Patents

Literature

141results about How to "Easy to mix and handle" patented technology

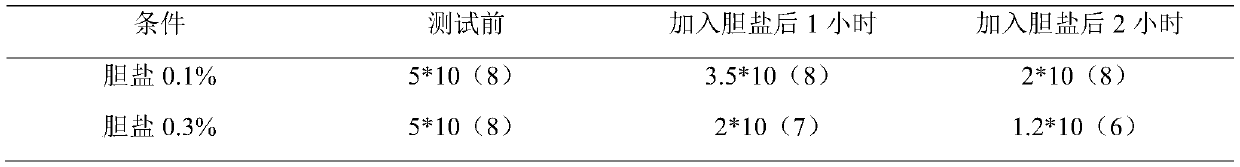

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Unsaturated carboxylic acid metal salt modified ethylene-propylene-diene monomer (EPDM) and preparation method thereof

ActiveCN103131088ANo pollution in the processSimple preparation processSuperoxideEthylene-propylene-diene-monomer

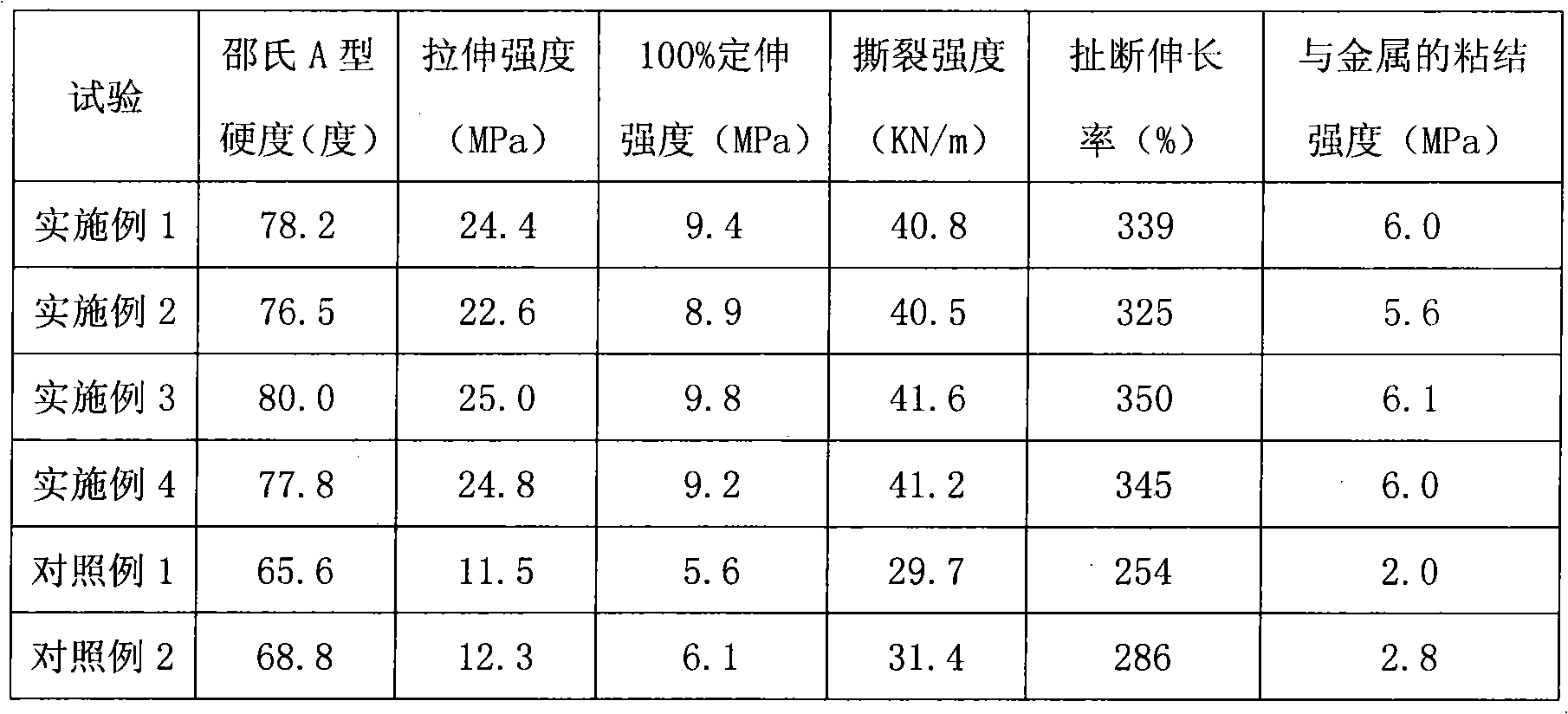

The invention discloses unsaturated carboxylic acid metal salt modified ethylene-propylene-diene monomer (EPDM) and a preparation method thereof. Carbon black, metallic compound, stearic acid, accelerant, inert filler, sulphur, superoxide and unsaturated carboxylic acid are added in the EPDM, then mixing treatment and sulfidizing are conducted, and therefore the unsaturated carboxylic acid metal salt modified EPDM is obtained. According to the unsaturated carboxylic acid metal salt modified EPDM and the preparation method thereof, unsaturated carboxylic acid metal salt in in-situ reaction is used for modifying the EPDM, preparation process is simple, modification effect is good, the prepared modified rubber has good physical mechanical performance and especially has good bonding strength with metal, and the application range is wide.

Owner:TIANJIN XINZHONGHE RUBBER IND

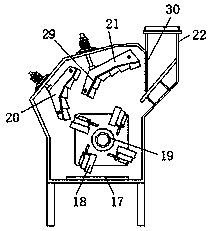

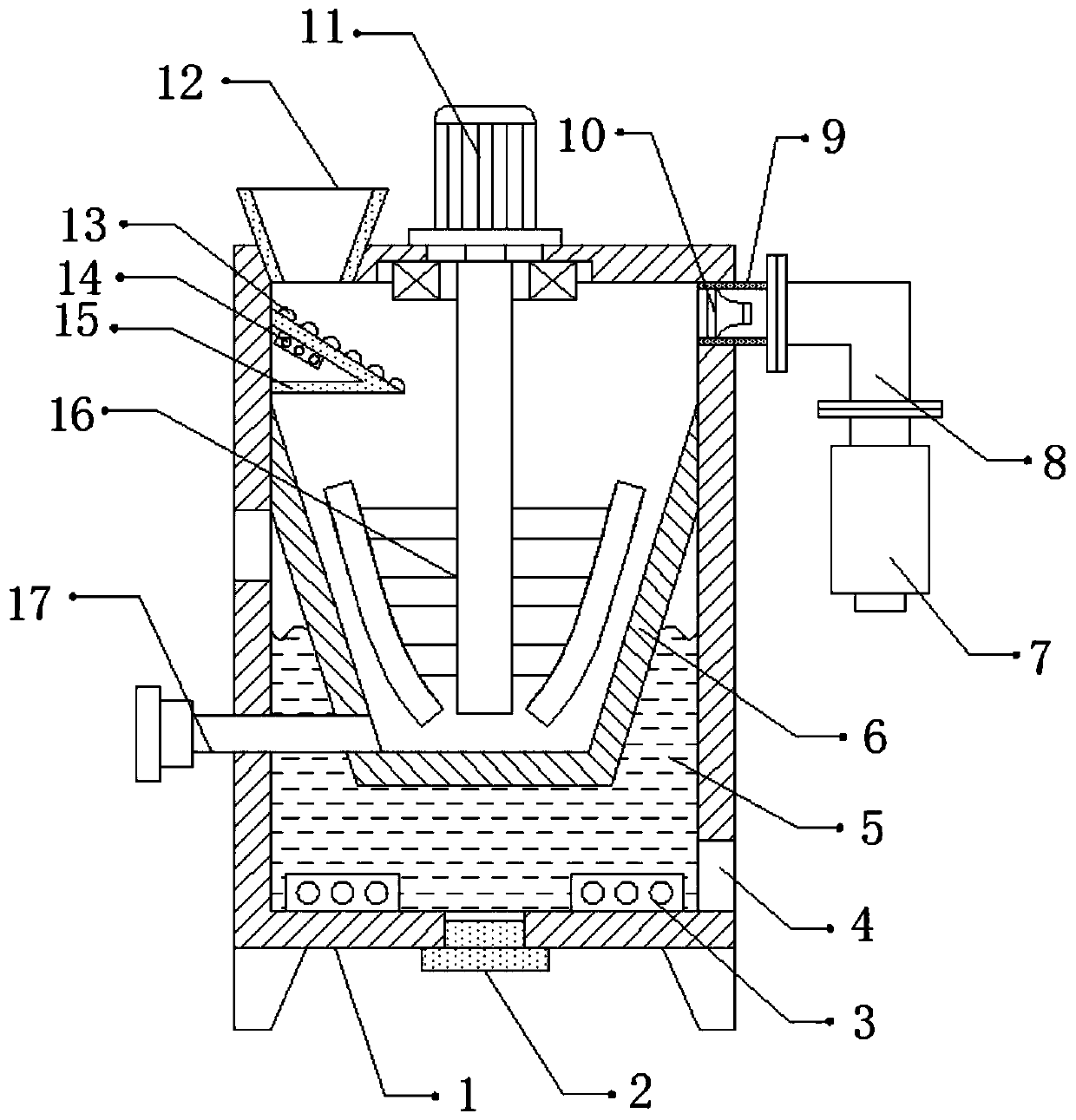

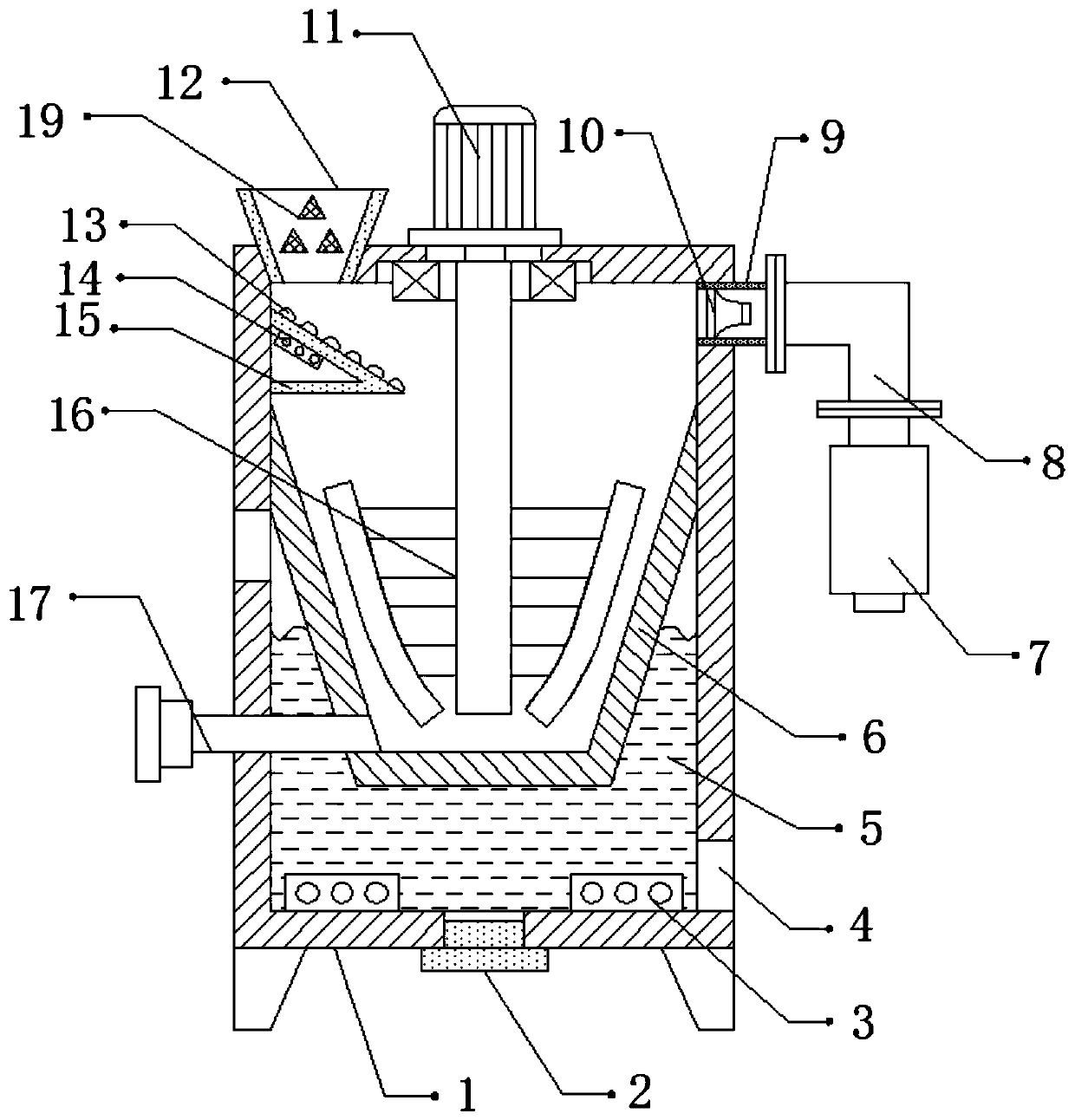

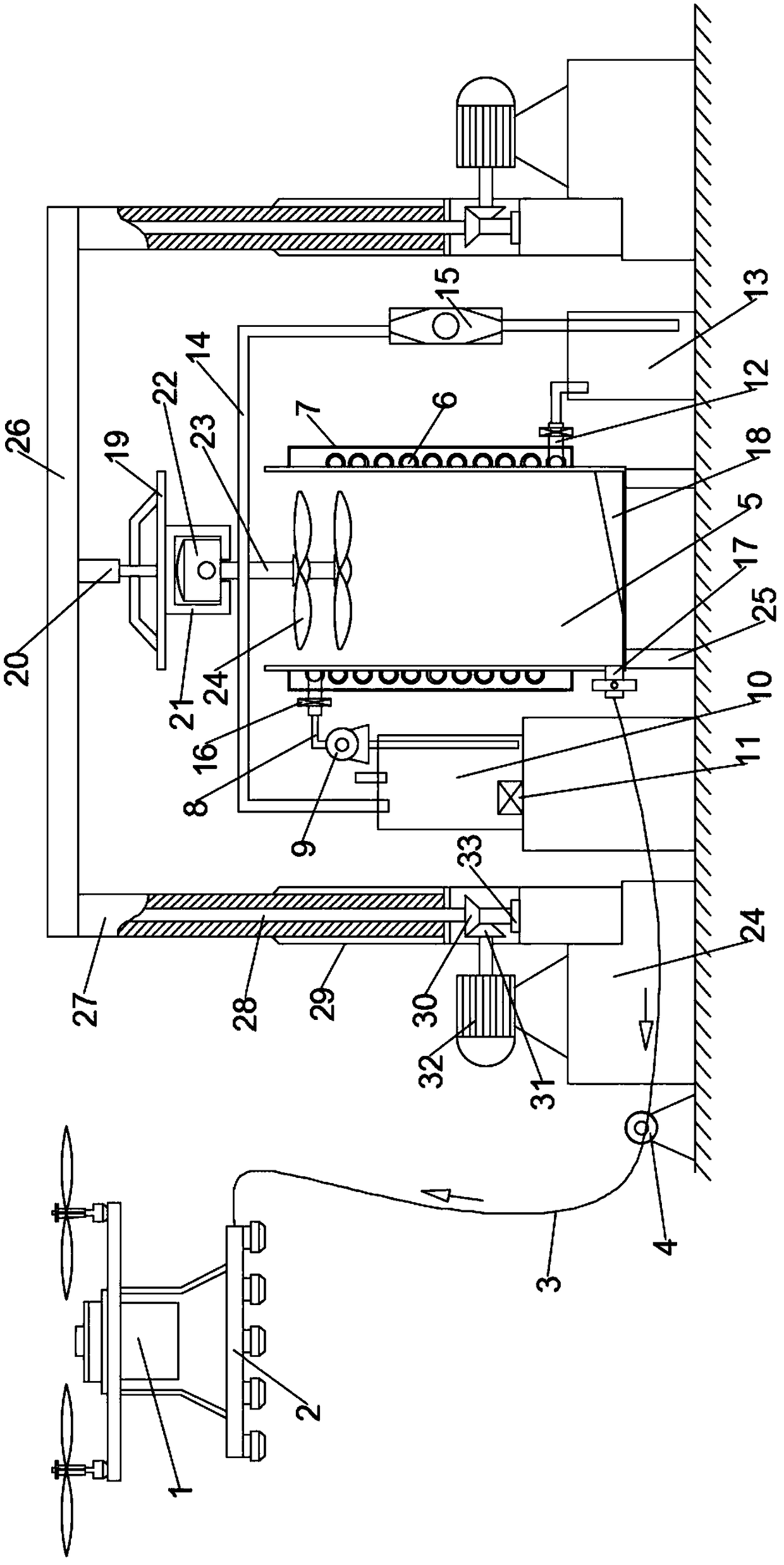

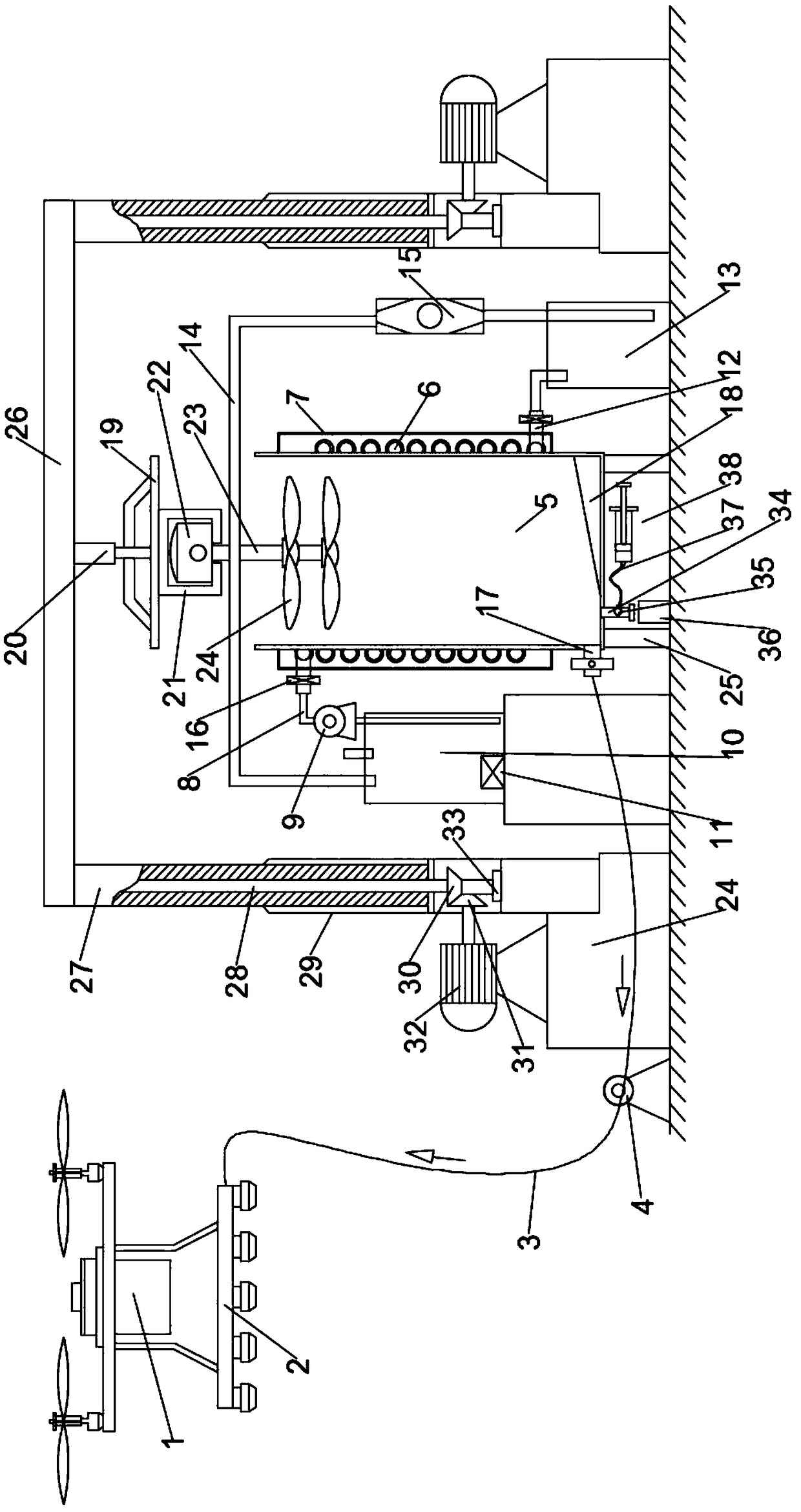

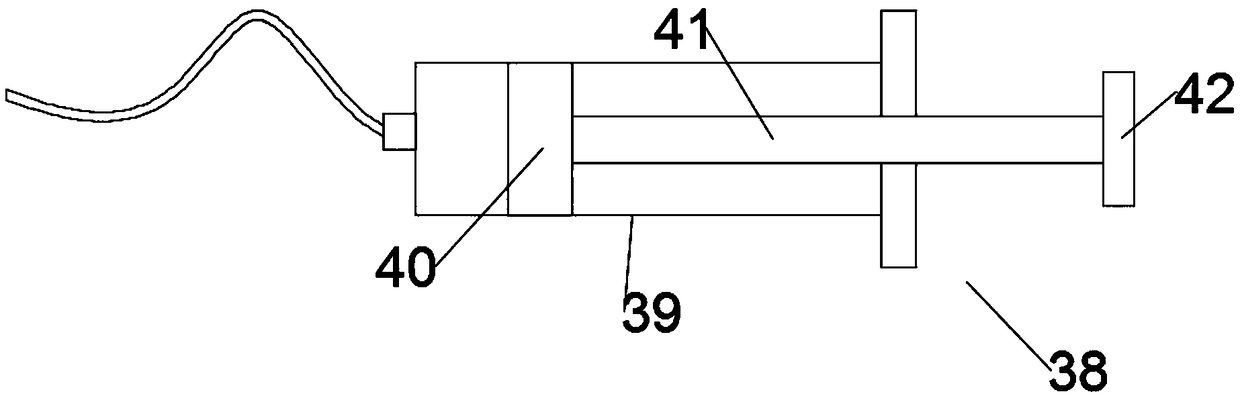

Continuous feeding type chemical industrial liquid and material mixing processor

InactiveCN107336354AEnhanced material activityImprove mixing effectCement mixing apparatusCleaning using liquidsChemical industryEngineering

