Patents

Literature

86results about How to "Easy to handle with dust removal" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Treatment method for deformation of massive lost foam

The invention relates to a treatment method for deformation of massive lost foam. The method comprises the following steps of: correcting a deformed white die, recovering the corrected white die, making a shelf in accordance with the shape of the white die by using square steel, making anti-deformation radian, fixing the white die on the shelf, hanging the white die together with the fixing shelf, filling rugged dead angles on the white die subjected to shakeout vibration by using resin sand, spreading bottom sand in a sand box, flatly placing the white die on the bottom sand in the sand box,fixing the easily deformed part of the white die by using a refractory brick, and starting uniform shakeout, wherein the front and back, left and right height fall does not exceed 15 centimeters; compacting for 45 seconds; and finally discharging the top sand, and performing compaction after the top sand is flush with the upper opening of the sand box. By the method, the deformation problem of the massive lost foam is effectively solved, human-made defects and waste products are reduced, and the produced product has high precision and high surface finishment.

Owner:翼城县福旺铸造实业有限公司

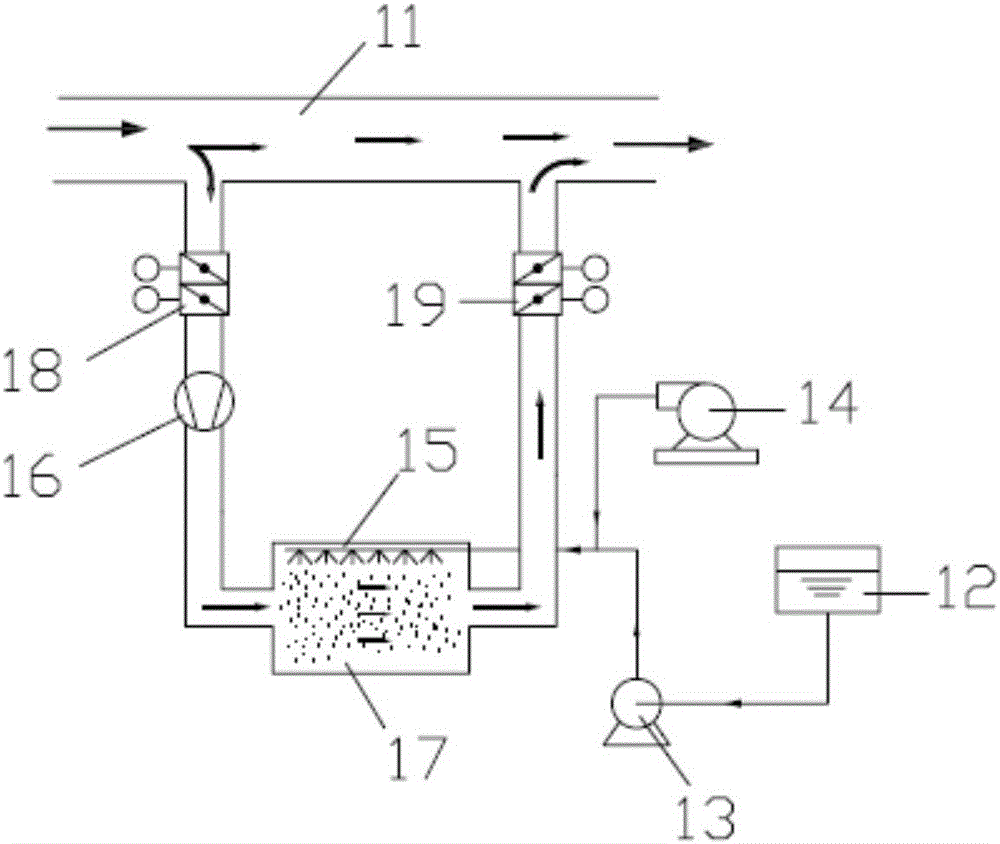

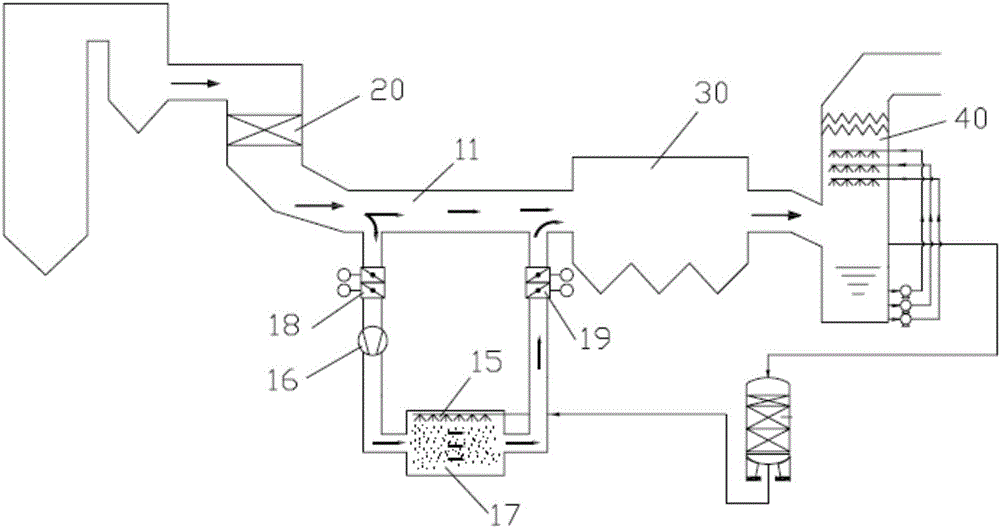

Power plant desulfurization wastewater bypass treatment system and method and flue gas treatment system and method

InactiveCN105879542AAvoid secondary pollutionSave energyCombination devicesWater/sewage treatment by heatingFlueEvaporator

The invention discloses a power plant bypass treatment system and method for desulfurization wastewater, and a flue gas treatment system and method. The power plant bypass system for desulfurization wastewater treatment includes: main flue, spray water tank, water pump, air compressor, atomization spray device, induced draft fan, evaporator, inlet baffle and outlet baffle; water pump and spray water tank respectively , The atomizing spray device is connected; the air compressor is connected with the atomizing spray device; the atomizing spray device is set in the evaporator; the first end of the main flue is connected with the induced draft fan; between the duct and the induced fan; the induced fan communicates with the evaporator; the evaporator communicates with the second end of the main flue; the outlet baffle is set between the evaporator and the main flue; end flows to its second end. The power plant bypass treatment system and method for desulfurization wastewater and the flue gas treatment system and method of the present invention realize zero discharge of desulfurization wastewater in the process of power plant flue gas treatment and avoid secondary pollution caused by desulfurization wastewater.

Owner:SHANGHAI LONGKING ENVIRONMENTAL PROTECTION

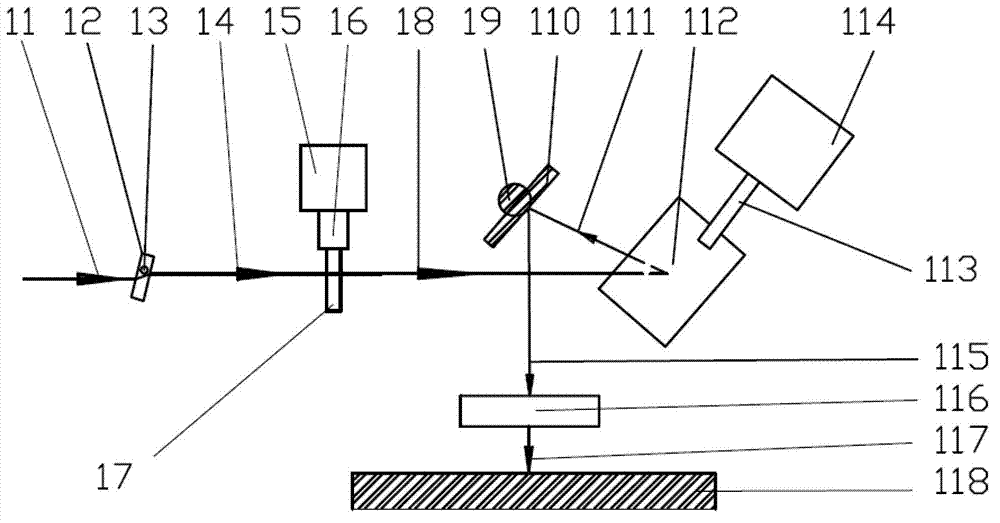

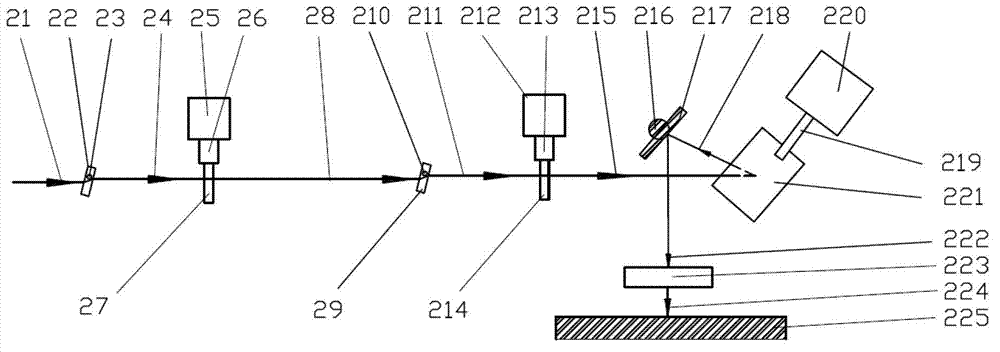

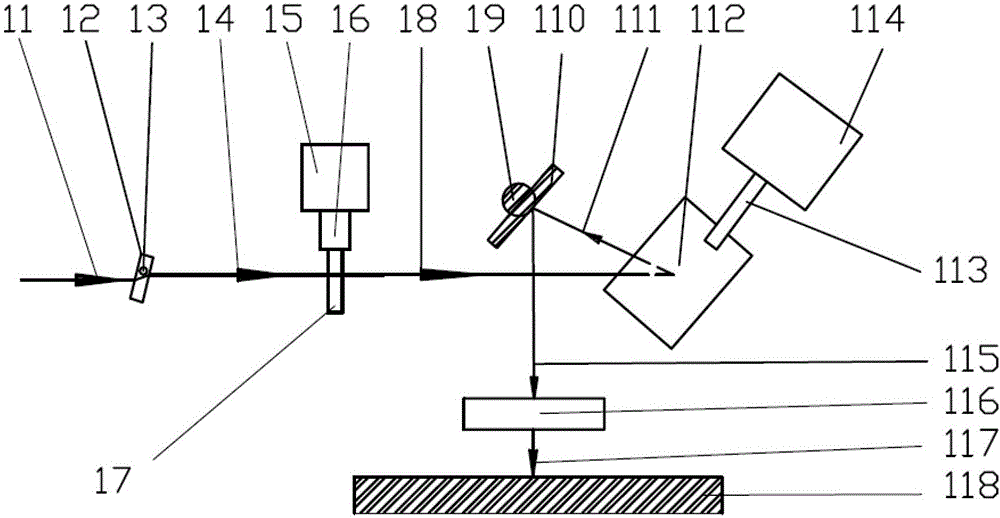

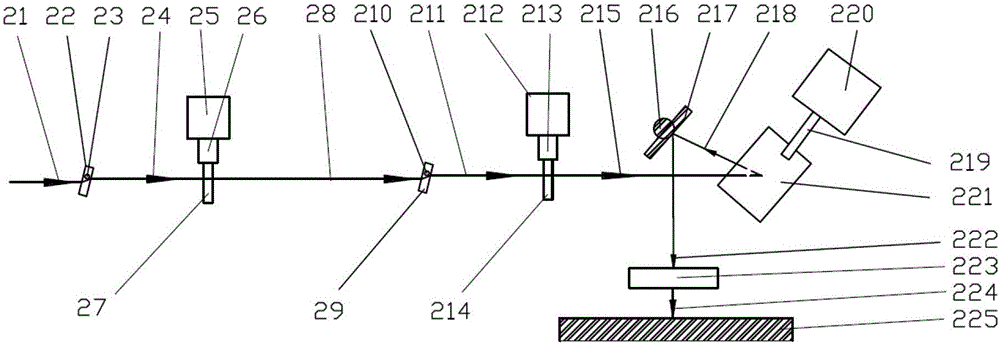

Large-size high-speed micropore drilling system

ActiveCN103203552AQuick switchImprove drilling efficiencyLaser beam welding apparatusFine structureLight beam

The invention relates to a large-size high-speed micropore drilling system which comprises a light beam space modulation module and a galvanometer scanning flat field focusing module. Particularly, the light beam space modulation module, particularly a plurality of transparent flat optical elements are combined with the galvanometer scanning flat field focusing module, the light beam space modulation module is used for modulating the space trace of a laser light beam, the galvanometer scanning flat field focusing module is used for focusing laser and rapidly switching laser spots at different machining positions, and the two modules are in division and cooperation. By the aid of the scheme, large-size micropore drilling can be realized, laser drilling efficiency and drilling quality are greatly improved, the large-size high-speed micropore drilling system is quite suitable for drilling straight holes, laser light beam filling and scanning shapes and sizes can be dynamically controlled, micropore drilling pore diameters can be dynamically changed, and fine structures can be flexibly machined.

Owner:张立国

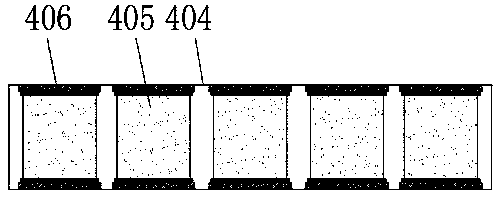

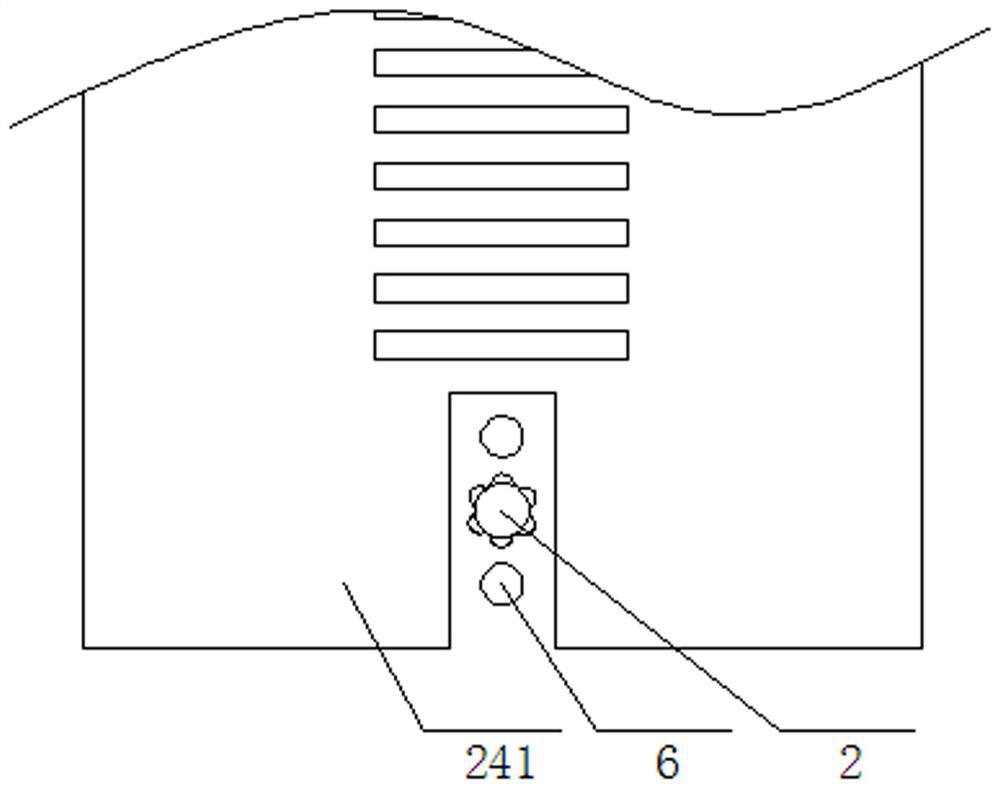

Belt conveyor with closed structure for mechanical manufacturing

InactiveCN107758235APrevent fallingClose contactLighting applicationsMechanical apparatusEngineeringConveyor belt

A belt conveyor with a closed structure for mechanical manufacturing, including a conveyor belt, an adjustment baffle and a lighting lamp; the bottom of the device body is set as a device support frame; the top of the device support frame is welded with a fixing frame; the The upper end of the fixed frame is fixedly provided with a cover plate fixing column, and the top of the cover plate fixing column is fixed with an upper cover plate by bolts; a vacuum cleaner is installed on the top of the upper cover plate, and the top of the vacuum cleaner is provided Dust suction pipe; the inner top of the upper cover is fixed with a spray pipe; the hinges on both sides of the upper cover are connected with side baffles; the side baffles are composed of a handle, a lock and an observation window. And the side baffle is fixed on the outer side wall of the fixing frame through the lock buckle. The belt conveyor with closed structure used for machine manufacturing is equipped with lighting lamps symmetrically arranged on the inclined wall inside the upper cover plate, which is convenient for lighting and observation of the transmission situation inside the device body, so as to find problems in time and solve them as soon as possible.

Owner:金坤学

Novel conveying equipment for garment production

ActiveCN111115141ANot easy to slipWill not be damagedMechanical cleaningPressure cleaningManufacturing lineSizing

Novel conveying equipment for garment production comprises an electric sliding rail of a hanging type conveyer. A plurality of first sliders are installed in the electric sliding rail in a matched mode. First electric telescopic rods with downward movable rods are fixedly installed at the bottoms of the first sliders correspondingly. Vertical plates are hinged to the lower ends of the movable rodsof the first electric telescopic rods. Rectangular blocks are fixedly installed on the front side walls of the movable rods of the first electric telescopic rods. Fifth electric telescopic rods are arranged on the lower sides of the rectangular blocks. Elastic telescopic pipes with closed upper and lower end openings are fixedly installed at the bottoms of the vertical plates through connection rods. Through a reasonable structure, garment sizing, garment dedusting, garment ironing, garment folding, packaging and other series of automatic processing procedures are achieved, a garment production line is shortened, thus the needed plant area and garment production time are reduced, the garment processing process is more automatic, the phenomenon of too many unqualified garment products caused by errors of manual garment treatment is avoided, and garment production quality is improved.

