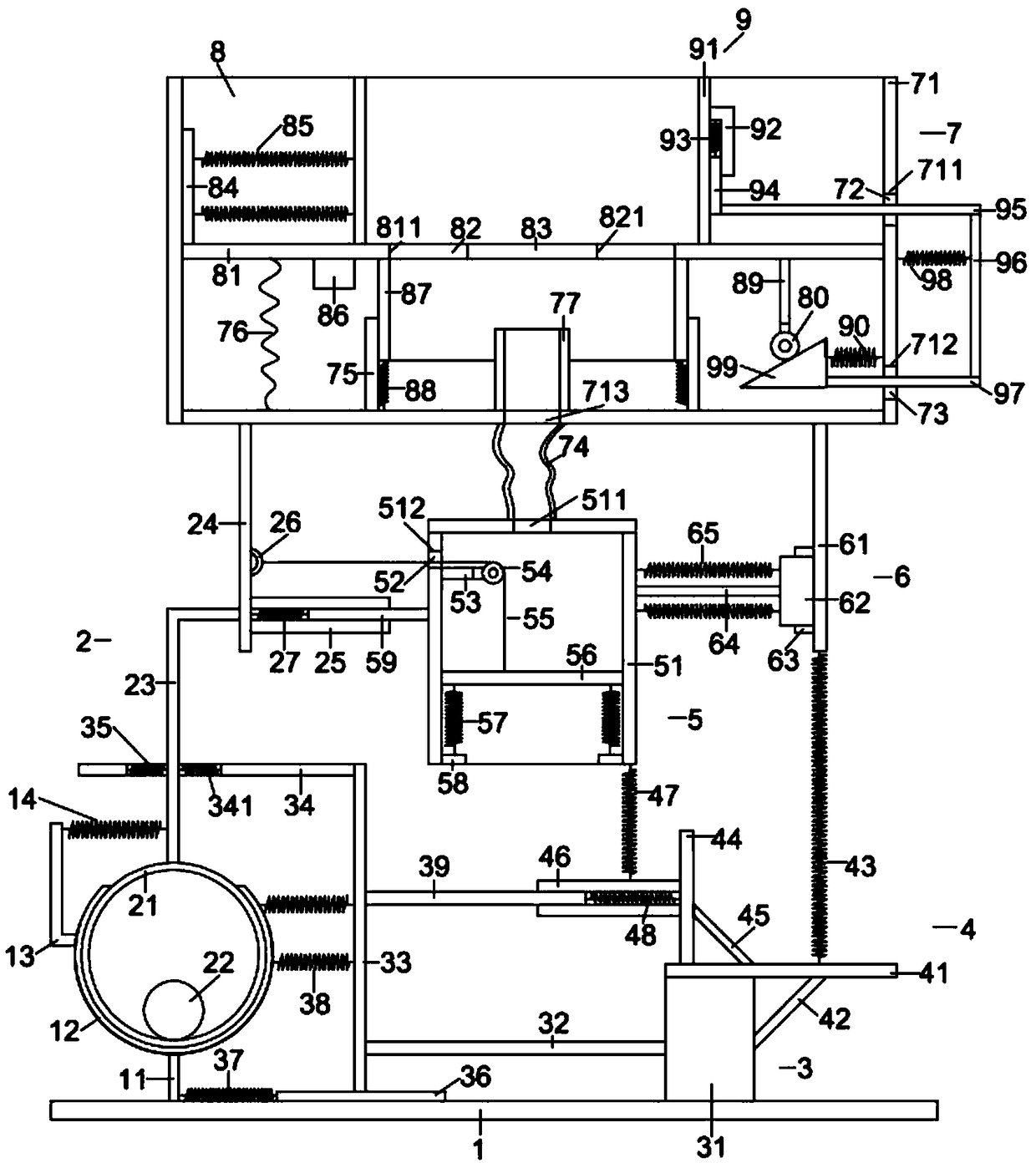

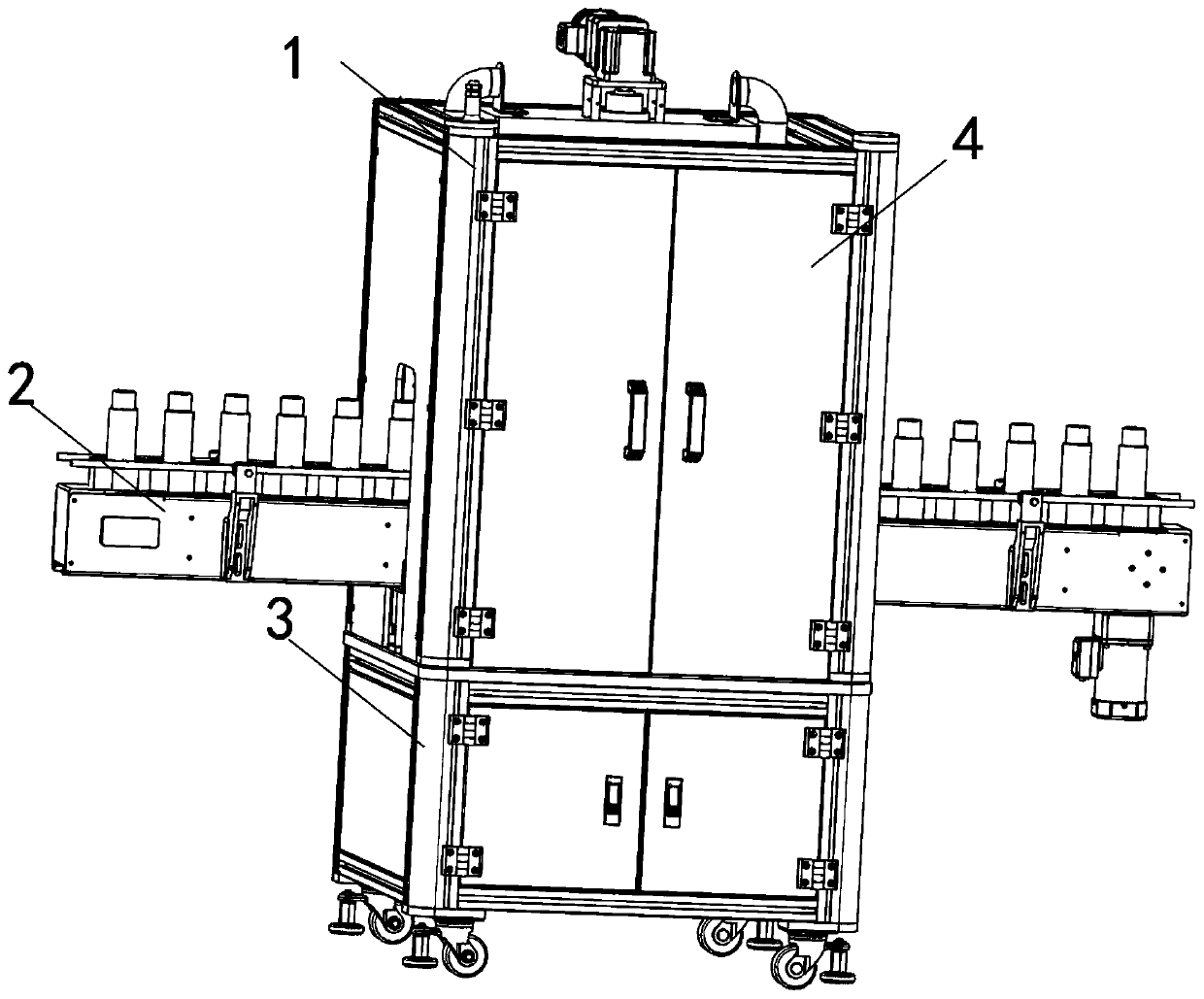

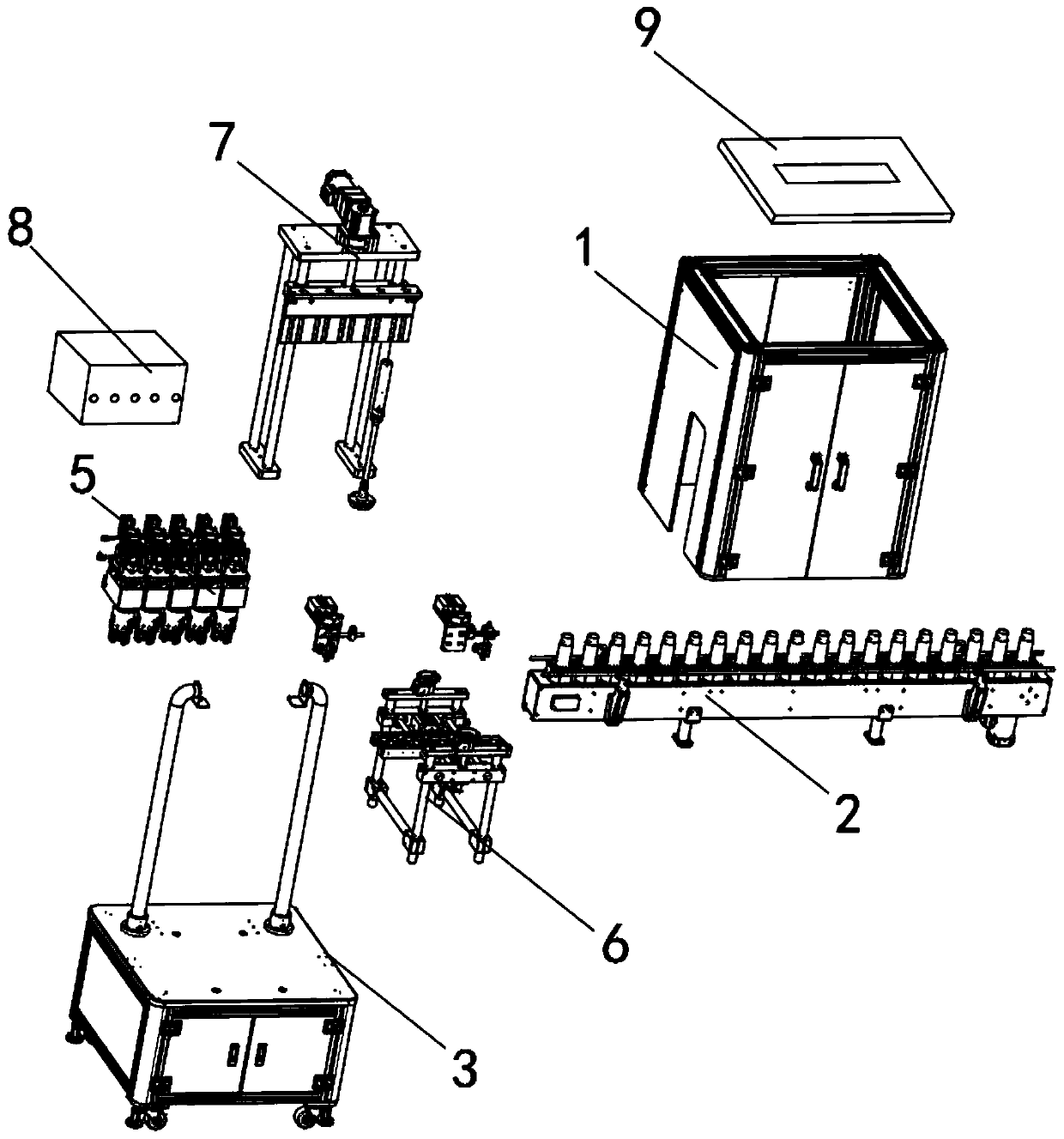

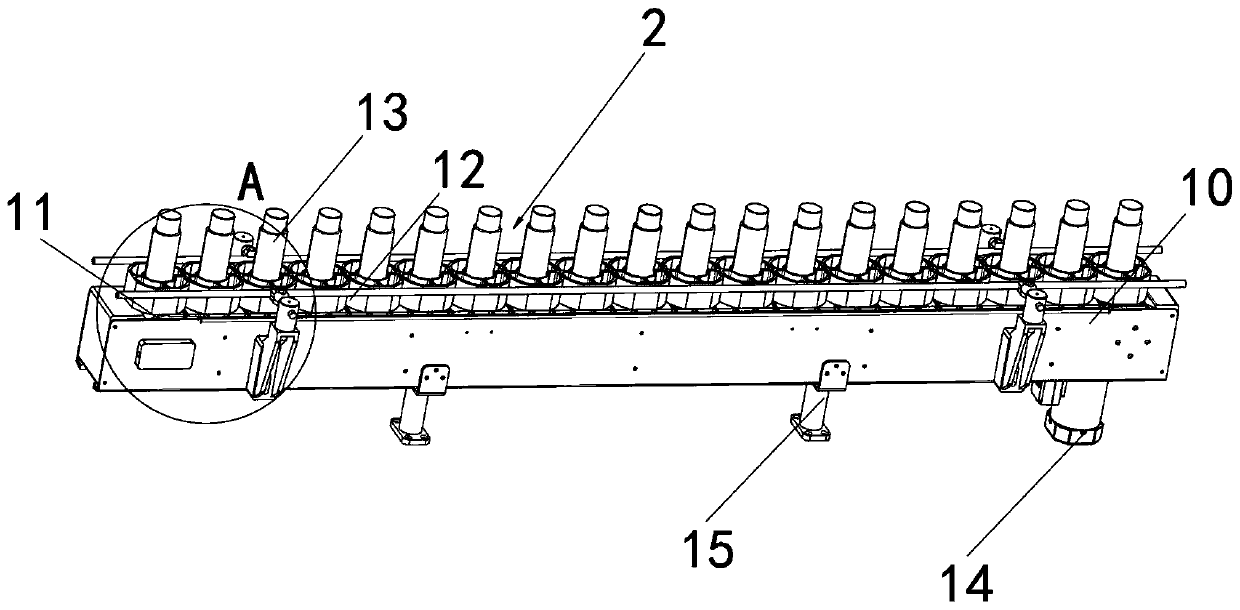

The invention relates to novel biomass pellet production and processing equipment in the field of new energy. The novel biomass pellet production and processing equipment comprises a bottom plate, a connecting device positioned above the bottom plate, a push device arranged on the bottom plate, a locating device arranged on the push device, a piston device arranged on the locating device, a driving device arranged at the right side of the piston device, a frame body device located above the piston device, a lifting device contained in the frame body device, and a mixing frame device arranged on the frame body device. The novel biomass pellet production and processing equipment can realize the sufficient and effective mixing treatment of biomass pellets, and is sufficient in mixing; furthermore, the biomass pellets can be driven to fully roll, so that the biomass pellets are comprehensively mixed, and the mixing efficiency of the biomass pellets is increased; a mixing frame is driven tomove left and right by means of the up and down movement of a lifting plate, and the air ejected upwards can be sprayed onto the biomass pellets through filter holes of a filter screen, so that the mixing of the biomass pellets is promoted.

Owner:SHENZHEN ANSIKE ELECTRONICS TECH CO LTD

High-precision quantitative yogurt filling equipment

PendingCN109956439APrevent fallingHigh degree of automationSafety device in filling machineryHydraulic pumpEngineering

The invention discloses high-precision quantitative yogurt filling equipment. The high-precision quantitative yogurt filling equipment comprises a filling box, a carrying platform and a supporting cabinet, wherein the filling box is of a hollow cuboid structure, the supporting cabinet is arranged below the filling box, and the carrying platform is horizontally arranged between the filling box andthe supporting cabinet in a penetrating mode. The high-precision quantitative yogurt filling equipment has