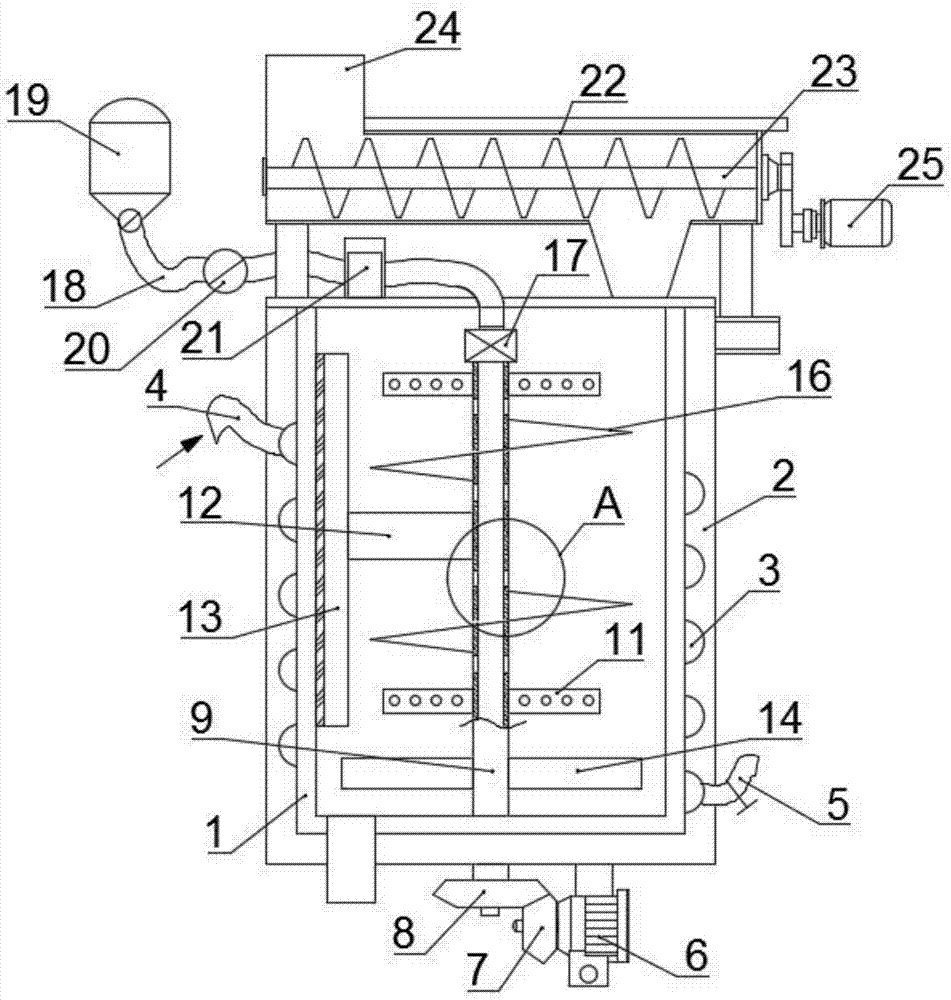

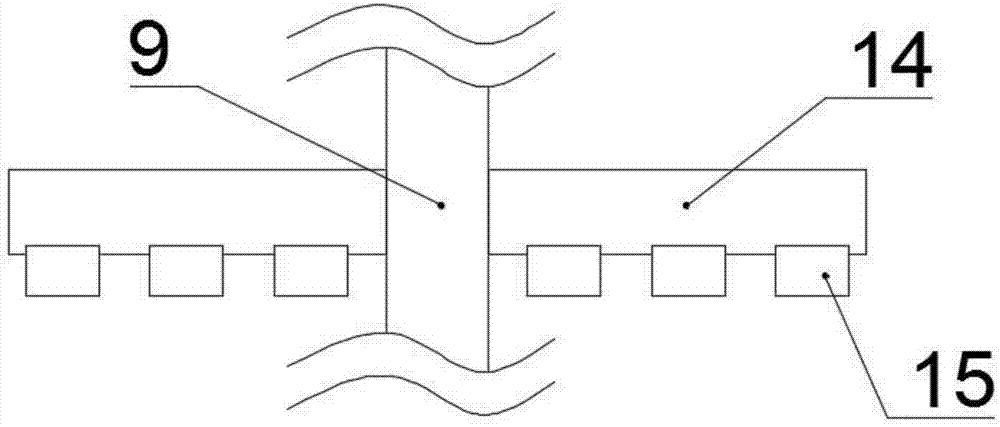

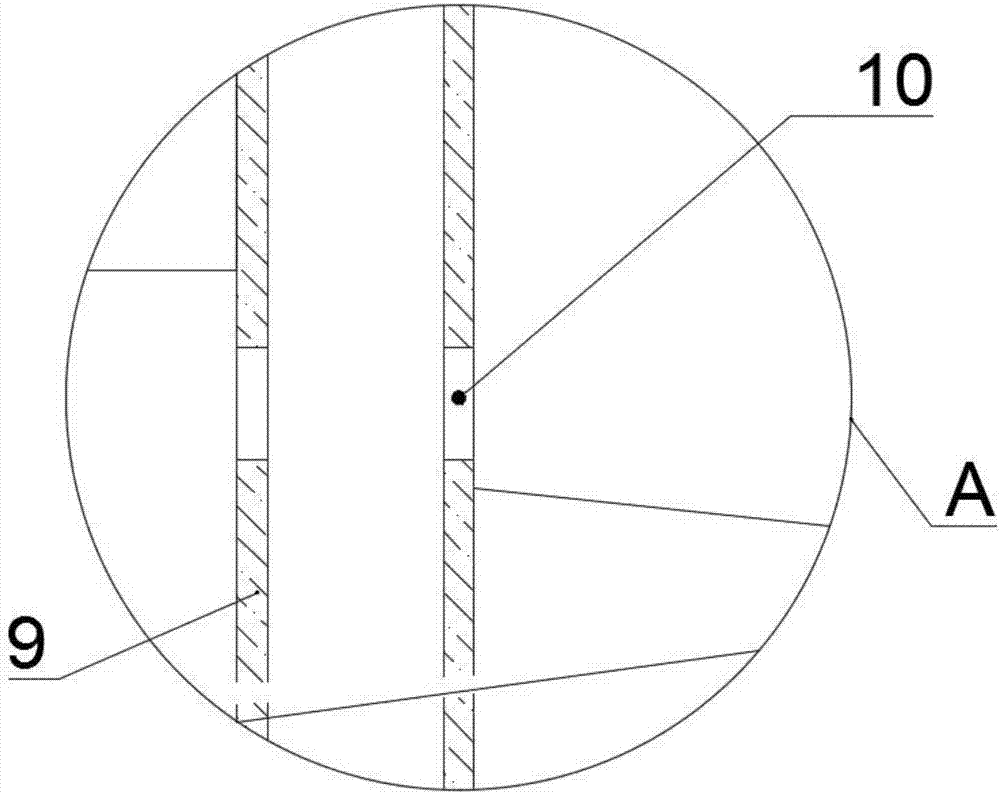

The invention discloses a continuous feeding type chemical industry liquid material mixing processor, which comprises a mixing shell, a heating coil arranged in a spiral shape is arranged on the outer wall of the mixing shell, and the inside of the shaft body of the mixing and stirring shaft is A hollow structure is provided and several small spraying holes are opened on the outer wall of the shaft body, a flow control switch and a small water pump are installed on the body of the water delivery pipeline, and plate-type Stirring blades and spiral stirring blades, a strip scraper is installed at the end of the horizontal support rod, a premix conveyor is fixed above the mixing shell, and a universal roller is installed at the lower end of the hydraulic telescopic rod through a connecting sleeve . The invention can achieve rapid temperature rise, realize automatic cleaning of the inner cavity after work, fully stir, improve the mixing effect of subsequent materials, facilitate moving and positioning, and save time and effort.

Owner:孙洁

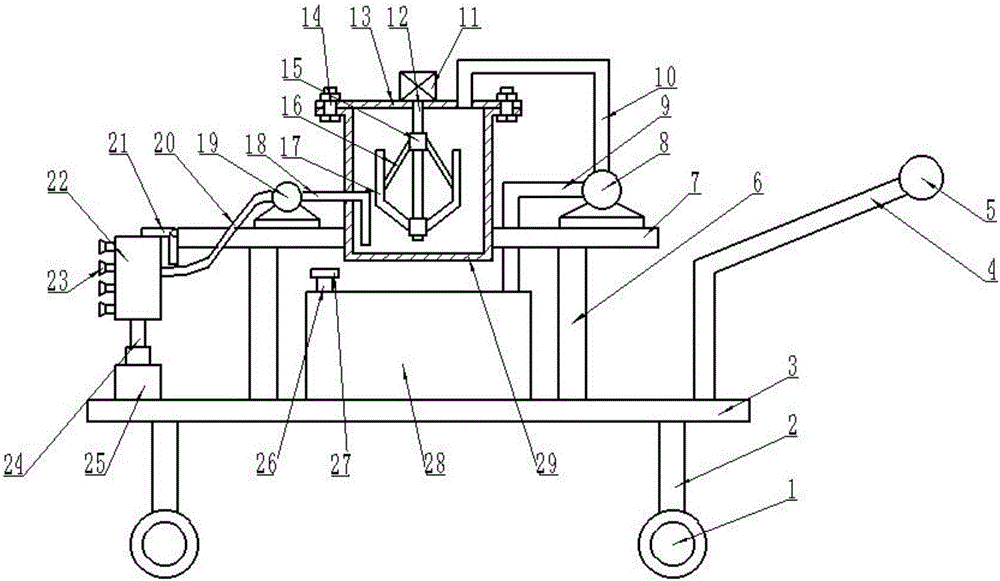

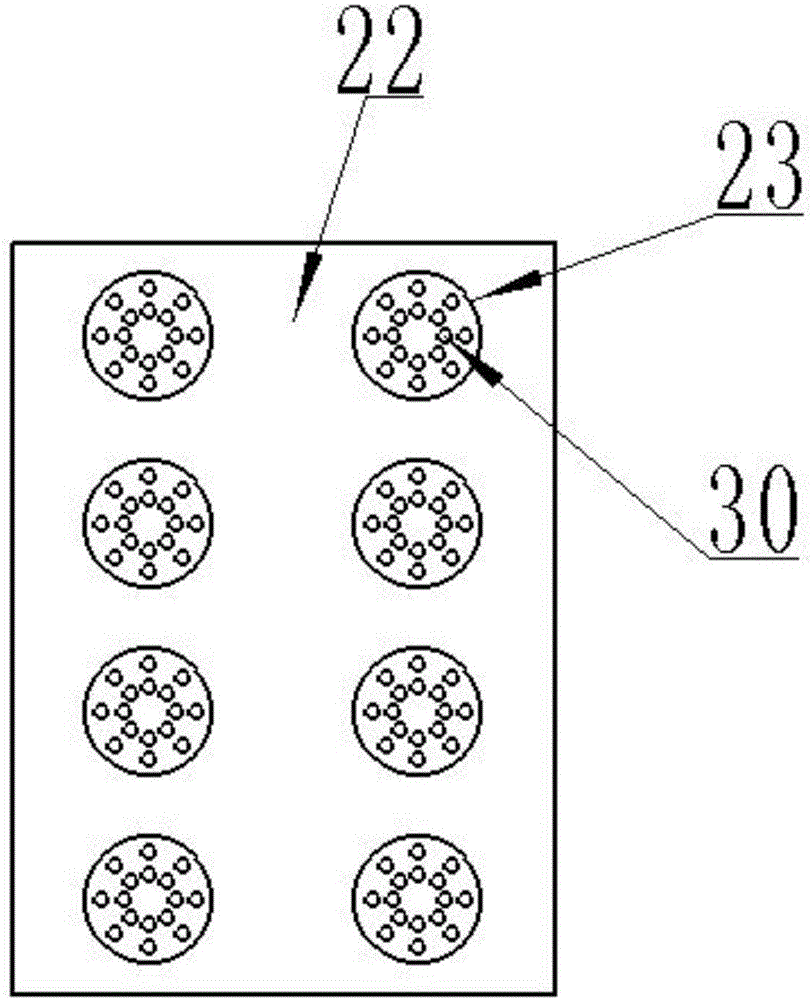

Spraying device for building finishing surface

InactiveCN106677496AStir wellEasy to sprayTransportation and packagingRotary stirring mixersAgricultural engineeringLiquid storage tank

The invention provides a spraying device for building finishing surface comprising a movable liquid feeding stirring device and a liquid pumping spraying device. The movable liquid feeding stirring device comprises vehicle wheels, a liquid pumping liquid feeding pump, a liquid storage tank and a stirring tank. The vehicle wheels are fixedly arranged on vehicle wheel supporting frames; the stirring tank is welded on the left side face and the right side face of two carrying plates; the liquid storage tank is fixedly arranged between two supporting plates; and the liquid pumping liquid feeding pump is fixedly arranged on the right side carrying plate. The liquid pumping spraying device comprises a pressurizing type liquid pumping pump, a spraying tank and spraying heads. The spraying tank is fixedly arranged on the side face of the left side carrying plate through a hinge; the multiple spraying heads are fixedly arranged on the left side face of the spraying tank; and the pressurizing type liquid pumping pump is fixedly arranged on the left side carrying plate. According to the building finishing surface spraying device, coating can be uniformly stirred and treated, spraying treatment can be better conducted on the building finishing surface, and the performance of the building finishing surface is improved.

Owner:河南常青藤信息科技有限公司

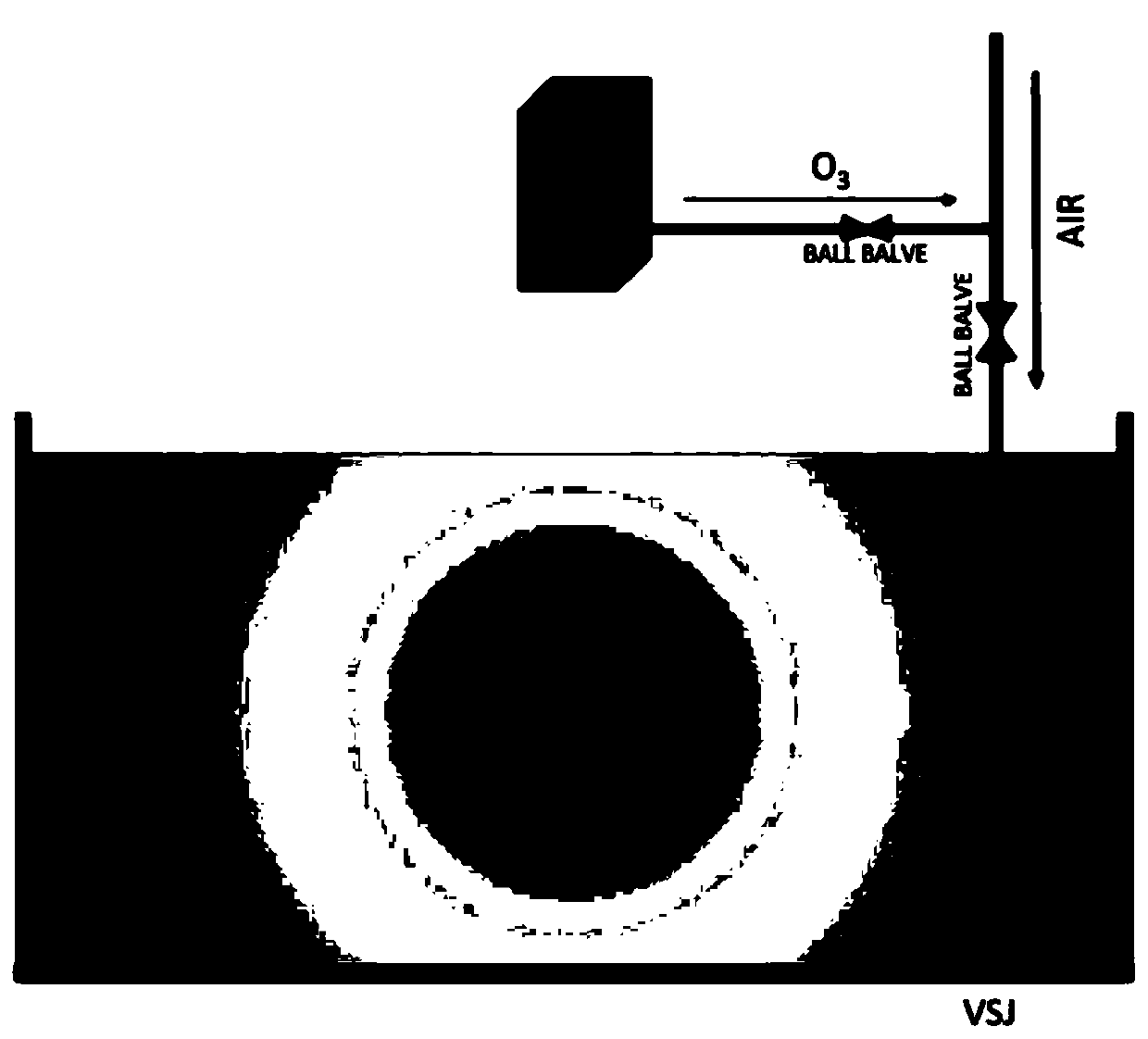

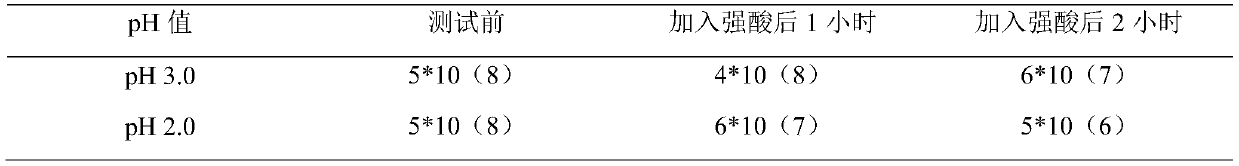

Mixed treatment process of feces and urine

InactiveCN110156276AIncrease dissolved oxygen concentrationImprove the ability to decompose organic matterTreatment using aerobic processesTreatment with aerobic and anaerobic processesMicro nanoFeces

The invention discloses a mixed treatment process of feces and urine, and belongs to the field of feces and urine treatment. The treatment process comprises the following steps: 1) introducing feces and urine into a biochemical treatment tank for aerobic biological treatment, periodically adding a microbial bacterial liquid to the biochemical treatment tank, and simultaneously performing micro-nano aeration treatment; 2) introducing the treated water body in the step 1) into a sedimentation tank for solid-liquid separation; and 3) introducing the obtained supernatant liquid after treatment inthe step 2) into a deep treatment tank, introducing a small amount of ozone to generate a large amount of hydroxyl radicals by using a micro-nano aeration apparatus in the deep treatment tank, performing high-efficiency oxidation, and simultaneously performing micro-nano aeration treatment on the water body. The microbial bacterial liquid added in the step 1) comprises lactobacillus QV1, lactobacillus QV1 is deposited in the General Microbiology Center of the China Microbial Culture Collection Management Committee, and the preservation number is CGMCC No.16350. The treatment process has high treatment efficiency, and the discharge can meet the standard after two weeks of treatment.

Owner:浙江亲水园生物科技有限公司

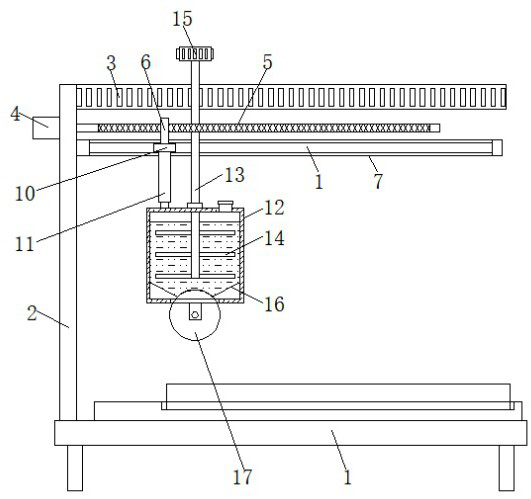

Novel rod hydraulic head cutting and tail cutting scissors

InactiveCN111112732AGuaranteed accuracyPlay a guiding roleMetal-working feeding devicesShearing machinesStructural engineeringMachine

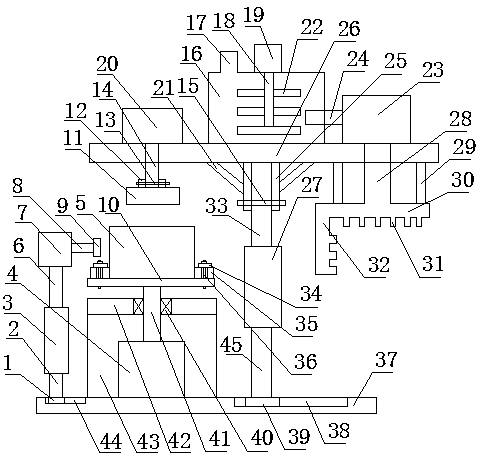

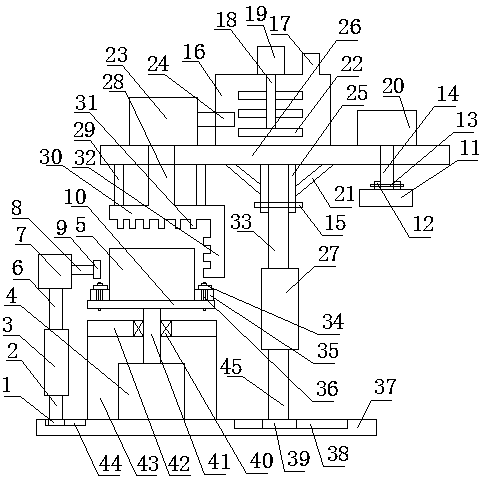

The invention discloses novel rod hydraulic head cutting and tail cutting scissors comprising a machine body. A plurality of support seats are fixedly connected to the lower end of the machine body. Two vertical rods are symmetrically arranged on the upper side of the machine body and are fixedly connected. The upper ends of the two vertical rods are jointly fixedly connected with an installationplate. Two second hydraulic oil cylinders are fixedly connected to the upper side of the installation plate. A lifting plate is arranged between the two vertical rods. The two vertical rods are each sleeved with a sliding barrel capable of moving up and down. Both the two sliding barrels are fixedly connected with the lifting plate. A cutter is fixedly connected to the lower side of the lifting plate. The novel rod hydraulic head cutting and tail cutting scissors are reasonable in structural design, excess materials cut off from the head and the tail can directly fall into a collection box tobe collected, manual picking and collection are not needed, the workload of a worker can be reduced, in addition, cutting fluid can be filtered and reused, the use effect of the cutting fluid is improved, and meanwhile, a blocking condition in a fluid storage cavity is avoided.

Owner:福州英迪特智能科技有限公司

Mechanical part surface grinding and spraying rust-prevention treatment system

InactiveCN108970888AImprove grinding efficiencyEasy to grindGrinding drivesGrinding machinesSurface grindingEngineering

The invention relates to a mechanical part surface grinding and spraying rust-prevention treatment system which comprises a mounting base plate. A first sliding groove and a second sliding groove arecorrespondingly formed in the left and right sides of the upper portion of the mounting base plate, a motor cavity is formed between the first sliding groove and the second sliding groove, and a firstsliding block and a second sliding block are correspondingly arranged in the first sliding groove and the second sliding groove. A first supporting column and a second supporting column are fixedly mounted on the upper portions of the first sliding block and the second sliding block correspondingly, a first air cylinder and a second air cylinder are correspondingly arranged on the upper portionsof the first supporting column and the second supporting column, a second motor and a top plate are correspondingly arranged on the upper portion of a first cylinder telescopic rod on the upper portion of the first air cylinder and the upper portion of a second cylinder telescopic rod on the upper portion of the second air cylinder, and a first machining grinding wheel piece is fixedly mounted ona second motor shaft of the right side of the second motor. According to the mechanical part surface grinding and spraying rust-prevention treatment system, the upper surfaces and side faces of mechanical parts can be simultaneously subjected to rust prevention liquid spraying treatment by simultaneously using a liquid outlet horizontal tube and a liquid outlet vertical tube, and the spraying efficiency is high.

Owner:陈宗泉

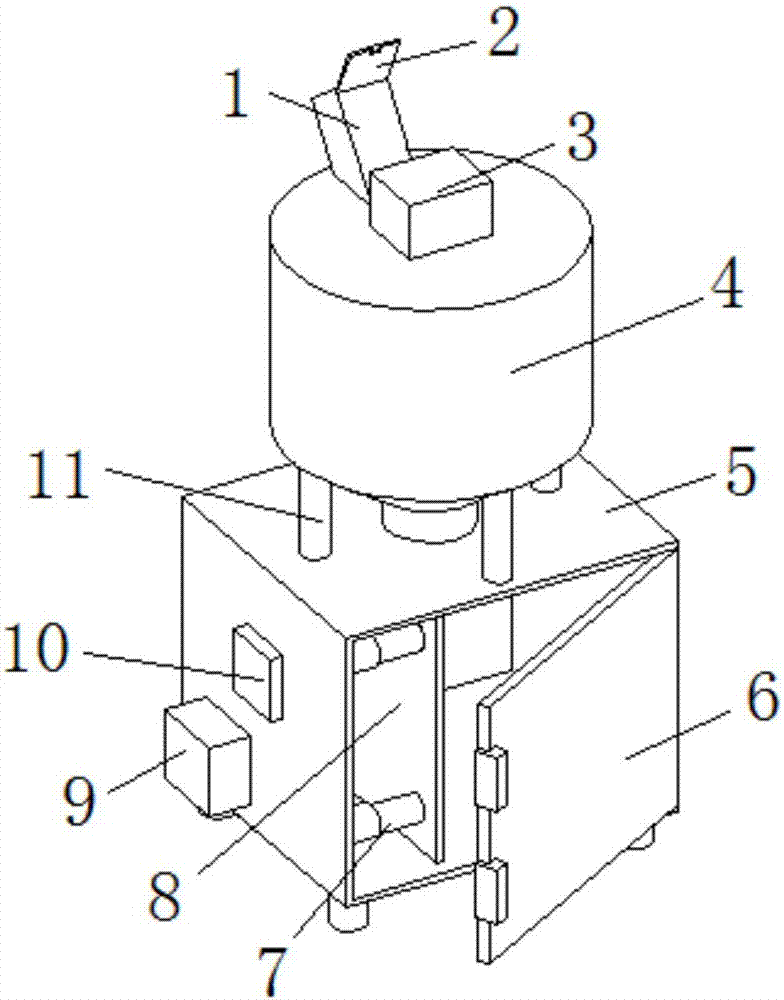

Efficient treatment device for waste bricks and tiles

InactiveCN108745585AReduce pollutionPromote environmental protectionGrain treatmentsEngineeringFuel tank

The invention discloses an efficient treatment device for waste bricks and tiles. The efficient treatment device comprises a box. A hydraulic pump, a hydraulic oil tank and a smashing box are fixedlyconnected to the inner bottom of the box through bolts. The hydraulic oil tank is located between the hydraulic pump and the smashing box. A breaking box is fixedly connected to the top of the smashing box through bolts. A feed hopper is fixedly connected to the top of the breaking box through a bolt. A support ring is welded to the inner wall of one side of the feed hopper. A baffle is rotationally connected to the outer wall of the side, away from the feed inlet, of the support ring through a hinge. The baffle is connected with the feed hopper through a spring. A limiting plate is installedin the position, close to the upper portion of the baffle, of the top of the support ring. According to the efficient treatment device, the waste bricks and tiles are broken, screened and ground in arelatively sealed environment in the whole process, the problem that dust produced by the waste bricks and tiles pollutes the work environment and the atmosphere is avoided effectively, environmentalfriendliness of the treatment device is improved, and trouble of manual cleaning is reduced.