Owner:潜江东颢制衣有限公司

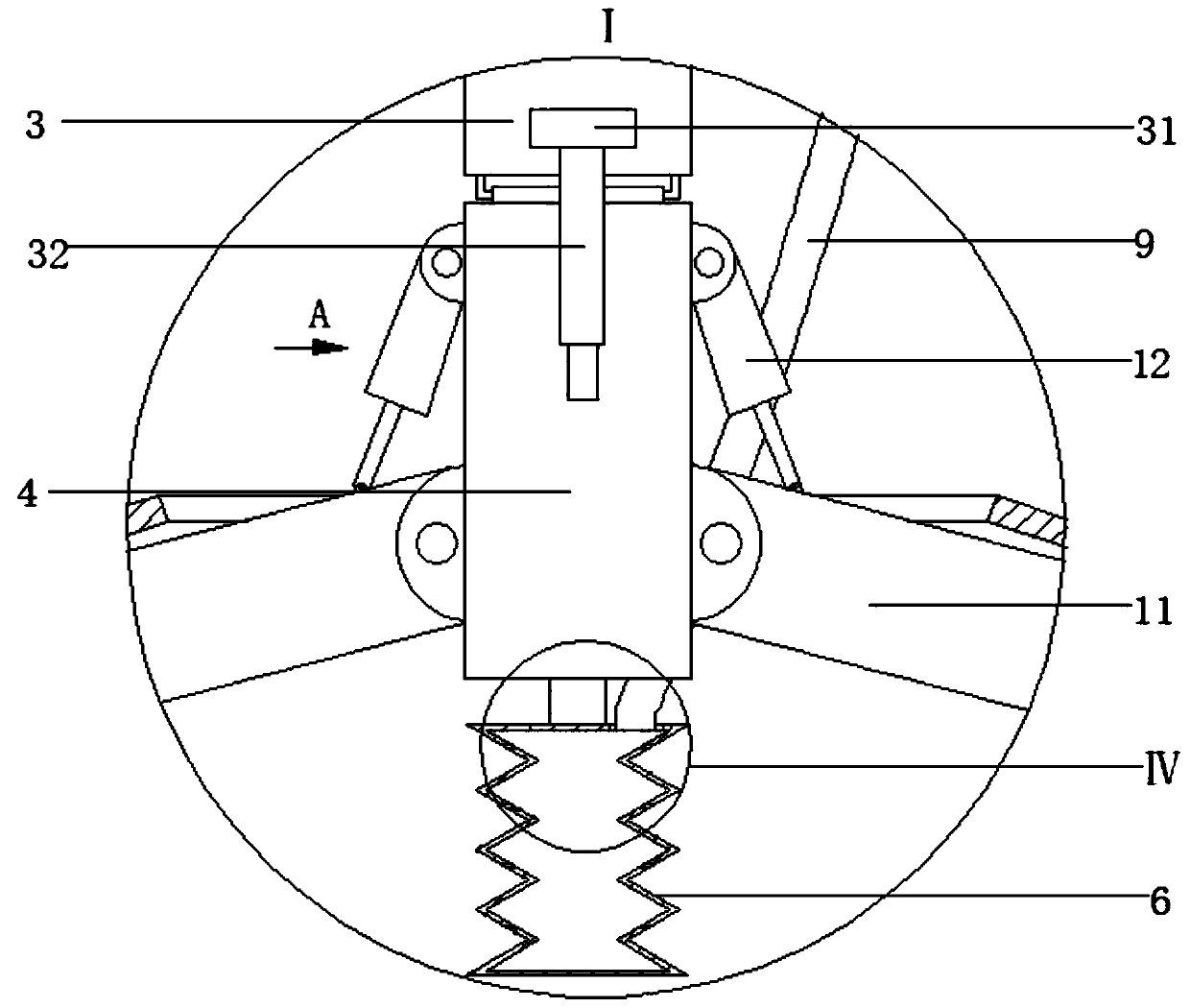

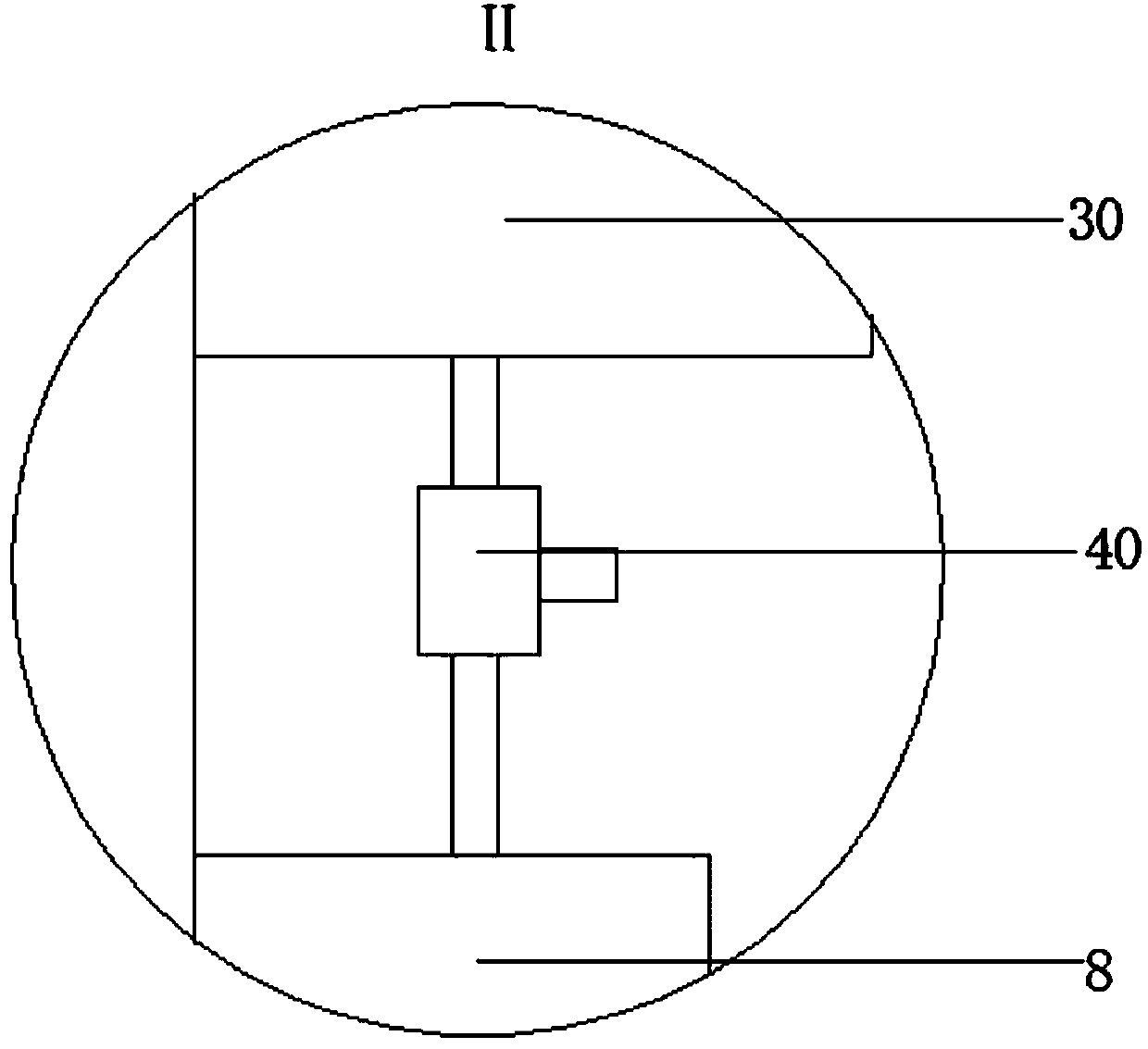

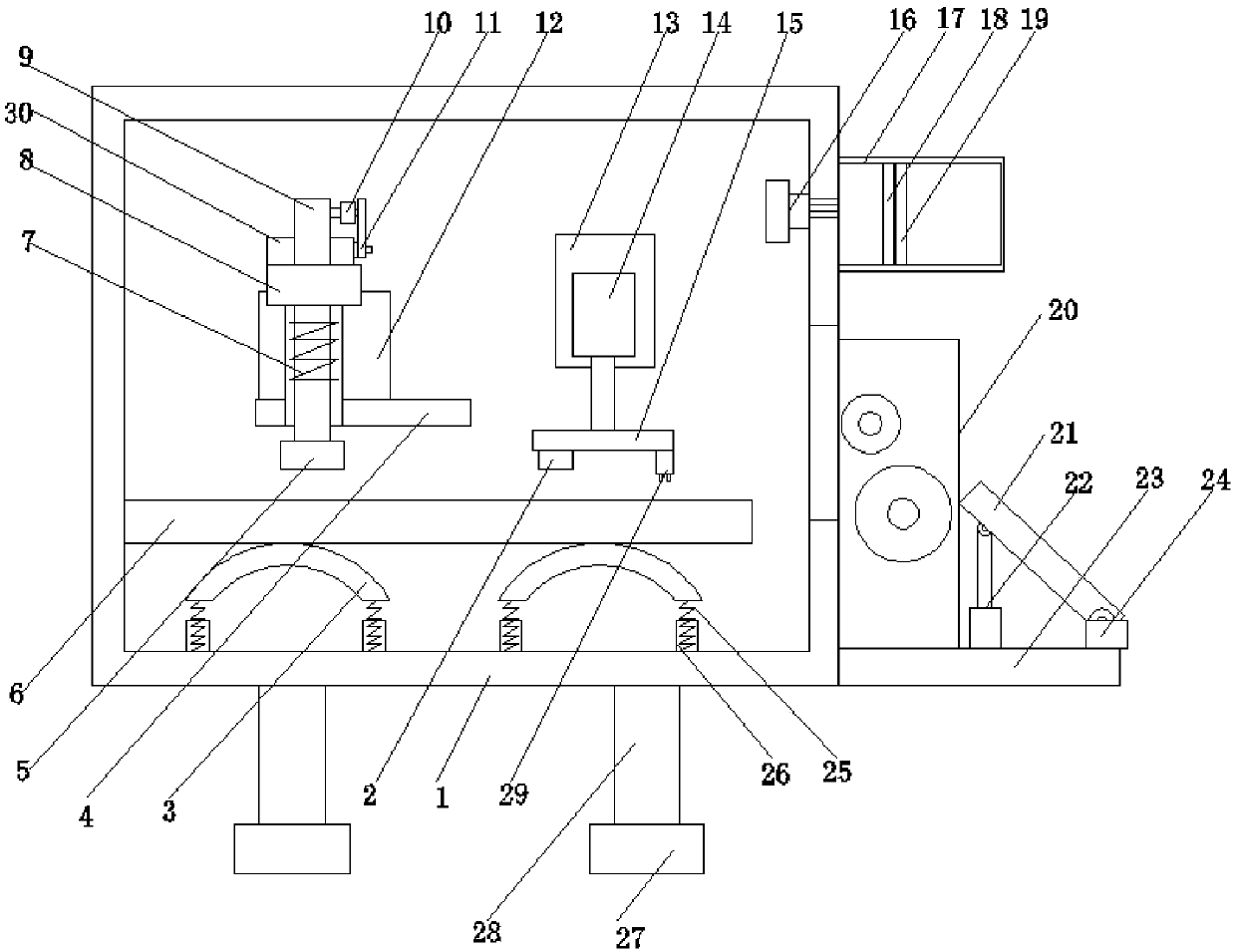

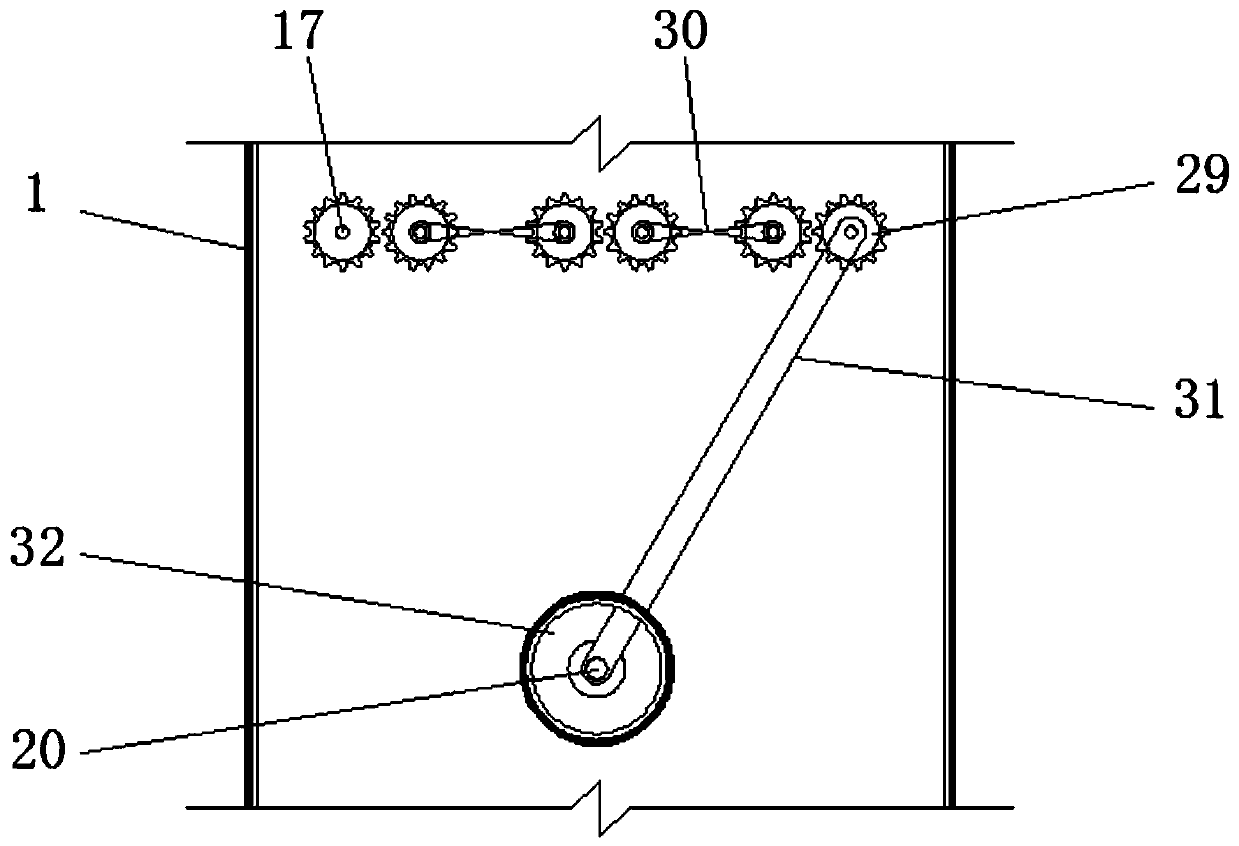

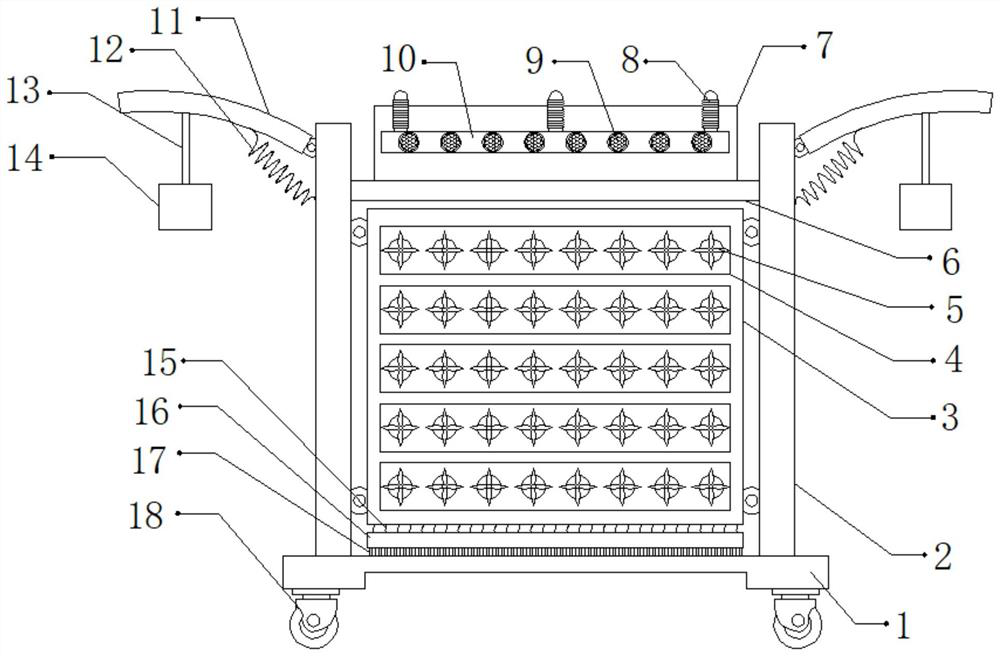

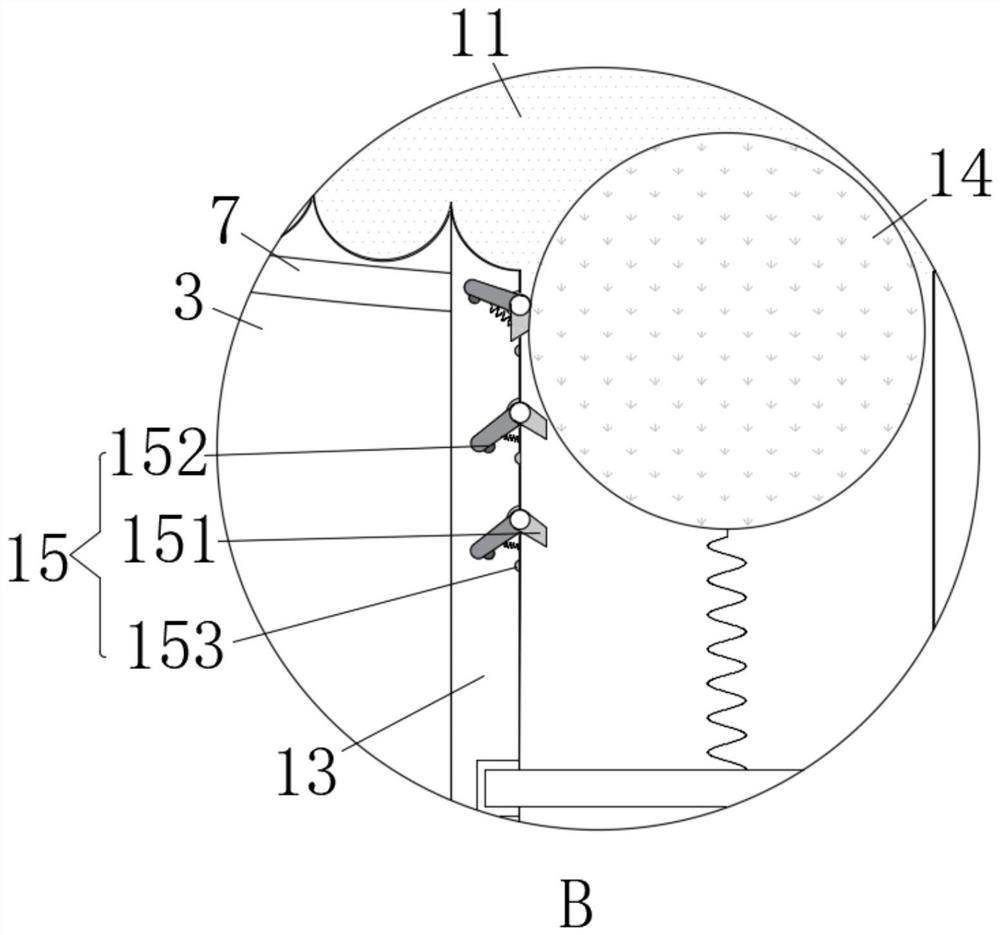

Beating dust removal device for leatherworking

InactiveCN107723388AIncrease the swing frequencyImprove dust removal efficiencySkins/hides/leather/fur manufacturing apparatusCouplingEngineering

The invention discloses a beating dust removal device for leatherworking. The beating dust removal device comprises a machine body. A mounting plate is fixedly connected to the inner wall of the machine body. A support is fixedly connected to the top of the mounting plate. The left side of the support is fixedly connected with a supporting rod. The right side of the support is fixedly connected with a connecting rod. A first adjusting rod is hinged to one side of the support through a pin shaft. According to the beating dust removal device, through the arrangement of a first motor, a connecting shaft and a rotating rod, by means of operation of the first motor, a driving gear is driven by a rotary shaft to rotate, the driving gear is engaged with a driven gear, and therefore the connectingshaft and the rotating rod are driven to rotate; a third adjusting rod is driven by the rotating rod to rotate, a lifting rod is driven to operate up and down through transmission of a second adjusting rod, and left-and-right swing of the first adjusting rod is driven by motion of the second adjusting rod; and buffering of a spring to the swing force (amplitude) and the opposite acting force of the spring to the first adjusting rod are adjusted, the swing frequency of the first adjusting rod is improved, and therefore the lifting frequency of the lifting rod is improved, and the dust removalefficiency is improved.

Owner:郑艳峰

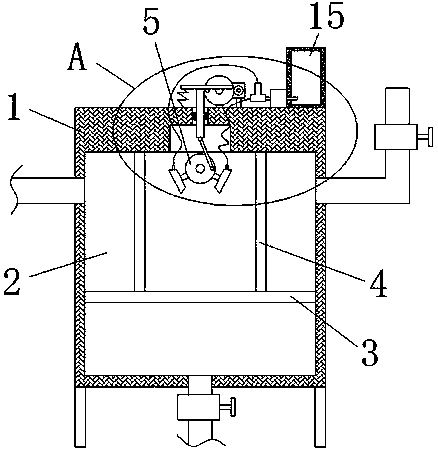

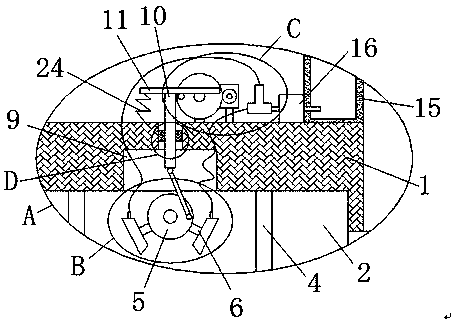

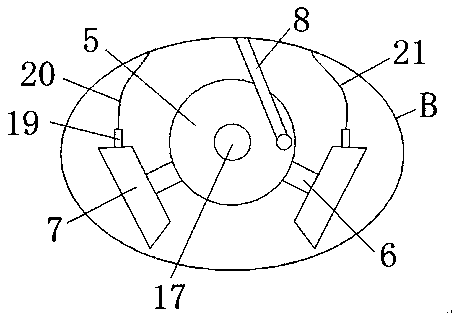

Waste gas treatment device of coating mechanical equipment

ActiveCN108970283ARealize dust removalFully contactedDispersed particle filtrationSpray nozzleMechanical equipment

The invention discloses a waste gas treatment device of coating mechanical equipment. The waste gas treatment device comprises a treatment box, the treatment box is provided with a cavity chamber, a filter plate which is horizontally arranged in fixedly mounted on the side wall of the cavity chamber, a rotary disc is rotatably mounted in the cavity chamber, filter nets fixedly mounted on the sidewall of the cavity chamber are arranged on the two sides of the rotary disc respectively, the bottoms of the filter nets are fixedly connected with the top of the filter plate, two mounting rods whichare symmetrically arranged are fixedly mounted on the outer side of the rotary disc, a spray nozzle is fixedly mounted at the end, away from the rotary disc, of each mounting rod, a traction rod which is obliquely arranged is rotatably arranged on one side of the rotary disc, and the inner wall of the top of the cavity chamber is provided with a groove. The waste gas treatment device is reasonable in design, high in practicality, and simple in structure, the spray nozzles can swing conveniently, and evenly spray clean water onto the filter nets, so that the filter nets remain the wet states all the time, thus dust particles in the waste gas can be conveniently absorbed, and dust removing treatment can be conveniently conducted on the waste gas.