the beneficial effects that before a filling nozzle on a filling assembly is used for fillinga yogurt bottle, a first hydraulic pump drives a hanging plate and the filling assembly to move up and down through a hydraulic rod, so that it is guaranteed that the position of the filling nozzle extending into the yogurt bottle is more accurate, efficiency is high, and the filling height of the filling nozzle is more suitable for yogurt bottles with different diameters and heights; the fillingamount is more accurate, and the two ends of a material box are connected to sliding columns I in a sleeving mode to drive the filling assembly to be adjusted up and down, so that the filling assembly is moved more stably and smoothly; when the filling assembly is adjusted up and down, two second hydraulic pumps on the two sides of the carrying platform drive a base and the conveying platform tobe adjusted up and down through third liquid pumps so as to ensure that the process that the filling nozzle extends into the yogurt bottle for filling is more efficient.

Owner:ANHUI XIQIANG DAIRY GROUP

An automatic multi-layer mixing equipment for dry powder mortar production

ActiveCN113478654BWell mixedMixed comprehensiveMixing operation control apparatusHollow article cleaningEngineeringMechanical engineering

The invention discloses an automatic multi-layer mixing equipment for dry powder mortar production, relates to the technical field of dry powder mortar mixing equipment, comprising a mixing tank, the inner wall of the mixing tank is fixedly connected with a transmission tube, and the inner wall of the mixing tank is rotatably connected There is a rotating plate 1, the inner wall of the rotating plate 1 is connected with the rotating plate 2, the inner wall of the rotating plate 2 is respectively connected with a rotating rod and two stirring rods, and the inner wall of the rotating plate 1 is connected with two stirring rods respectively. A brush plate, the lever arm of the rotating rod is provided with a conveying auger, and the lower part of the rotating plate one is provided with a transmission part that makes the