Owner:傅花宁

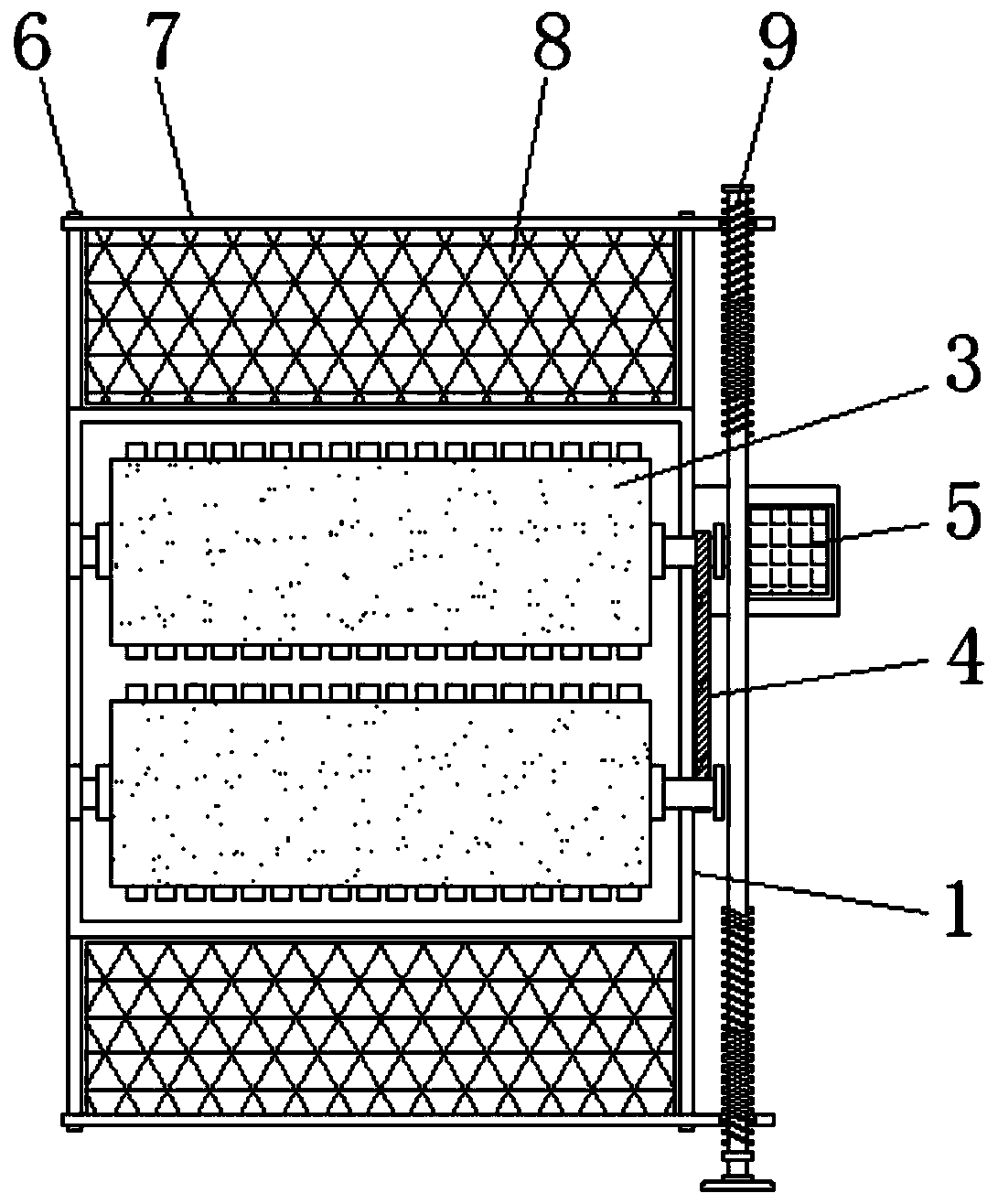

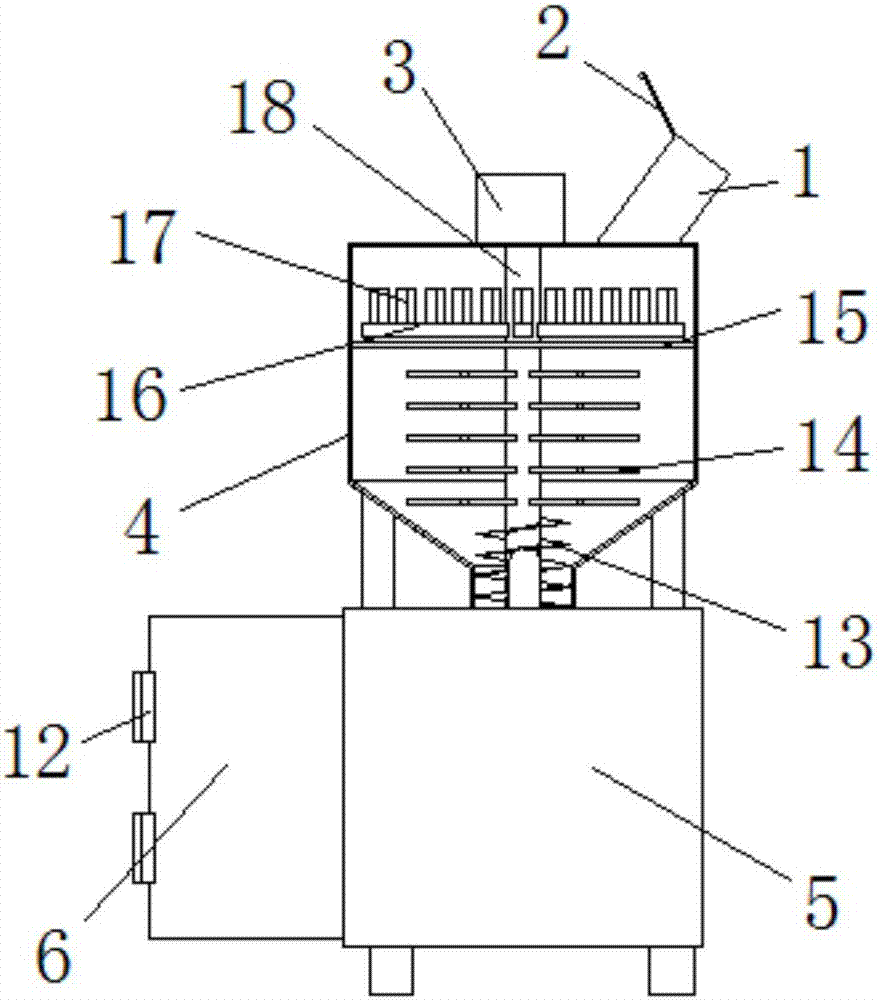

Crushing device used for construction waste and convenient for classification and collection

ActiveCN111359752AEasy to sort and collectEasy to handle with dust removalSievingScreeningElectric machineArchitectural engineering

The invention discloses a crushing device used for construction waste and convenient for classification and collection. The crushing device comprises a box body, a first motor, a second motor, fine crushing rollers, an electromagnetic cylinder, a wire plug and a third motor. A feed inlet is formed in the upper end of the box body, the right ends of single bodies of crushing rollers are in transmission connection through a first belt, the front side and the rear side of the upper end of the box body are fixedly connected with sliding rods, connecting rods are welded with dustproof plates, the left side of the box body is fixedly connected with a conveying cylinder, the lower end of a spiral rod is fixedly connected with the second motor through a bolt, a feed port is formed in the left lower side of the conveying cylinder, sieve plates are arranged on the lower sides of the crushing rollers, and guide plates are arranged on the lower sides of the sieve plates. The crushing device used for construction waste and convenient for classification and collection is convenient for dustproof treatment, at the same time, layered crushing treatment can be conveniently conducted on the construction waste, different types of garbage can be conveniently classified and collected, and recycling of useful garbage is facilitated.

Owner:广西青辉环保技术有限责任公司

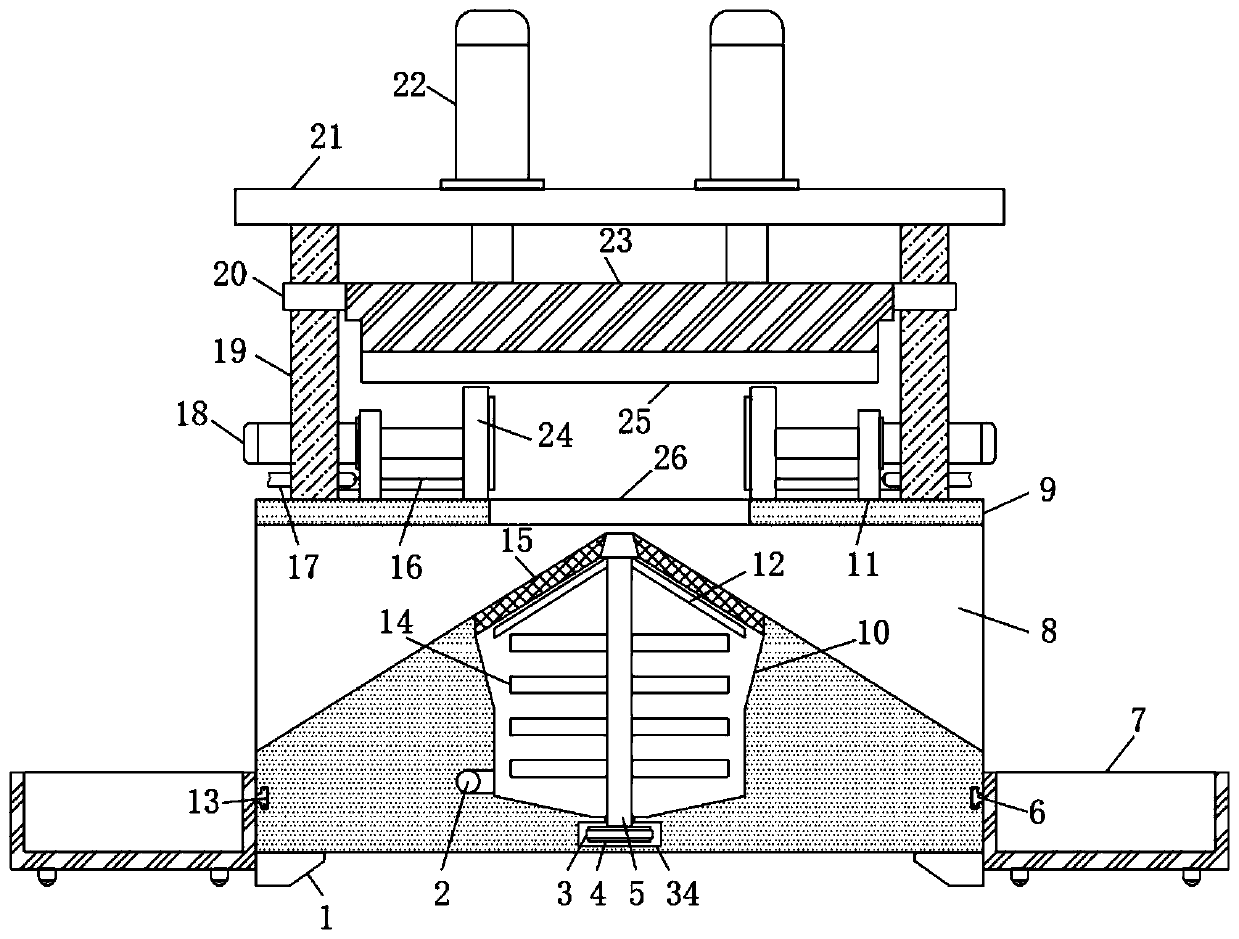

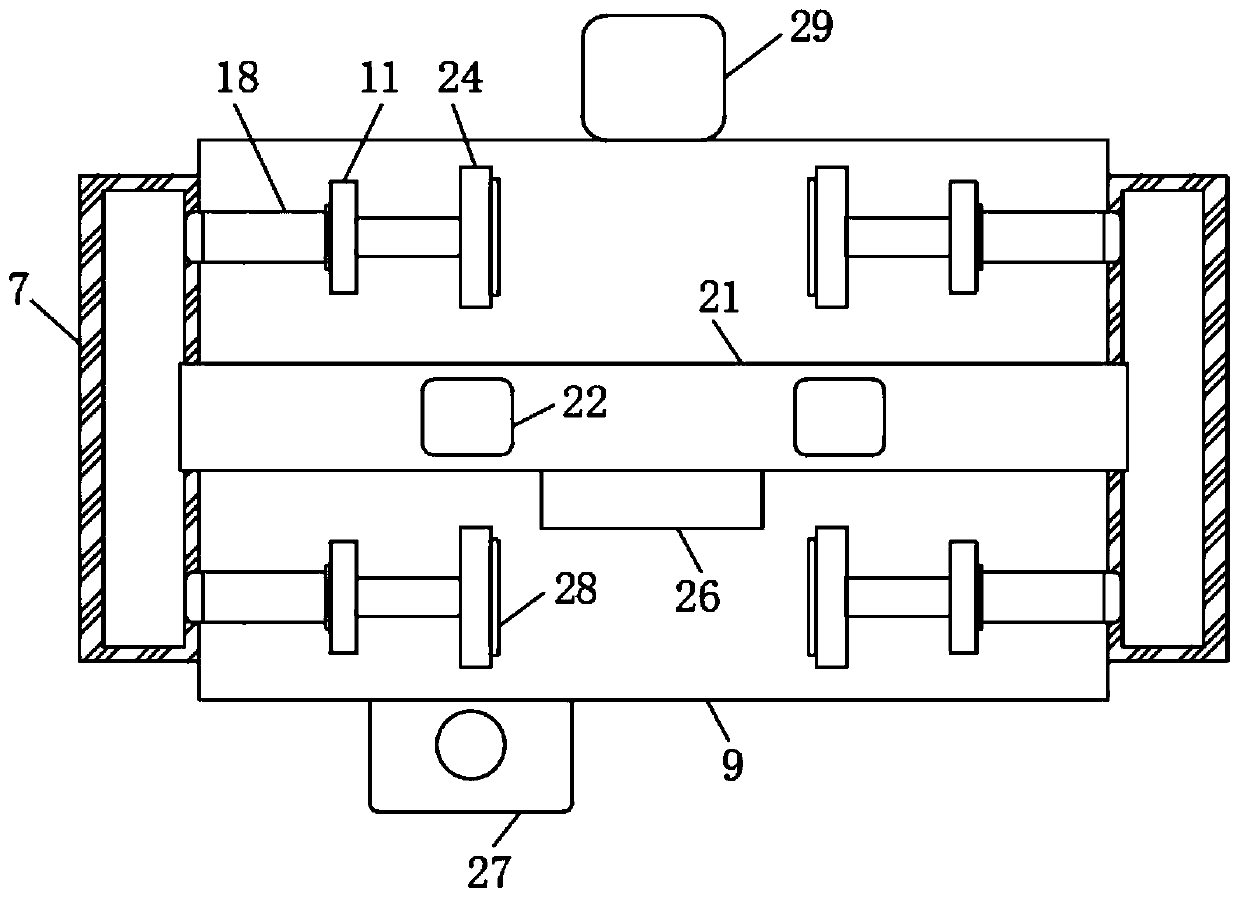

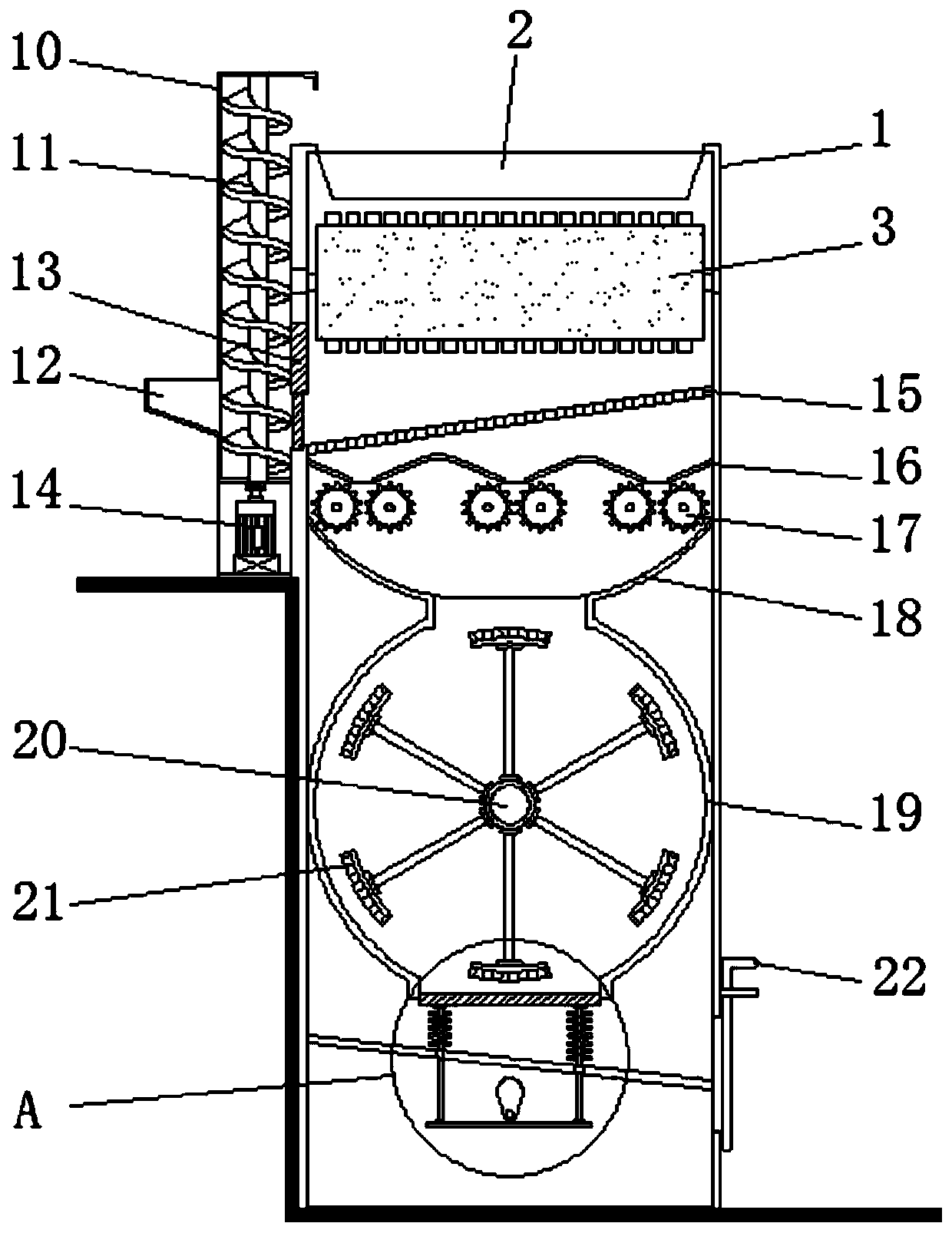

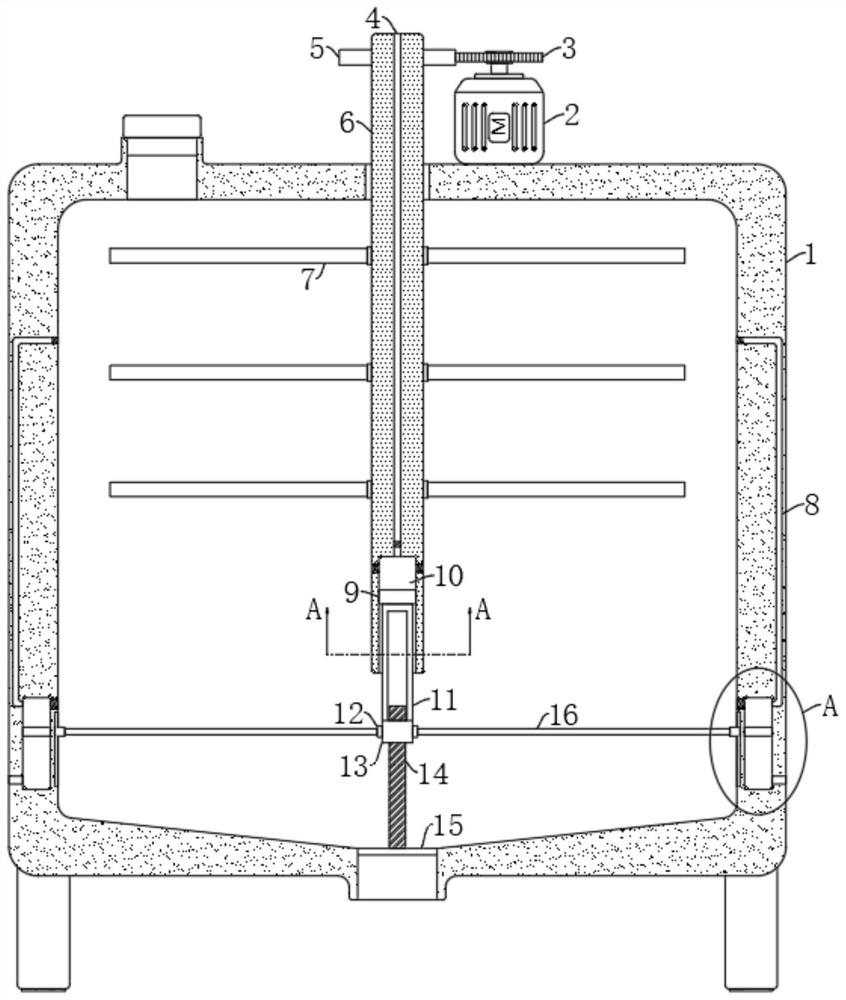

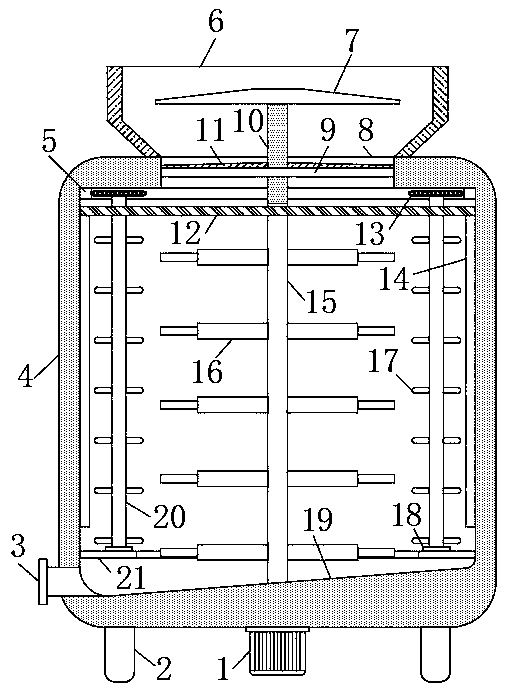

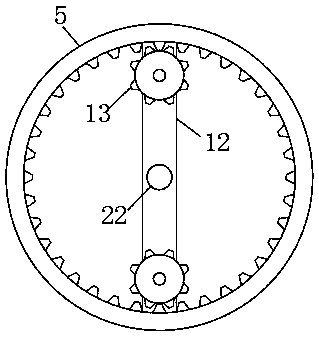

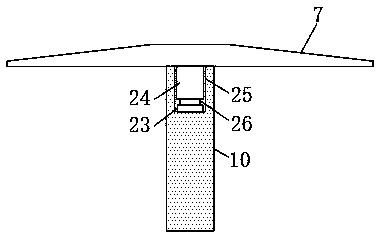

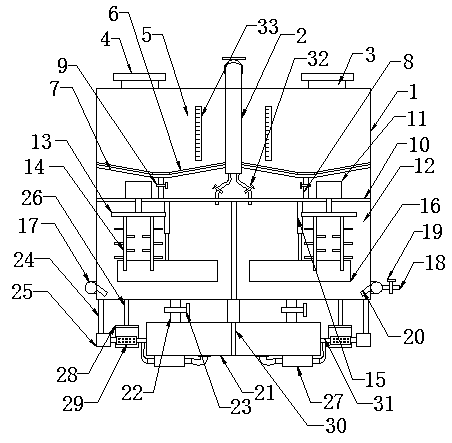

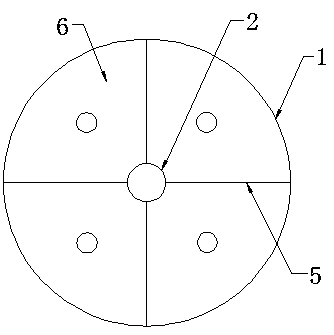

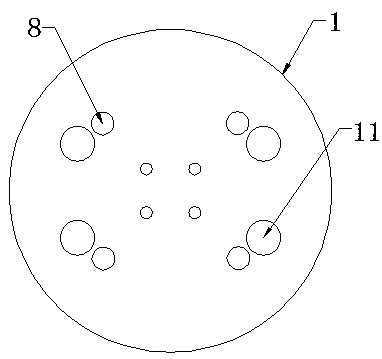

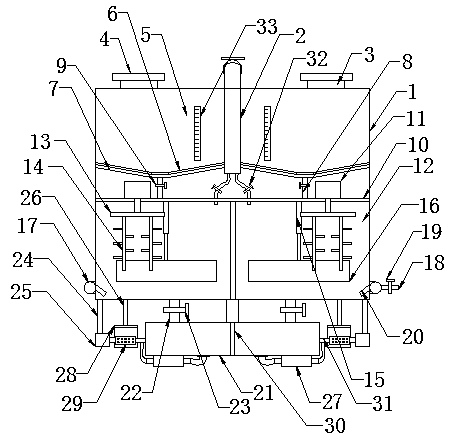

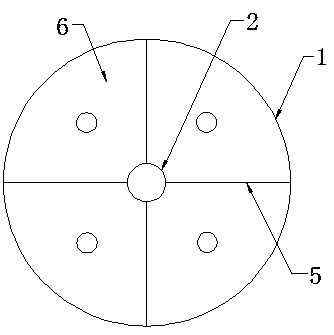

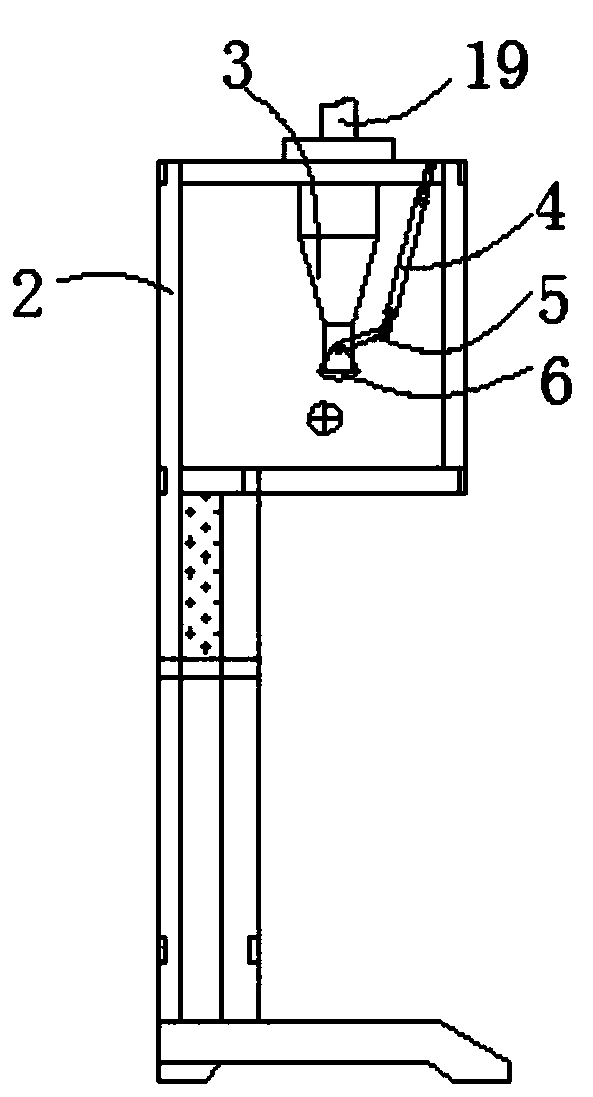

Instant stirring feed tank with dosing device

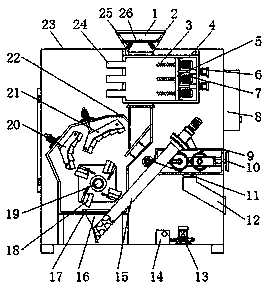

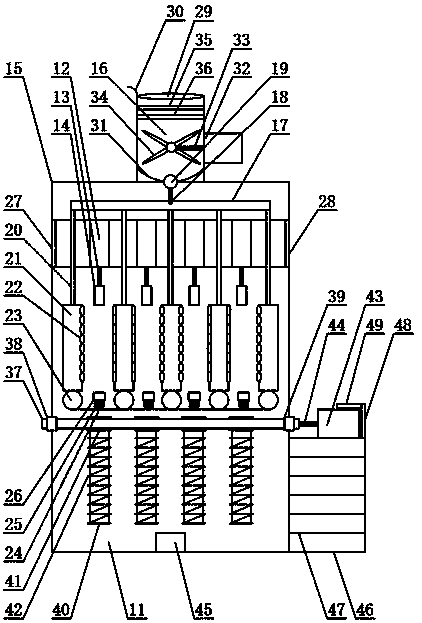

InactiveCN108311008AEasy to mix and handleGrowth aidTransportation and packagingRotary stirring mixersLivestockCam