Owner:广东熙霖节能环保工程咨询服务有限公司

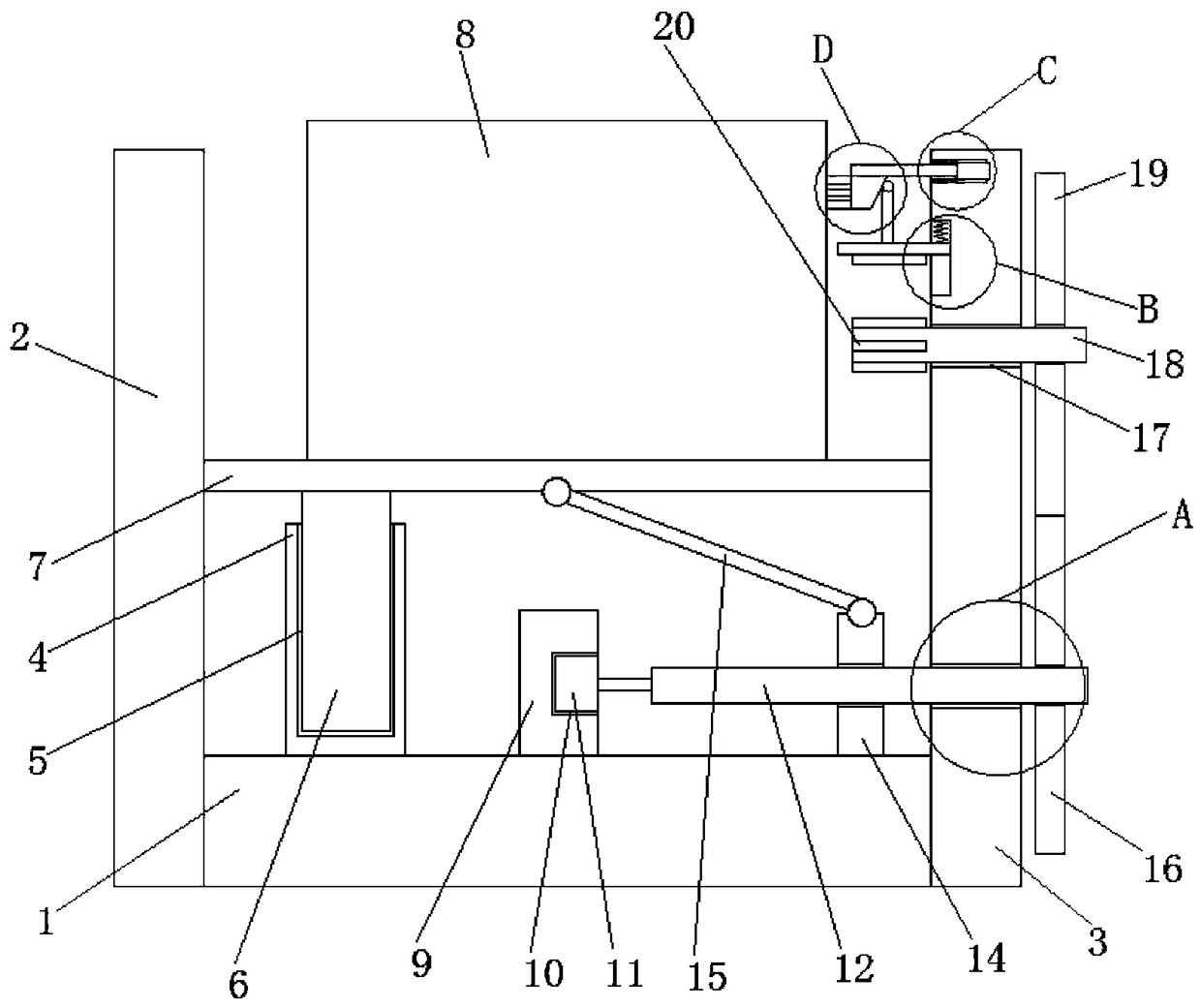

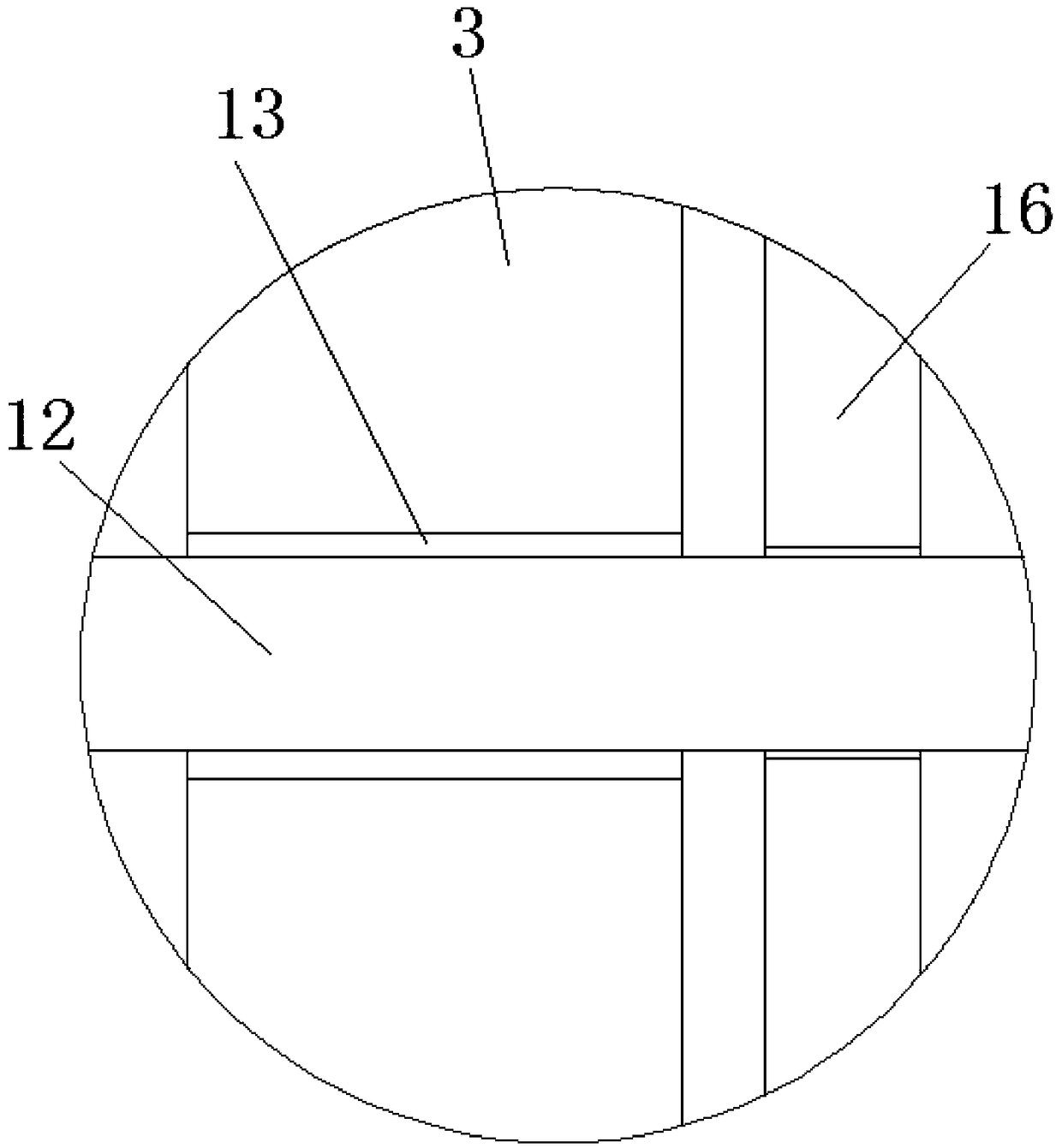

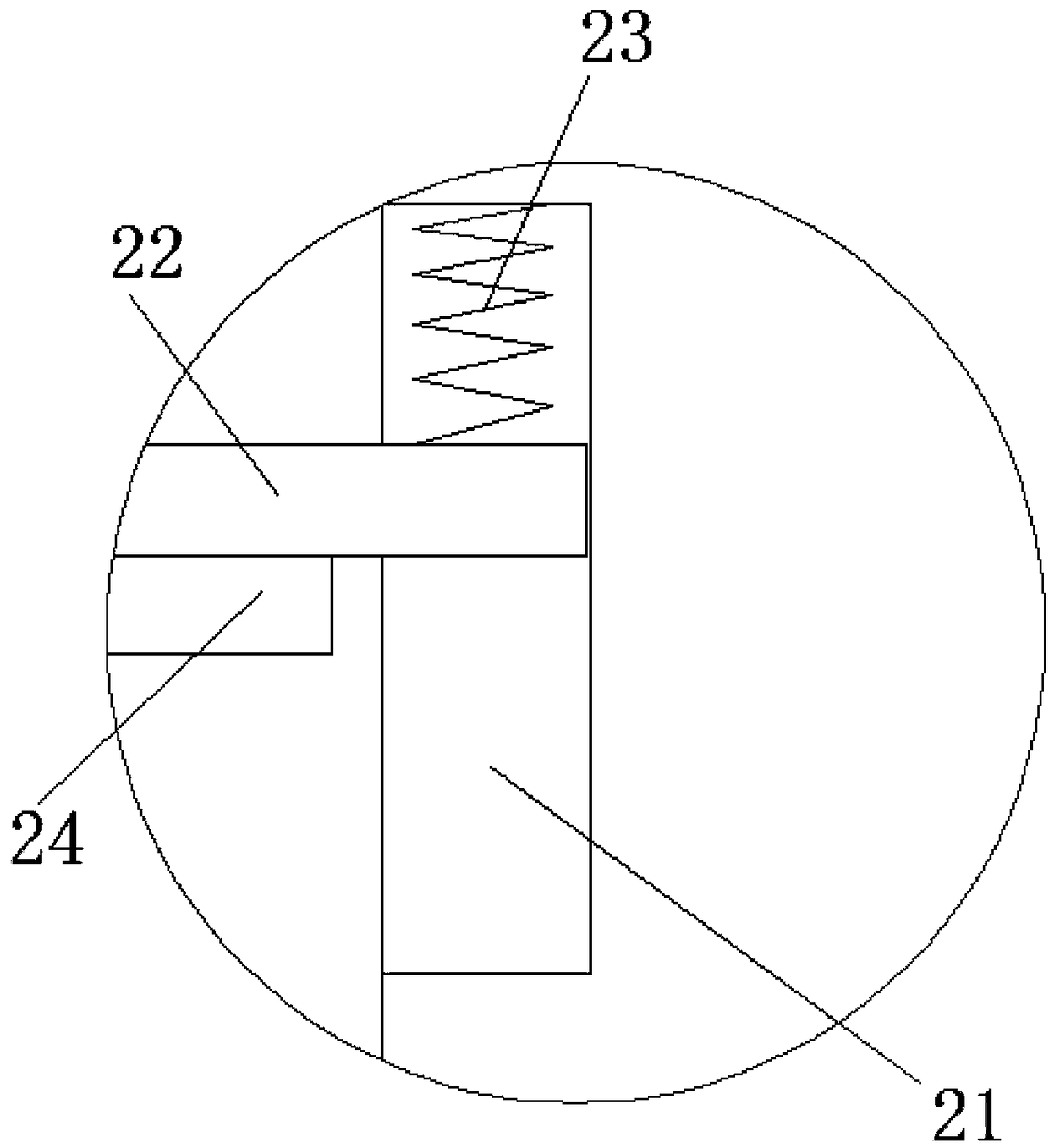

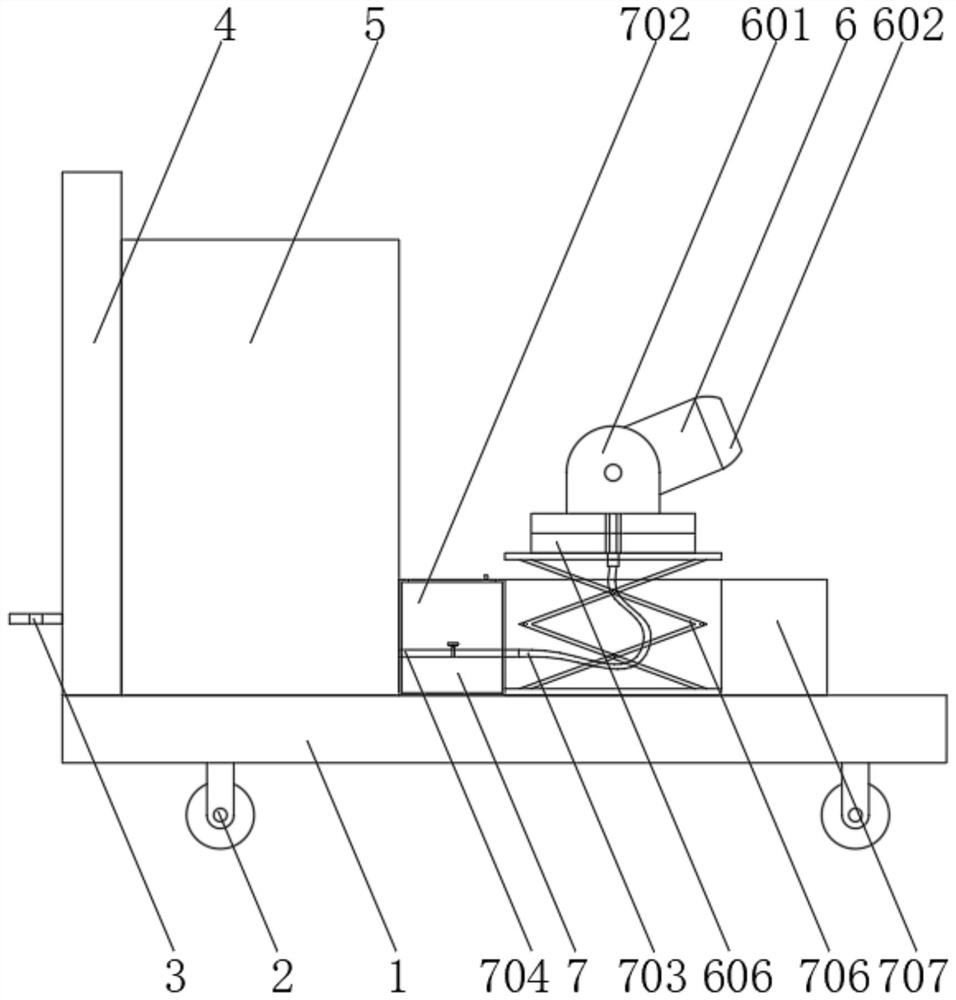

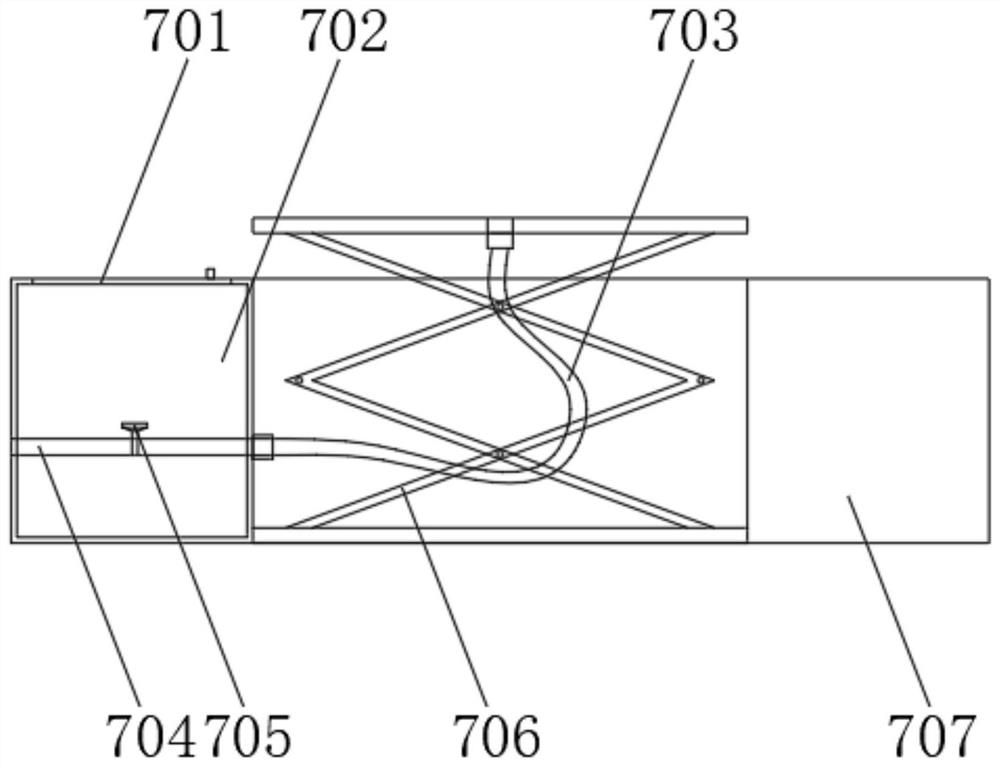

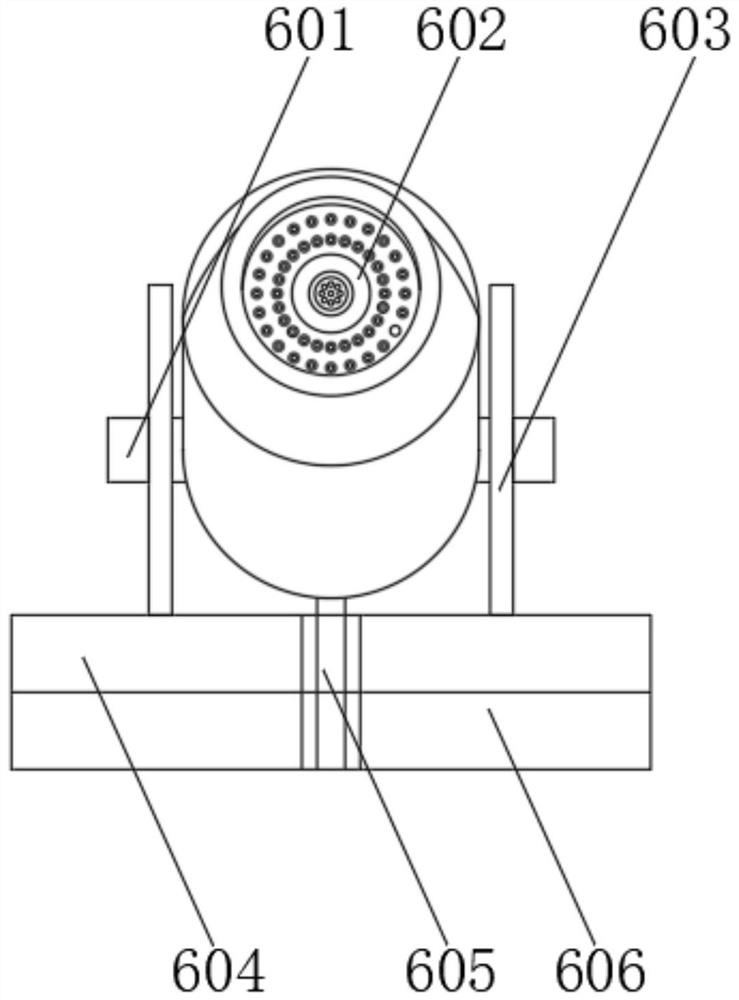

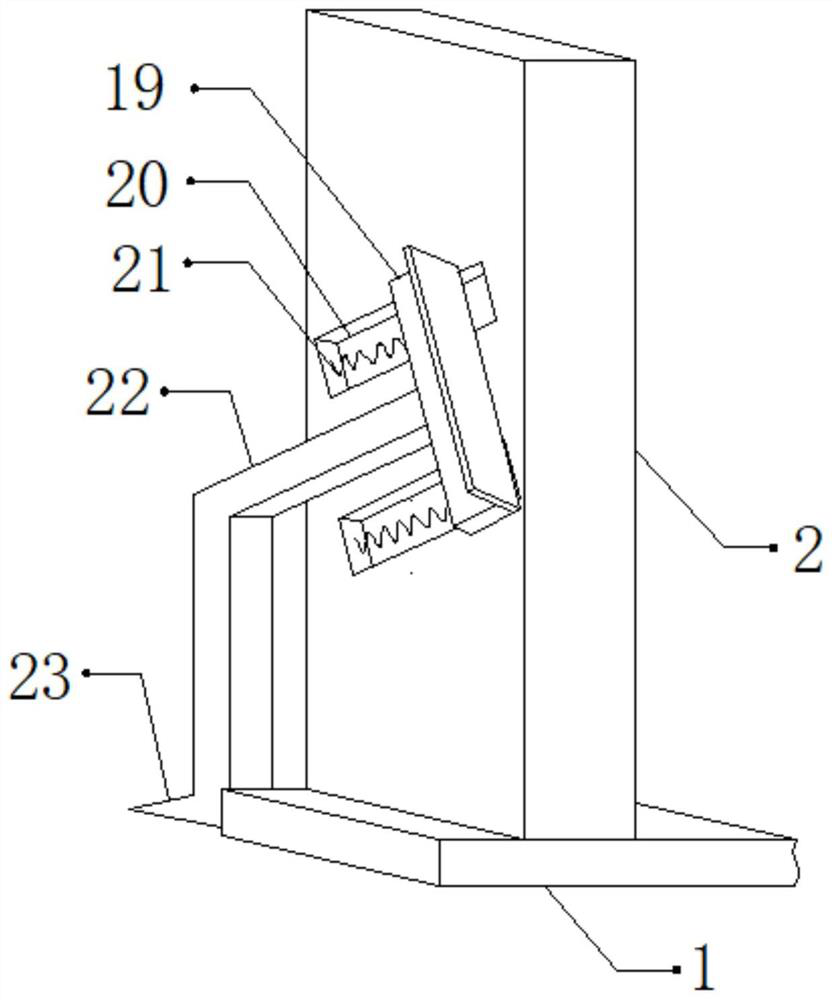

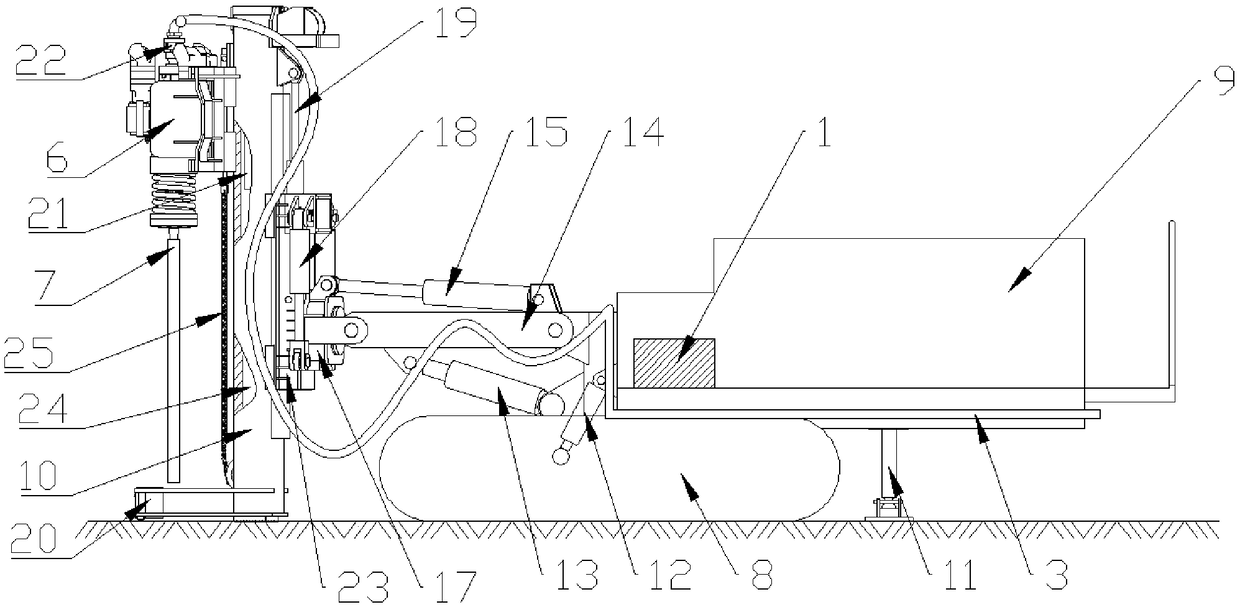

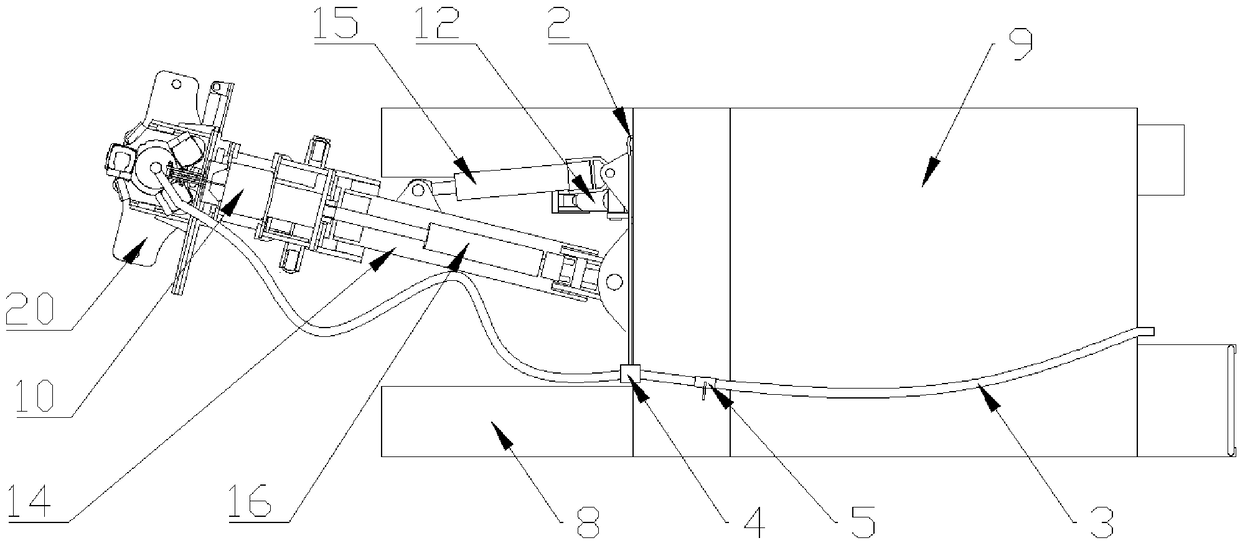

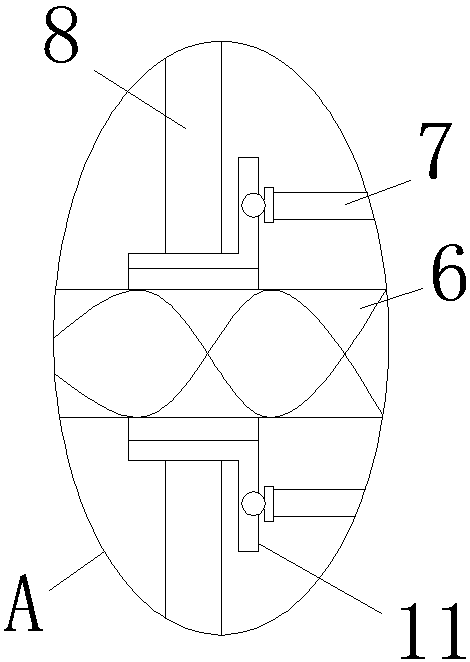

Device and method used for optimizing product design

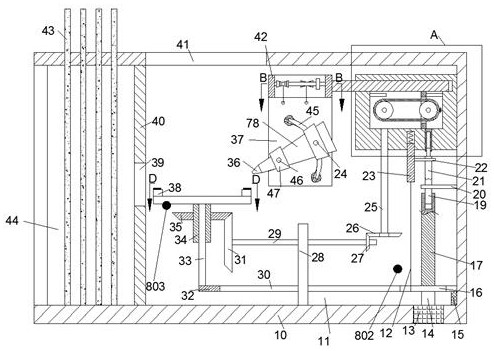

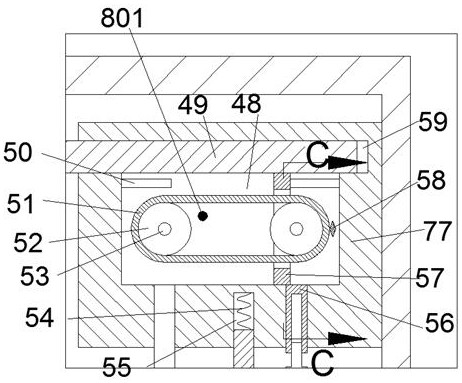

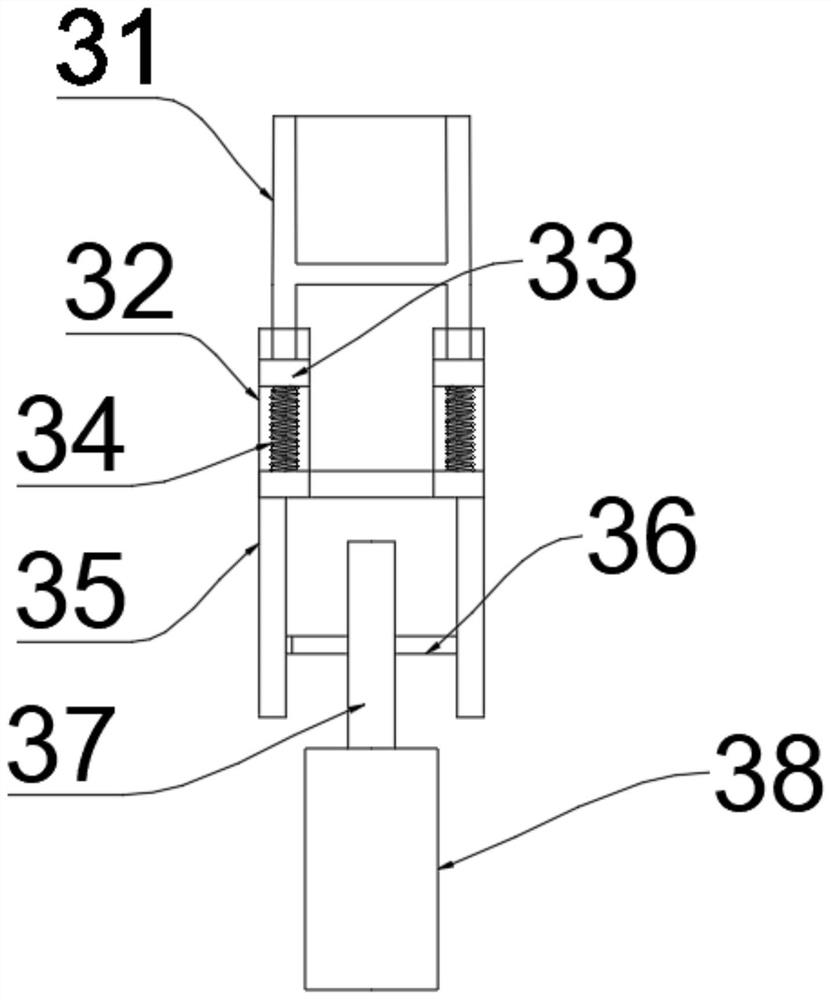

InactiveCN108706504AEasy height adjustmentEasy to handle with dust removalLifting framesCleaning processes and apparatusEngineeringDrive motor

The invention discloses a device and a method used for optimizing product design. The device comprises a device body, wherein a base is arranged below the device body; the two sides of the base are separately welded with a first plate and a second plate; the top of the base is welded with a first connecting column; a connecting slot is formed in the top of the first connecting column; a second connecting column is mounted in the connecting slot in a sliding mode; the top of the second connecting column is welded with a placing plate; the device body is fixedly mounted on the top of the placingplate; the center position of the top of the base is welded with a fixed plate; the fixed plate is positioned between the first connecting column and the second plate; a mounting slot is formed in one side, close to the second plate, of the fixed plate; a drive motor is mounted in the mounting slot; and a lead screw is welded on the output shaft of the drive motor. The device is high in practicability; the height of the device body is conveniently regulated through a traction rod and the placing plate; and dust-removal treatment is conveniently performed on the device body in a lifting process through a right-angled trapezoidal block and a rubber column.

