Hot flattening device for film laminating processing

A film-coating, stirring and heating technology, which is applied to lamination devices, layered products, lamination, etc., can solve the problems of inconvenient film lamination, low efficiency, and easy generation of air bubbles, etc., to achieve convenient and uniform heating and simple operation , the effect of improving the efficiency of heat conduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

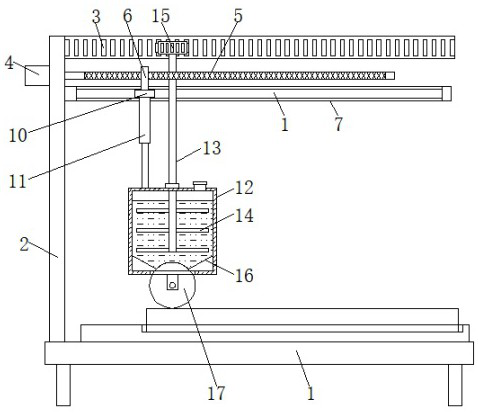

[0027] refer to Figure 1-3 and Figure 6 : A thermal smoothing device for film coating, comprising a placement plate 1, a support plate 2 is fixedly connected to the left side of the top of the placement plate 1, a rack 3 is fixedly connected to the right side of the support plate 2, and a There is a lateral movement mechanism, a fixed plate 7 fixedly connected to the support plate 2 is arranged below the lateral movement mechanism, and a heat-pressing mechanism is arranged under the fixed plate 7, and the lateral movement mechanism is fixedly connected with the heat-pressing mechanism, and the inside of the heat-pressing mechanism Equipped with a stirring heating mechanism.

[0028] In the present invention, the lateral movement mechanism includes a drive motor 4 fixedly connected to the left side of the support plate 2, the output shaft of the drive motor 4 is fixedly connected with a reciprocating screw mandrel 5, and the external threaded sleeve of the reciprocating scre...

Embodiment 2

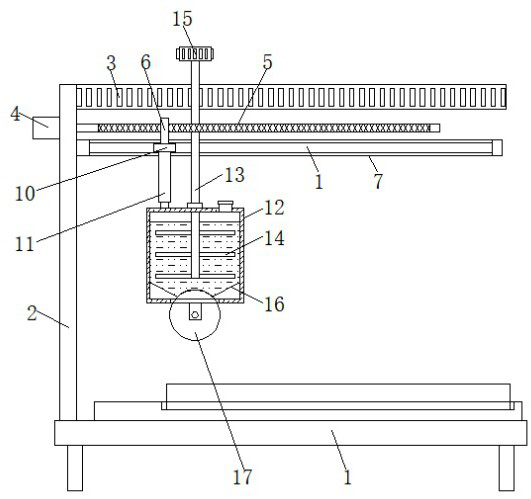

[0032] refer to figure 1 , Figure 3-5 : A thermal smoothing device for coating processing. In the present embodiment, the stirring heating mechanism includes a rotating shaft 13 that is movably sleeved inside the water storage tank 12, and the side array of the rotating shaft 13 stretching into the water storage tank 12 is provided with multiple The electric heating rod 14, the top of the rotating shaft 13 is fixedly connected with a gear 15, and the gear 15 is meshed with the rack 3 for transmission; when the water storage tank 12 moves horizontally, it will drive the rotating shaft 13 to move, and the rotating shaft 13 will drive the gear 15 on the surface of the rack 3 Rotate, thereby drive rotating shaft 13 to rotate, and rotating shaft 13 drives electric heating rod 14 to rotate again, makes things convenient for electric heating rod 14 to heat water evenly like this.

[0033] In the present invention, the bottom of the water storage tank 12 is provided with an installa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com