The invention discloses an instant stirring feed tank with a dosing device. The instant stirring feed tank comprises a tank body, wherein the tank body is of a hollow structure; in addition, the innerpart of the tank body is divided into a material storage cavity and a stirring cavity by a separation board which is transversely arranged; the material storage cavity is positioned above the stirring cavity; two communicating ports are symmetrically formed in the separation board; besides, the material storage cavity is communicated with the stirring cavity by the communicating ports; a feedingopening communicated with the material storage cavity and discharging openings communicated with the stirring cavity are also formed in the side walls of the tank body; a first mounting cavity is formed in the separation board, is positioned between the two communicating ports, and is communicated with the two communicating ports; a first driving motor is arranged on the inner wall of the first mounting cavity; a cam is fixedly arranged on an output shaft of the first driving motor in a sleeving manner; two fixed blocks are also symmetrically arranged in the first mounting cavity. The instantstirring feed tank disclosed by the invention has the advantages that charging is facilitated, water is conveniently added into dry food for stirring to obtain a wet material which is conveniently eaten by livestock, and further the growth of the livestock is benefited.

Owner:安徽金源农林专业合作社

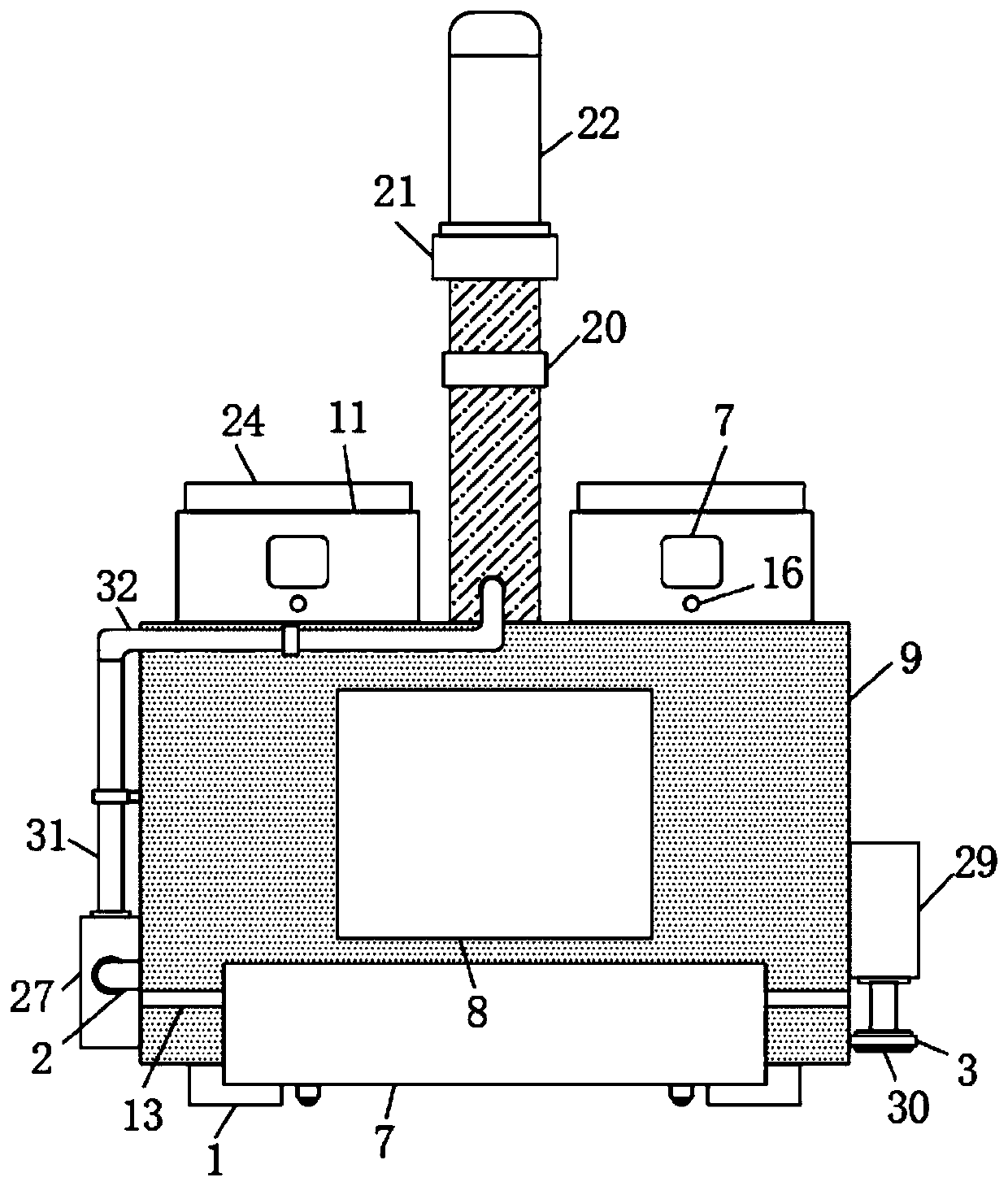

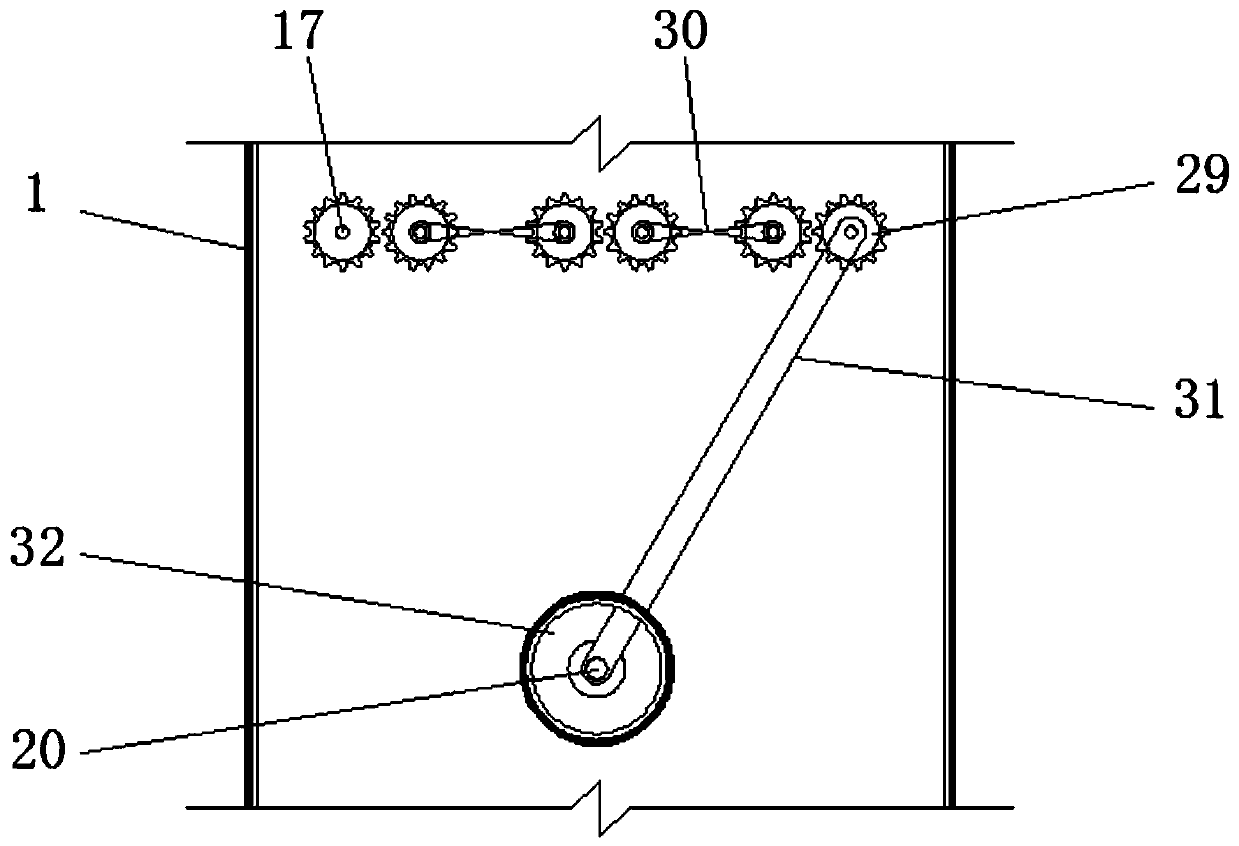

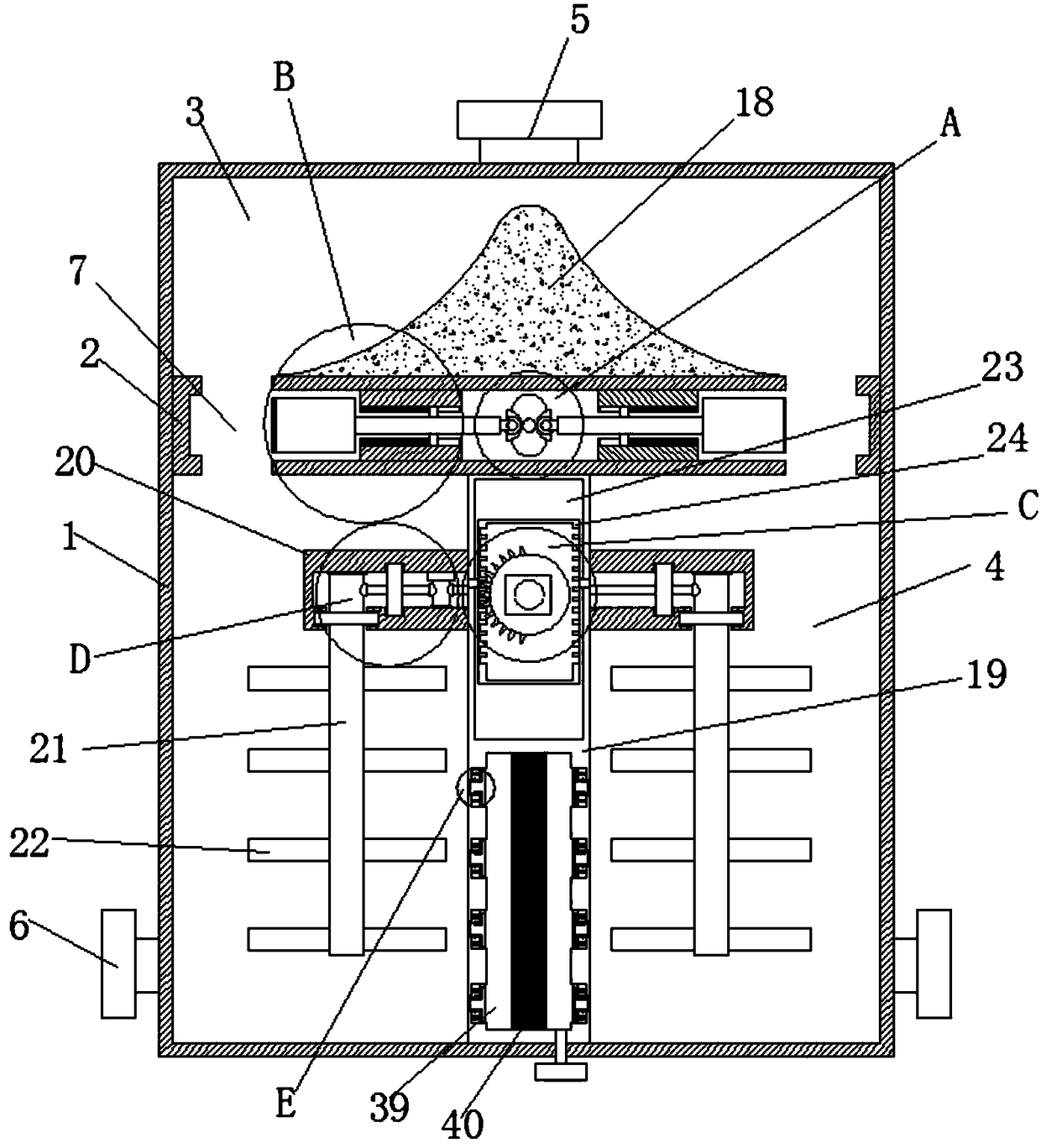