Owner:SHANDONG UNIV OF TECH

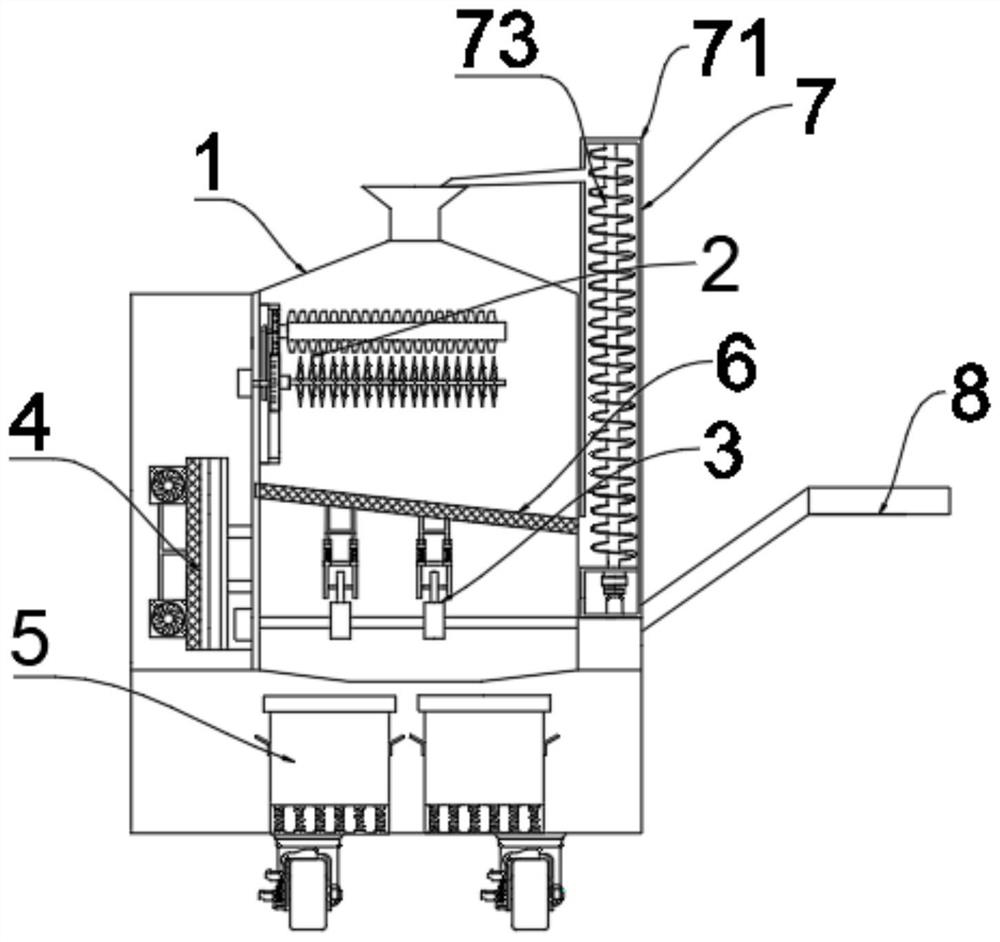

Crushing device used for construction waste and convenient for classification and collection

ActiveCN111359752AEasy to sort and collectEasy to handle with dust removalSievingScreeningElectric machineArchitectural engineering

The invention discloses a crushing device used for construction waste and convenient for classification and collection. The crushing device comprises a box body, a first motor, a second motor, fine crushing rollers, an electromagnetic cylinder, a wire plug and a third motor. A feed inlet is formed in the upper end of the box body, the right ends of single bodies of crushing rollers are in transmission connection through a first belt, the front side and the rear side of the upper end of the box body are fixedly connected with sliding rods, connecting rods are welded with dustproof plates, the left side of the box body is fixedly connected with a conveying cylinder, the lower end of a spiral rod is fixedly connected with the second motor through a bolt, a feed port is formed in the left lower side of the conveying cylinder, sieve plates are arranged on the lower sides of the crushing rollers, and guide plates are arranged on the lower sides of the sieve plates. The crushing device used for construction waste and convenient for classification and collection is convenient for dustproof treatment, at the same time, layered crushing treatment can be conveniently conducted on the construction waste, different types of garbage can be conveniently classified and collected, and recycling of useful garbage is facilitated.