two stirring rods rotate in opposite directions and simultaneously drives the conveying auger to operate synchronously, Through the mutual cooperation between the above-mentioned structures, the present invention has the effect of comprehensively mixing the mortar, avoiding the effect of the mortar sticking to the inner wall of the device during mixing, and solving the problem that raw materials with small specifications are easy to accumulate at the bottom of the device during mixing. The problem that mortar is easy to stick to the inner wall of the device.

Owner:南通晶德盈节能环保科技有限公司

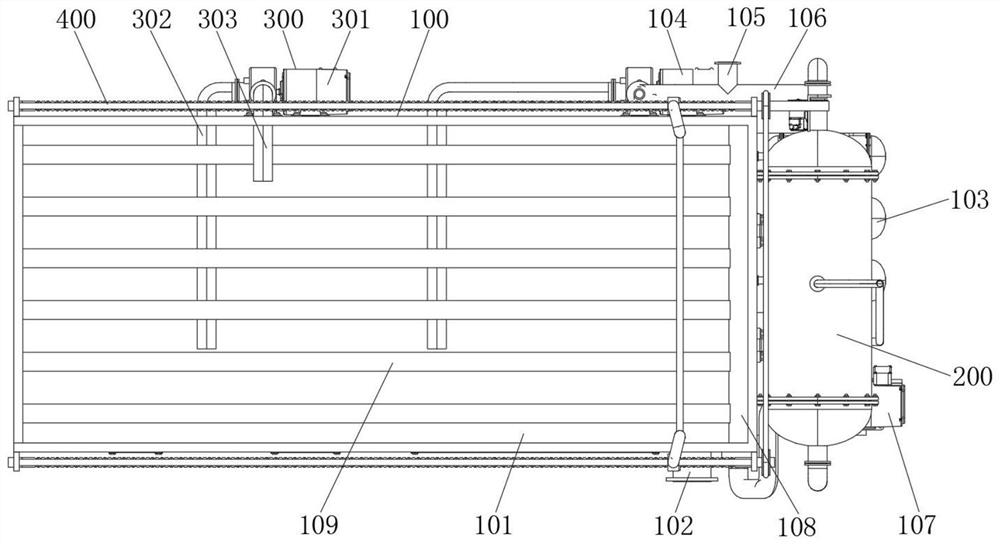

Diethyltoluenediamine solution filtering device

PendingCN114797277AWell mixedMixed comprehensiveAmino compound purification/separationSettling tanks feed/dischargeElectric machineryEngineering

The invention discloses a diethyl toluenediamine solution filtering device, and relates to the technical field of chemical equipment, the diethyl toluenediamine solution filtering device comprises a box body, a driving motor, a stirring shaft and a stirring rod, the upper surface of the box body is fixedly communicated with a liquid inlet pipe, and the driving motor is installed on the upper surface of the box body. The device is reasonable in design structure, each L-shaped rod can be driven to move up and down in a reciprocating mode through reciprocating operation of an electric push rod, then a filtering cylinder is driven to move up and down in a reciprocating mode through each connecting plate, and a solution and hydrochloric acid in the filtering cylinder are more fully mixed through stirring of a stirring rod; when the filtering cylinder reciprocates up and down, a solution in the box body and the filtering cylinder can be mixed with hydrochloric acid, and when the filtering cylinder descends, the bottom surface of the filtering cylinder is in contact with the inner bottom wall of the box body, so that the solution at the bottom in the box body flows into the filtering cylinder through a first water inlet hole; therefore, the solution in the box body can be comprehensively mixed.