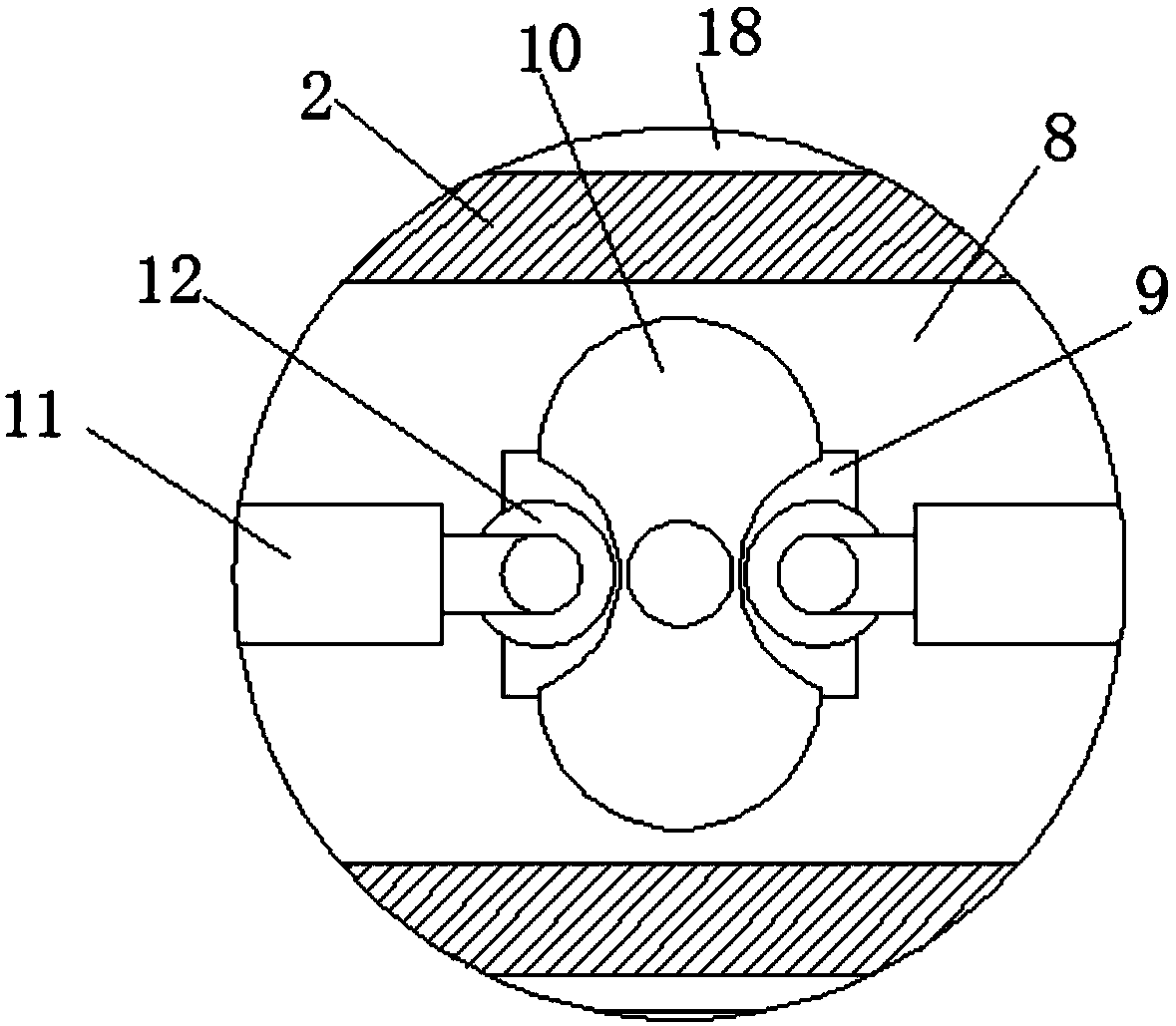

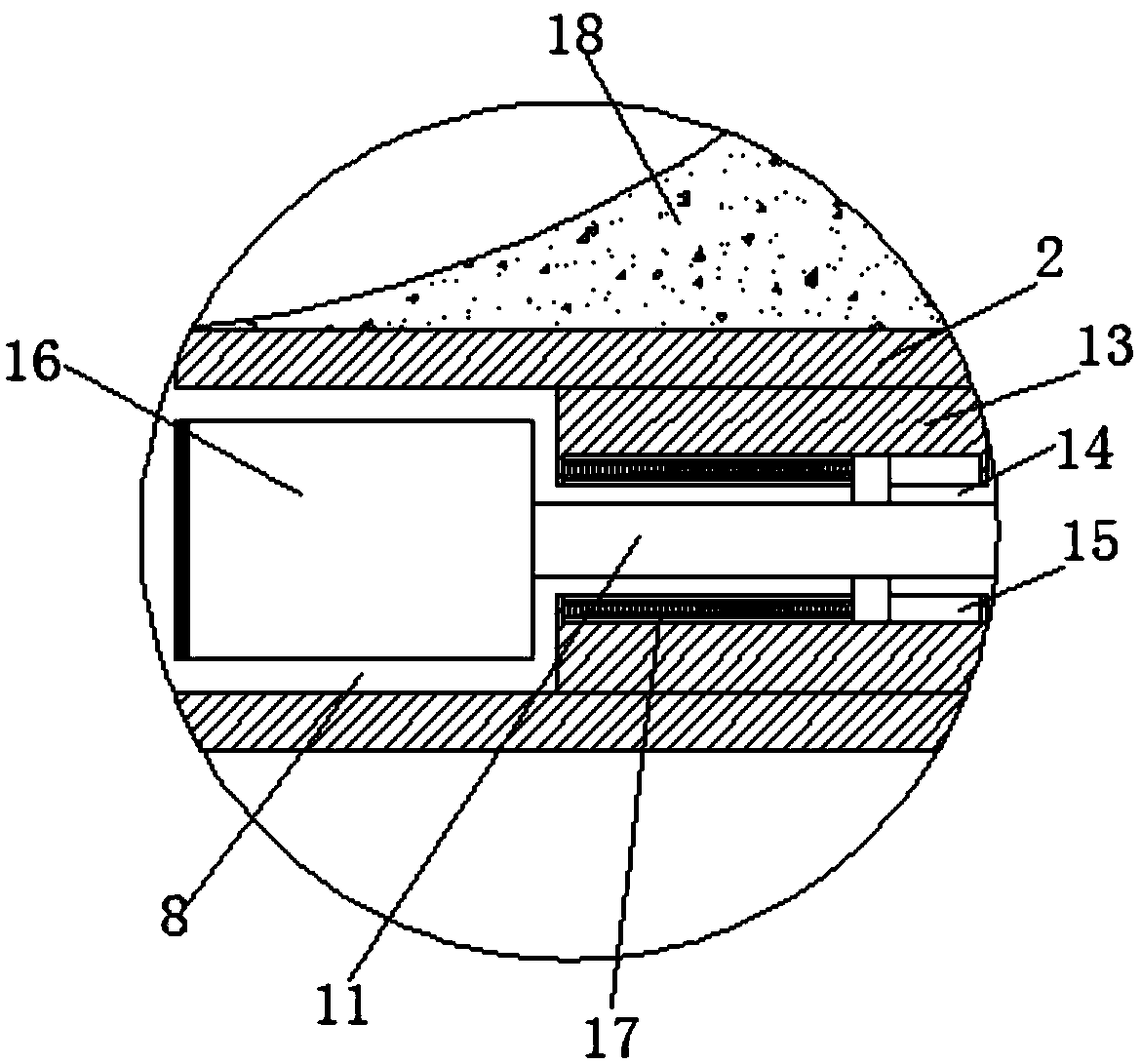

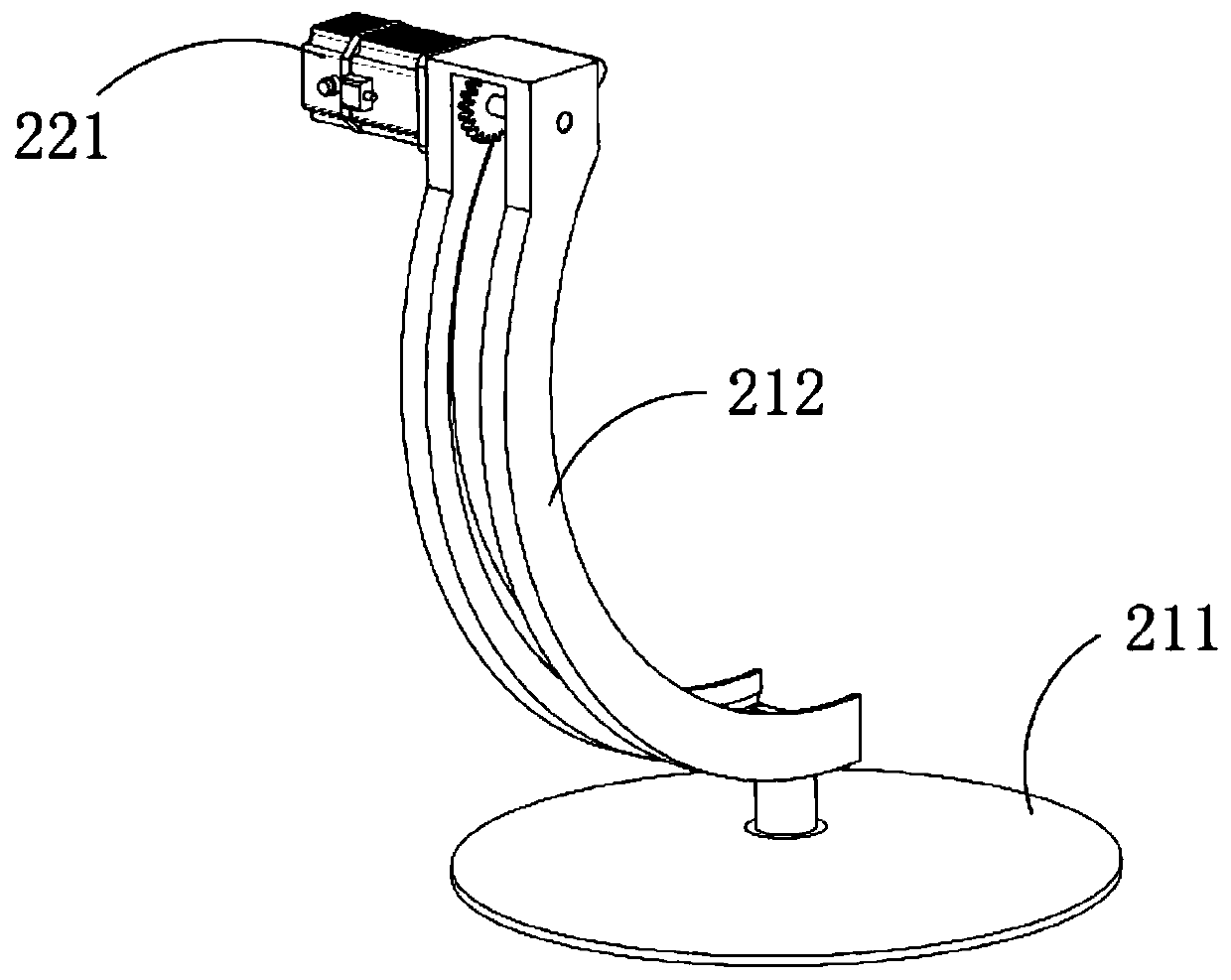

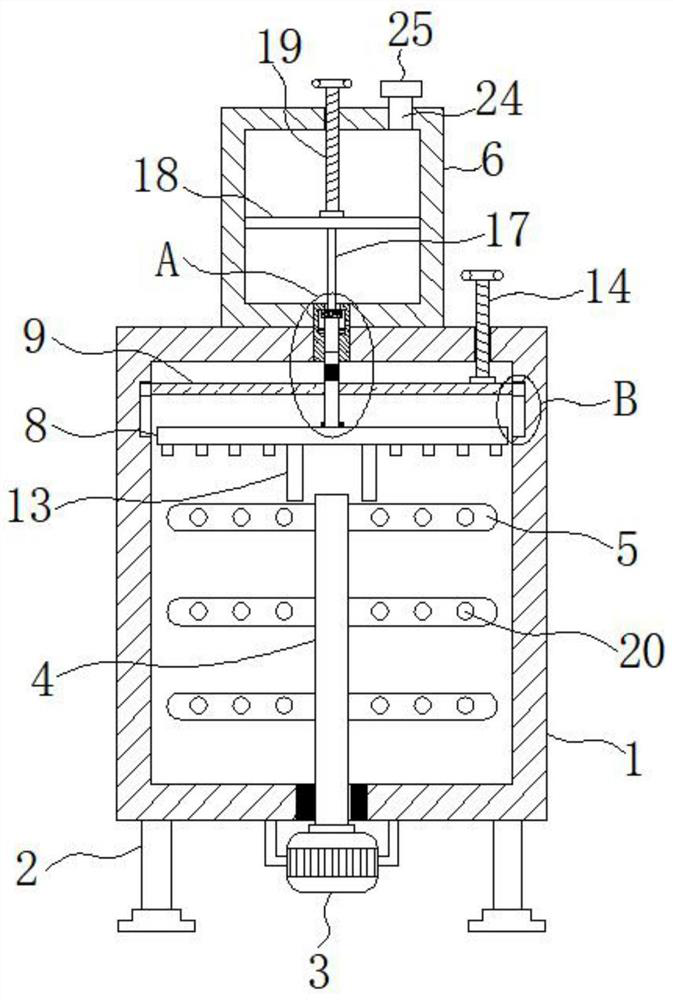

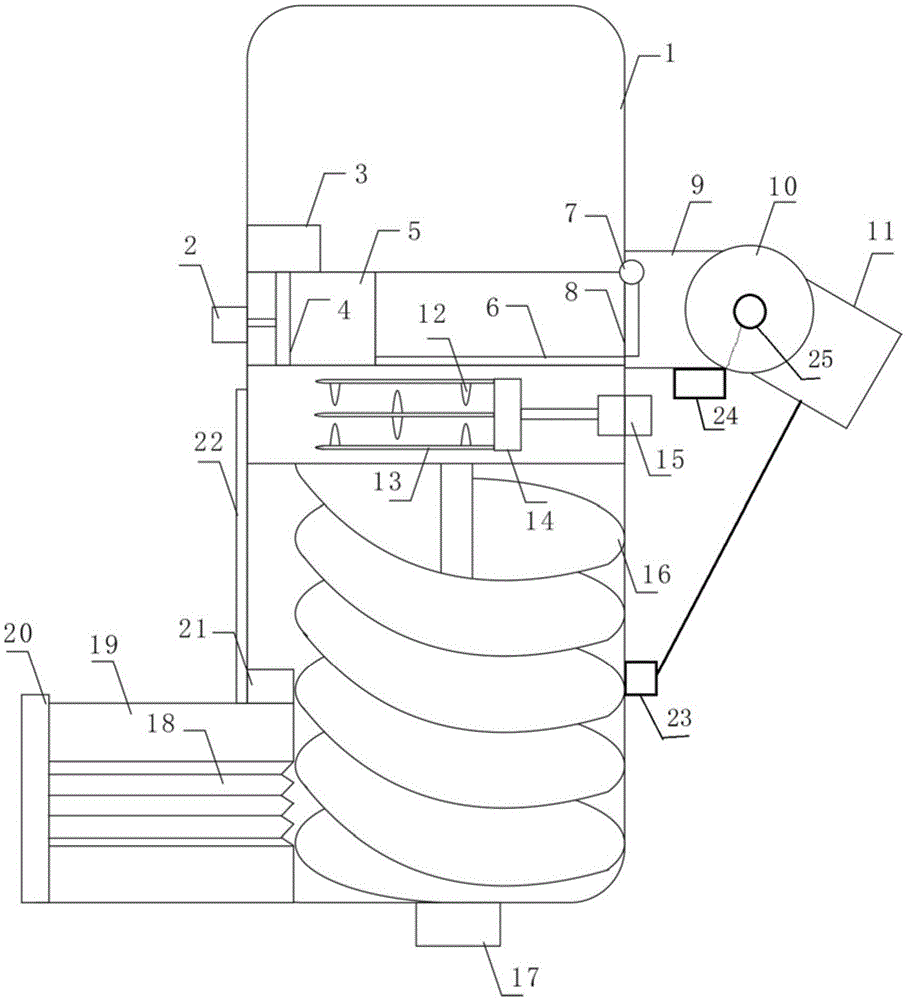

Self-circulation pesticide processing and mixing system

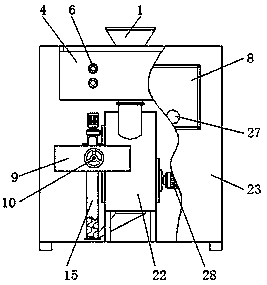

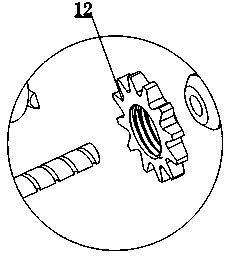

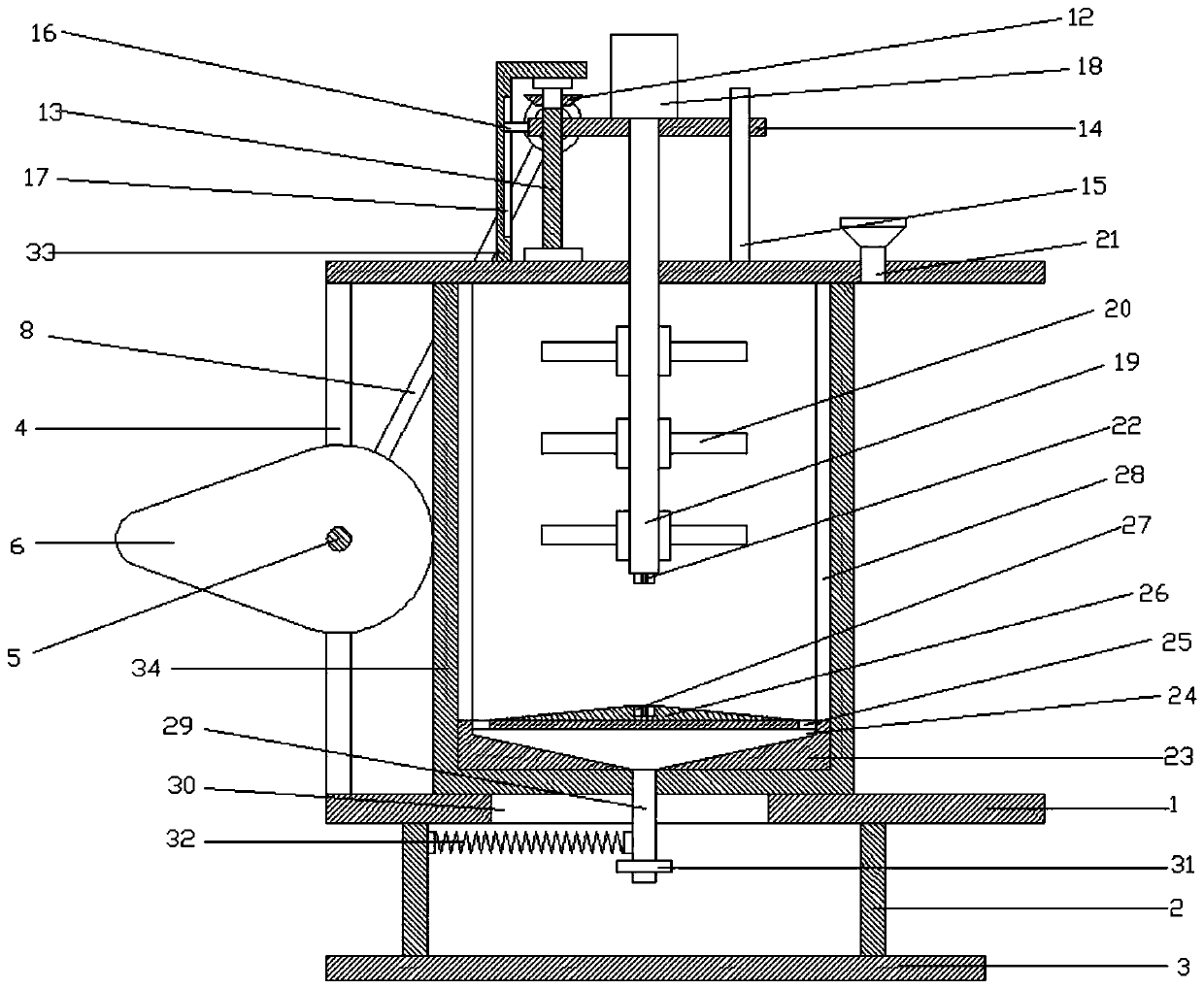

InactiveCN111871290AEasy to mix and handleImprove the mixing effectFlow mixersTransportation and packagingGear wheelElectric machinery

The invention discloses a self-circulation pesticide processing and mixing system which comprises a box body, a stirring mechanism is arranged in the box body, the stirring mechanism comprises a rotating shaft arranged on the upper side of the box body in a penetrating mode, a second gear is fixedly connected to the outer side of the rotating shaft; a first gear is fixedly connected to the tail end of an output shaft of the driving motor, the first gear and a second gear are meshed with each other, and a plurality of stirring blades are fixedly connected to the outer side, located in the box body, of the rotating shaft; a gas injection mechanism used for liquid mixing is arranged in the box body, the gas injection mechanism comprises a groove formed in the lower end of the rotating shaft,and a gas inlet hole communicated with the groove is formed in the upper end of the rotating shaft. By means of the system, liquids can be blown to roll over, liquid circulation can be achieved, thenthe liquid mixing effect is improved, and the product quality of pesticide is guaranteed.

