Self-circulation pesticide processing and mixing system

A mixing system and self-circulation technology, applied in mixers, mixers with rotary stirring devices, fluid mixers, etc., can solve the problems of single stirring method, insufficient mixing of multiple raw materials, and affecting the quality of pesticide products, etc. To improve the mixing effect and improve the sufficient effect of mixing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

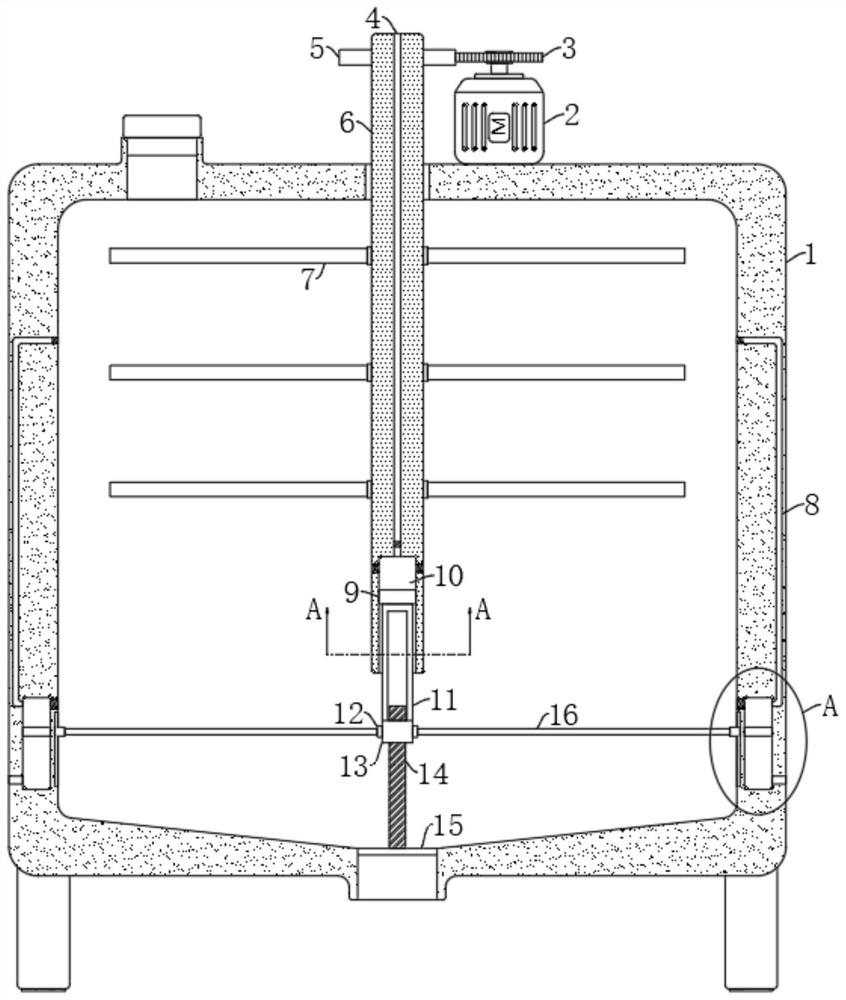

[0023] refer to Figure 1-3 , a self-circulating pesticide processing and mixing system, comprising a box body 1, a stirring mechanism is arranged inside the box body 1, the stirring mechanism includes a rotating shaft 6 that runs through and is arranged on the upper side of the box body 1, and the outer side of the rotating shaft 6 is fixedly connected with a second Gear 5, the drive motor 2 is fixedly connected to the upper side of the box body 1, the end of the output shaft of the drive motor 2 is fixedly connected to the first gear 3, the first gear 3 and the second gear 5 mesh with each other, and the rotating shaft 6 is located in the box body 1. A plurality of stirring blades 7 are fixedly connected to the outside of the inside, and the rotation of the stirring blades 7 can process the liquid;