Owner:河南雷佰瑞新材料科技有限公司

High-dehydration-rate sludge drying method

InactiveCN114349298AReduce moisture contentFast processingSludge treatment by de-watering/drying/thickeningScrew conveyorProcess engineering

The invention discloses a high-dehydration-rate sludge drying method which comprises the following steps: firstly, sludge is put into a concentration tank, preliminary dehydration is carried out on the sludge, the concentration tank is mainly used for reducing interstitial water of the sludge, and the concentrated sludge still keeps flowability; injecting the concentrated sludge into a conditioning tank through a feeding device; starting a stirring device, stirring the sludge in the conditioning pool, and injecting a conditioning agent, a guiding agent and a breaking aid into the conditioning pool at the same time; treating the sludge treated by the modified wall breaking unit by a filter press to remove water in the sludge; feeding the sludge treated by the filter press into a sludge crusher through a screw conveyor, and crushing and scattering the sludge; finally, the crushed sludge is forcibly air-dried.

Owner:中科德源(浙江)科技有限公司

Blast furnace fly ash treatment device and using method thereof

InactiveCN112705096AAchieve storageRealize automatic feeding processTransportation and packagingMixer accessoriesDusting powdersCoke

The invention relates to the technical field of blast furnace fly ash treatment, in particular to a blast furnace fly ash treatment device and a using method thereof. The blast furnace fly ash treatment device comprises feeding mechanisms, two storage mechanisms, a discharging mechanism and a grinding mechanism. The two oppositely-arranged feeding mechanisms achieve automatic feeding of coke powder and dusting powder at the same time, the storage mechanisms arranged on the surfaces of the two feeding mechanisms realize storage of the coke powder and dusting powder and facilitate feeding of the feeding mechanisms, and when the feeding mechanisms rotate, the storage mechanisms are shaken to facilitate feeding. The two feeding mechanisms extend into the discharging mechanism, mixing of coke powder and dusting powder is achieved, timed feeding is achieved when one ends of the feeding mechanisms rotate, and the operation is easy. The interiors of the feeding mechanisms are connected with the grinding mechanism for grinding coke powder and dusting powder, particles are ground when one end of the discharging mechanism rotates, and comprehensive mixing of the coke powder and the dusting powder is facilitated.

Owner:日照市德衡信息技术有限公司

An oil residue mixing device for oil refining

ActiveCN110280161BHigh nutritional valueWell mixedTransportation and packagingRotary stirring mixersNutritive valuesOil and grease

The invention discloses an oil residue mixing device for oil refining, which comprises a mounting bracket, an upper mixing box, an operating platform, a handrail and a ladder. An upper mixing box is arranged above one end of the mounting bracket, and A cover plate is provided, an operation platform is provided at one end of the installation bracket, and a handrail is provided on one side of the operation platform, and a step is provided under one end of the handrail. The staff puts the refined oil residue into the upper mixing box, and then the hydraulic pump drives the cover plate to move downward through the hydraulic rod, and the motor drives the mixing frame to rotate to mix and stir the oil residue, and while stirring, the upper mixing The two spray seats at both ends of the box simultaneously spray the nutritional ingredients on the oil residue in the upper mixing box to ensure that the oil residue and the nutritional ingredients are mixed more evenly and fully, and to ensure that the oil residue is mixed as feed and has a higher nutritional value. , the nutrient content is more uniform and rich; the device has good social benefits and is suitable for popularization and use.

Owner:鲁控环保(苏州)有限公司

Novel soil treatment equipment in field of resource processing

The invention discloses novel soil treatment equipment in the field of resource processing. The novel soil treatment equipment comprises a base plate, a bracket device located on the upper part of thebase plate, an electric cylinder device arranged on the bracket device, a moving device, a collecting device arranged on the moving device, a driving device located above the collecting device, a frame device arranged on the driving device, a grinding device arranged in the frame device, and a motor device. According to the novel soil treatment equipment in the field of resource processing, block-shaped soil can be sufficiently and effectively grinded into powder, the grinding effect is remarkable; the soil can be sufficiently grinded for many times until being grinded to the required particle size, and the strength between first and second grinding plates can be adjusted to ensure that the soil is effectively grinded into powder, the processing and treatment effects of the soil are ensured, and the quality of the soil after grinding is improved.

Owner:吉效晋

Simple processing method of wheat germ powder

InactiveCN108740782AMix thoroughlyWell mixedNatural extract food ingredientsFood ingredient functionsWheat germComputer science

The invention provides a simple processing method of wheat germ powder, and relates to the technical field of processing of wheat. The simple processing method is characterized by comprising the following operation steps of screening, soaking, airing, grinding, mixing and crushing. The method disclosed by the invention is reasonable and convenient to operate, and the wheat germ powder is rich in nutrients.

Owner:安徽雁飞粮油有限责任公司

Oil residue mixing device for oil refining

ActiveCN110280161AHigh nutritional valueWell mixedRotary stirring mixersTransportation and packagingOil and greaseSocial benefits

The invention discloses an oil residue mixing device for oil refining. The oil residue mixing device comprises a mounting bracket, an upper mixing tank, an operation table, an armrest and a ladder, wherein the upper mixing tank is arranged above one end of the mounting bracket, a cover plate is arranged above the upper mixing tank, the operation table is arranged at one end of the mounting bracket, the armrest is arranged on one side of the operation table, and the ladder is arranged below one end of the armrest. Oil residues after oil refining are put into the upper mixing tank by staff, then the cover plate is driven to move downward by a hydraulic pump through a hydraulic rod, a mixing and stirring frame is driven by a first motor to rotate for mixing and stirring the oil residues, and at the same time of stirring, nutrient ingredients are sprayed on the oil residues in the upper mixing tank by two spray booths at the two ends of the upper mixing tank simultaneously, thus it is ensured that the oil residue and the nutrient ingredients are more evenly and fully mixed, it is also ensured that when the oil residue is mixed and prepared into a feed, the nutritional value is higher, and the nutrient content is more uniform and richer; the oil residue mixing device has good social benefits and is suitable for popularization.