Owner:广西青辉环保技术有限责任公司

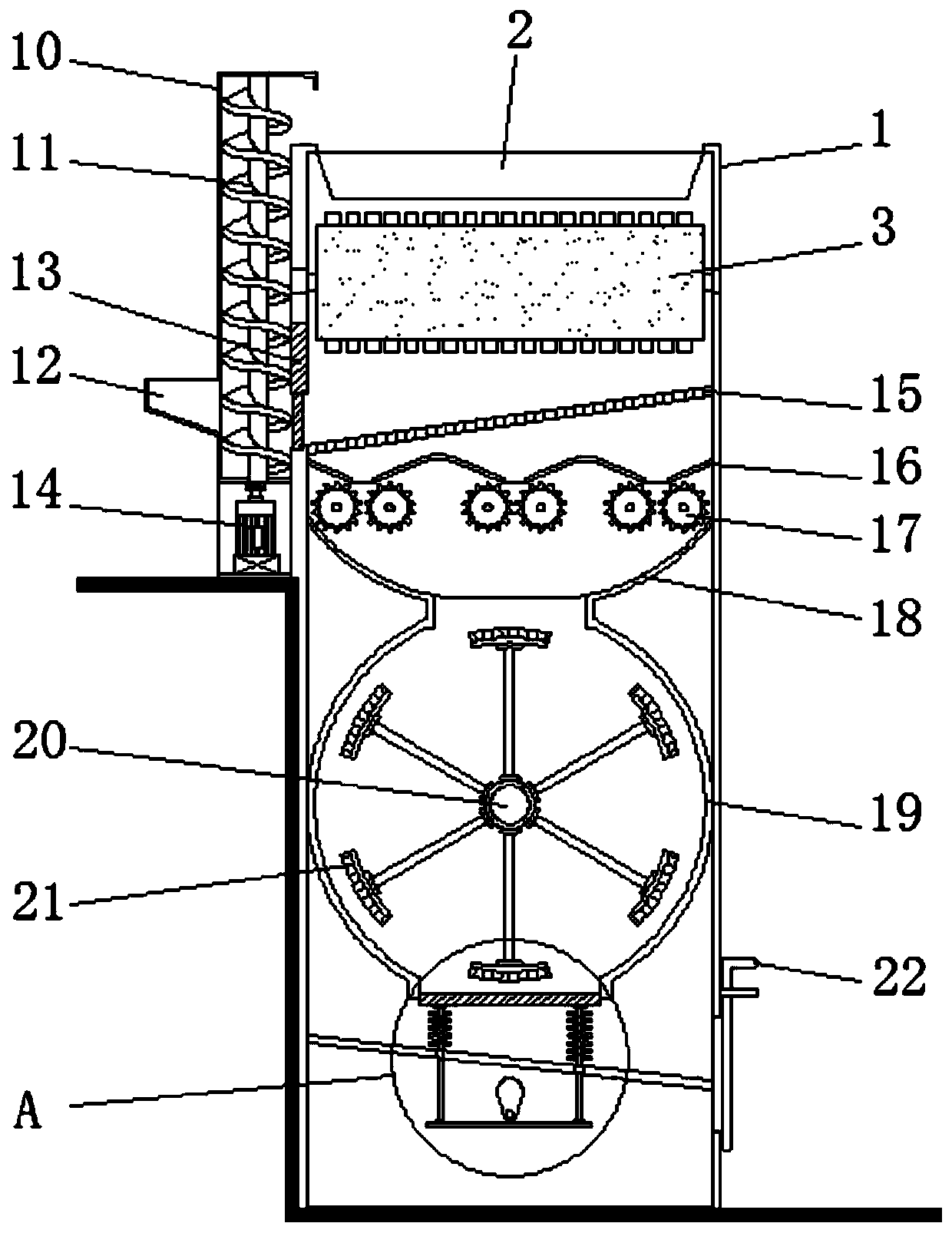

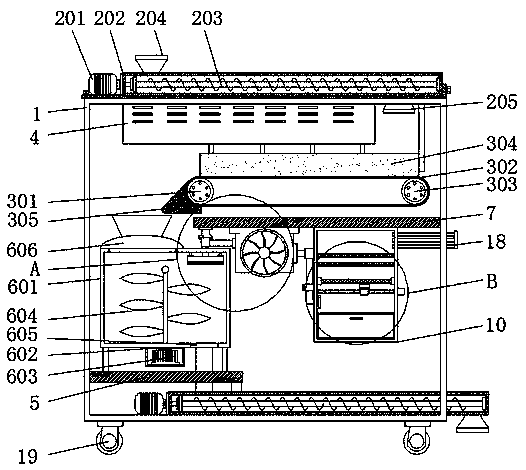

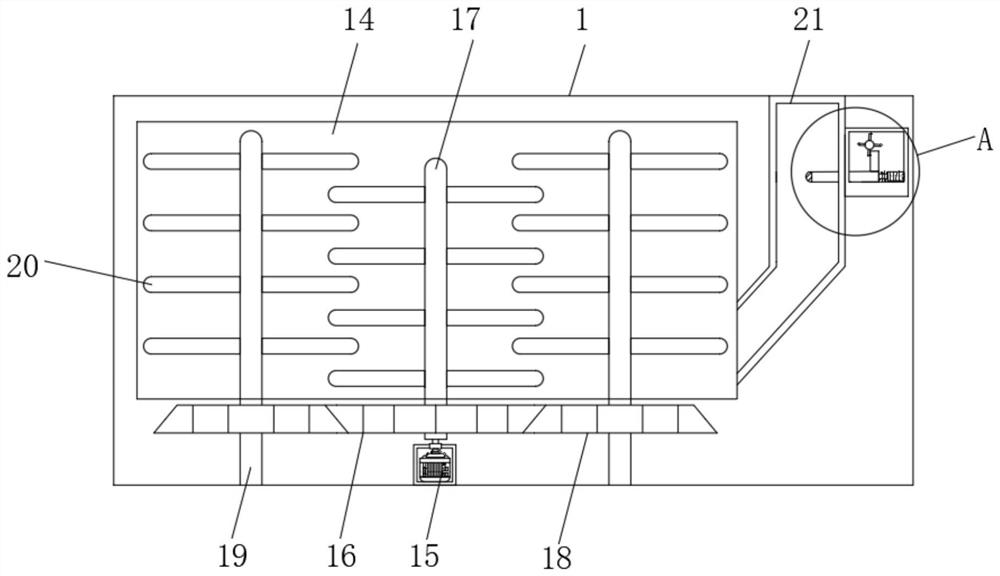

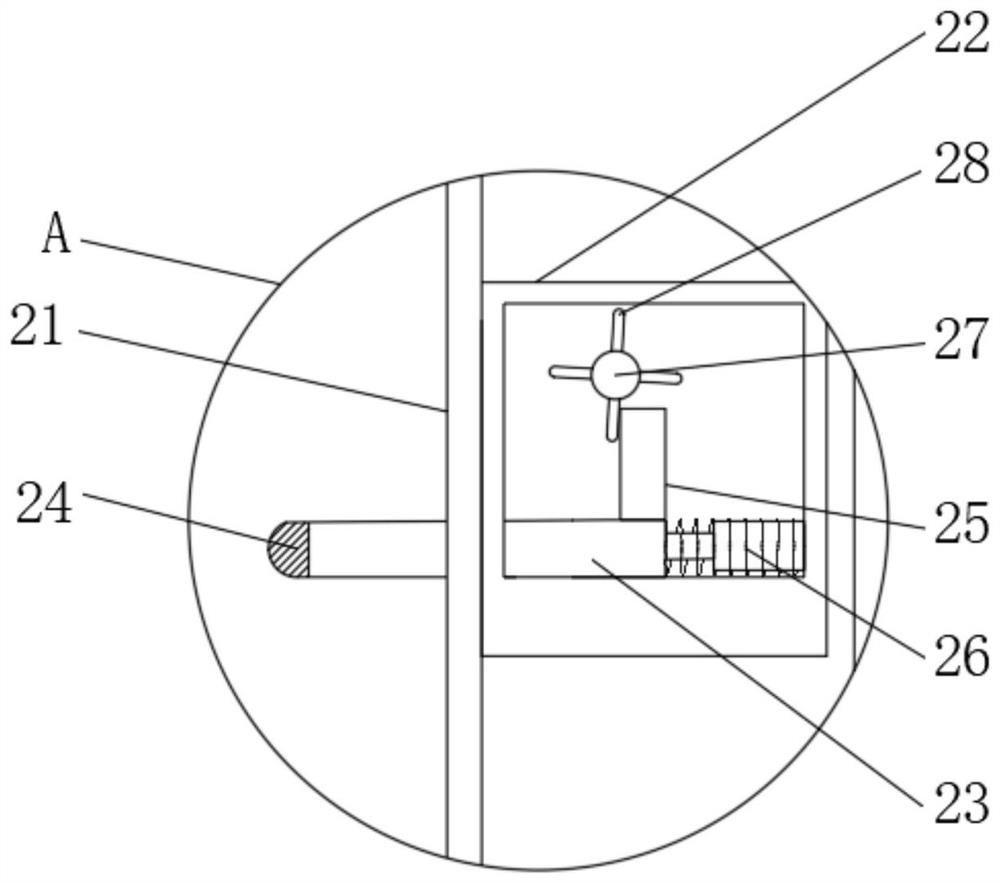

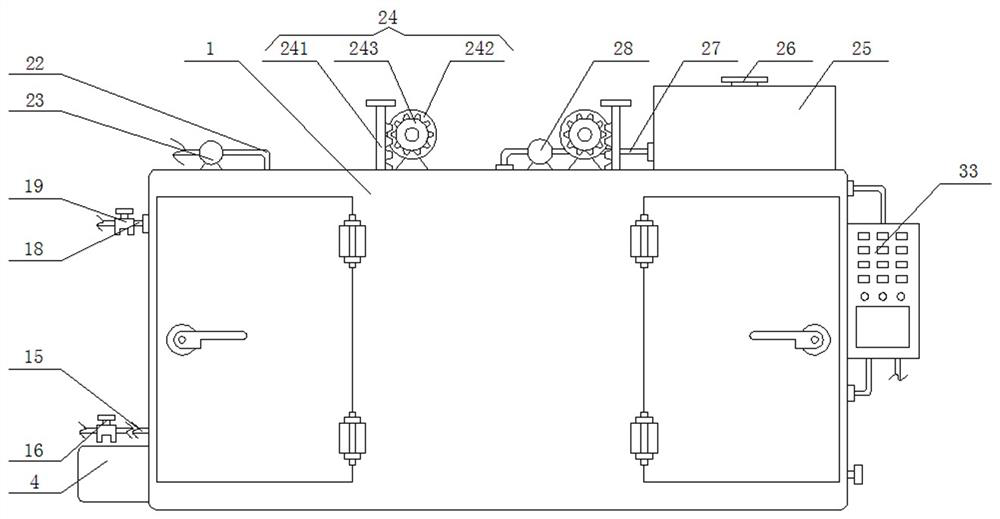

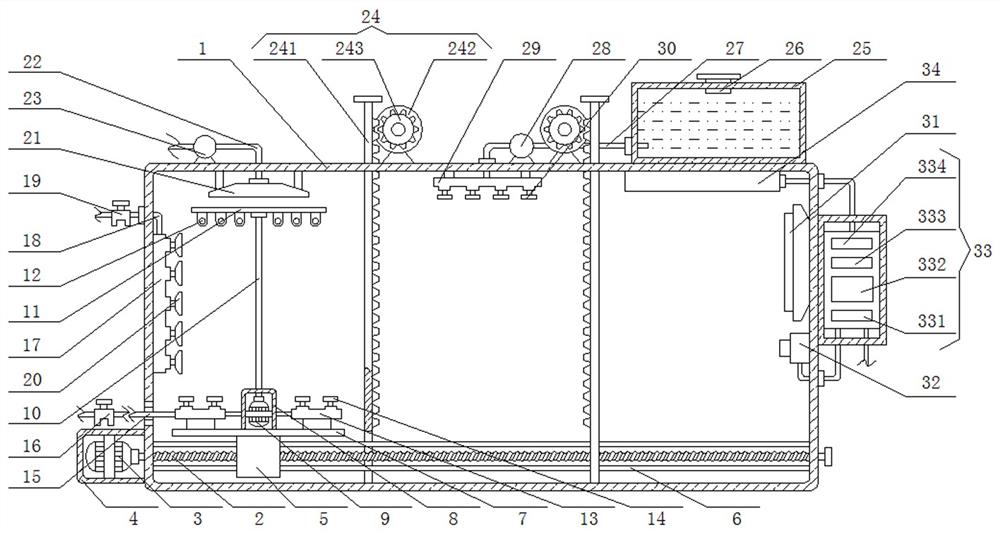

Mechanical drying device for rice

PendingCN108850151APrevent drynessSave human effortDispersed particle filtrationRotary stirring mixersPulp and paper industryDust fall

The invention discloses a mechanical drying device for rice. The mechanical drying device comprises a box body, wherein rice transported on a transmission transportation device is dried through the drying device; air blown out from a fan is heated through a heating sheet, so that water stain on the rice can be fast dried; the drying work procedure required before the rice storage is avoided; the labor and the time for rice drying are saved; through a stirring device, the dried rice can be stirred; the storage inconvenience due to agglomeration adhesion of some rice can be avoided; meanwhile, through the stirring on the rice, dust adsorbed on the rice surface can be flapped, so that the dust floats; the subsequent dust removal treatment is facilitated; through a draft fan, the floating dustin the stirring box can be discharged into a treatment box through the draft fan; filtering is performed through a filtering net plate; meanwhile, a hair brush is driven to brush and wash the filtering net plate through a third electric motor, so that the dust falls into a dust collection drawer; workers can clean regularly the device.

Owner:泉州市顶优优工业设计有限公司

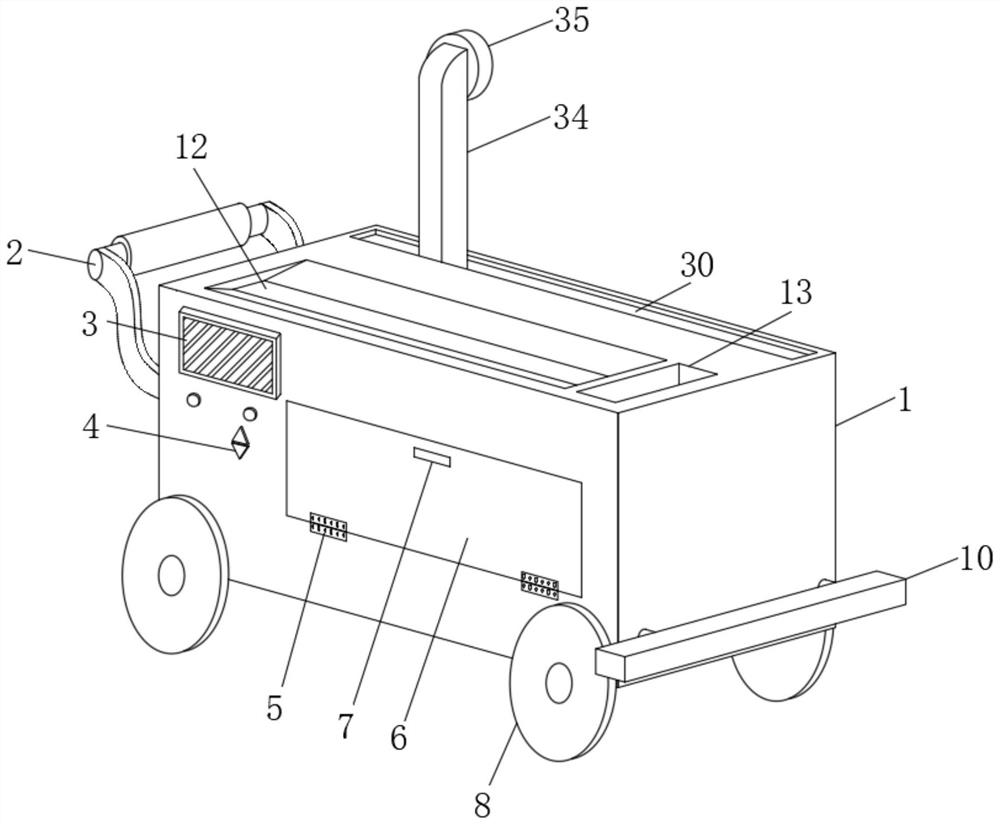

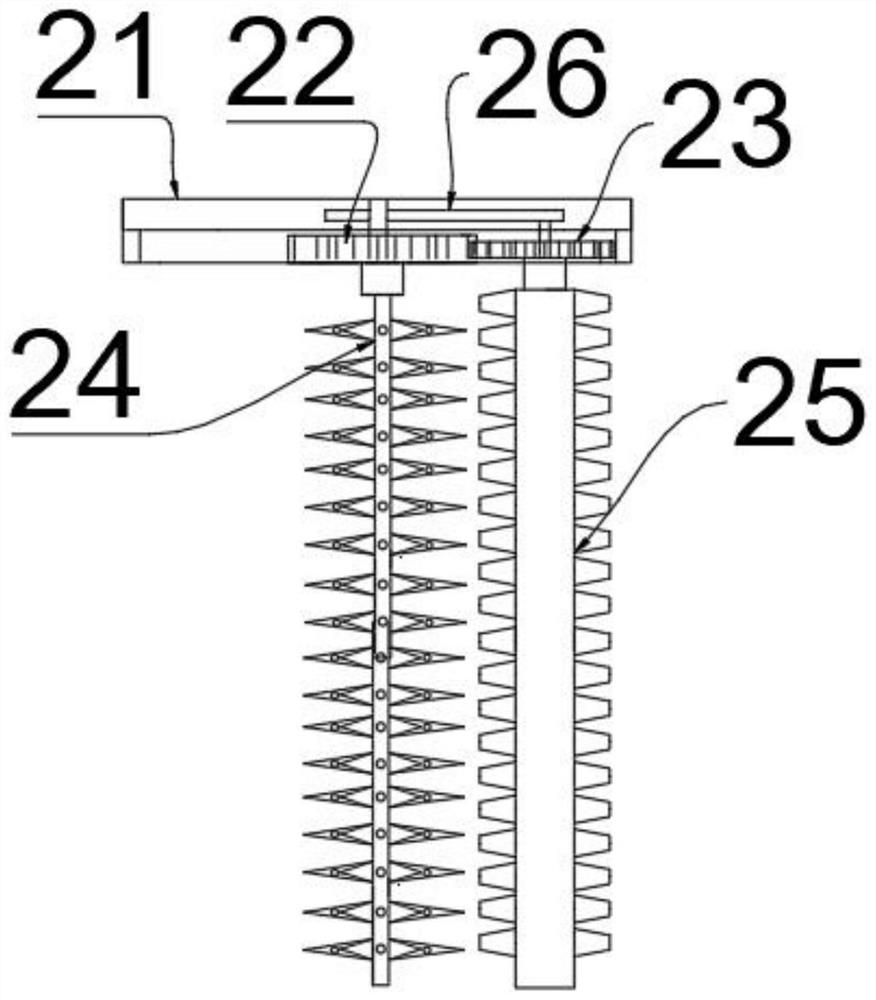

Novel construction site dust falling device for constructional engineering

InactiveCN111957142AHeight adjustableExpand the range of dust suppressionUsing liquid separation agentSeparation devicesArchitectural engineeringStructural engineering

The invention discloses a novel construction site dust falling device for constructional engineering. The device comprises a base; wheels are arranged at the lower end of the base; a side plate, a water tank and a lifting table are arranged at the upper end of the base; a connecting block is arranged on one side of the side plate; a fixed table is arranged at the upper end of the base; a sprayingdevice is arranged at the upper end of the fixed table; a control box and a lifting frame are arranged in the fixed table; a water outlet and a water valve are arranged in the control box; a hose is arranged on one side of the control box; a fixed plate is arranged at the upper end of the lifting frame; a rotating plate is arranged at the upper end of the fixed plate; and connecting pipes are arranged in the fixed plate and the rotating plate. According to the novel construction site dust falling device for constructional engineering, the dust falling height is controlled through the arrangedlifting table; the arranged spraying device swings up and down and left and right, so that the dust falling range is enlarged, and better use prospects are brought.

Owner:孙宏梅

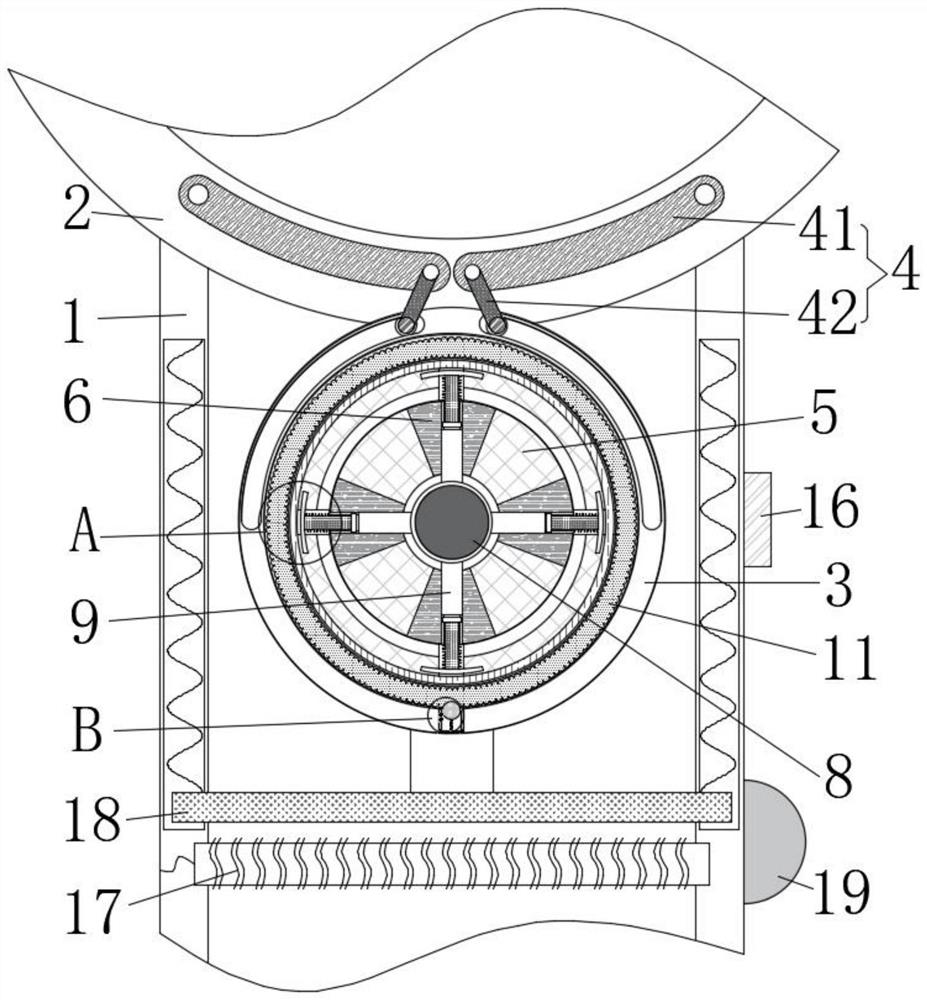

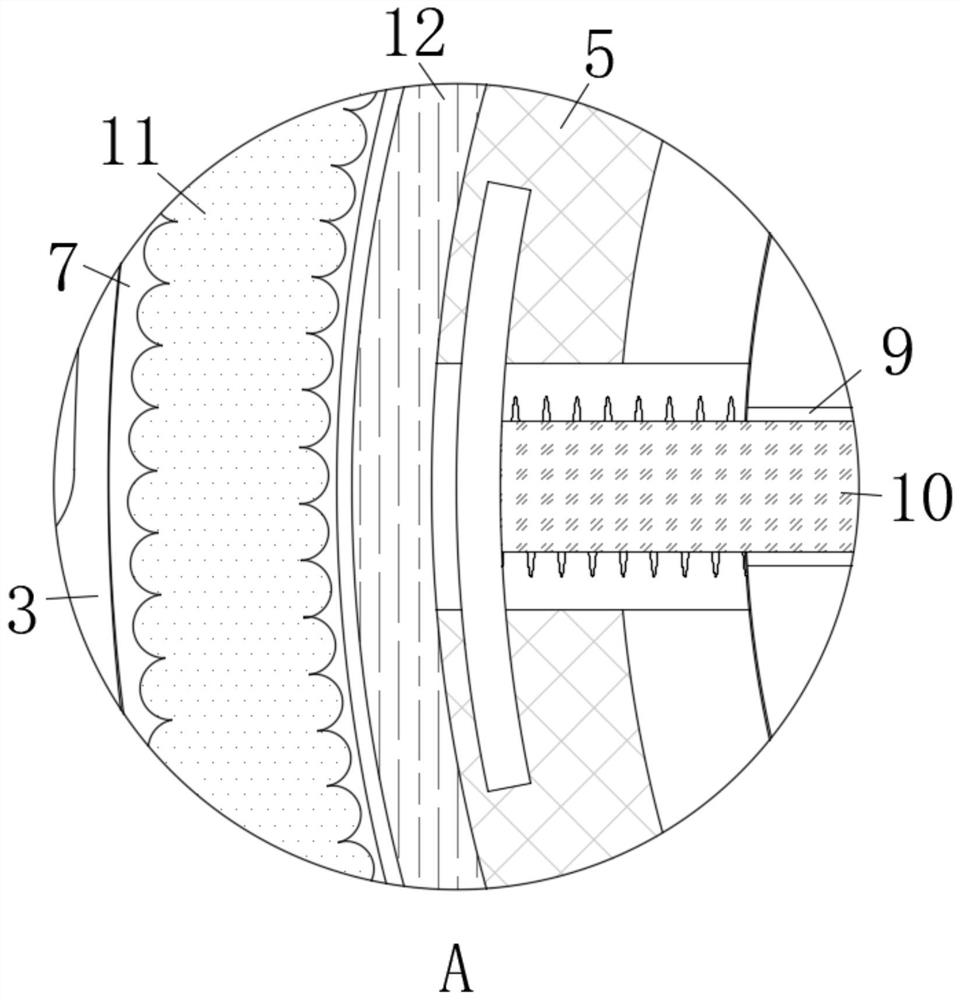

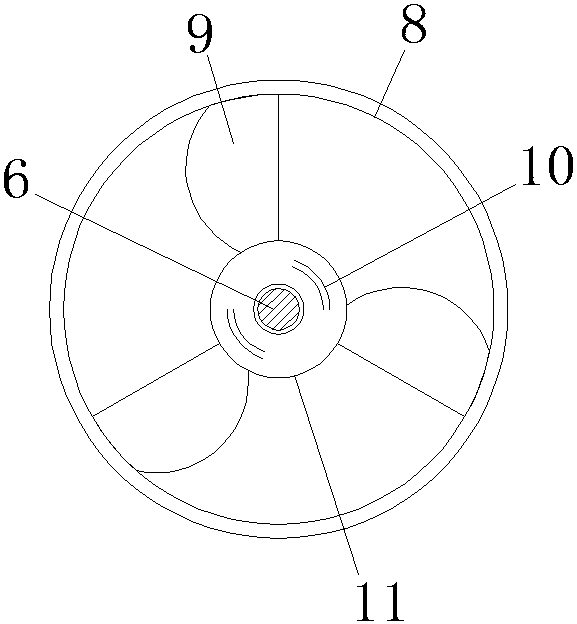

Dedusting and deashing device for circuit board welded with components

InactiveCN111940415AEasy and very comprehensive dust removalEasy to handle with dust removalCleaning using gasesDust controlEngineering

The invention discloses a dedusting and deashing device for a circuit board welded with components. The dedusting and deashing device for the circuit board welded with the components comprises a dedusting box, wherein a dedusting cavity is formed in the dedusting box; an inlet for placing the circuit board penetrates through the top wall of the dedusting cavity; a partition plate is arranged at the left end of the dedusting cavity; an air outlet is formed on the partition plate; the left side of the air outlet communicates with a purification cavity; a dust isolation plate with a dust isolation degree which is gradually increased from right to left is arranged in the purification cavity; and a transmission box is fixedly arranged on the right wall of the dedusting cavity. The angle of a fan can be continuously changed, the circuit board can also rotate and blow air at different angles, and therefore a great and comprehensive dedusting effect is achieved; and meanwhile, the blown air containing dust can be greatly subjected to dust isolation treatment, so that the situation that when operation is carried out in a warehouse, the dust is accumulated on the circuit board again due to the problem of no air circulation after being discharged into the warehouse, is avoided, and the situation that the air is polluted by the dust during dedusting is also avoided.

Owner:PUJIANG LECHENG ELECTRONICS TECH CO LTD

Dust falling device for building blasting

The invention discloses a dust falling device for building blasting. The dust falling device comprises a fixing seat, wherein fixing plates are fixedly connected to two sides of the outer wall of thetop of the fixing seat; blades are connected to the outer walls of one sides of the two fixing plates through hinges; first springs are fixedly connected between the blades and the outer walls of onesides of the fixing plates; lifting ropes are bolted to the outer walls of the bottoms of the two blades; fixing blocks are bolted to the outer walls of the bottoms of the two lifting ropes; a baffleis connected between the outer walls of the opposite sides of the two fixing plates through hinges; and a supporting plate is fixedly connected between the outer walls of the opposite sides of the twofixing plates. According to the dust falling device disclosed by the invention, the condition that the device cannot effectively perform dust falling treatment on dust due to the fact that the dust flies upwards can be avoided, the condition that the device falls due to impact force generated during blasting so as to influence dust falling of the device can be avoided, and the condition that thedust removal efficiency of the device is reduced due to high flowing speed of the dust can be avoided.

Owner:袁国初

Rapid and accurate detection mechanism for organic waste gas bag type dust removal device

The invention provides a rapid and accurate detection mechanism for an organic waste gas bag type dust removal device, which belongs to the technical field of organic waste gas treatment equipment. The rapid and accurate detection mechanism comprises a base, a movable seat is slidably connected in the base, an opening and closing mechanism is connected with the movable seat, a filter screen, an impeller and a detection seat are sequentially arranged in the movable seat in the waste gas conveying direction, and an annular air bag and an annular rubber ring are sequentially arranged in the detection seat from outside to inside. According to the rapid and accurate detection mechanism for the organic waste gas bag type dust removal device, under the combined connection action of the opening and closing mechanism, the filter screen, the annular rubber ring, the annular air bag and a detection conversion mechanism, a damaged filter bag can be rapidly and accurately determined, the efficiencyand speed of detecting the damaged filter bag are improved, and the purpose of improving the waste gas treatment effect is achieved; and meanwhile, the dust removal effect of filter bags can be detected, so that the filter bags which most accord with the actual situation can be selected to remove dust from the organic waste gas, and the overall treatment effect of the organic waste gas is furtherimproved.