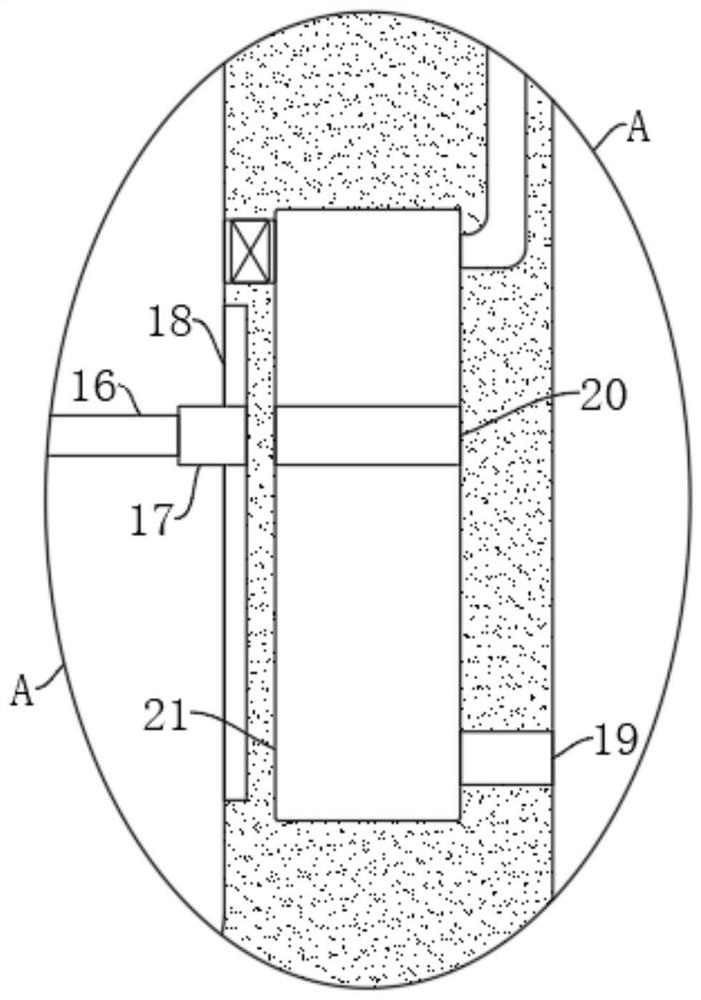

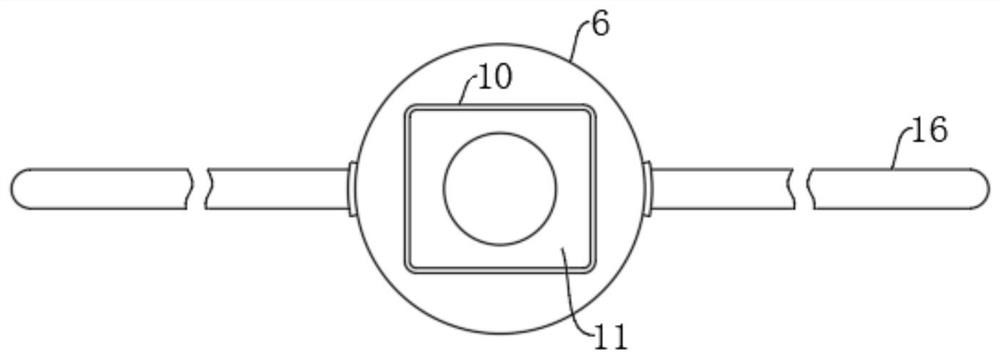

[0024] The inside of the box body 1 is provided with an air injection mechanism for liquid mixing. The air injection mechanism includes a groove 10 arranged at the lower end of ...

Embodiment 2

[0030] refer to Figure 4-5 , a self-circulating pesticide processing and mixing system, two arc-shaped grooves 27 are arranged symmetrically on the inner side of the box body 1, and a magnetic slider 26 is slidably connected to the inside of the arc-shaped groove 27, and the side wall of the magnetic slider 26 is connected to the arc-shaped The inner sides of the grooves 27 are elastically connected by a spring 25, the liquid suction port is connected with a telescopic bellows 23, the telescopic bellows 23 is fixedly connected with the magnetic slider 26, and the outer side of the rotating shaft 6 is symmetrically fixedly connected with two fixed plates 22, the fixed plate The side of 22 away from the rotating shaft 6 is fixedly connected with a magnetic plate 24 matching with the magnetic slider 26 .

[0031] In this embodiment, the fixed plate 22 can be driven to rotate during the rotation of the rotating shaft 6, and the fixed plate 22 can drive the magnetic plate 24 to ro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com