Owner:鲁控环保(苏州)有限公司

Preparation method of stomach-nourishing nutritional flour

InactiveCN110074320AImprove maintenance effectGood nourishing effectBioreactor/fermenter combinationsBiological substance pretreatmentsLactobacillusPendulum

The invention discloses a preparation method of stomach-nourishing nutritional flour. The preparation method specifically comprises the following steps: weighing the following raw materials in parts by mass: 430-460 parts of wheat, 90-110 parts of highland barley, 40-55 parts of tofu, 26-32 parts of chocolate powder, 82-88 parts of soybeans and 2-3 parts of lactic acid bacteria; washing the tofu,grinding, then mixing the ground tofu with the chocolate powder, the soybeans and the lactic acid bacteria, placing the mixture in a decoction pot of a mixing device, and then enabling a rolling belton a conveying and moving tray to drive the decoction pot to move and to place the decoction pot on a supporting frame. The preparation method has the beneficial effects that the flour prepared by themethod can also strengthen the spleen and stomach while a more nutritious effect is achieved in eating, and a very good nourishing effect on a human body is achieved; the various raw materials are scraped by a plurality of pendulum bars II arranged in a rotating bucket in an equal radian manner and driven by a motor VIII on a movable seat II, the various raw materials are ensured to be mixed andagitated more sufficiently, the quality of the fermentation of the various raw materials is improved, and the edible taste and nutrition of the prepared flour are improved; the stomach-nourishing effect of eating the flour is greatly improved.

Owner:安徽正宇面粉有限公司

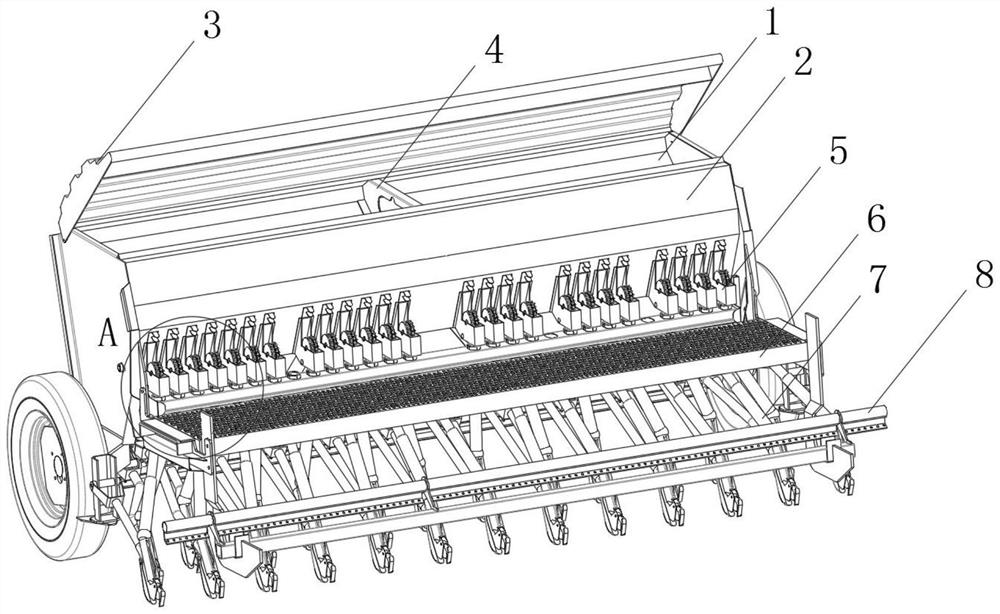

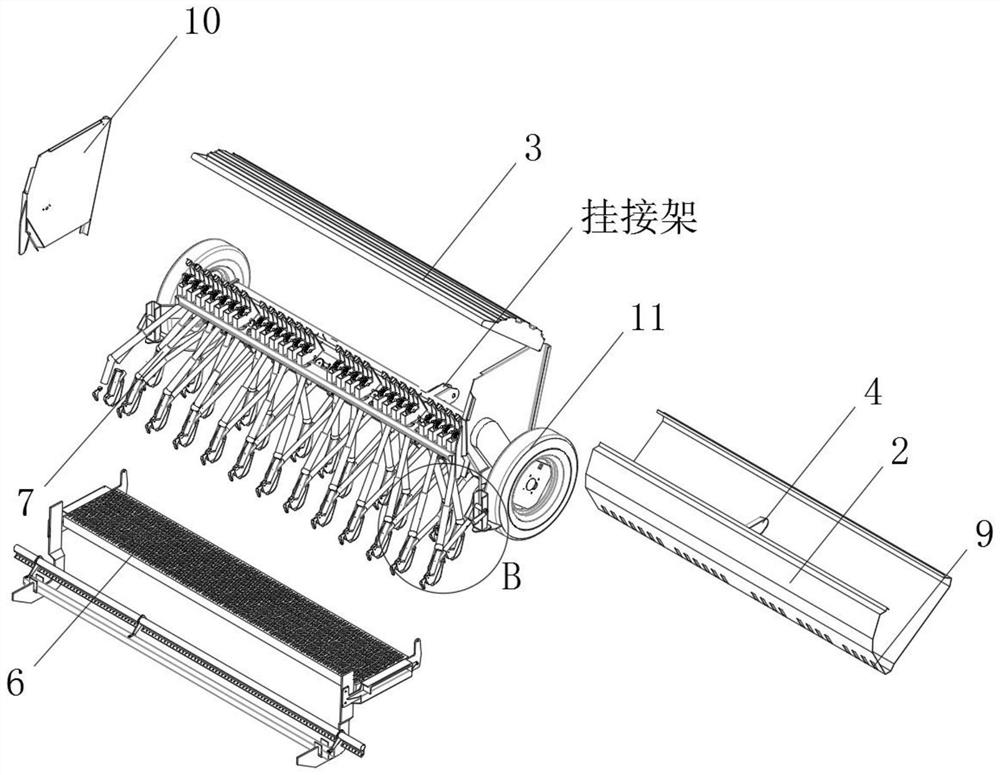

Equipment for mixing poultry and livestock manure when planting green glutinous rice and its working method

ActiveCN110024527BEfficient mixingWell mixedShaking/oscillating/vibrating mixersTransportation and packagingAgricultural scienceLivestock manure

The invention discloses a poultry and livestock manure mixed application equipment when green glutinous rice is planted and a working method thereof. One end of the fertilizer box is provided with a pinch plate, and the pinch plate is sleeved with a stirring seat, and a number of transfer hoppers are arranged under one end of the fertilizer box, and one end of each of the several transfer hoppers is provided with a spreading plate, And above several of the applicator discs are horizontally arranged with separate drop trays. The beneficial effects of the present invention are as follows: several fertilizing holes and several spreading discs are distributed at equal intervals, so as to ensure that the manure is spread out and spread in the field more comprehensively and widely, and when the manure is spread to the through frame, The rotating gear rotates continuously to continuously press the manure into the fertilizer guide pipe for discharge. On the one hand, the manure spread to the ground is smoother, and the flow rate of the spread manure is more constant. On the other hand, the equipment can be mixed to spread The work of manure is more automated, and the use of manure saves time and effort.