Owner:张春燕

Energy-saving environmental-friendly type asphalt dissolving furnace having function of heat recovery

InactiveCN108452693ACompact structureEasy to operateTransportation and packagingUsing liquid separation agentAsphaltEngineering

The invention discloses an energy-saving environmental-friendly type asphalt dissolving furnace having a function of heat recovery. The energy-saving environmental-friendly type asphalt dissolving furnace comprises a dissolving pot, wherein an outer housing is arranged on the outer side surface of the dissolving pot; a reflux cabin is arranged at the upper end of the inner side surface of the outer housing; a combustion cabin is arranged between the lower end surface of the dissolving pot and the inner side surface of the outer housing; a heat conducting oil storing cabin is arranged between the inner side surface of the outer housing and the outer side surface of the dissolving pot; a liquid outlet pipe is arranged at the middle part of the lower end surface of the dissolving pot; a liquid outlet pipe valve is arranged on the liquid outlet pipe; the combustion cabin is connected with the reflux cabin through air guiding pipes; and an upper end cover is arranged right above the dissolving pot. The energy-saving environmental-friendly type asphalt dissolving furnace having the function of heat recovery disclosed by the invention is compact in structure, convenient to operate, and low in occupied space while in use; harmful gas generated in the dissolving process of asphalt can be effectively treated, and heat quantity of high-temperature flue gas can also be recovered; the atomizing nozzle is arranged, so that dust falling treatment of the flue gas is convenient; and air can be quickly blown in the combustion cabin through an air blower.

Owner:镇江新区恒盛物流有限公司

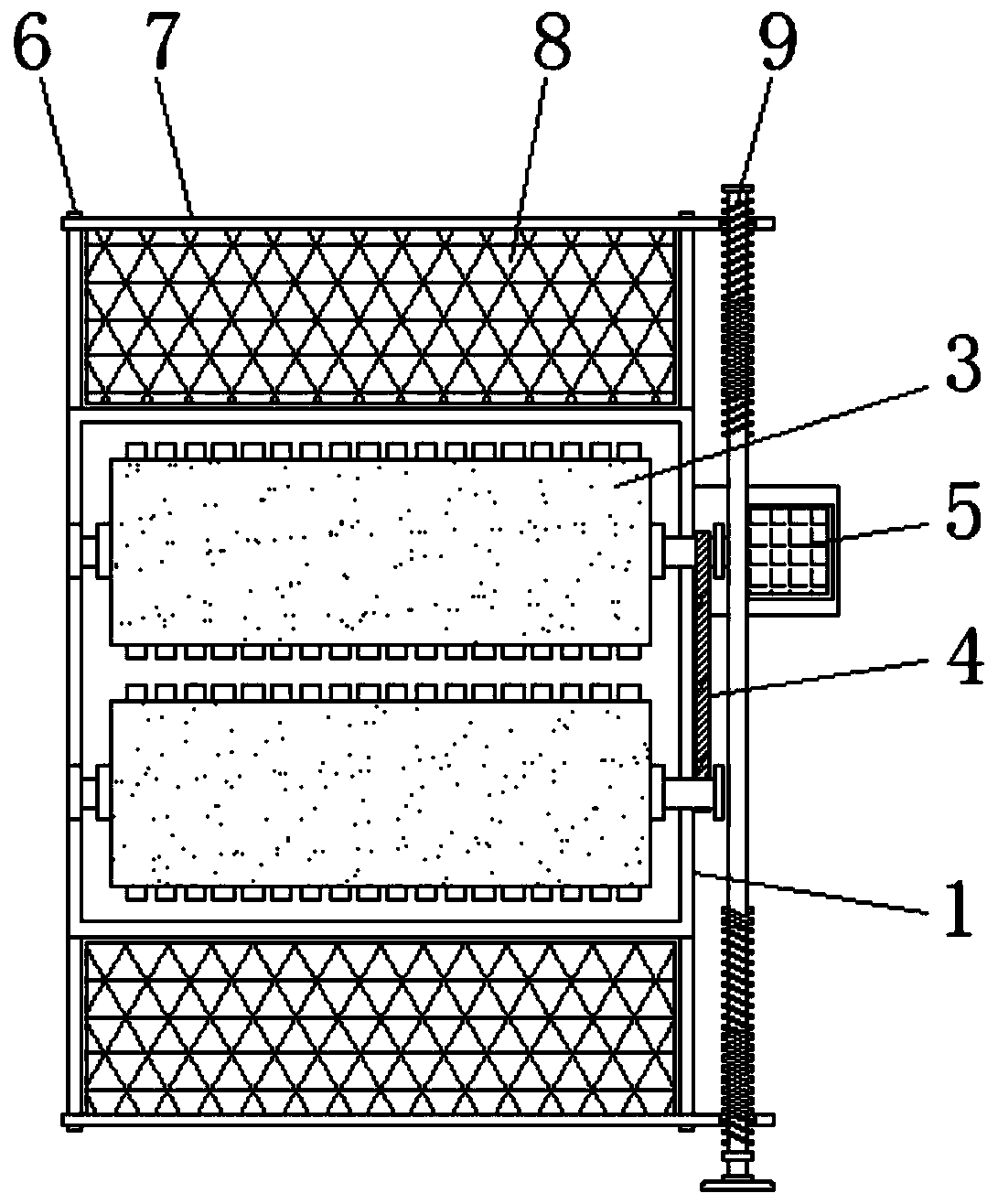

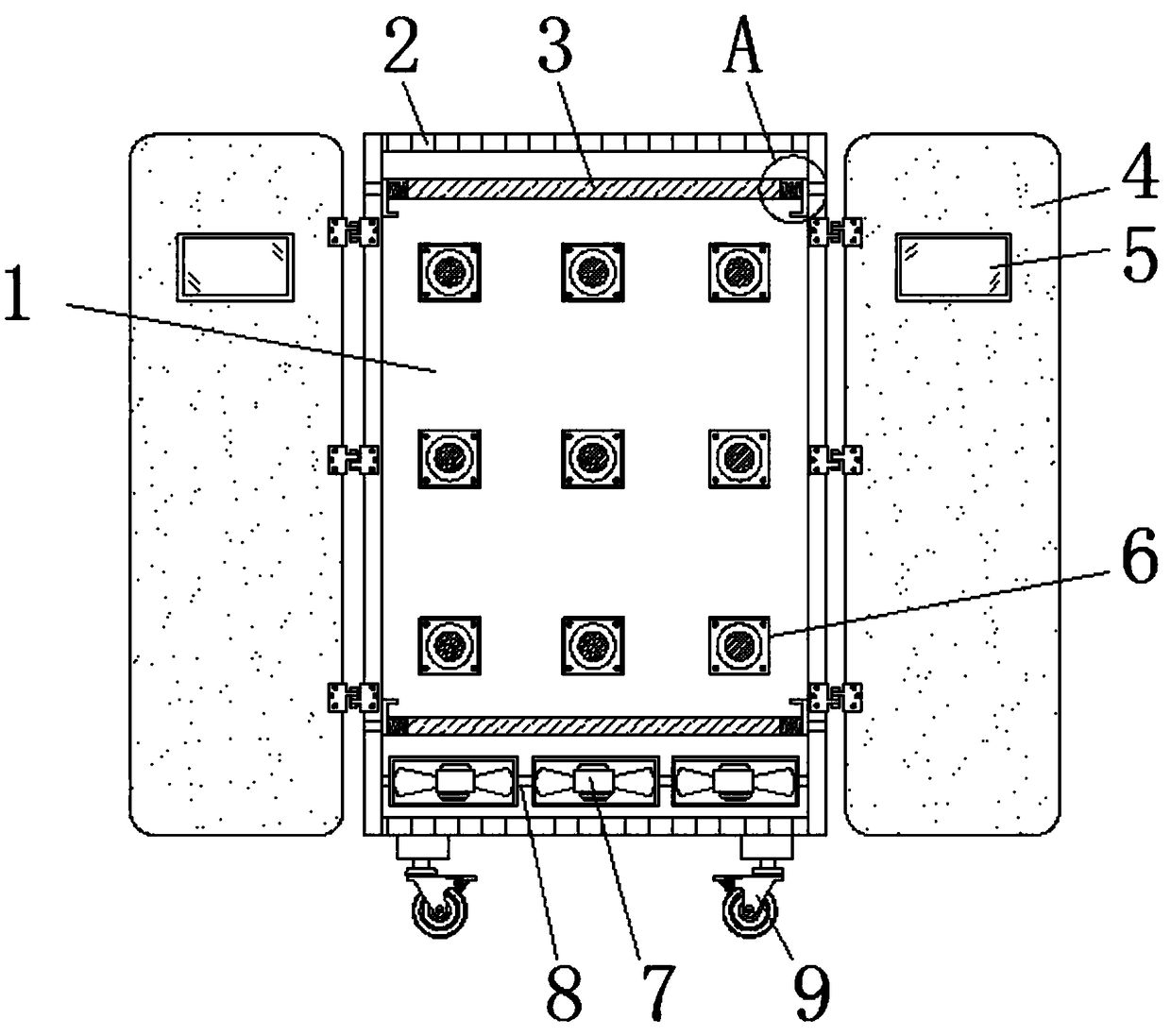

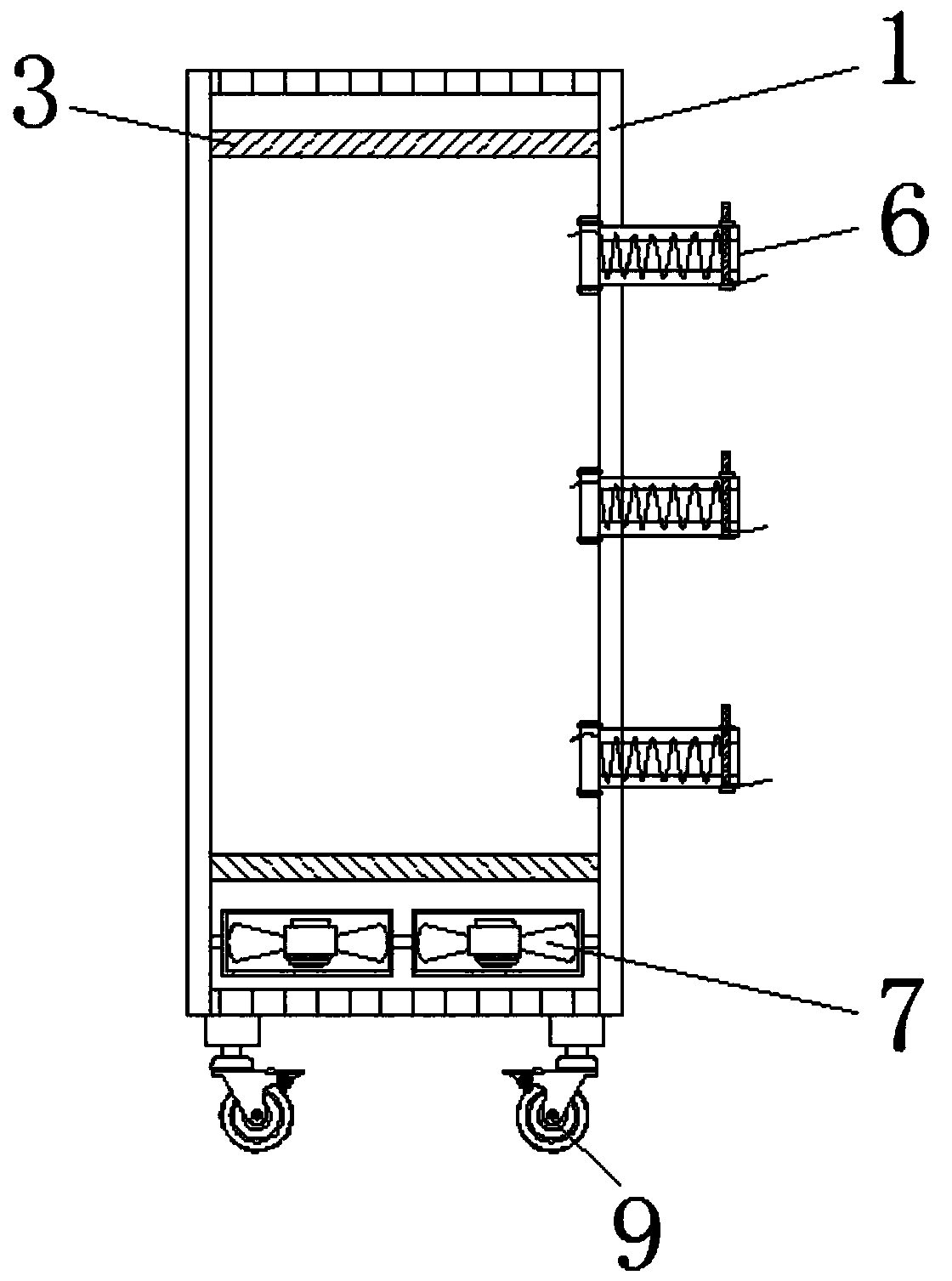

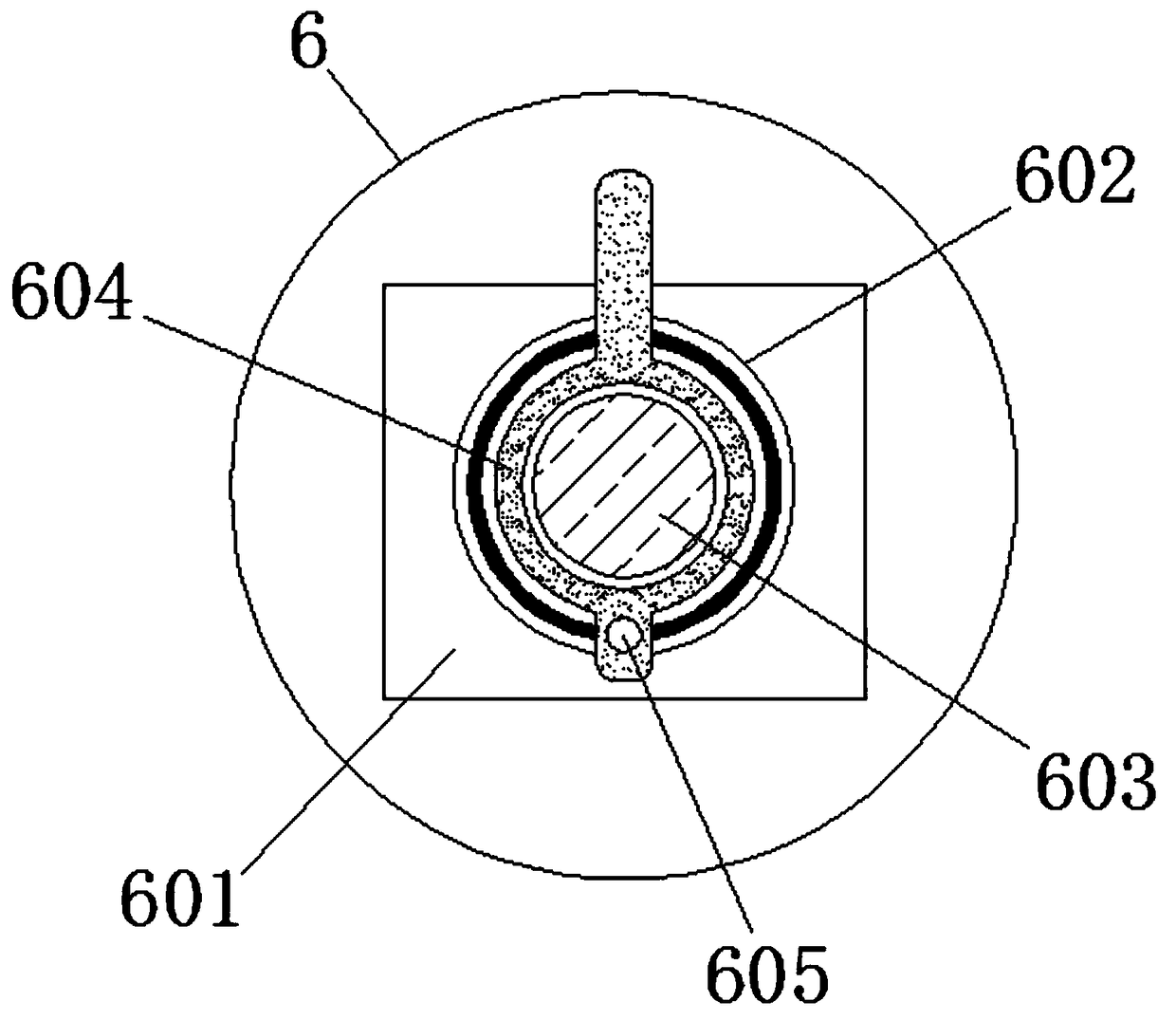

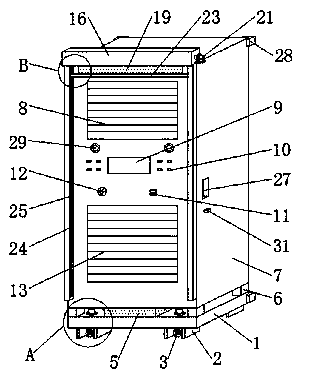

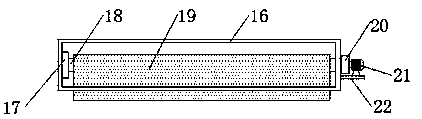

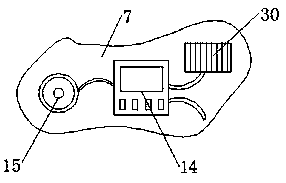

Explosion-proof electrical cabinet convenient for ventilation and heat radiation

InactiveCN108541164AEasy to ventilate and dissipate heatEasy to organize and intersperseCasings/cabinets/drawers detailsCooling/ventilation/heating modificationsEngineeringElectric wire

The invention discloses an explosion-proof electrical cabinet convenient for ventilation and heat radiation. The explosion-proof electrical cabinet comprises a cabinet body, blowers and pull rods. Theupper and lower ends of the cabinet body are provided with ventilation ports, and the internal side of the cabinet body is provided with lead devices. The left and right sides of the cabinet body areprovided with cabinet doors, and the cabinet doors are provided with windows. The lower end of the cabinet body is provided with universal wheels, and clamp blocks are connected on the left and rightinternal side surfaces of the cabinet body. Clamp blocks are fixed on the external side of the pull rods, and springs are connected on the internal side of the pull rods. Dust screens are connected on the springs, and springs are connected on the left and right ends of the dust screens. The blowers are arranged on the internal side lower end of the cabinet body, and connecting blocks are connected on the left and right ends of the blowers. According to the explosion-proof electrical cabinet convenient for ventilation and heat radiation, arrangement and penetration of various electric wires can be facilitated so that connection and utilization can be facilitated, internal ventilation and heat radiation of the electrical cabinet can be facilitated, dustproof processing can also be facilitated and use is convenient.

Owner:HEFEI DEJIE ENERGY CONSERVATION & ENVIRONMENTAL PROTECTION TECH CO LTD

Transmission device for garment production and with dust removal function and for conveniently fixing garment

The invention relates to a transmission device for garment production and with the dust removal function and for conveniently fixing the garment. The transmission device includes a bracket, a supporting shaft, a working table supporting frame, a belt wheel, and a gear groove, a dust removal box is arranged above the bracket, a driving shaft is arranged on the left side of the dust removal box, a driven shaft is mounted on the right side of the dust removal box, and the driven shaft and the driving shaft are connected with the dust removal box through a supporting plate; and a ring pipe is arranged at the top of a water spring pipe, a first connecting pipe is arranged below the ring pipe, and a second connecting pipe is mounted on one side of the ring pipe. According to the transmission device for the garment production and with the dust removal function and for conveniently fixing the garment, the garment is squeezed between transmission nets, the garment can be more conveniently fixedin the process of transmission and dust removal, the garment is laid to be more flat, the interior of a mesh bag can be atomized and moisture by arranging an atomization nozzle, and the garment is prevented from being secondarily contaminated due to the fact that the dust, fiber and the like are raised secondarily.