Owner:于伟

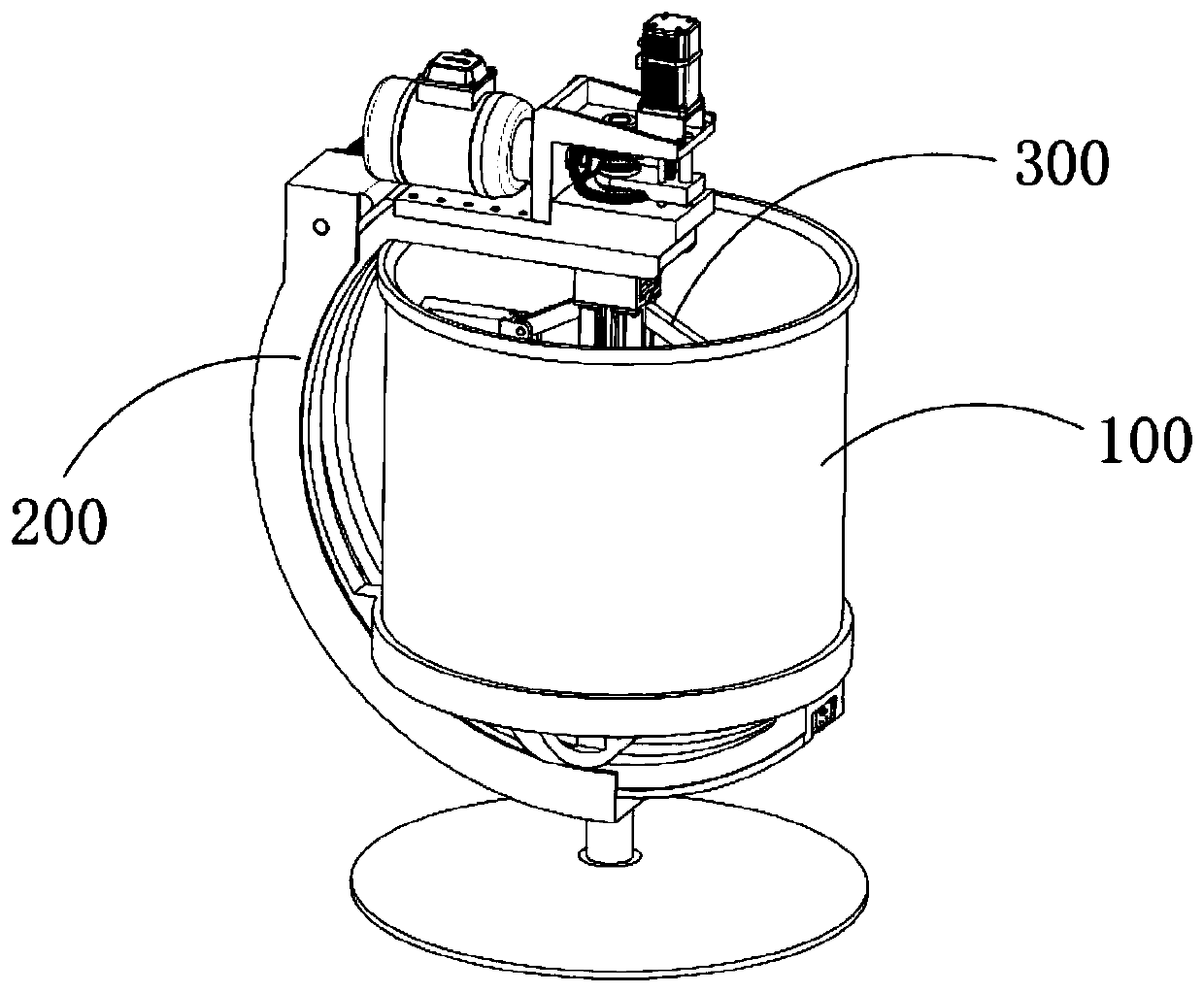

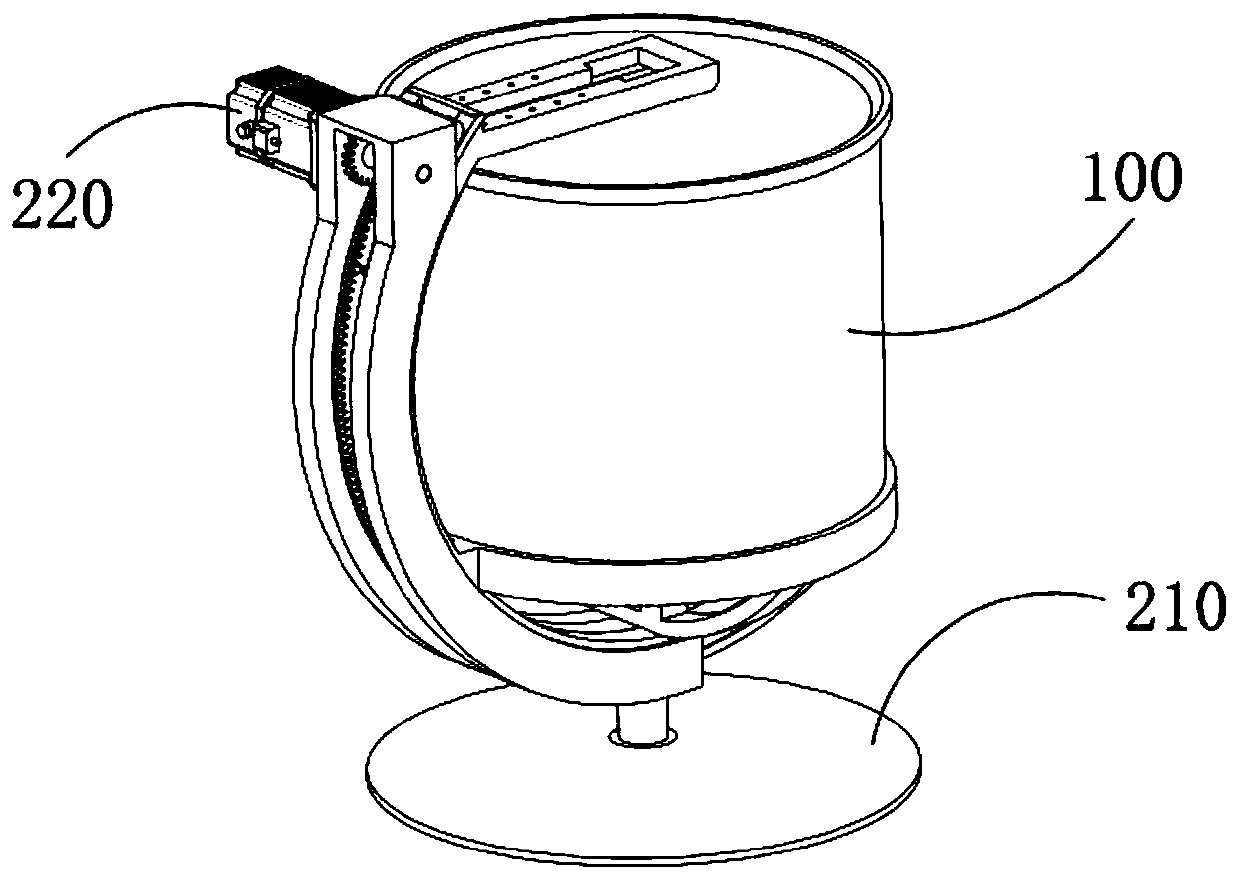

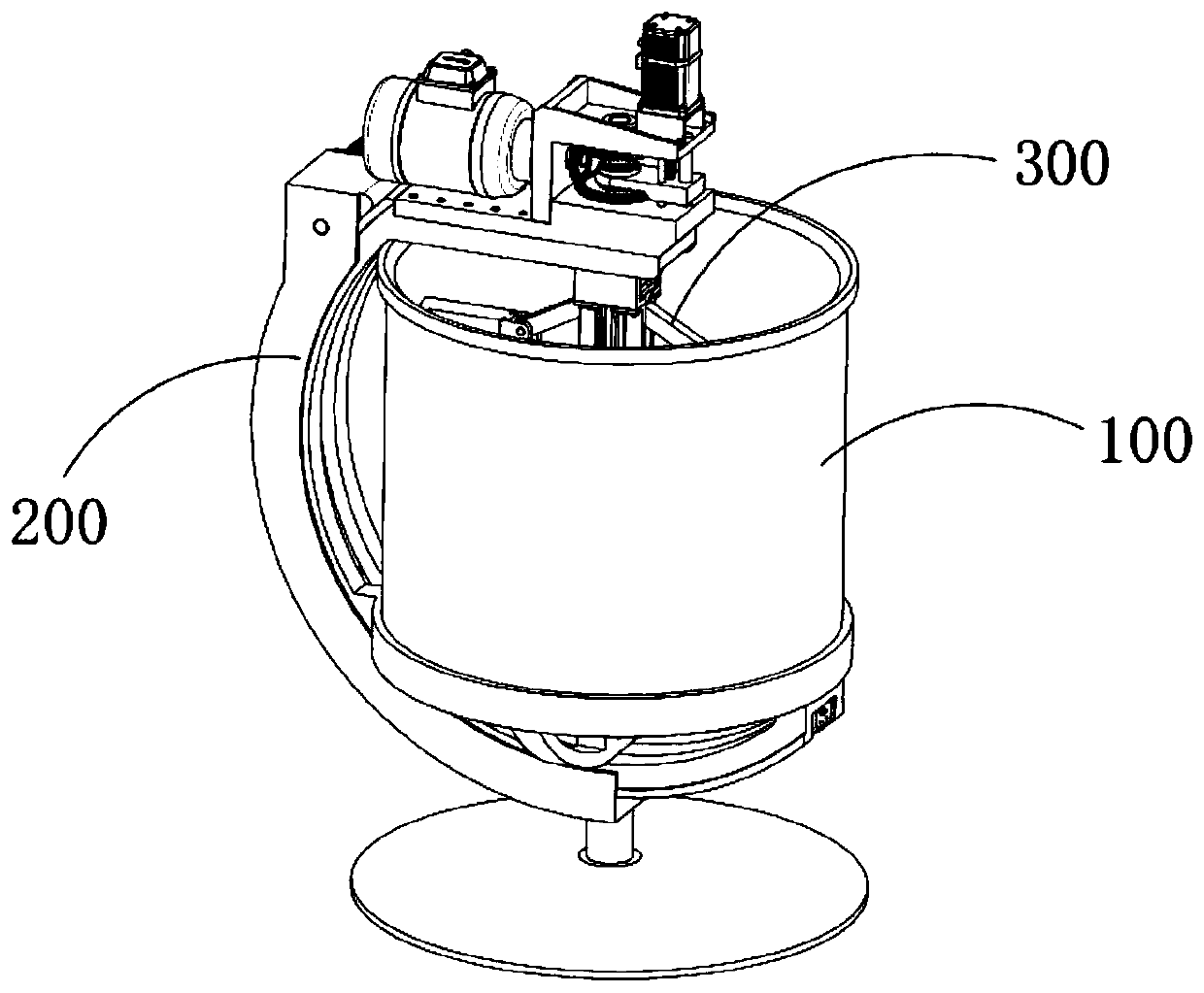

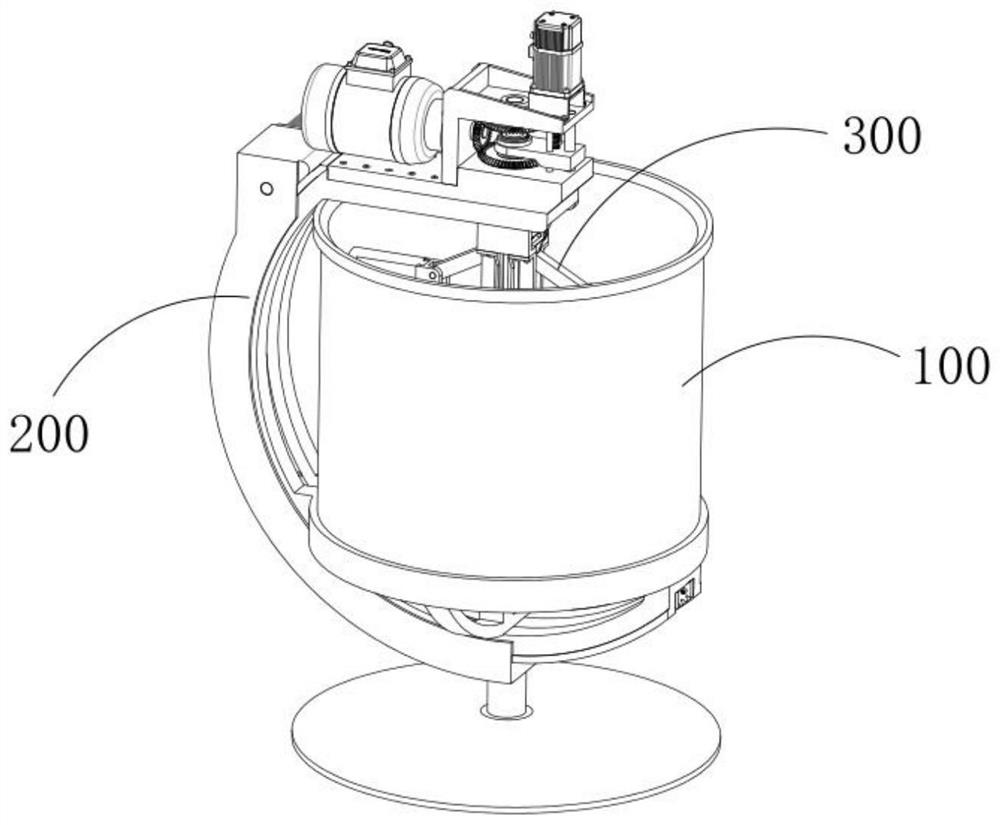

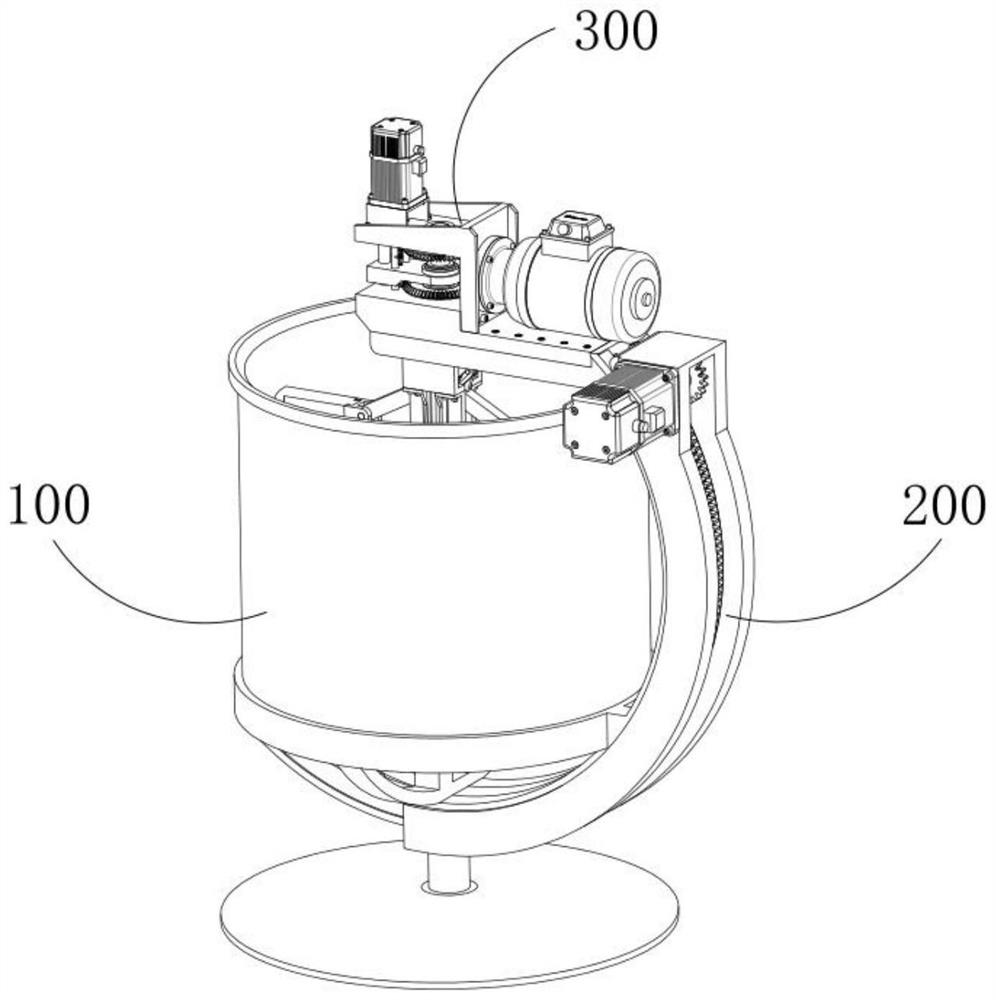

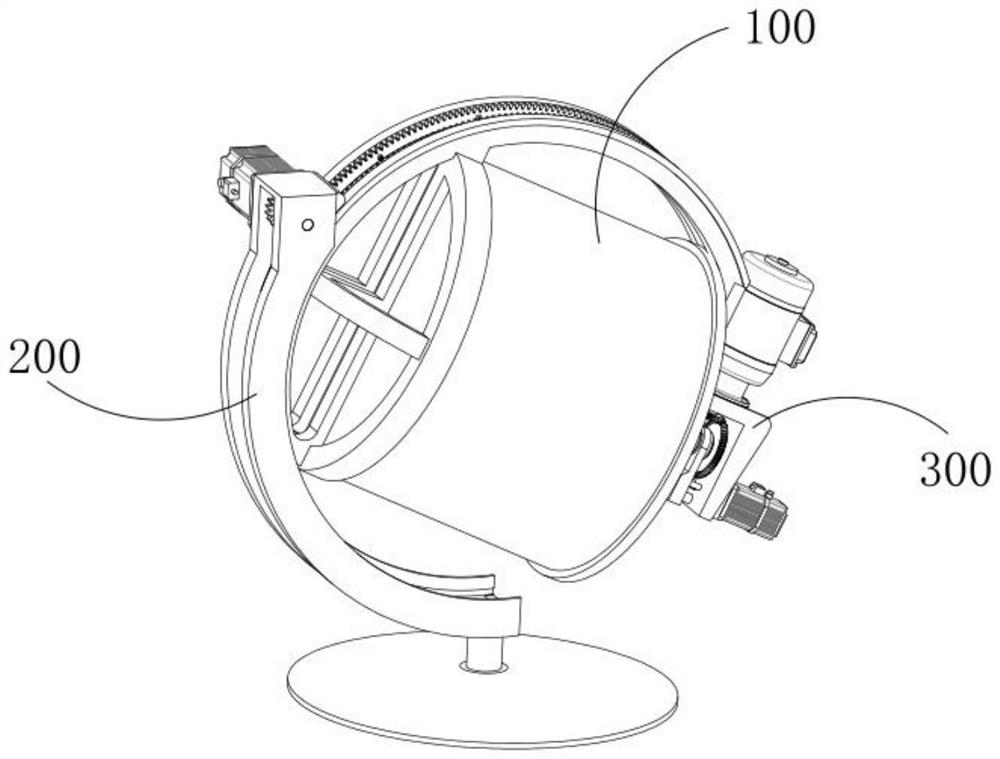

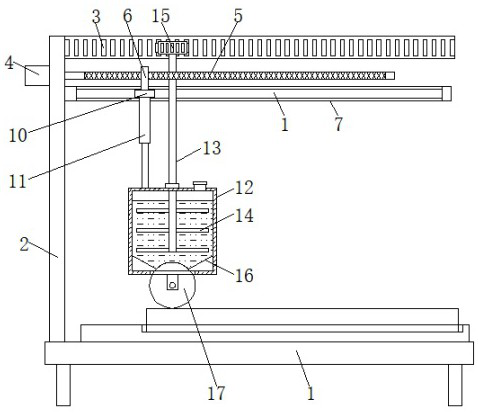

Different-direction stirring and mixing method for chemical raw materials

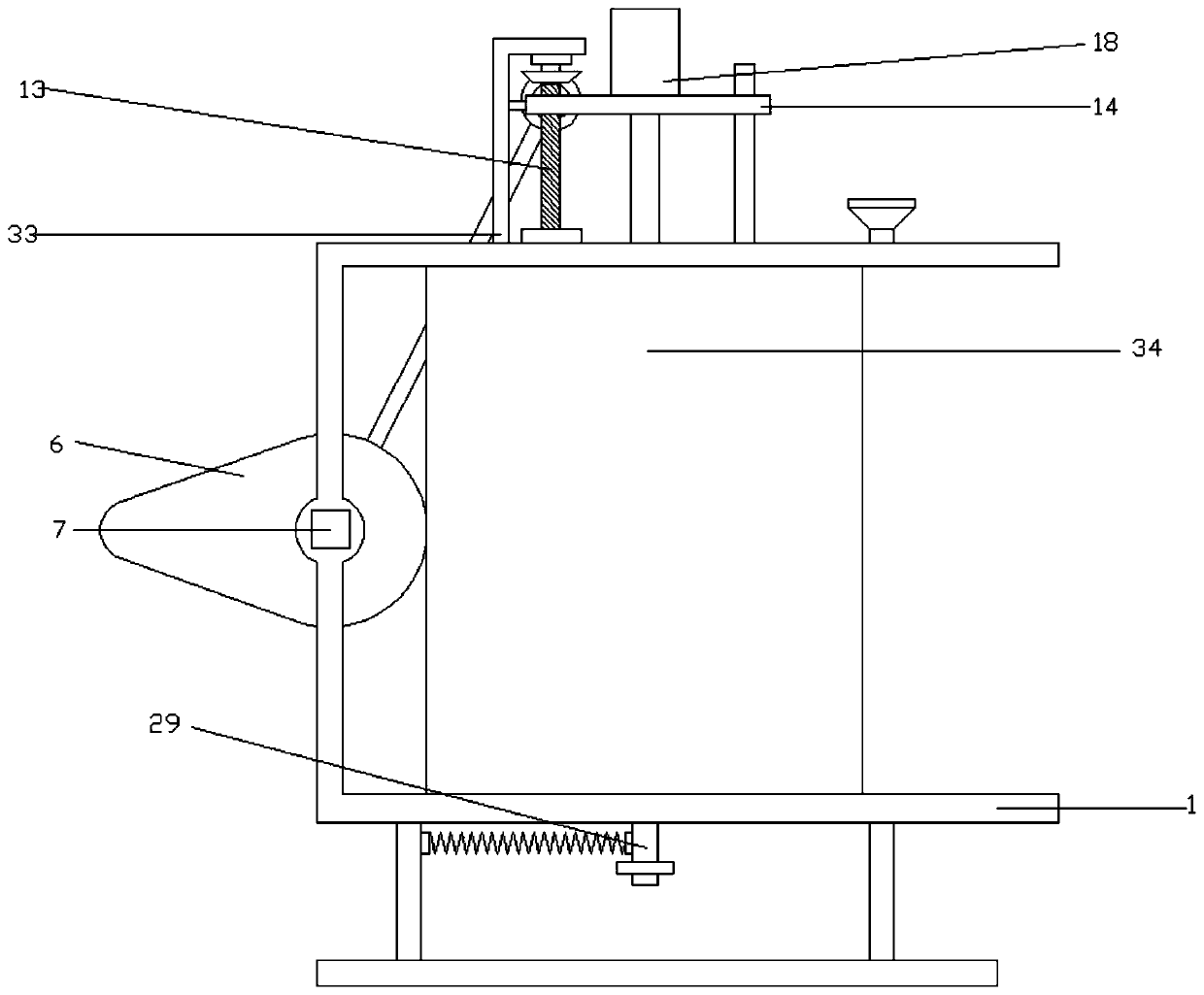

ActiveCN110652906AReduce labor intensityGood mixing effectRotary stirring mixersTransportation and packagingProcess engineeringBLENDER/MIXER

The invention discloses a different-direction stirring and mixing method for chemical raw materials. The method comprises the following steps: sequentially putting to-be-stirred materials into a stirring tank by an operator; fully and uniformly stirring the obtained inner ring mixture by using an inner ring stirring part; fully and uniformly stirring the obtained outer ring mixture by an outer stirring part during the stirring of the inner ring mixture with the inner stirring part; stopping running of a different-direction stirring mechanism after the mixture is fully and uniformly stirred, turning on an automatic pouring mechanism to make the stirring tank obliquely arranged in order to pour out the uniformly stirred mixture in the stirring tank, reversely running the automatic pouring mechanism to recover the stirring tank to the original position, and performing the next round of mixture stirring. The whole mixture discharging process is fully automatic without manual operation of workers, so the labor intensity of the workers is greatly reduced; and the inner ring and outer ring different-direction stirring mode is adopted, so the mixture can be fully and evenly stirred, and the stirring effect is good.

Owner:重庆安盛钾业有限公司

Energy-saving and environment-friendly pulping device for papermaking and printing

ActiveCN110552222AAffect the blending effectEasy to cleanRaw material divisionPapermakingElectric machinery

The invention discloses an energy-saving and environment-friendly pulping device for papermaking and printing. The pulping device comprises a box body, the lower end of the box body is fixedly connected with a plurality of supporting feet, a discharge port is arranged at the middle and lower position of the side wall of the box body, the middle part of the upper end of the box body is provided with a feed inlet, the upper end of the box body is fixedly connected with a feed hopper at a position corresponding to the feed port, the lower end of the box body is fixedly connected with a motor, theend of the output shaft of the motor penetrates through the lower end of the box body and is fixedly connected with a rotating rod, the output shaft of the motor is rotatably connected with the box body, a plurality of crushing knives are arranged at equal intervals along the axial direction on the outer side of the rotating rod, a rotating plate is sleeved on the rotating rod, and the two are fixedly connected. The invention has reasonable structural design, can disperse materials into the inside of the box body, is beneficial to improving the pulping effect, can fully mix the materials, andcan also prevent the materials from adhering to the inner wall of the box body.

Owner:温州市金龙纸业有限公司

Sewage treatment dosing apparatus

ActiveCN108854809AAvoid cakingPrevent spoilageTransportation and packagingMixer accessoriesMedicineMoisture absorption

The invention discloses a sewage treatment dosing apparatus. The sewage treatment dosing apparatus comprises a dosing box main body, a central water pipe and a chemical discharging box, wherein four dosing pipes are arranged on the top end of the dosing box main body at intervals, the top end of the dosing pipe is provided with a dosing cover, four sides of the top of the dosing box main body arerespectively provided with an observation groove, a glass plate is embedded inside the observation groove, the glass plate is provided with scales, a central water pipe is fixedly arranged on the center of the top inside the dosing box main body, four funnel-shaped plates are fixedly arranged on the top inside the dosing box main body at intervals, and a first separation plate is fixedly arrangedbetween two adjacent funnel-shaped plates. According to the sewage treatment dosing apparatus, by virtue of the cooperative design of the first separation plate and the funnel-shaped plates, the innertop of the dosing box main body can be divided into four chemical chambers for separately storing four chemicals; and by designing a funnel-shaped moisture absorption mat, the moisture in the chemical can be absorbed, and the agglomeration and deterioration of the chemical can be avoided.

Owner:HUNAN CITY UNIV

A sewage treatment dosing device

ActiveCN108854809BAvoid cakingPrevent spoilageTransportation and packagingMixer accessoriesPharmacyDrug dosing

The invention discloses a sewage treatment dosing device, which comprises a main body of a dosing box, a central water pipe and a medicine outlet box. Four dosing pipes are arranged at intervals on the top of the main body of the dosing box, and a dosing cover is installed on the top of the dosing pipe. The four sides of the top of the main body of the dosing box are provided with observation slots, the inside of which is embedded with a glass plate, and the glass plate is provided with scales, and the center of the top of the main body of the dosing box is fixed with a central water pipe. Four bucket-shaped plates are fixed at intervals on the top of the interior, and a first partition is fixed between two adjacent bucket-shaped plates. A sewage treatment dosing device of the present invention, the first partition and the bucket-shaped plate With the design, the top of the main body of the dosing box can be divided into four pharmacy chambers, which store four kinds of medicaments respectively; the design of the bucket-shaped moisture-absorbing pad can absorb the moisture in the medicament to avoid the agglomeration and deterioration of the medicament.

Owner:HUNAN CITY UNIV

Textile fabric active dip dyeing device

InactiveCN111748943AFully impregnatedGood dyeing efficiencyTextile treatment containersLiquid/gas/vapor treatment machines driving mechanismsHydraulic cylinderDrive shaft

The invention discloses a textile fabric active dip dyeing device. The textile fabric active dip dyeing device comprises a base, wherein a dip dyeing tank is arranged on the base; an unwinding rolleris arranged on one side of the top of the dip dyeing tank; a winding roller is arranged on the other side of the top of the dip dyeing tank; a driven gear is arranged at the outer end of the winding roller; a driving motor is arranged on the outer side of the dip dyeing tank; a driving shaft is arranged at the front part of the driving motor; a driving gear is arranged on the peripheral surface ofthe driving shaft; the driving gear is meshed with the driven gear; a traction frame is arranged in the dip dyeing tank; a pair of bearing seats is arranged on each of the two sides of the lower partof the traction frame; a traction roller is mounted on each bearing seat; a main hydraulic cylinder is arranged on the outer side of the dip dyeing tank; a main piston rod is arranged at the lower part of the main hydraulic cylinder; the upper end of the main piston rod is connected with the lower part of the main hydraulic cylinder; and the lower end of the main piston rod is connected with thetraction frame. The textile fabric active dip dyeing device can conveniently stir active fuel and can also conveniently scrape the surface of a textile fabric in a rotating manner, so that the textilefabric is more fully dip-dyed in the active dye, and the dip dyeing efficiency is higher.

Owner:新昌县丙辰储能科技有限公司

Microbial agent adding device for microbial fertilizer production

ActiveCN111925244AControl flow rateEasy to addBio-organic fraction processingOrganic fertiliser preparationMicroorganismAgricultural science

The invention relates to the technical field of microbial fertilizers. The invention further discloses a microbial agent adding device for microbial fertilizer production. The microbial agent adding device comprises a charging barrel, a plurality of supporting legs are fixedly installed at the bottom of the charging barrel, a driving motor is fixedly installed at the bottom of the charging barrelthrough a rack, a stirring shaft is fixedly connected to the output end of the driving motor, the stirring shaft penetrates through the center of the bottom of the charging barrel and extends upwards,and the stirring shaft is rotationally connected with the bottom of the charging barrel through a first sealing bearing; a plurality of evenly-distributed stirring blades are welded to the outer rodwall of the stirring shaft, a liquid storage tank is fixedly installed at the top of the charging barrel, a flow guide pipe is fixedly communicated between the liquid storage tank and the charging barrel, a flow control mechanism is installed between the flow guide pipe and the liquid storage tank, a transverse pipe is arranged in the charging barrel, and the transverse pipe is located above the stirring shaft. According to the invention, the flow rate of a microbial fertilizer inoculant can be controlled in the adding process, the adding uniformity of the inoculant liquid is ensured, and themixing effect is effectively ensured.

Owner:MAANSHAN KEBANG ECO FERTILIZER

Anti-carbonization device for vegetable drying

ActiveCN111609688AAvoid carbonizationEasy to pick upWithdrawing sample devicesDrying gas arrangementsComposite materialEngineering

The invention discloses an anti-carbonization device for vegetable drying. The anti-carbonization device comprises a drying box body, wherein the upper end of the drying box body is provided with a second motor; the drying box body communicates with a feed port; a drum connected with the second motor is arranged in the drying box body; a heating cavity is formed in the drum; a heating plate is arranged in the heating cavity; a plurality of stirring plates are uniformly arranged on the outer side wall of the drum; an inclined screen is arranged below the drum; a ball outlet is formed in the side surface of the lower part of the drying box body, positioned on one side of the inclined screen, and communicates with a ball outlet pipe; the ball outlet pipe is connected with a ball return pipe through an elevator; a quality inspection groove is formed between the ball outlet pipe and the ball return pipe; a plurality of quality inspection balls are arranged in the quality inspection groove;material storage openings are formed in the quality inspection balls; a spraying assembly is arranged on the other side of the second motor; and the lower end of the ball return pipe communicates witha second cylindrical box. According to the anti-carbonization device for the vegetable drying, materials are dried conveniently, the real-time drying condition of the materials can be effectively detected, and the material carbonization is prevented.