Owner:凤台县农业科学研究所

Fuel oil uniform mixing and burning system of double air ports diesel engine

InactiveCN101451463BWell mixedMix in timeInternal combustion piston enginesFuel injection apparatusCombustion chamberEngineering

The present invention relates to a fuel equipartition mixture and combustion device design proposal of two valve diesel. A fuel injector set on the cylinder cap and an inlet channel; a burning compartment is below the fuel injector and inlet channel; the inlet channel is eddy flow type inlet channel; a drop pit shape shrunk burning compartment in the shape of letter W is set above the valve; headsection of the fuel injector stretches out of the bottom of the cylinder cap and against the burning compartment. Parameter design of cylinder cap, fuel injector and burning compartment make fuel andair adequate distribution in certain rules on axial and circumferential direction within effective combustion space, and realize oil gas mixing design of equal excess air factor within effective combustion space. Under effect of high jet pressure and air-intake transverse currents of fuel injection system, oil gas inside the cylinder mixes uniformly, velocity of combustion quicker, duration short, oil spout can be postponed, and high-efficiency quick burning of low discharge can be realized. Engine synthetic performance can be optimized through the invention, and engine power can be improved while nocuousness discharged object can be reduced.

Owner:JIANGSU UNIV

Simple universal type humus making machine

PendingCN111978111AImprove processing effectFull flipBio-organic fraction processingOrganic fertiliser apparatusTemperature controlEngineering

The invention discloses a simple universal type humus making machine. The humus making machine comprises a processing barrel body, and a driving mechanism is arranged on the processing barrel body; asealing mechanism for sealing the processing barrel body is arranged on the processing barrel body; a vertical rotating mechanism which rotates around a vertical shaft and a transverse rotating mechanism which rotates around a transverse shaft are arranged in the processing barrel body; a linkage mechanism for driving the transverse rotating mechanism to rotate when the vertical rotating mechanismrotates is arranged between the vertical rotating mechanism and the transverse rotating mechanism; the vertical rotating mechanism is in connection transmission with the vertical rotating mechanism through the linkage mechanism; and a crushing mechanism is arranged on the transverse rotating mechanism, and a temperature sensor and a temperature controller are arranged in the processing barrel body. According to the present invention, the simple universal type humus making machine is domestic humus production equipment suitable for domestic humus production, further has functions of automaticcrushing, automatic mixing, automatic aerobic composting, automatic turning and automatic decomposition, and further has characteristics of comprehensive turning, reasonable mixing and quality assurance.