Owner:广州绅威鞋业实业有限公司

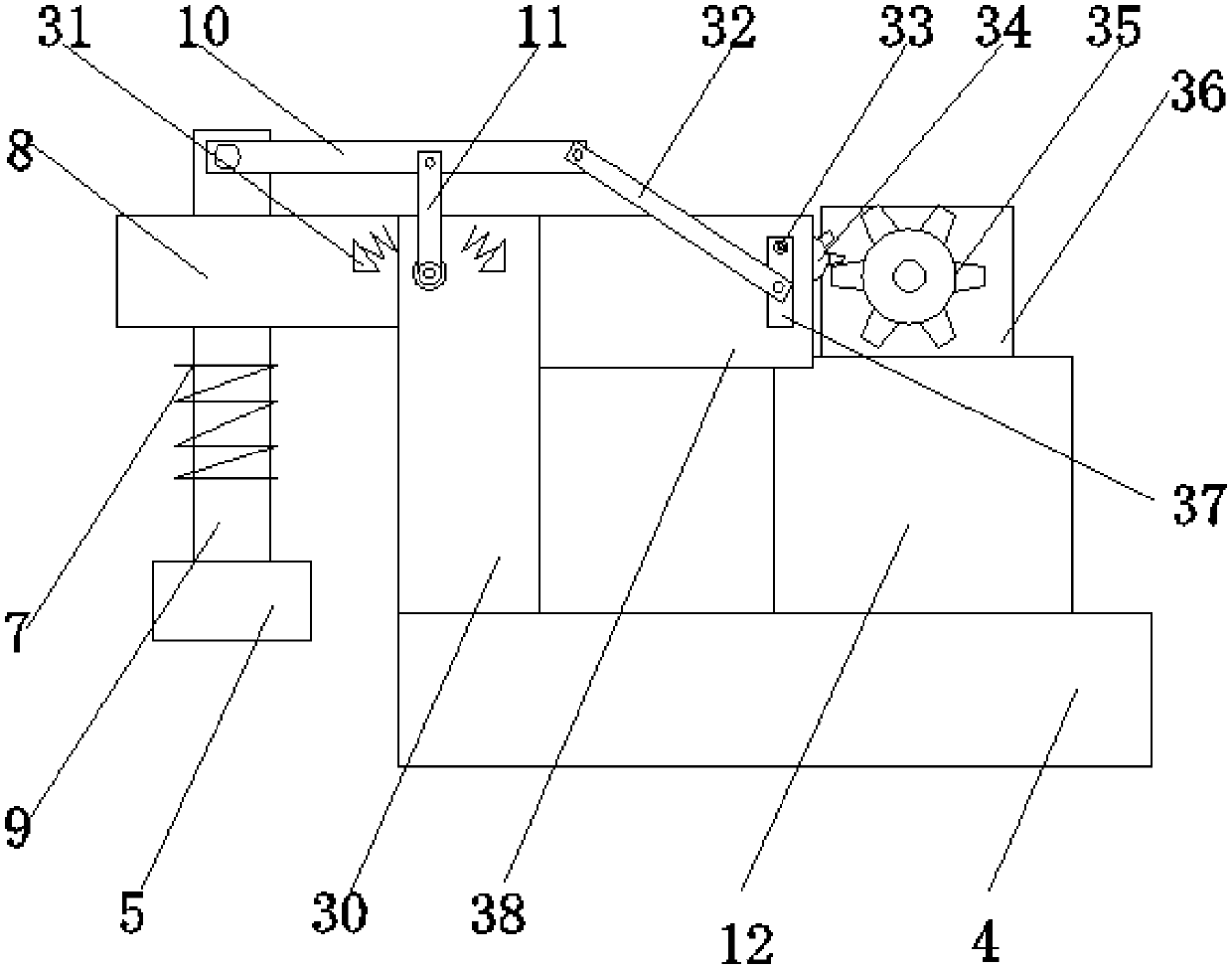

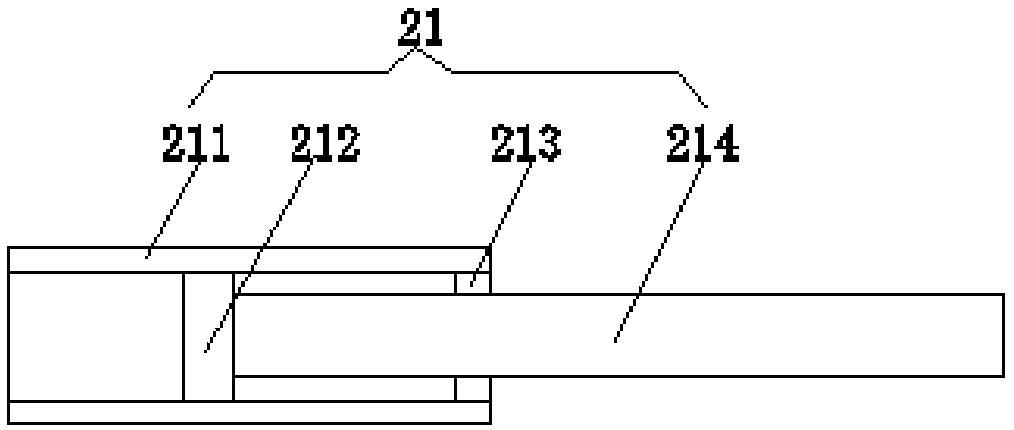

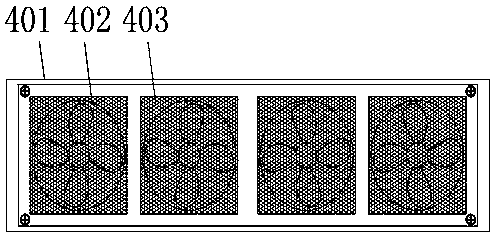

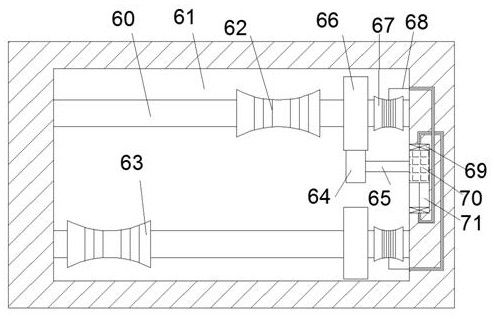

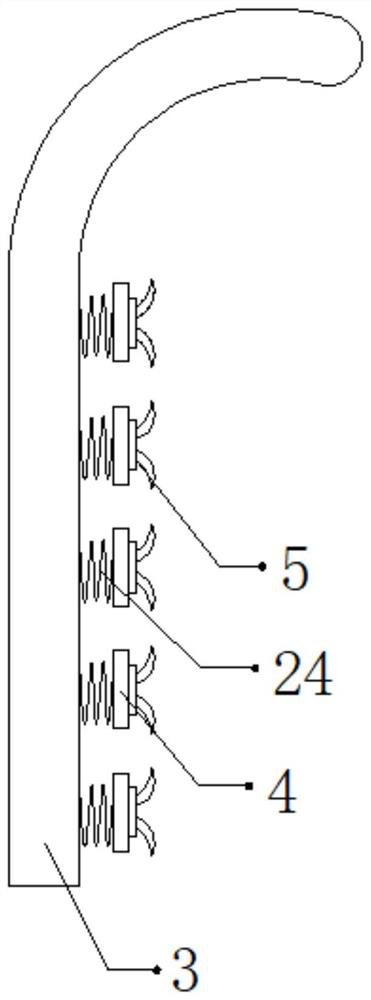

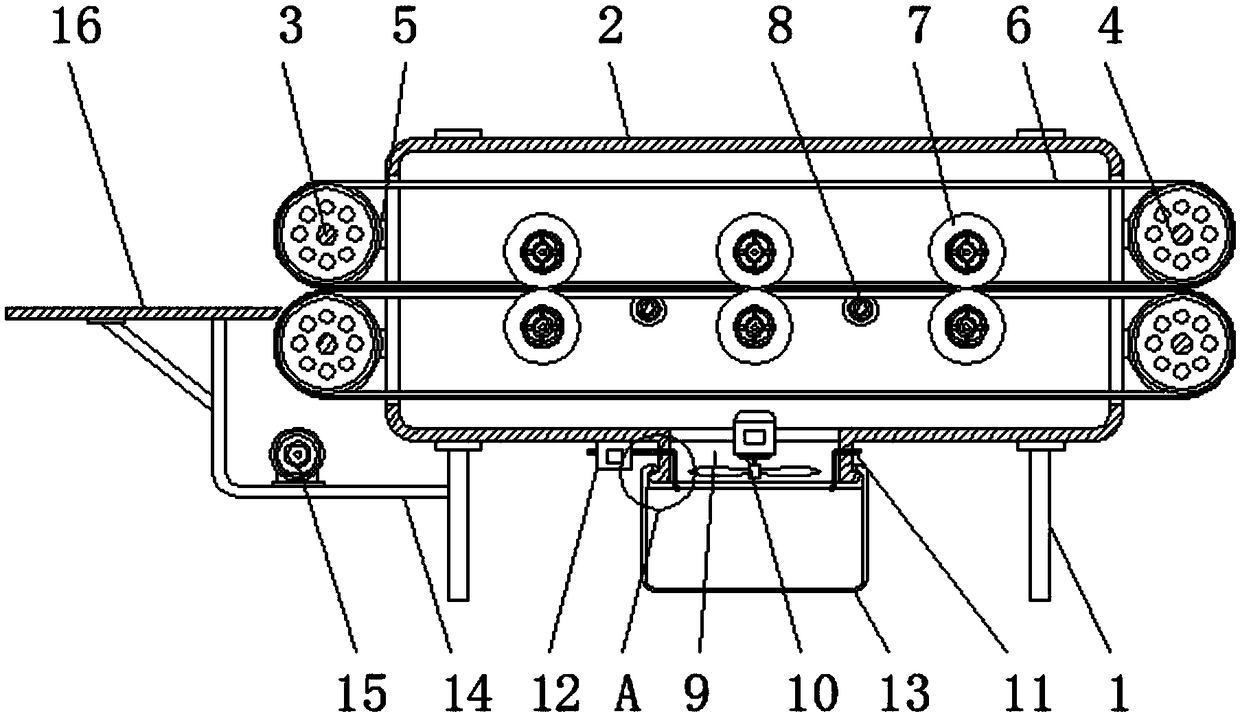

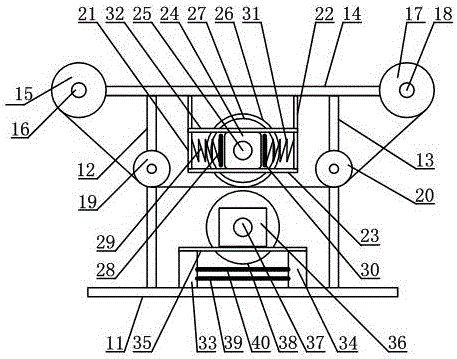

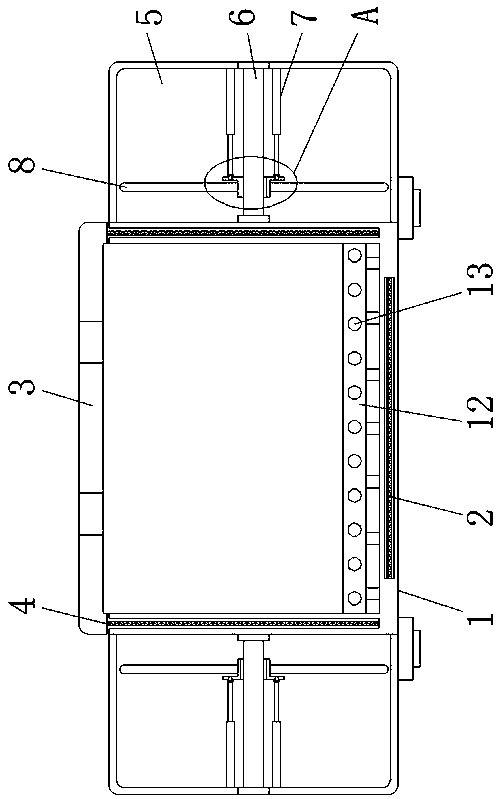

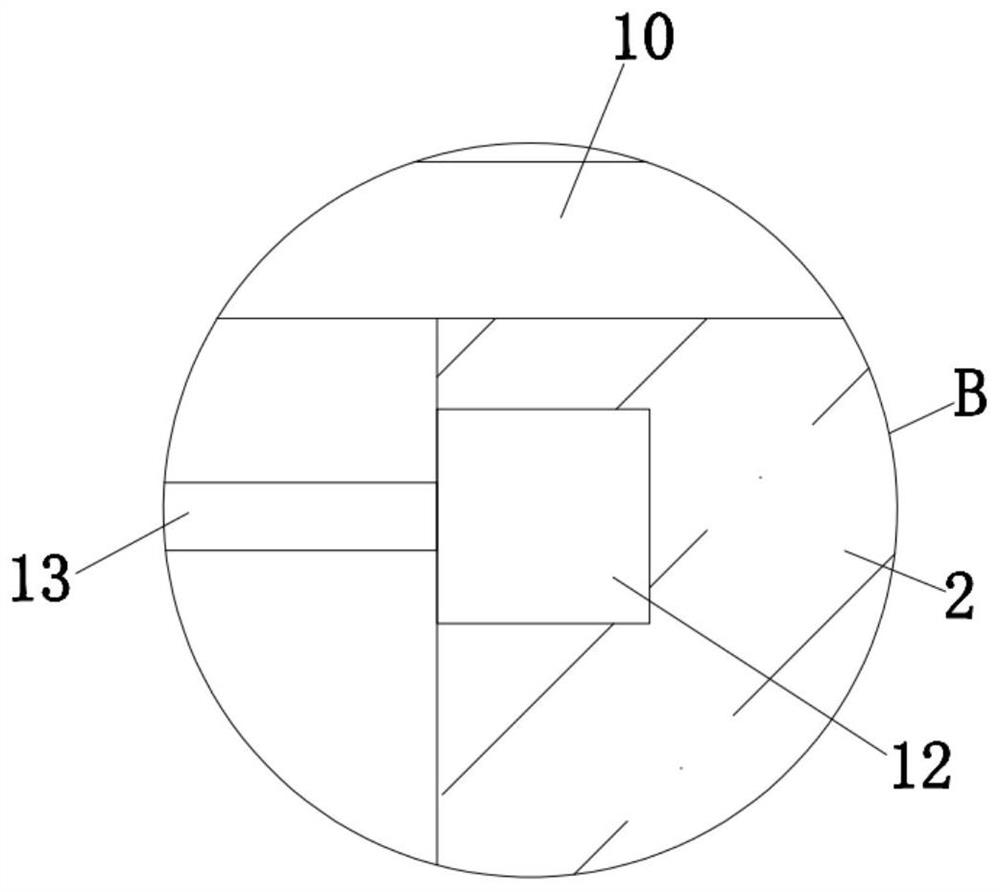

Bristle brush wheel adjusting device for aluminum laminated film dust removal

InactiveCN106493099AEasy to handle with dust removalImprove dust removal efficiencyCleaning using toolsEngineeringConductor Coil

The invention discloses a bristle brush wheel adjusting device for aluminum laminated film dust removal. The bristle brush wheel adjusting device comprises a base plate, and the base plate is provided with side plates. A top plate is arranged between the ends of the side plates. An unwinding wheel is arranged at one side of the top plate, and a winding wheel is arranged at the other side of the top plate. The side plates are provided with traction wheels. Suspended ceiling side plates are arranged on the lower portion of the top plate, and a carrying plate is arranged between the lower portions of the suspended ceiling side plates. The carrying plate is provided with a first driving motor, and a first driving shaft is arranged on the front portion of the first driving motor. The outer circumferential face of the first driving shaft is sleeved with a first bristle brush wheel. The base plate is provided with a carrying base, and the carrying base is provided with a second driving motor. A second driving shaft is arranged on the front portion of the second driving motor. One end of the second driving shaft is connected with the second driving motor, and the other end of the second driving shaft is sleeved with a second bristle brush wheel. The second bristle brush wheel corresponds to the first bristle brush wheel. According to the bristle brush wheel adjusting device, the front face and the back face of an aluminum laminated film can be conveniently scrubbed through the bristle brush wheels, and dust removal efficiency for the aluminum laminated film is greatly improved.

