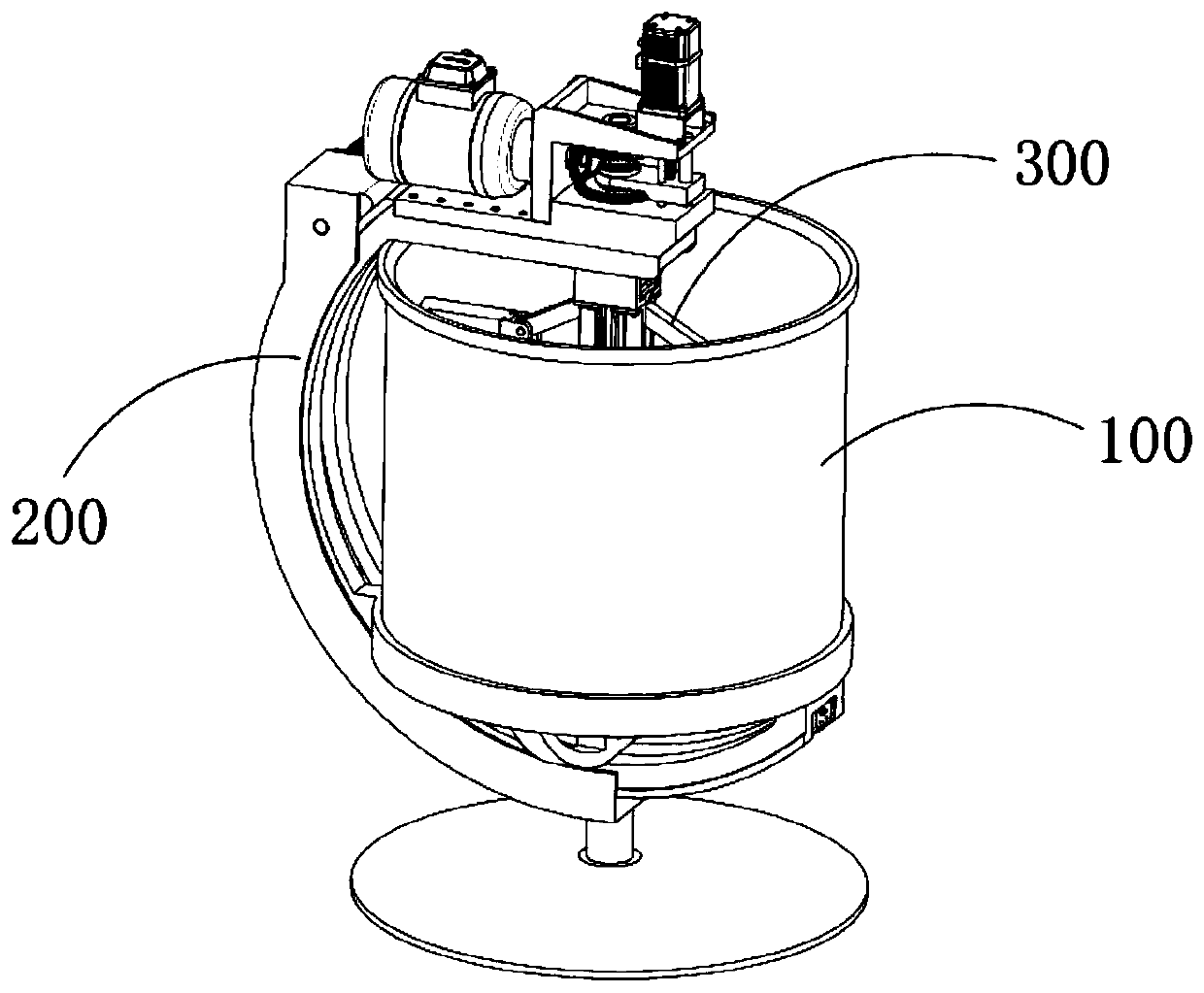

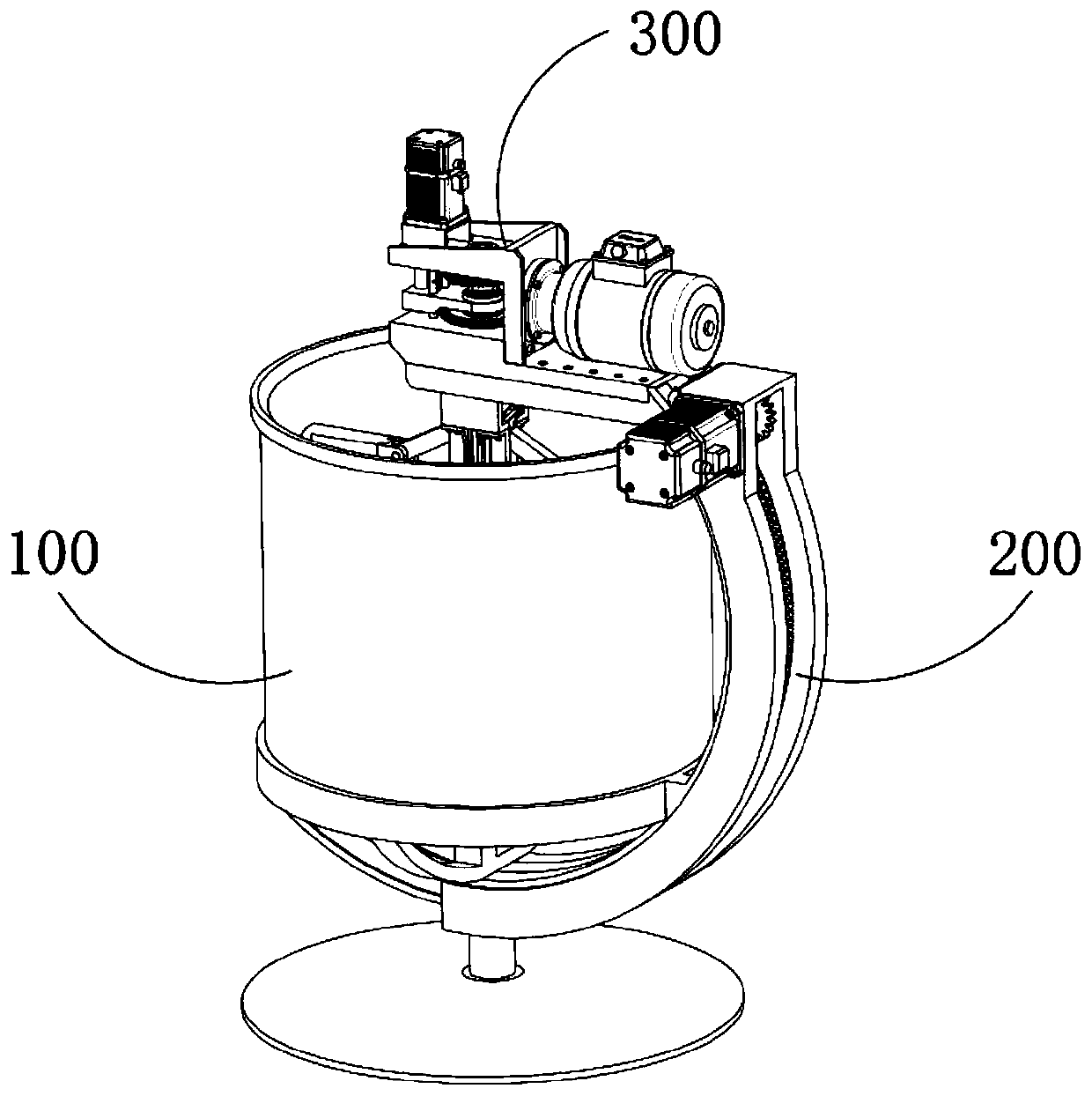

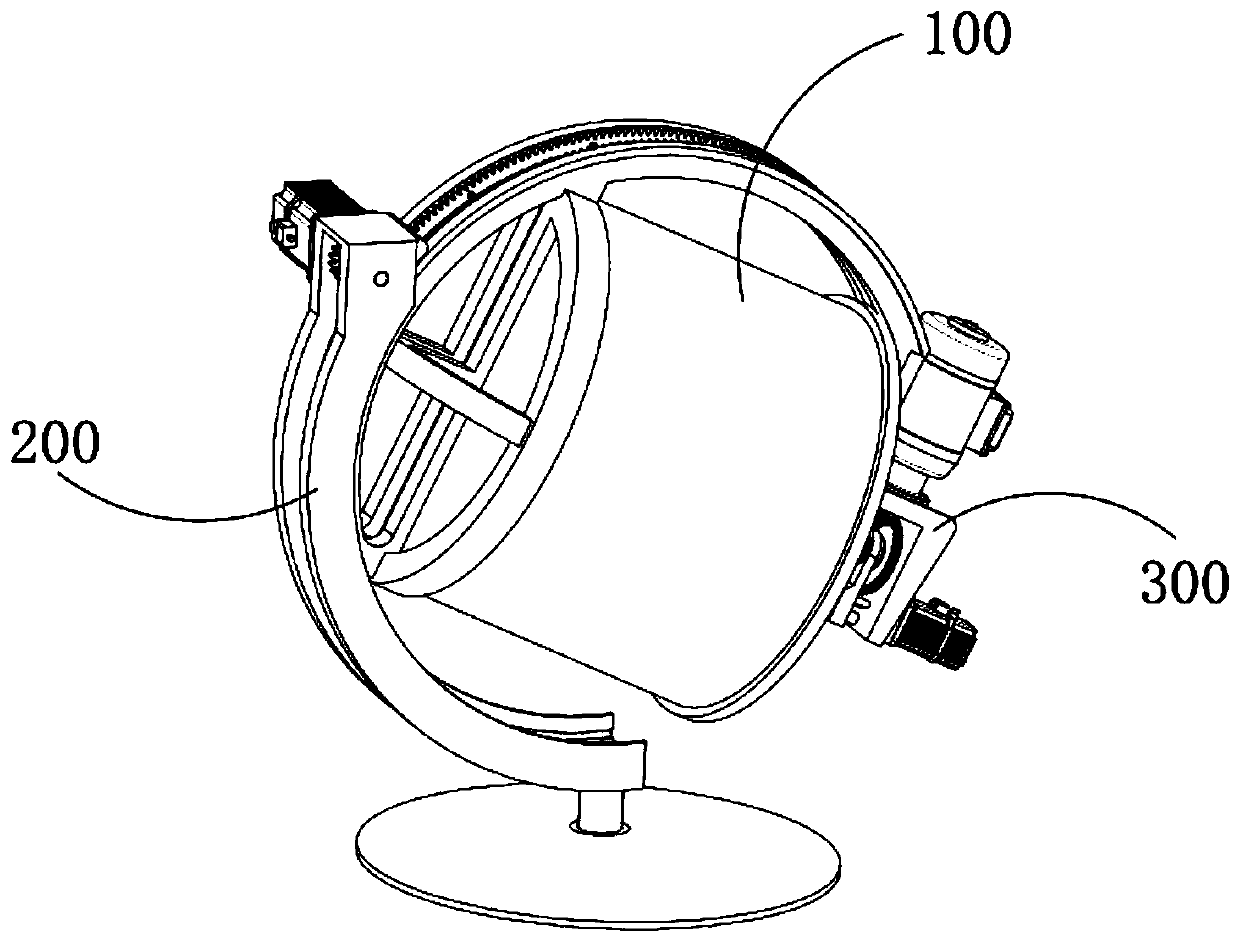

Coaxial opposite-direction self-unloading stirring equipment for promoting uniform mixing of chemical raw materials

A technology of uniform mixing and chemical raw materials, applied in mixers, mixer accessories, shaking/oscillating/vibrating mixers, etc., can solve the problems of high labor intensity and uneven mixing, etc., to reduce labor intensity and achieve better mixing effect. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0068] The advantage of the present invention for stirring the mixture is that the automatic dumping mechanism can be opened after the mixture is fully stirred evenly and the stirring tank is arranged in an inclined manner, then the mixture can be poured out, and then the automatic dumping mechanism can be reversed to restore the stirring tank To the original state, the entire discharge process of the mixture is fully automated, without the need for manual operation by the staff, which greatly reduces the labor intensity of the staff; the counter-rotating stirring mechanism adjusts the inner ring mixture through the cooperation of the stirring block rotation, up and down lifting, and close to / away from the rotating shaft. Thoroughly and uniformly stir the mixture through the rotation of the stirring plate, up and down, and close to / away from the rotating shaft to fully and evenly stir the mixture of the outer ring. At the same time, the rotation of the stirring plate is opposite...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com