Owner:广东中苗景观有限公司

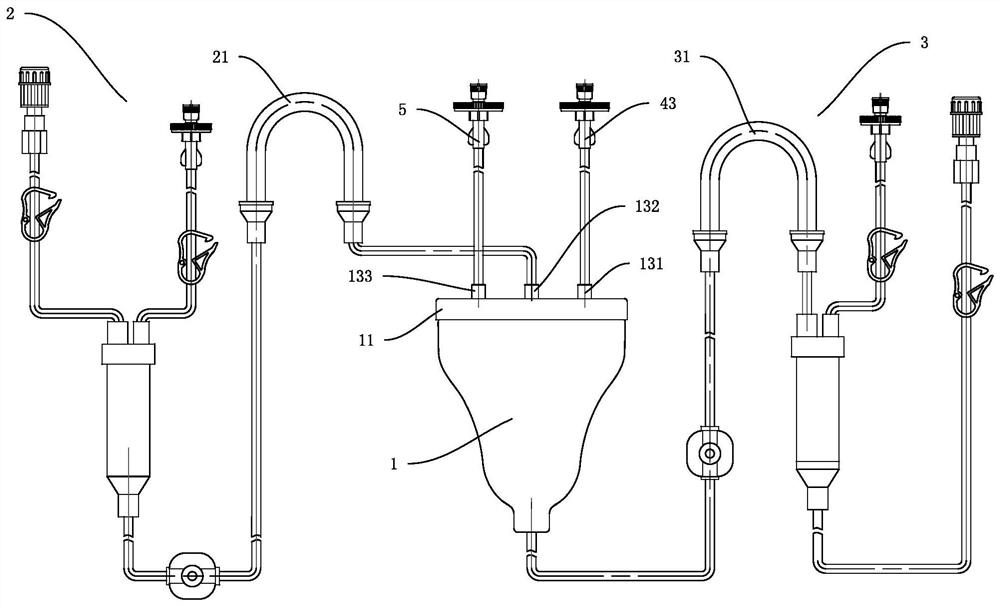

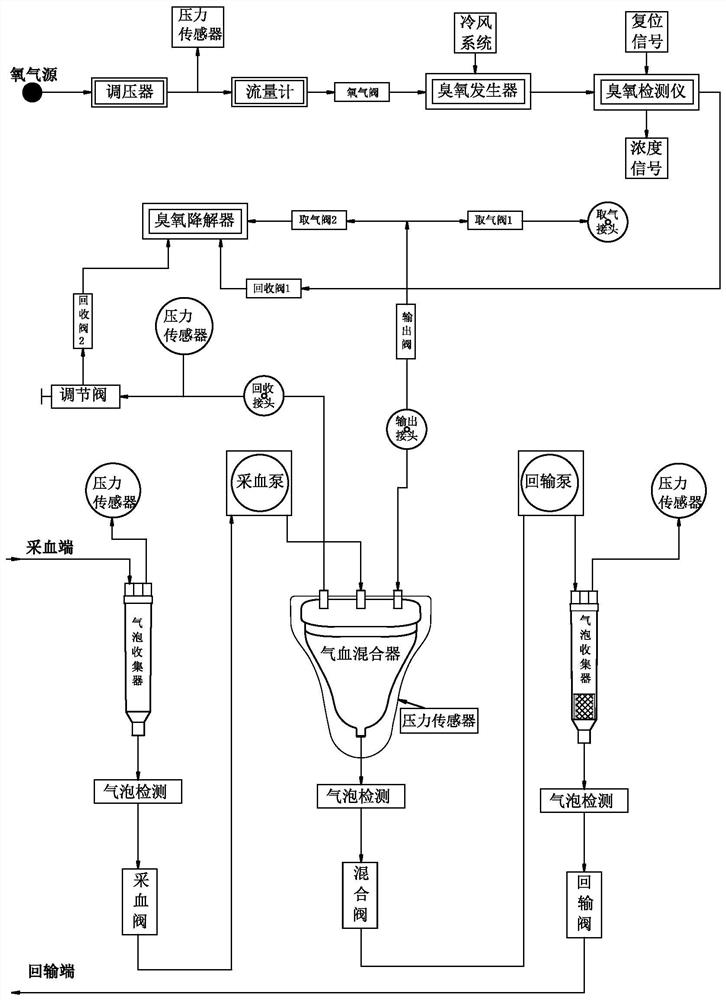

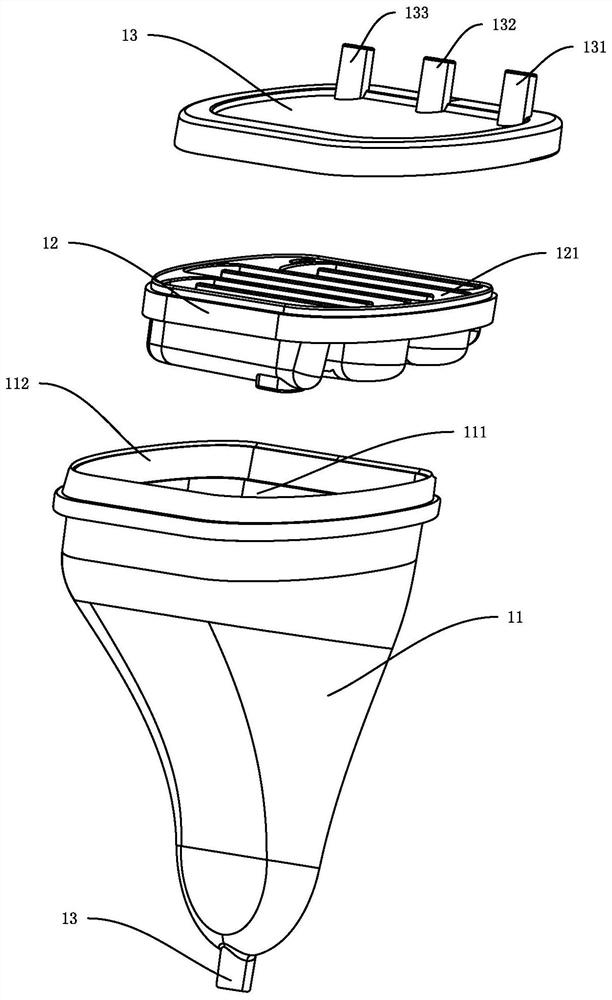

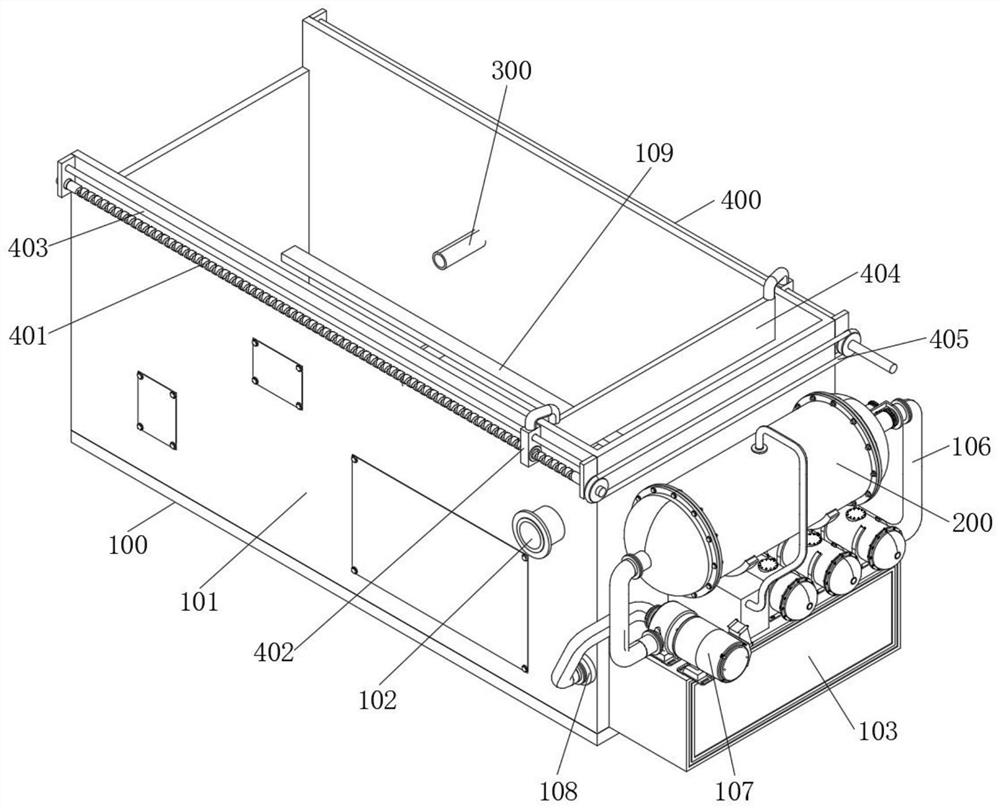

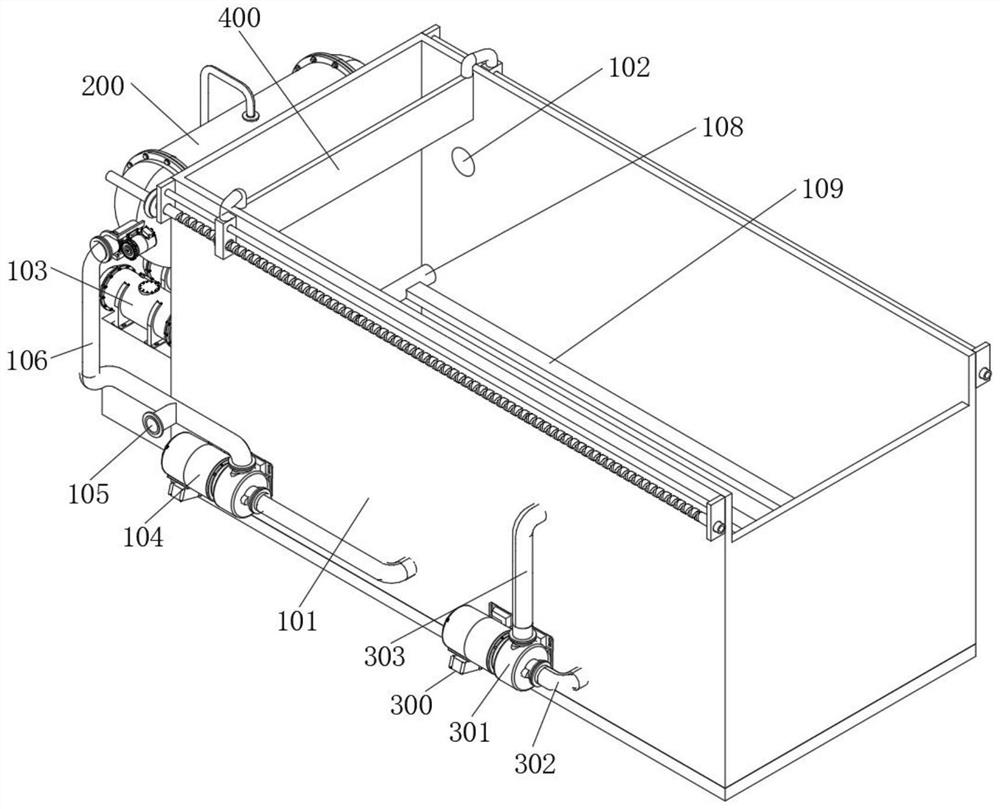

Ozone treatment device

ActiveCN112755292AAvoid cross infectionMixed comprehensiveOther blood circulation devicesMedical devicesEnvironmental engineeringBlood sampling

