Unsaturated carboxylic acid metal salt modified ethylene-propylene-diene monomer (EPDM) and preparation method thereof

A technology of EPDM rubber and carboxylic acid metal salt, which is applied in the field of in-situ generation of unsaturated carboxylic acid metal salt modified EPDM rubber and its preparation, and can solve the problem of the adhesion between EPDM rubber and metal limited and other problems, to avoid poor compatibility, simple preparation process, and increase the effect of cross-linking density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

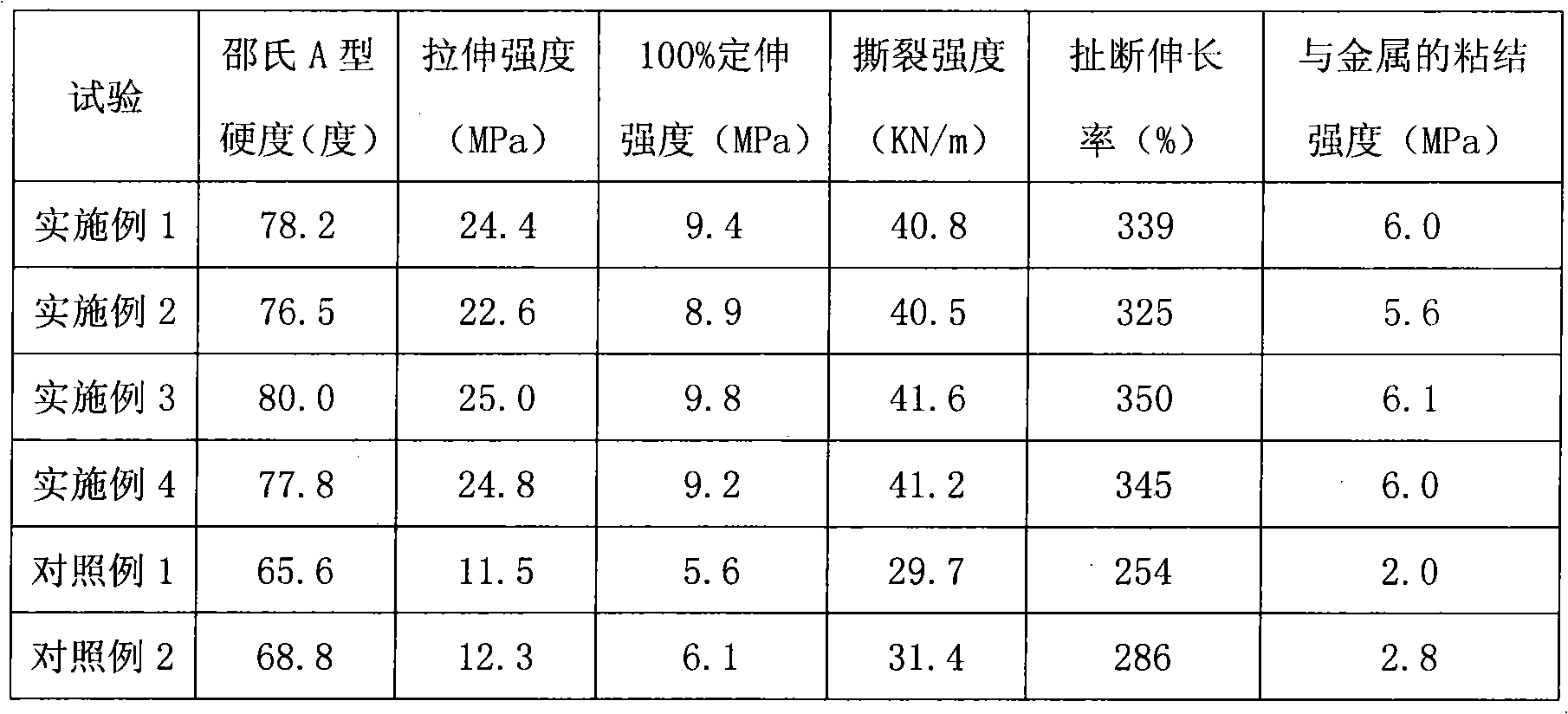

Examples

Embodiment 1

[0042] The calcium carbonate of 8 parts by weight, the sulfur of 0.5 parts by weight, the dicumyl peroxide (DCP) of 4 parts by weight and the methacrylic acid (MAA) of 18 parts by weight are mixed homogeneously, make filler mixture;

[0043] First add the EPDM rubber of 100 parts by weight in the internal mixer, then add the zinc oxide of 23 parts by weight, the N-(diethylene oxide)-2-benzothiazole sulfenamide of 0.8 parts by weight (ie Accelerator NOBS) and 0.3 parts by weight of stearic acid, then add 40 parts by weight of carbon black, finally add all the filler mixtures prepared above, after mixing for 8 minutes at 110 ° C, degum, and the discharged rubber material is placed in Thin pass on the open mill according to the conventional method, and park for 24 hours after cooling to room temperature (20-30° C.) to obtain a mixed rubber. The molar ratio of methacrylic acid and zinc oxide in the mixed rubber is 0.75: 1;

[0044] The mixed rubber was re-milled on the open mill, ...

Embodiment 2

[0048] 10 parts by weight of talcum powder, 0.3 parts by weight of sulfur, 2 parts by weight of α, α'-bis(tert-butylperoxy) dicumyl and 15.5 parts by weight of maleic acid were mixed uniformly to prepare a filler mixture ;

[0049] First add the EPDM rubber of 100 parts by weight in the internal mixer, then add the calcium oxide of 15 parts by weight, the N-cyclohexyl-2-benzothiazole sulfenamide (being accelerator CBS) of 0.5 parts by weight and 0.4 parts by weight of stearic acid, then add 50 parts by weight of carbon black, and finally add all the filler mixtures prepared above, and after mixing for 5 minutes at 115 ° C, the rubber is discharged, and the discharged rubber is placed on the open mill according to the routine The method is simple, cool to room temperature (20-30 ℃), and park for 12 hours to obtain a mixed rubber. The molar ratio of maleic acid and calcium oxide in the mixed rubber is 0.5:1;

[0050] The mixed rubber was re-milled on the open mill, and after th...

Embodiment 3

[0053] 5 parts by weight of clay, 0.8 parts by weight of sulfur, 5 parts by weight of di-tert-butyl peroxide and 31 parts by weight of acrylic acid (AA) are mixed uniformly to prepare a filler mixture;

[0054] First add 100 parts by weight of EPDM rubber in the internal mixer, then add 25 parts by weight of magnesium hydroxide, 1 part by weight of N, N-dicyclohexyl-2-benzothiazole sulfenamide (promoting agent DCBS) and 0.5 parts by weight of stearic acid, then add 30 parts by weight of carbon black, and finally add all the filler mixtures prepared above, and after mixing for 7 minutes at 120 ° C, the glue is removed, and the discharged glue is placed in the open Thin pass on the mill according to the conventional method, and park for 20 hours after cooling to room temperature (20-30° C.), to obtain a mixed rubber. The molar ratio of acrylic acid and magnesium hydroxide in the mixed rubber is 1:1;

[0055] The mixed rubber was re-milled on the open mill, and after the sheet wa...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| Shore hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com