Owner:ANHUI ZHAORI AGRI TECH CO LTD

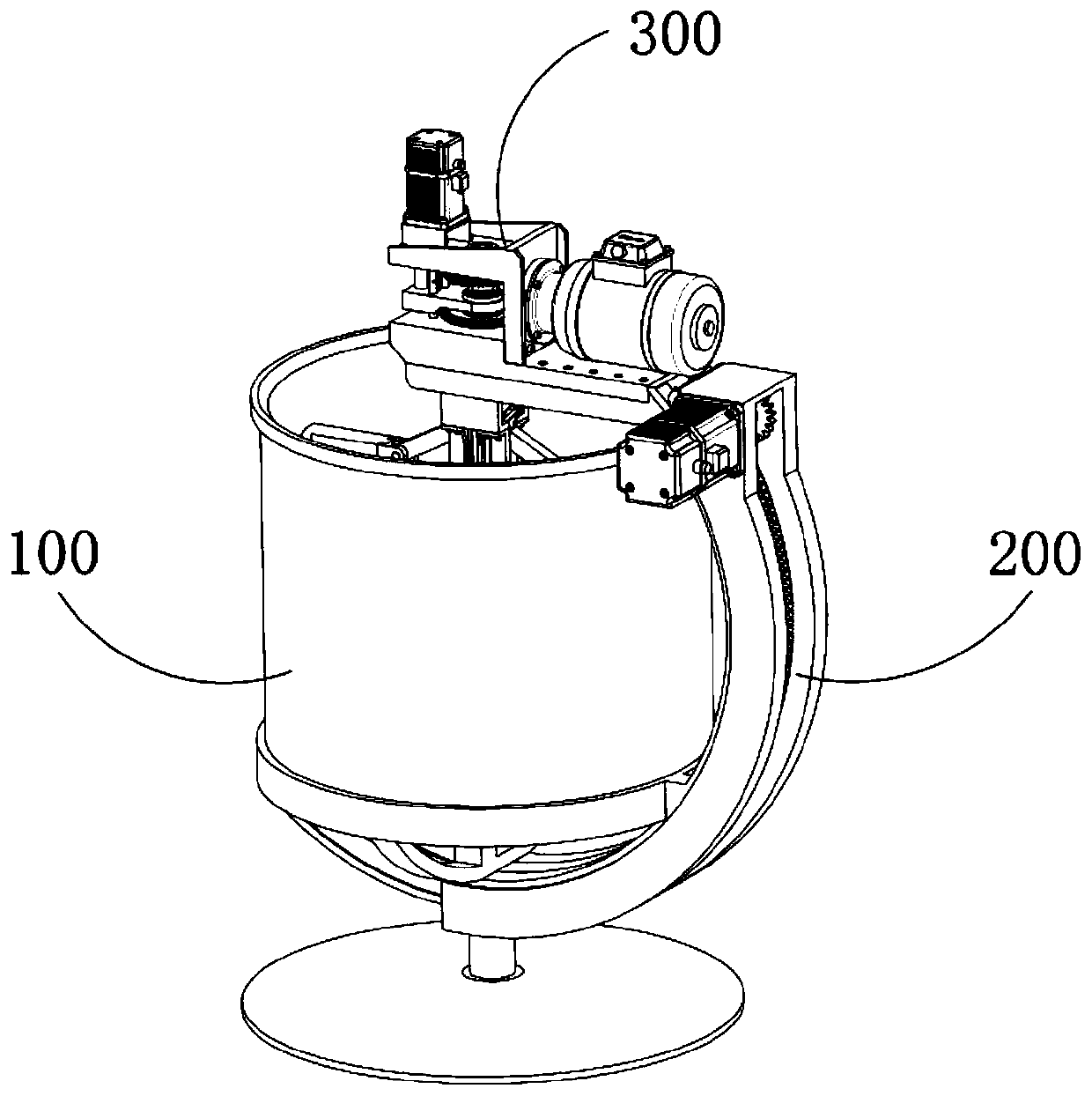

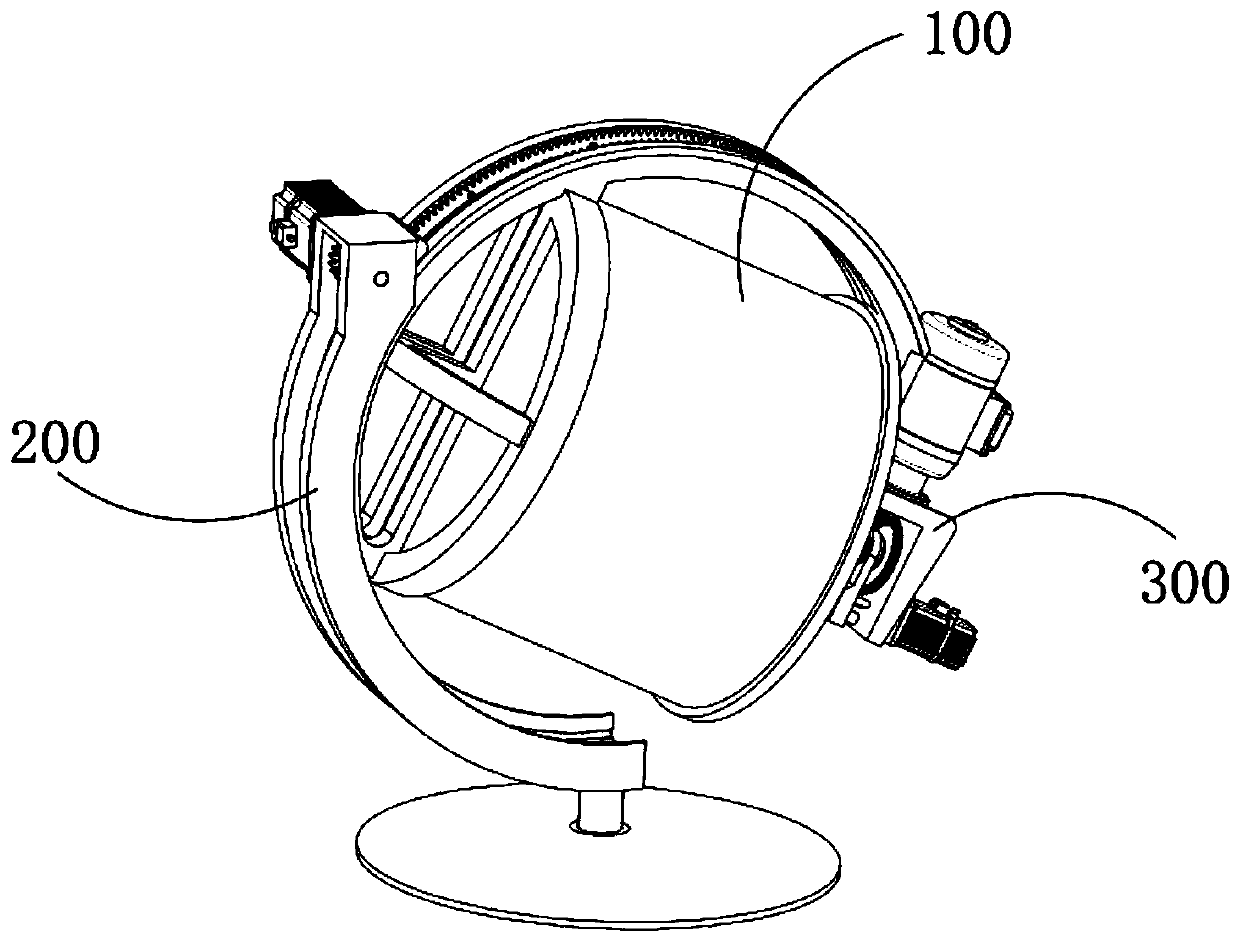

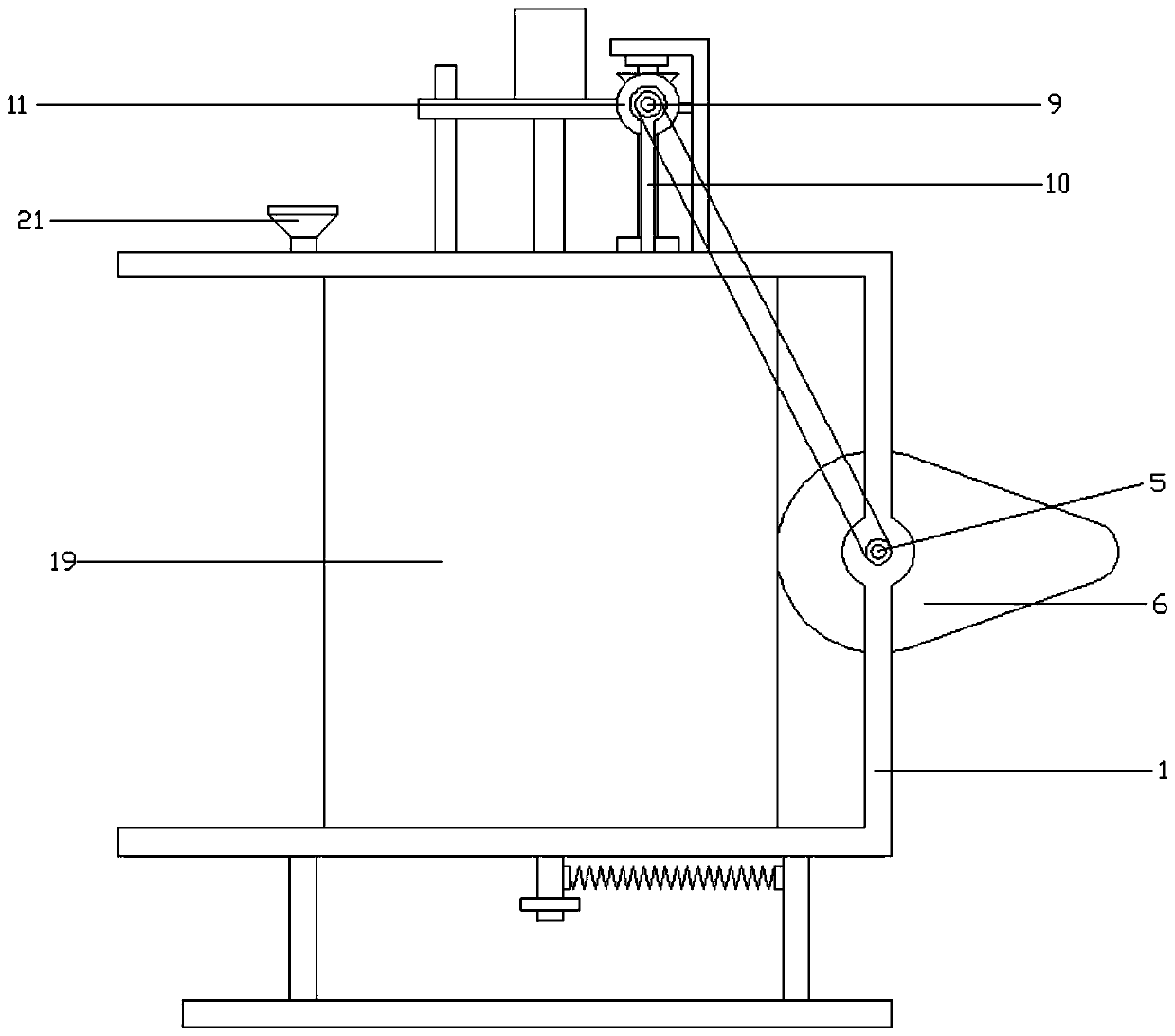

Coaxial opposite-direction self-unloading stirring equipment for promoting uniform mixing of chemical raw materials

ActiveCN110585967AStir wellStir well stir wellShaking/oscillating/vibrating mixersTransportation and packagingEngineeringUltimate tensile strength

Owner:山西瑞峰百合化工有限公司

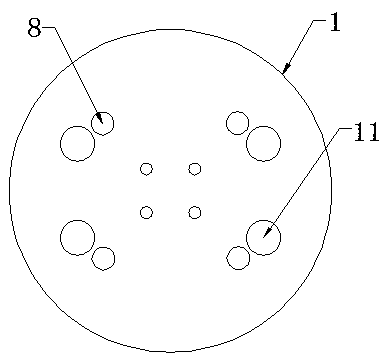

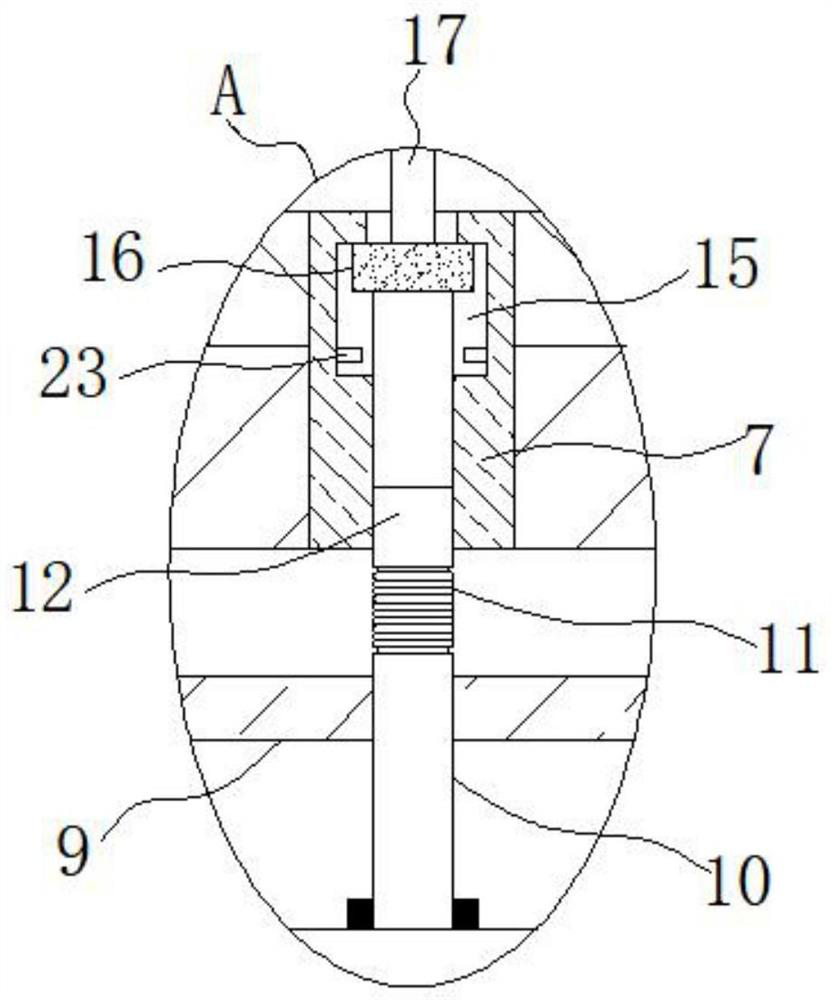

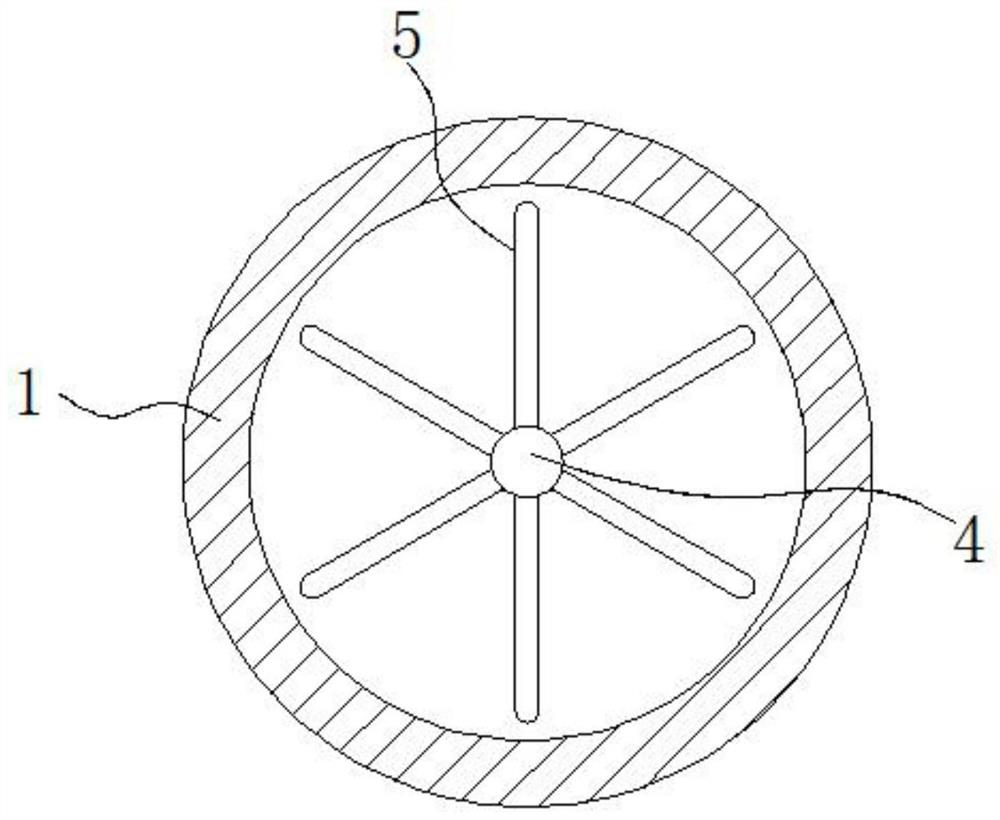

Polyvinyl chloride paste rotating stirring device for agitation tank

InactiveCN109200847AEasy to mix and handleImprove mixing efficiencyRotary stirring mixersTransportation and packagingEngineeringPolyvinyl chloride

The invention discloses a polyvinyl chloride paste rotating stirring device for an agitation tank. The device includes a rotating stirring mechanism, a rotating shaft is disposed at an axial positionof the rotating stirring mechanism, a first plane bearing is disposed between the rotating shaft and one end of the rotating stirring mechanism, and a second plane bearing is disposed between the rotating shaft and the other end of the rotating stirring mechanism. The rotating stirring mechanism comprises a first positioning disc and a second positioning disc, the peripheral surface of the first positioning disc is equipped with a plurality of first clamp slots, the peripheral surface of the second positioning disc is equipped with second clamp slots, the second clamp slots are corresponding to the first clamp slots, and rotating stirring rods are clamped between the second clamp slots and the first clamp slots. The second positioning disc is equipped with a sleeve disc, the sleeve disc issleeved at the end of the rotating shaft and is equipped with a positioning tube, and a drive gear is sleeved at the peripheral surface of the positioning tube. According to the invention, rotation of the rotating stirring device can be controlled conveniently, and the rotating stirring device can be convenient for stirring treatment on the polyvinyl chloride paste in the agitation tank, thus greatly improving the stirring treatment efficiency of polyvinyl chloride paste.

Owner:季晓鸣

Environment-friendly landscape garden dry branch and fallen leaf treatment system

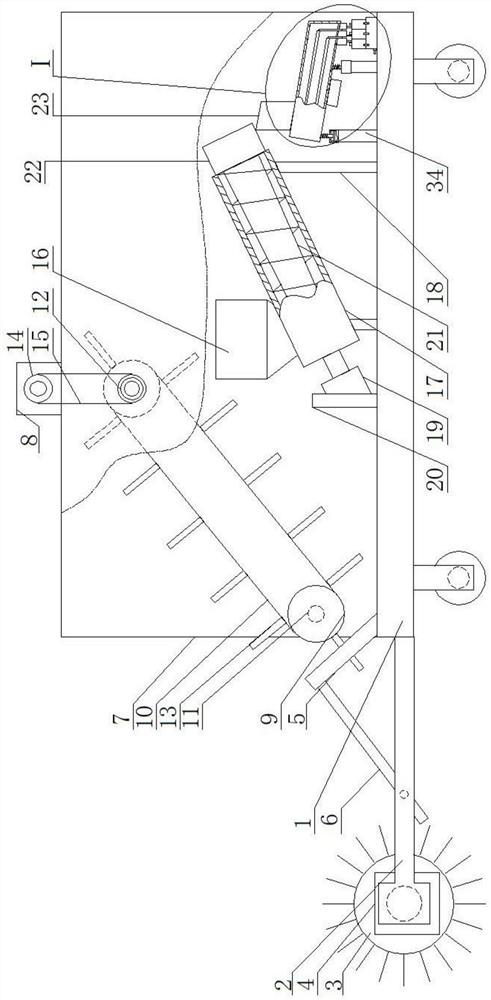

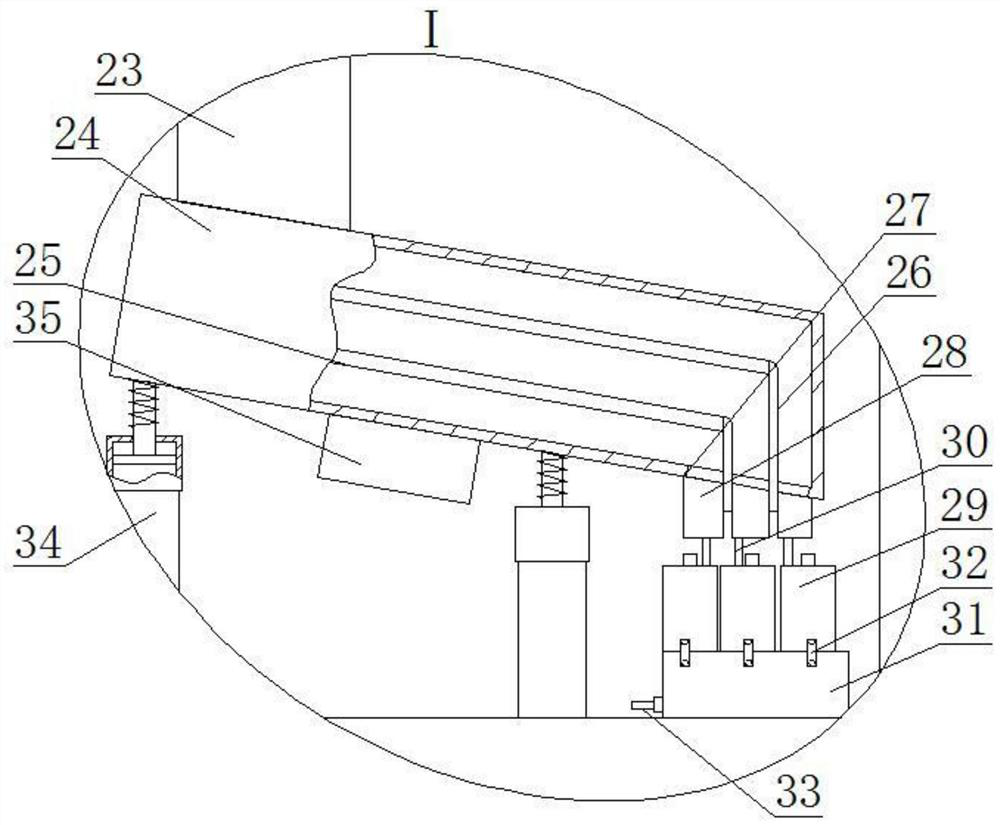

PendingCN113182331AIncreased CorruptionEasy to mix and handleSolid waste disposalRoad cleaningLeaf fallAgricultural engineering

The invention discloses an environment-friendly landscape garden dry branch and fallen leaf treatment system, and relates to the technical field of forest dry branch and fallen leaf treatment. The environment-friendly landscape garden dry branch and fallen leaf treatment system comprises a trolley frame body, wherein the trolley frame body is provided with a driving system; connecting frames are fixedly arranged at the front side and the back side of one side of the trolley frame body; a cleaning roller is arranged between the two connecting frames; and a cleaning motor is fixedly arranged at the front end of the cleaning roller; the cleaning motor is fixedly connected with the connecting frame in front. The environment-friendly landscape garden dry branch and fallen leaf treatment system has the advantages that the structural design is reasonable; the use is convenient; dry branches and fallen leaves in a garden can be collected; the collected dry branches and fallen leaves can be subjected to crushing treatment; the crushed dry branches and fallen leaves can be subjected to screening treatment; the mesh hole blockage can be avoided; the crushed dry branches and fallen leaves and a rotting liquid are subjected to sufficient mixing treatment, so that the rotting speed of the crushed dry branches and fallen leaves is accelerated; in the later period, leaves treated by the rotting liquid are buried into planting pits; the treatment on the leaves is effectively completed; and the practicability is high.

Owner:李玉敏

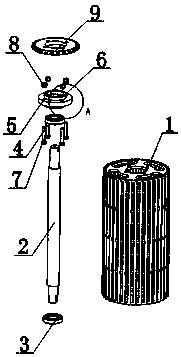

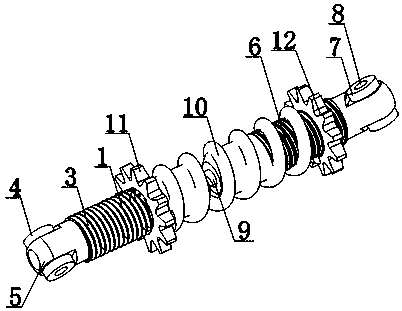

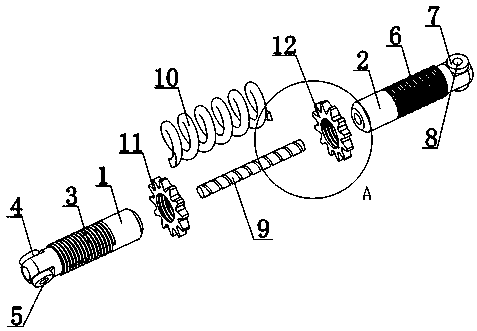

Stirring rod driving device for tissue pounding machine

InactiveCN109248775AEasy to mix and handleQuick stirring processRotary stirring mixersTransportation and packagingButt jointScrew thread

The invention discloses a stirring rod driving device for a tissue pounding machine, wherein the stirring rod driving device comprises a first rotary tube and a second rotary tube. The outer surface of the first rotary tube is provided with a first external thread, and one end of the first rotary tube is provided with a first installation tube; the axial position of the first installation tube isprovided with a first installation groove; the outer surface of the second rotary tube is provided with a second external thread, and one end of the second rotary tube is provided with a second installation tube; the axial position of the second installation tube is provided with a second installation groove; the first installation tube is arranged perpendicular to the second installation tube; the other end of the first installation tube is in butt joint with the other end of the second installation tube through a butt joint shaft; the peripheral surface of the first rotary tube is sleeved with a first driven gear, the first driven gear is connected with the first external thread through a thread, the peripheral surface of the second rotary tube is sleeved with a second driven gear, and the second driven gear is connected with the second external thread by a thread. The rotary tubes are driven to achieve rotation by the driven gears, so a stirring rod can be controlled to realize rotation.

Owner:黄春生

Coaxial and counter-rotating self-unloading mixing equipment to promote uniform mixing of chemical raw materials

ActiveCN110585967BStir wellStir well stir wellShaking/oscillating/vibrating mixersTransportation and packagingBLENDER/MIXERProcess engineering

Owner:山西瑞峰百合化工有限公司

Extraction device for pharmacy

The invention discloses an extraction device for pharmacy. The extraction device comprises an extraction tank. An inner tank is fixed on the inner wall of the extraction tank. The inner tank is made of a thermo-conductive material. A heating cavity is formed between the inner tank and the extraction tank. The inner wall of one side of the heating cavity is provided with a water inlet. The inner wall of one side of the heating cavity and the inner wall of the bottom of the heating cavity are both provided with a water outlet. The inner walls of the water outlets and the inner wall of the waterinlet are all provided with a sealing plug. Two sides of the inner wall of the bottom of the heating cavity are both fixedly provided with a heater. One side of the outer wall of the top of the extraction tank is provided with a feed inlet. A feed hopper is fixed on the inner wall of the feed inlet. The outer wall of one side of the extraction tank is provided with an exhaust pipe. The provided extraction device can avoid the situation that the temperature in direction heating is uncontrollable and the extraction is influenced; and moreover, the extraction device can inhibit the degradation ofheating efficiency. The phenomenon that the medicaments are spilled out due to the quick stirring speed of a stirring rack, or the work efficiency is low due to the low stirring speed of the stirringrack can be avoided.

Owner:湖北正通药业有限公司

Hot flattening device for film laminating processing

PendingCN113085329AEasy and quick smoothingImprove applicabilityLaminationLamination apparatusEngineeringHot press

The invention discloses a hot flattening device for film laminating processing, and relates to the technical field of film laminating processing. Aiming at the problems that bubbles are easy to generate during film laminating of products in the prior art, and bubbles are manually smoothed, so that the efficiency is relatively low, and the film laminating is inconvenient, the following scheme is provided: the device comprises a containing plate, a supporting plate is fixedly connected to the left side of the top of the containing plate, a rack is fixedly connected to the right side of the supporting plate, a transverse moving mechanism is arranged below the rack, a fixing plate fixedly connected with the supporting plate is arranged below the transverse moving mechanism, a hot pressing mechanism is arranged below the fixing plate, the transverse moving mechanism is fixedly connected with the hot pressing mechanism, and a stirring and heating mechanism is arranged in the hot pressing mechanism. According to the invention, a hot-pressing roller can be uniformly heated conveniently, the heat conduction efficiency is improved, hot-pressing and flattening can be automatically carried out conveniently, the flattening efficiency is improved, and fitting of a laminated film is facilitated.