The invention discloses an ozone treatment device. The ozone treatment device comprises a gas-blood mixing mechanism and an ozone generating device, wherein the gas-blood mixing mechanism comprises a gas-blood mixer, a blood sampling pipeline and a feedback pipeline; the gas-blood mixer comprises a shell, a mixing body and a cover body; a circuitous mixing groove is formed in the mixing body; the bottom of the mixing groove is inclined downwards from a starting point to a terminal point; an outlet of the mixing groove is fitted with an inner wall of the shell; the blood sampling pipeline is provided with a blood sampling pump; the blood sampling pump is connected onto the gas-blood mixer; the feedback pipeline is provided with a feedback pump; the feedback pipeline is connected onto the gas-blood mixer; the ozone generating device comprises an ozone generator, an oxygen source and an ozone pipeline; the oxygen source is connected with the ozone generator; the ozone generator is connected with the ozone pipeline; and the ozone pipeline is further connected with the gas-blood mixer. The ozone treatment device has the advantages that cross infection is avoided, no foam is generated and ozone gas and blood are mixed more preferably.

Owner:宁波天益医疗器械股份有限公司

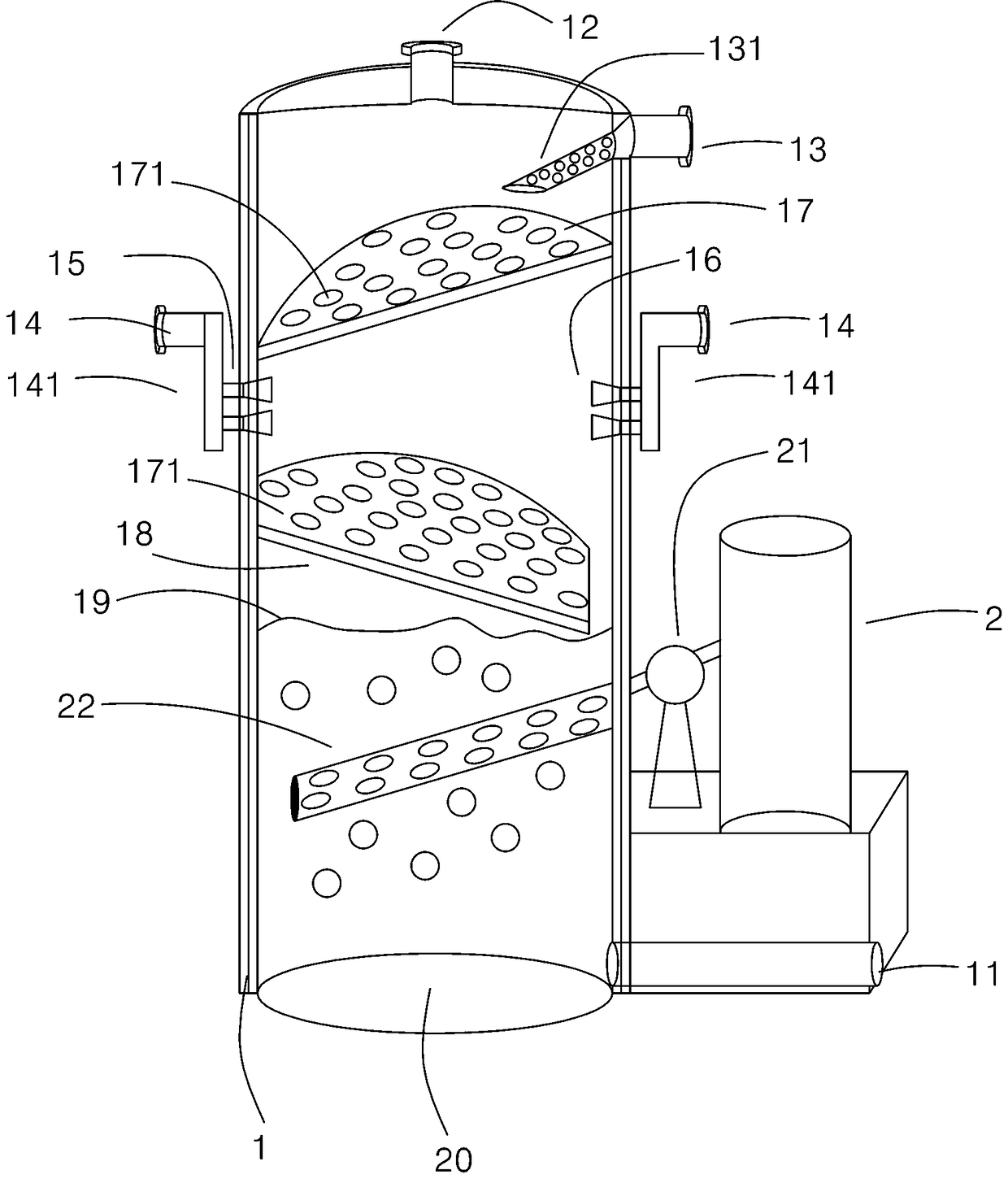

Floating-gas-method sewage treatment and separation device with separation and isolation structure

PendingCN114314871AReduce processing costsAvoid direct contactFatty/oily/floating substances removal devicesMultistage water/sewage treatmentSewageSewage treatment

The invention relates to the technical field of sewage treatment, in particular to a floating gas method sewage treatment and separation device with a separation and isolation structure, which comprises a sewage treatment mechanism, the sewage treatment mechanism comprises a sewage pool, a water inlet pipe is fixedly communicated with the upper part of the front surface of the sewage pool, and a tiny gas supply machine is fixedly mounted on the right side of the sewage pool. A first water pump is fixedly installed on the back face of the sewage pool, the input end of the first water pump communicates with the interior of the sewage pool through a pipeline, and a discharge pipe is fixedly installed at the output end of the first water pump. The water-gas saturation mechanism is independently arranged on the outer side of the sewage pool, so that tiny gas is pumped into the sewage pool through a second water pump by taking clean filtered water as a medium, mixing with sewage in the sewage pool is realized, the sewage in the sewage pool is effectively prevented from being in direct contact with air holes in a ring pipe, and the water-gas saturation efficiency is improved. Suspended matters are conveniently prevented from blocking the air holes, and the sewage treatment cost of the device is effectively reduced.

Owner:李方东

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com