Owner:滁州晨润工贸有限公司

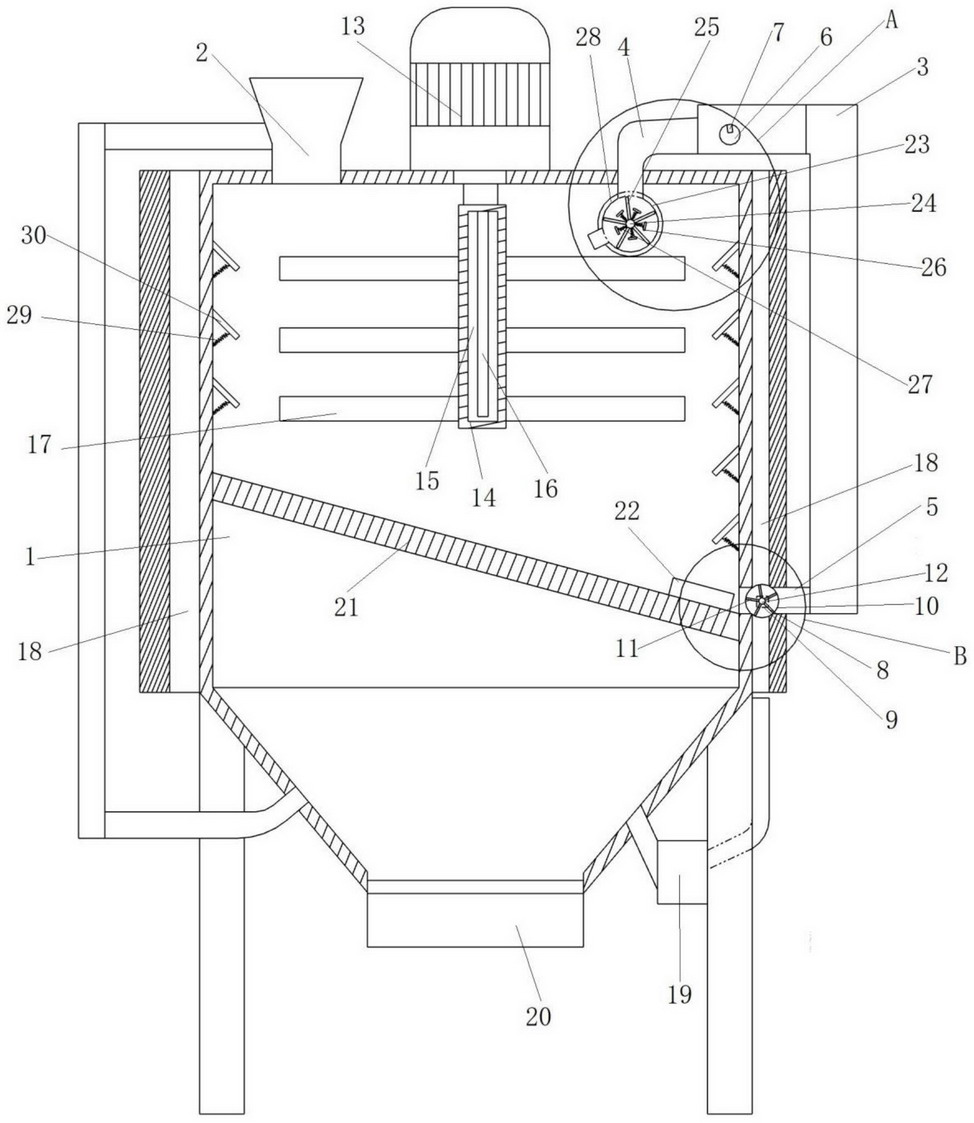

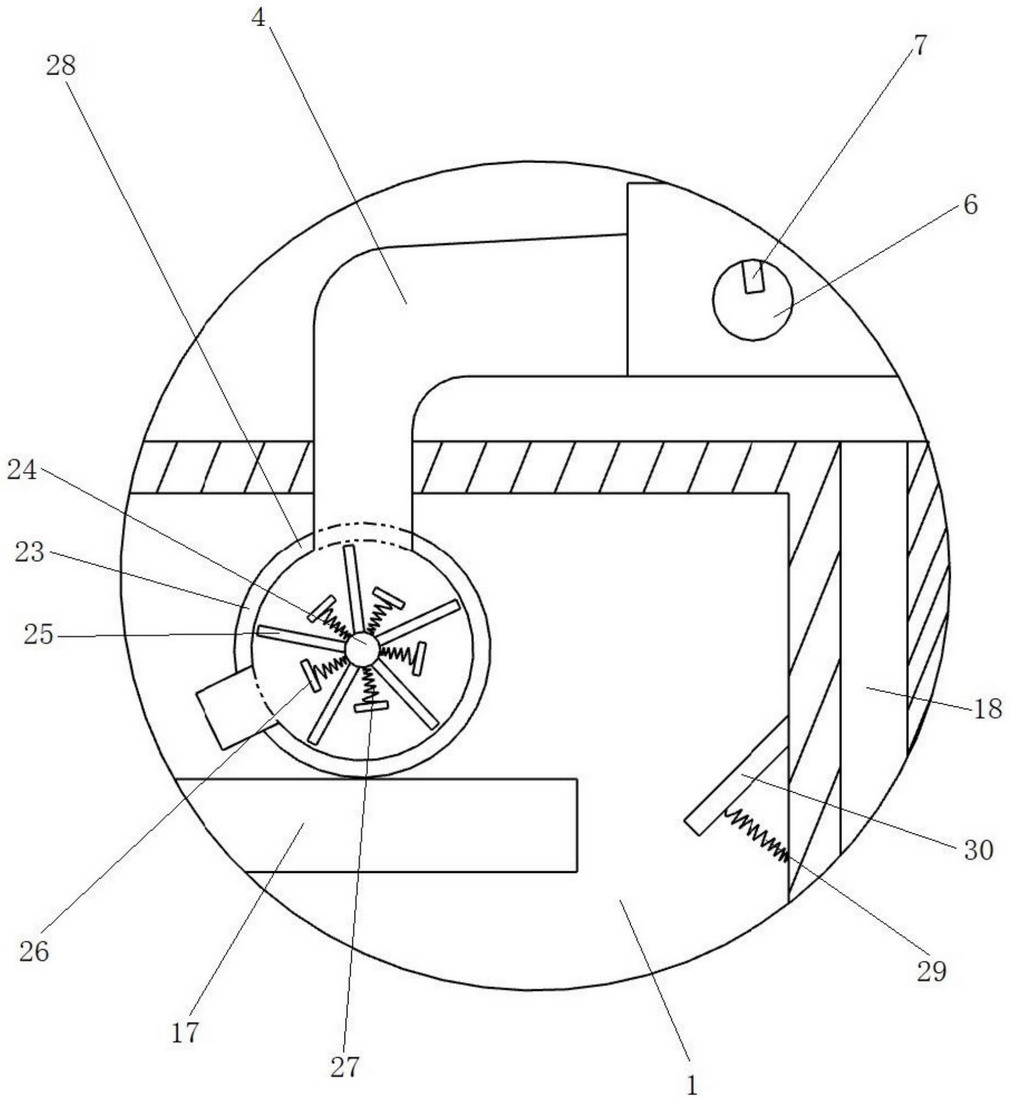

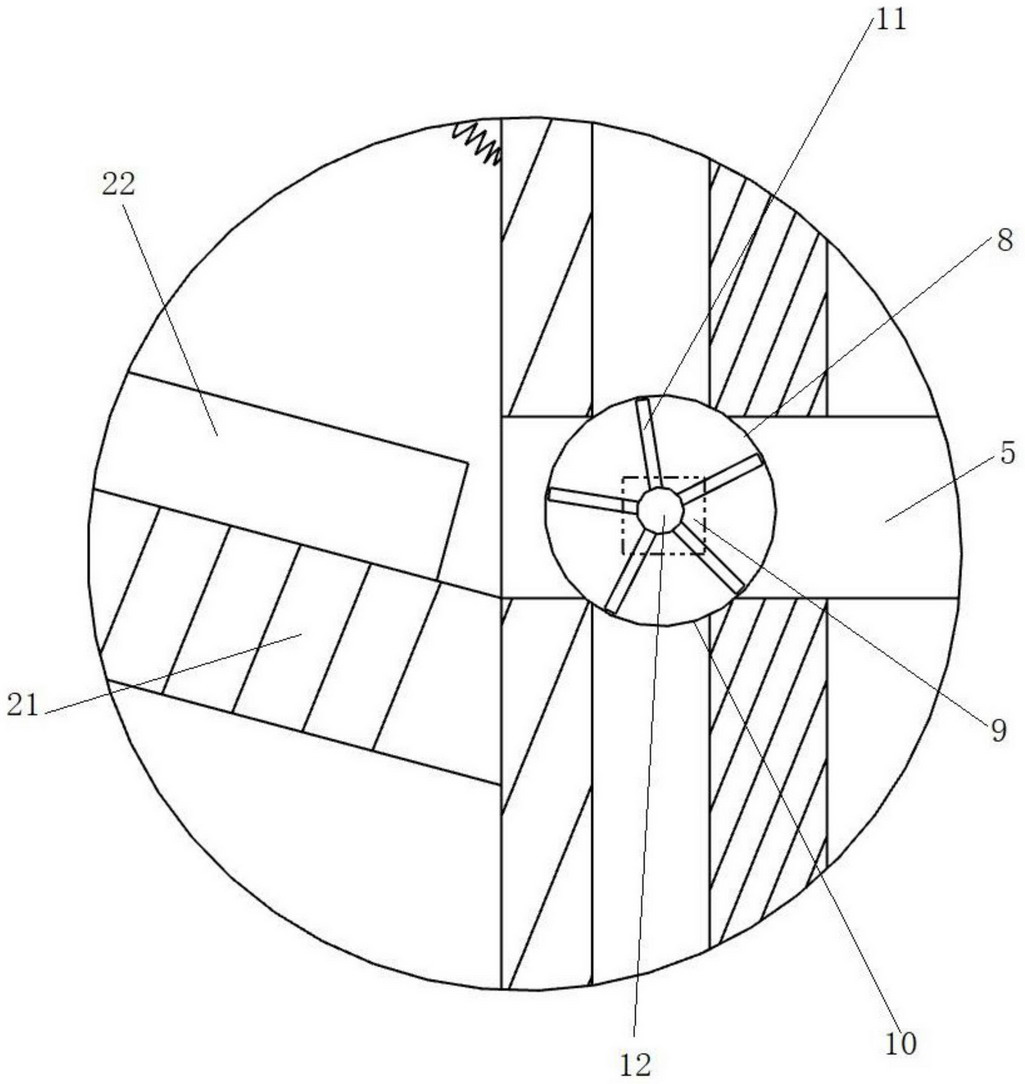

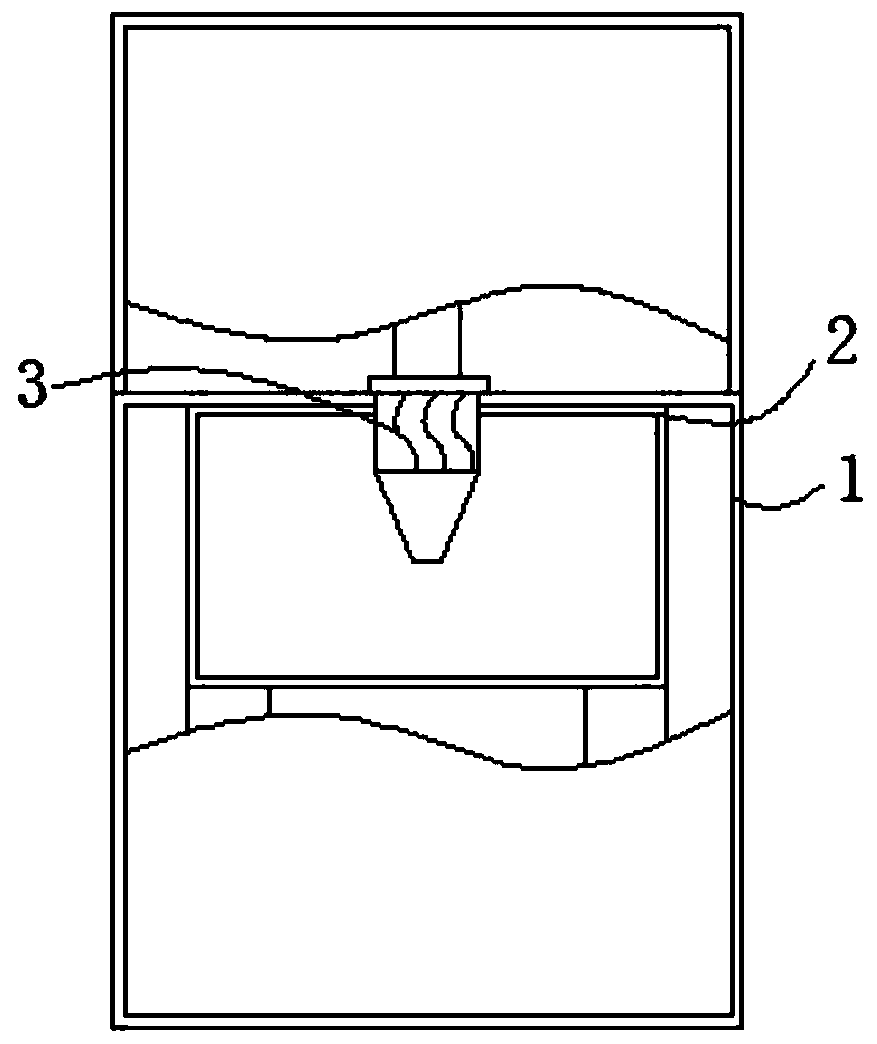

Closed household garbage stirring and treating equipment

InactiveCN107377590AStir wellEasy to mix and handleSolid waste disposalGrain treatmentsArchitectural engineeringEngineering

The invention discloses a closed domestic garbage mixing treatment equipment, which comprises a compression box, the upper surface of the compression box is provided with a stirring tank, the lower end of the mixing tank is a conical structure, the lower surface of the mixing tank and the compression box There are four connecting columns between the upper surfaces. The upper surface of the mixing tank is equipped with a motor. The output shaft of the motor runs through and extends to the inside of the mixing tank. The end of the output shaft of the motor is connected to the stirring shaft through a coupling. It can drive the stirring shaft to rotate, and the crushing rod can be driven to rotate through the stirring shaft, so that the garbage can be crushed, making it more convenient to crush the garbage. The compression plate can be driven to compress the garbage through the cylinder telescopic rod, so that the garbage can be compressed. The domestic waste mixing treatment equipment has a simple structure and is easy to operate. It can not only crush the garbage, but also stir the garbage, and can also compress the garbage, making it more convenient to dispose of the garbage.

Owner:成都市朗慧科技有限公司

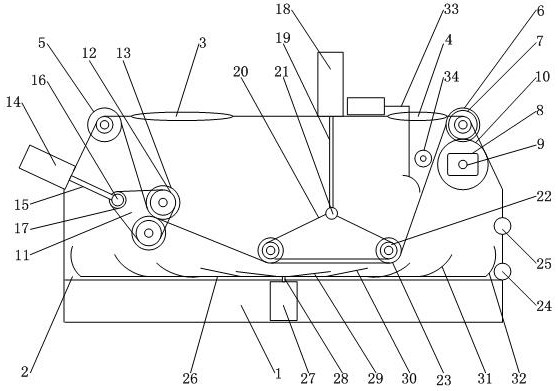

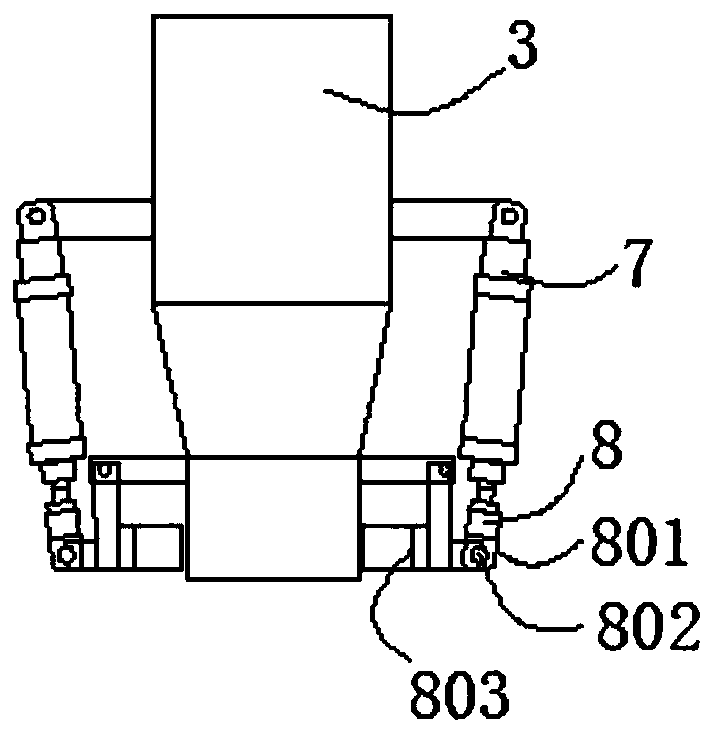

Strip-shaped side pull gauge hot-drying film forming device of printing machine

InactiveCN109367232AEasy to mix and handleQuick stirring processPrinting press partsHydraulic cylinderBiochemical engineering

The invention discloses a strip-shaped side pull gauge hot-drying film forming device of a printing machine. The strip-shaped side pull gauge hot-drying film forming device comprises a machine frame,wherein a plurality of hydraulic cylinders are arranged at the top of the machine frame, a piston rod is arranged at the lower part of the hydraulic cylinders, a lock cylinder is arranged at the lowerend of the piston rod, a top frame is arranged at the top of the machine frame, a liquid inlet tank is arranged on the top surface of the top frame, a liquid separation shell is arranged below the liquid inlet tank, an infusion pipe is arranged between the liquid separation shell and the liquid inlet tank, an infusion pump is arranged between the infusion pipe and the liquid inlet tank, a plurality of shunting pipes are arranged at the lower part of the liquid separation shell, a liquid spraying shell is arranged at the lower end of each shunting pipe, and a plurality of liquid spraying holesare formed in the surface of the liquid spraying shell; limiting pipes are arranged at the lower part of the liquid spraying shell, a connecting plate is arranged between the limiting pipes, a plurality of buffer springs are arranged on the connecting plate, a positioning cylinder is arranged on the upper portion of the buffer springs, and the positioning cylinder is arranged under the lock cylinder. According to the strip-shaped side pull gauge hot-drying film forming device, the rapid stirring treatment efficiency of the pasty polyvinyl chloride resin liquid is greatly improved; so that a protective film can be formed on the surface of the strip-shaped side pull gauge; and the film coating efficiency is greatly improved.

Owner:SUZHOU PISI SOFTWARE DESIGN CO LTD

Rapid powder stirring device for interior decoration

InactiveCN111558321AEasy to mix and handleReduce wasteShaking/oscillating/vibrating mixersTransportation and packagingElectric machineryLeft lateral wall

The invention relates to a large range, and especially relates to a rapid powder stirring device for interior decoration. The device comprises a connecting frame, a first opening is formed in the leftside wall of the connecting frame, the first opening is connected with a cam through a rotating shaft, the rotating shaft is connected with a connecting rod through a belt, a first helical gear is arranged on the front side of the connecting rod, the upper side of the first helical gear is engaged with a second helical gear, the second helical gear is mounted at the upper end of a threaded rod, the threaded rod is in threaded connection with a connecting plate, a stirring motor is mounted in the middle of the connecting plate, a stirring shaft is arranged below the stirring motor, a stirringrod is mounted on the stirring shaft, a connecting seat is mounted at the bottom of a stirring cylinder, a flow guiding tank is arranged in the connecting seat, material discharging ports are arrangedin four corners of the upper end of the flow guiding tank, and scraping plates are arranged at the left end and the right end of the upper side of the connecting seat. The stirring efficiency of thedevice can be effectively improved, the cleaning of the inner wall of the device is convenient, the powder waste is reduced, and the use of the device is convenient.

Owner:闫顺

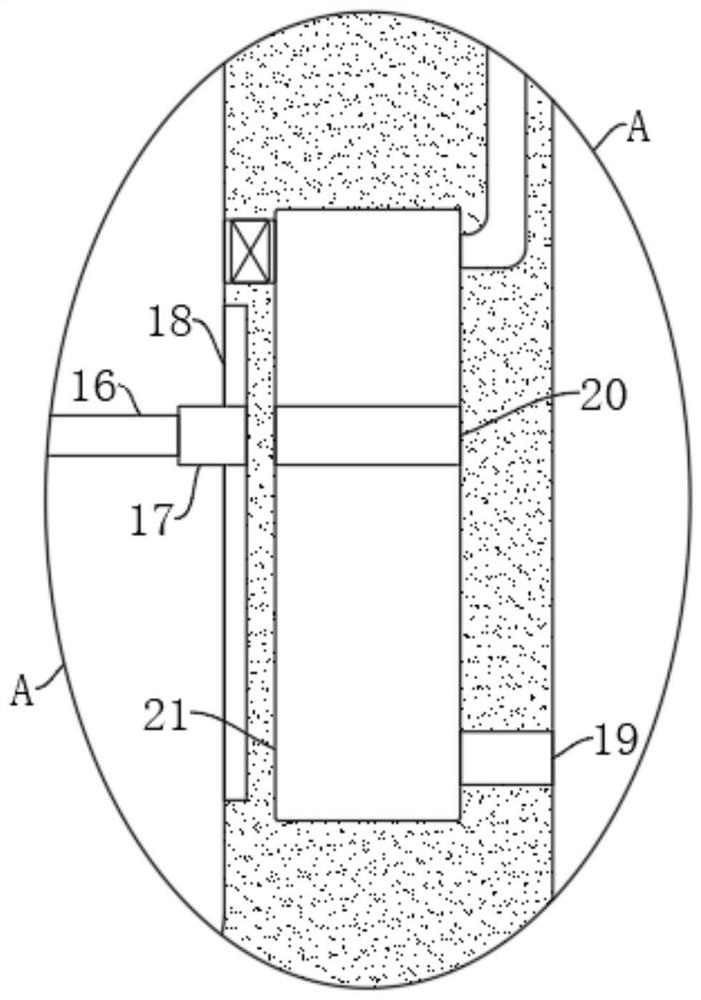

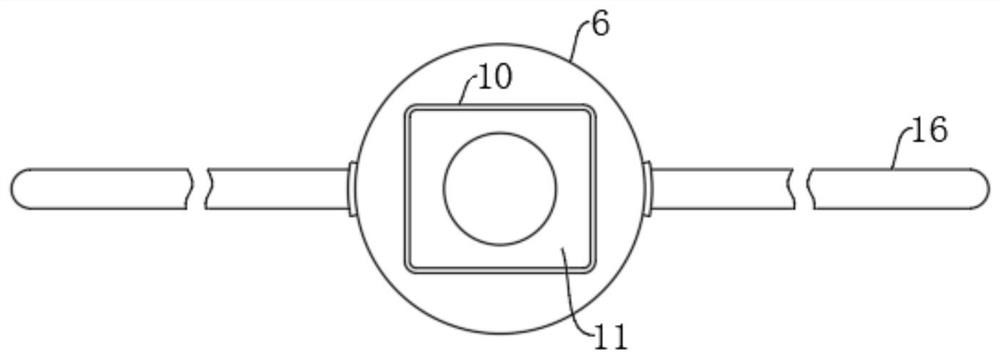

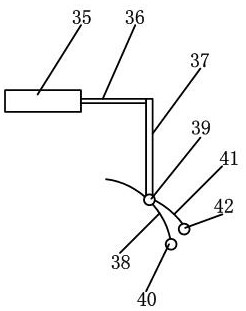

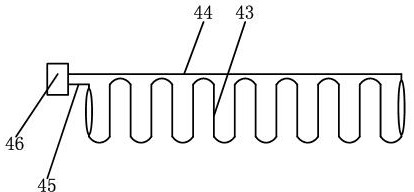

A pesticide spreading system based on an unmanned aerial vehicle and a pesticide storage station

InactiveCN108995811AImprove the mixing effectEasy to mix and handleAircraft componentsWithdrawing sample devicesChemical solutionEngineering

The invention discloses a pesticide spreading system based on an unmanned aerial vehicle and a pesticide storage station, which comprises a pesticide liquid treatment tank, a heating coil is also arranged on the outside wall of the pesticide liquid treating tank. a heat coil is uniformly coiled on a pesticide liquid treatment tank in a serpentine bend shape, an internal thread is arranged at the inner barrel center of the lifting inner barrel and an external thread adapted to the internal thread is arranged on the outer side wall of the rod body of the rotating screw, The agitating blade is arranged on the shaft body side wall of the agitating shaft, the spray coil pipe is fixedly installed on the unmanned aerial vehicle, and the inflatable balloon is connected to the manual air suction and deflation mechanism outwardly through the inflatable thin pipe. The invention improves the mixing effect of the pesticide liquid, can not only meet the stirring work of different height positions ofthe chemical solution in the tank body, but also facilitate the opening and closing of the top opening of the pesticide liquid treatment tank, and can carry out sampling operation.

Owner:HFEI PUBANG AGRI TECH CO LTD

Brick production feeder

InactiveCN105538493AChange the direction of outputEasy to mix and handleFeeding arrangmentsAuxillary shaping apparatusBrickEngineering

The invention provides a brick production feeder. The brick production feeder comprises a host machine; a main control device is arranged on the inner side edge of the host machine; a first extension motor is arranged on the outer side edge of the host machine, and is connected with a first compression plate arranged in the host machine; the first compression plate is arranged in a compression cavity in the host machine; a gravity sensor is arranged at the bottom of the compression cavity, and is electrically connected with a top rotating shaft arranged on the side wall of the host machine; the top rotating shaft is connected with a discharge opening plate; and the host machine is communicated with a discharge pipe.

Owner:WUQIAO BUILDING MATERIAL IND CO LTD OF YIBIN CITY SICHUAN PROVINCE

Integrated packaging machine

PendingCN109720651AEasy to mix and handlePrevent affecting the packaging effectSolid materialEngineeringPackaging machine

The invention discloses an integrated packaging machine, and relates to the technical field of packaging. The integrated packaging machine comprises a machine body and a bag clamping assembly. A machine frame is arranged on the inner side of the machine body, and a hopper penetrates through the top of the machine frame. The bag clamping assembly is arranged on an outer wall of the hopper, the bagclamping assembly internally comprises a connecting rod, and a clamping block is movably arranged on one side under the connecting rod. The integrated packaging machine has the beneficial effects thatthrough the arrangement of the clamping block, a connecting shaft, the connecting rod, a rotating shaft and a stirring rod, the clamping block and the connecting rod constitute a rotating structure through the connecting shaft; through the action of the clamping block, a packaging bag can be clamped, so that materials slipping from the bottom of the hopper enter the packaging bag; and under the action of the rotating structure composed of the clamping block and the connecting shaft, a second cylinder is enabled to start and then drive the connecting rod and the clamping block to move together, so that the packaging bag loaded with materials is unloaded, and the unloading operation is carried out repeatedly, so that packaging work of the materials is completed.

Owner:无锡励远智能装备有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com