Owner:SUZHOU HONGYE LAMP EQUIP CO LTD

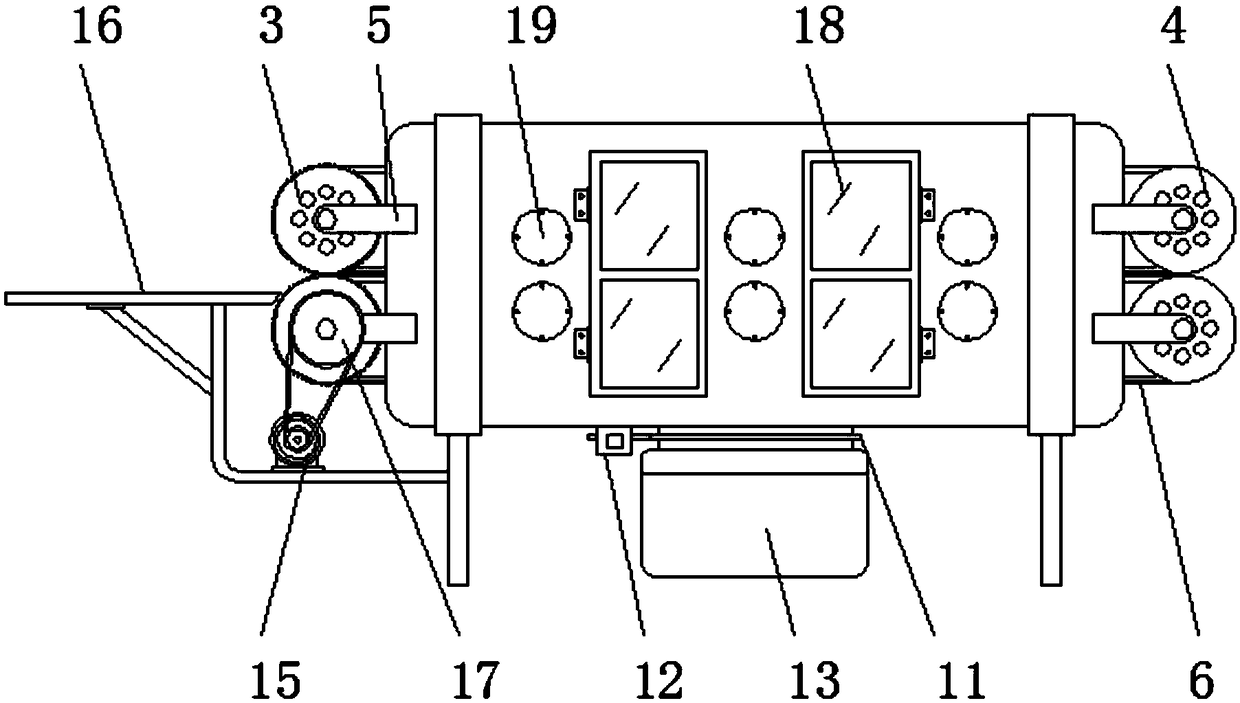

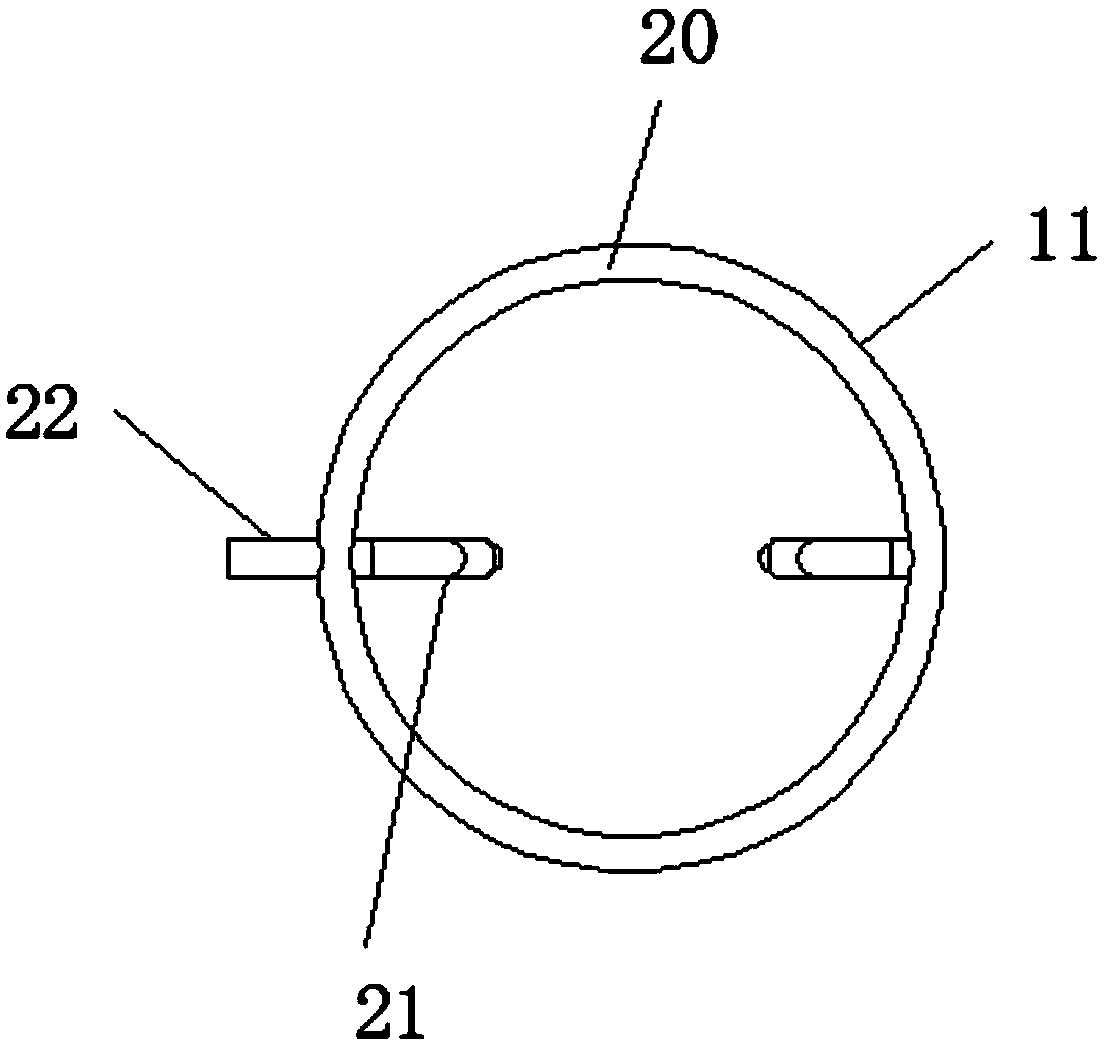

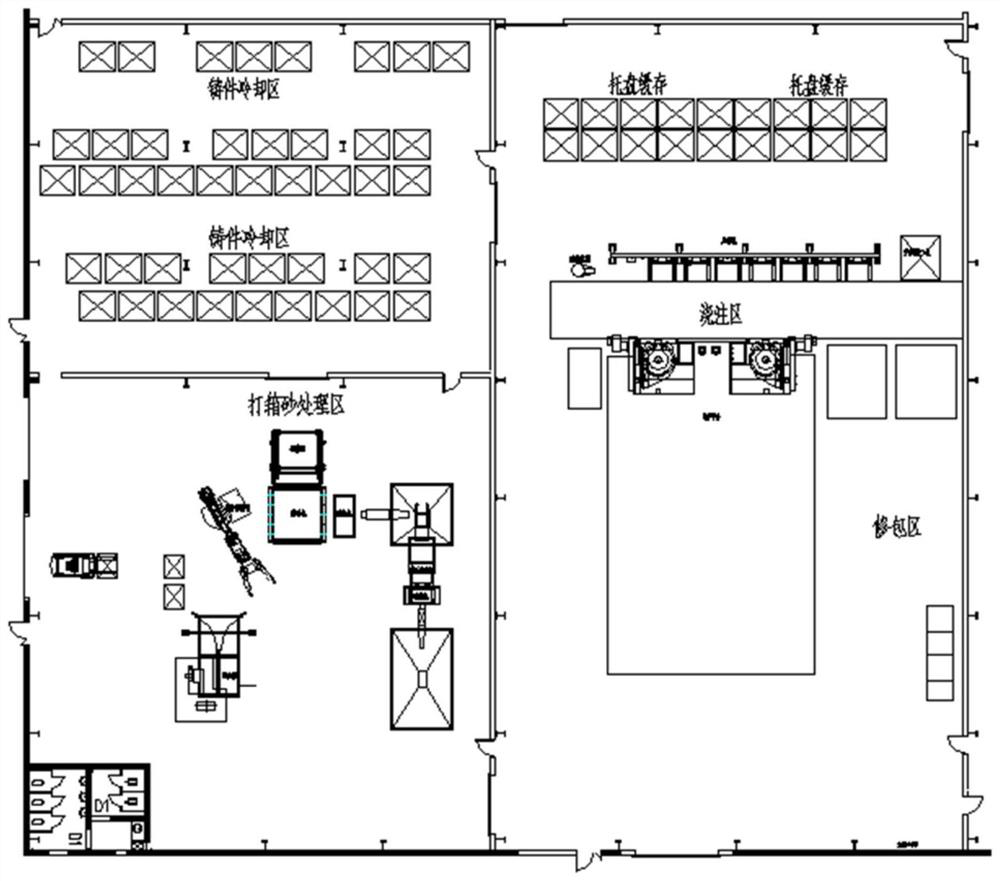

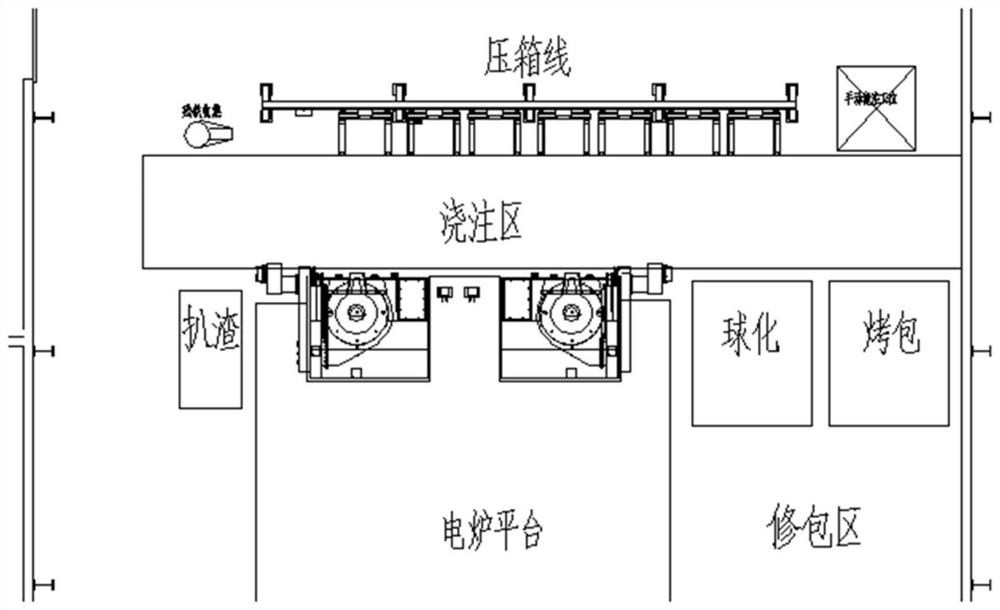

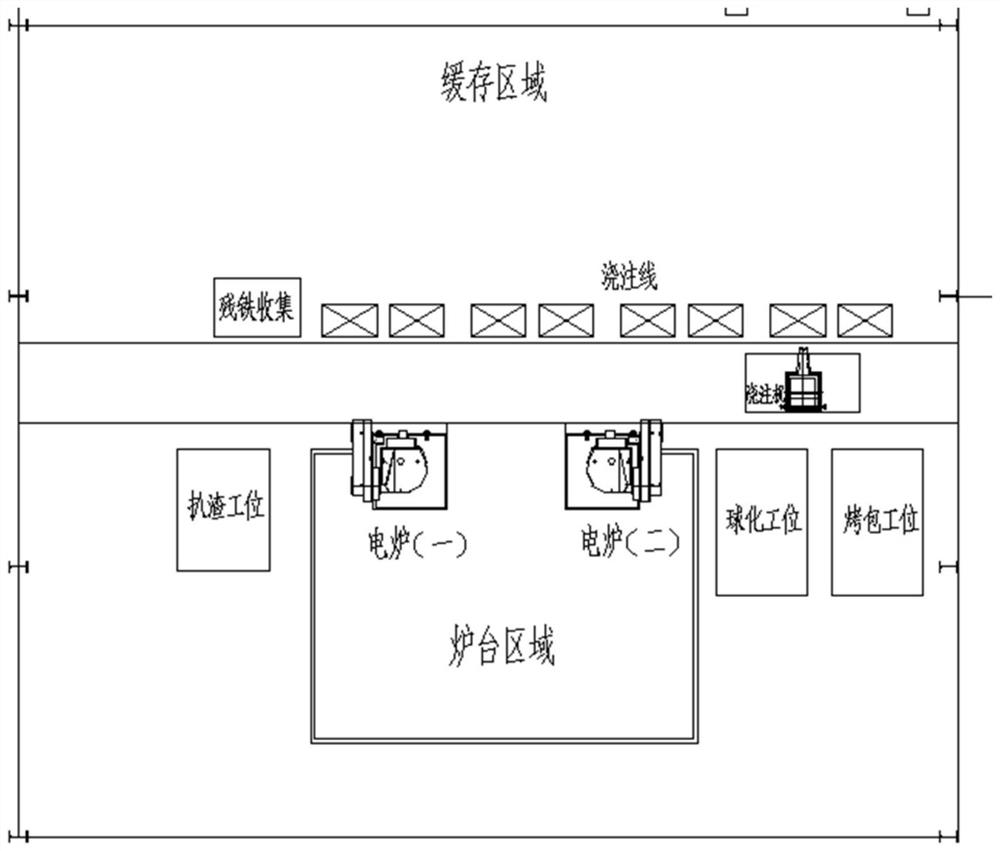

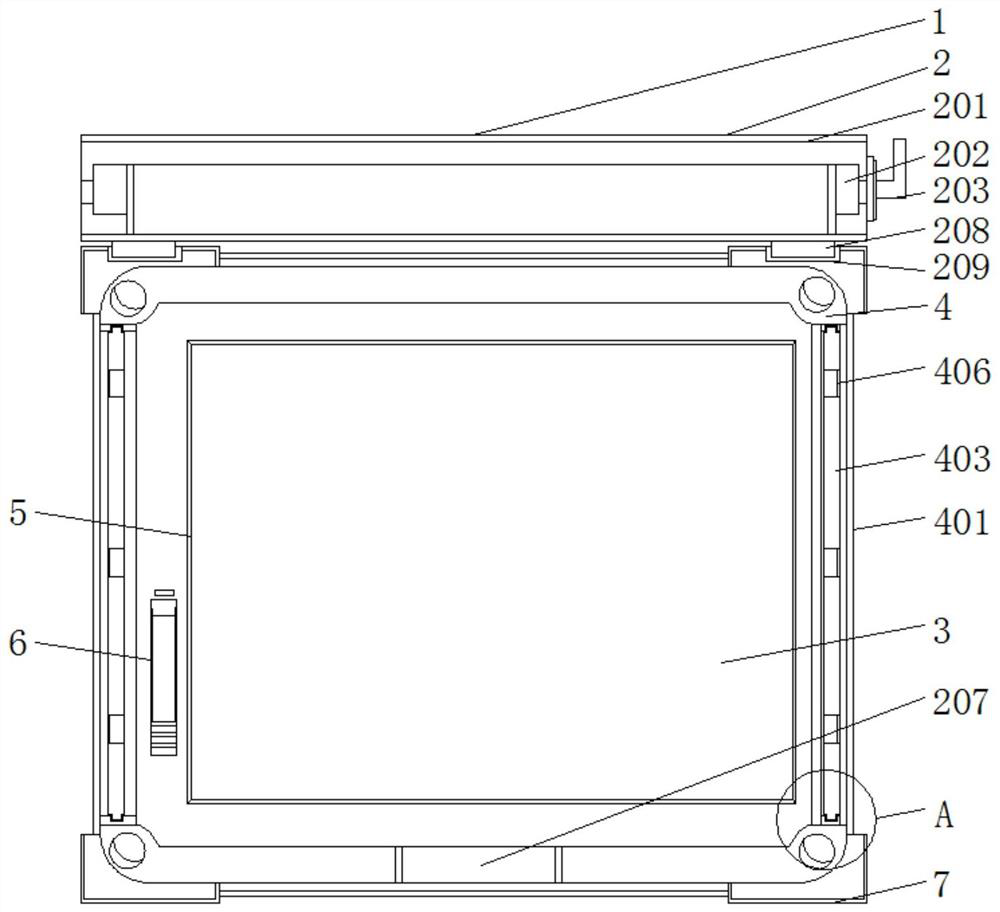

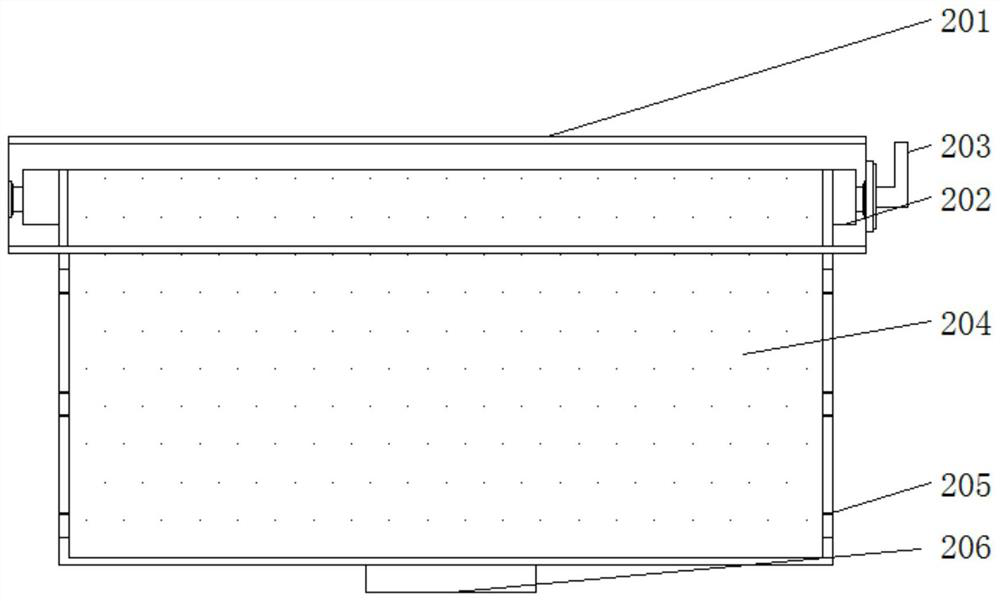

Intelligent smelting system and operation method thereof

PendingCN113523265AReduce in quantityShort process routeCasting plantsProcess engineeringElectric cables

The invention discloses an intelligent smelting system and an operation method thereof, and relates to the technical field of casting. The system comprises AGV transfer equipment, automatic pouring equipment, automatic box pressing equipment, a spheroidizing baking ladle, automatic box turning equipment, casting head removing equipment, shakeout equipment, shot blasting equipment and power and free equipment. The interior of the automatic pouring equipment comprises a barrel-shaped pouring ladle, a tilting mechanism, a transverse moving mechanism, a lifting mechanism, a pouring vehicle body, a rail system, a control and operation system, a safety system and a cable device, and the interior of the automatic box pressing equipment comprises a stand column, a cross beam, a lifting mechanism, a box pressing mechanism, a transverse moving mechanism and a lifting and transverse moving driving mechanism. The production area is compactly arranged, so that equipment is reasonably arranged, the number of production equipment can be reduced, the process route can be shortened, and the requirements of efficiency improvement, cost reduction and environment-friendly production are met.

Owner:烟台冰轮智能机械科技有限公司 +1

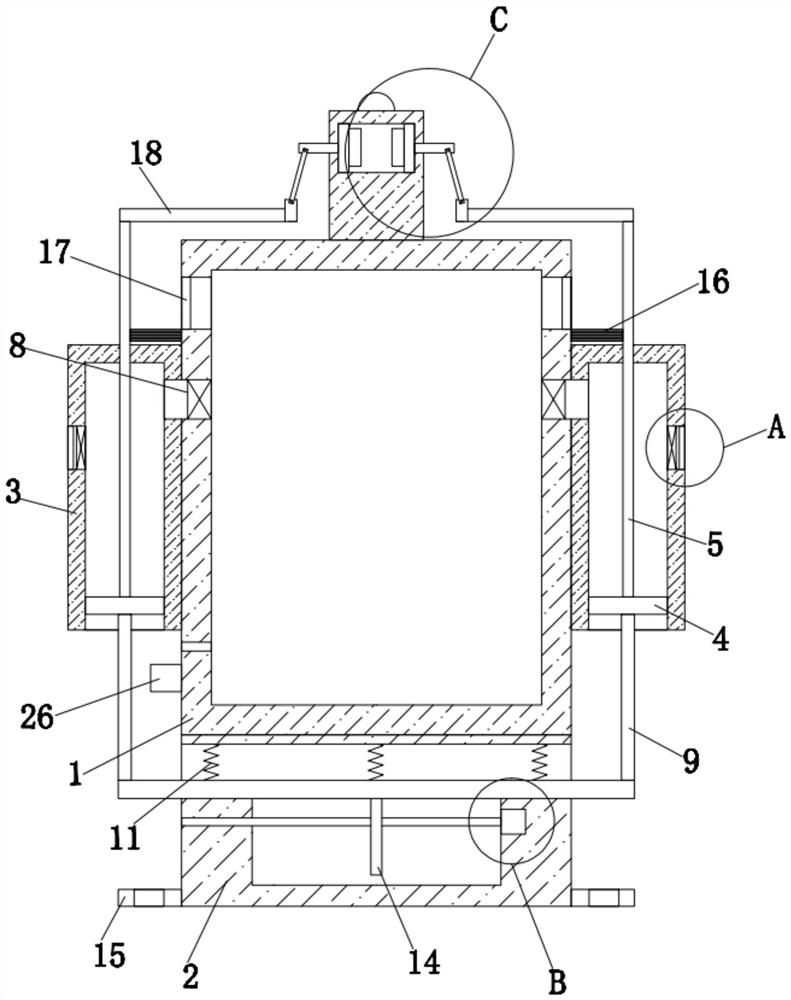

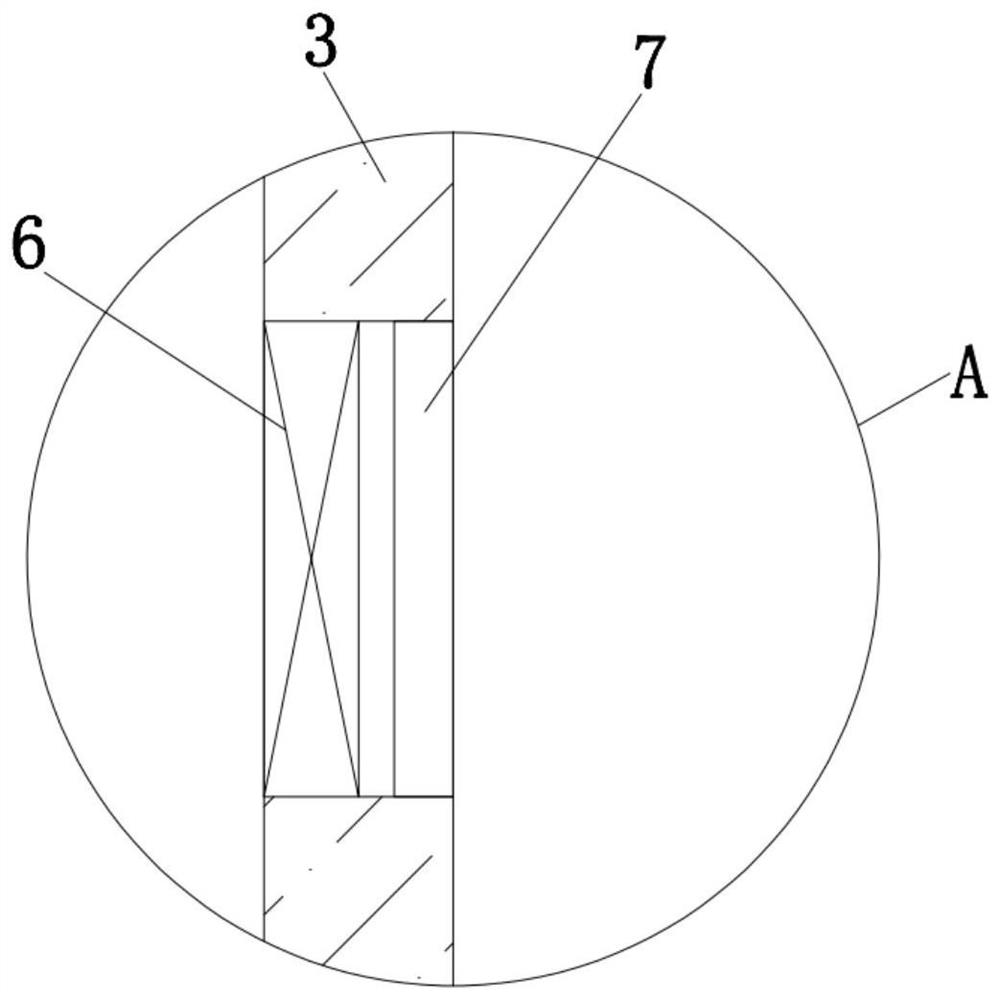

Computer display equipment with front-end protection structure

ActiveCN112224146AEasy to handle with dust removalEffective protectionElectric/fluid circuitIn vehiclePush-button

The invention discloses computer display equipment with a front-end protection structure. The computer display equipment comprises a main body, a protection mechanism is mounted at the top end of themain body, a display screen is fixed in the middle of the main body, fixing mechanisms are mounted at the left end and the right end of the display screen, a frame is mounted around the outer wall ofthe display screen, a button is mounted at one end of the left side of the frame, and mounting mechanisms are mounted at four corners of the body. The computer display equipment with the front-end protection structure is provided with the protection mechanism, so that a user can conveniently conduct dustproof treatment on a vehicle-mounted display screen, and the vehicle-mounted display screen iseffectively protected; a dustproof cloth strip is stretched from a top box through rotation of a center inner rod in the middle of the top box and a rotating handle, and through rotation contraction and rotation of the center inner rod, the dustproof cloth strip is fixed through magnets at the left end and the right end, so that poor sealing performance during covering is prevented; and the dustproof cloth strip is of a spinning structure, so that heat generated in the main body is effectively dissipated.

Owner:安徽砥砺信息科技有限公司

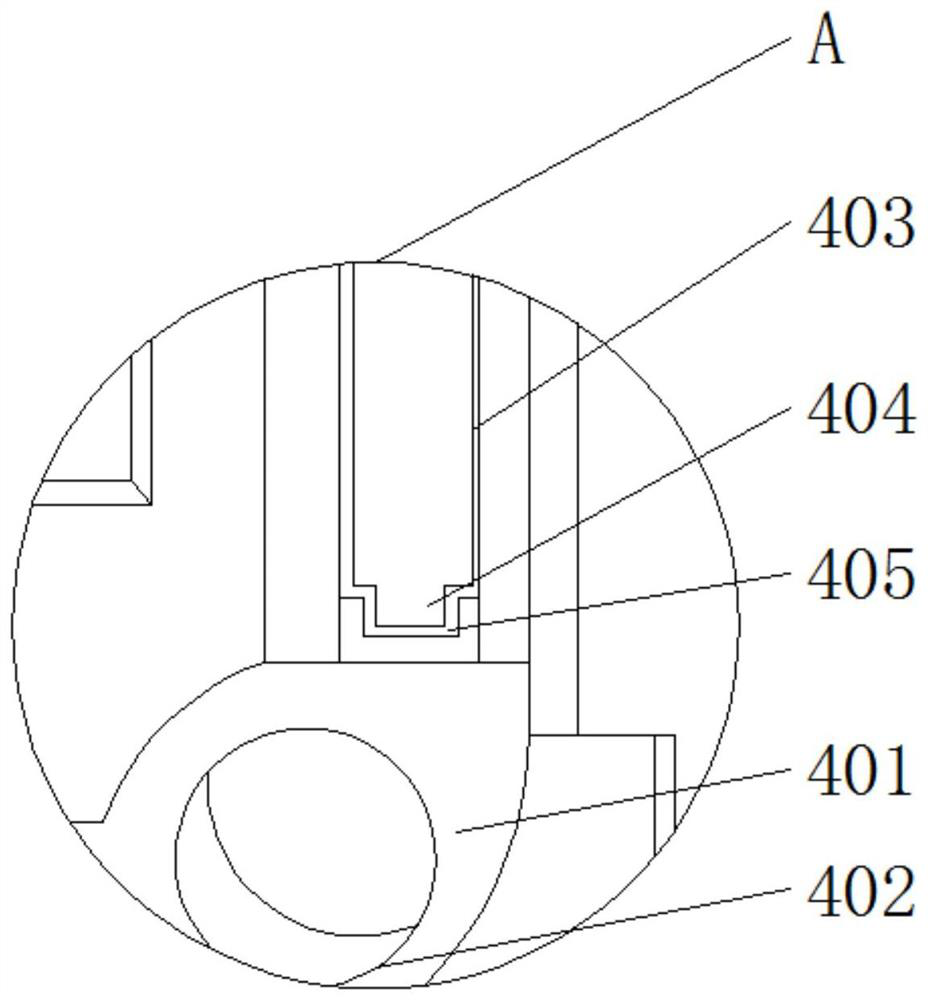

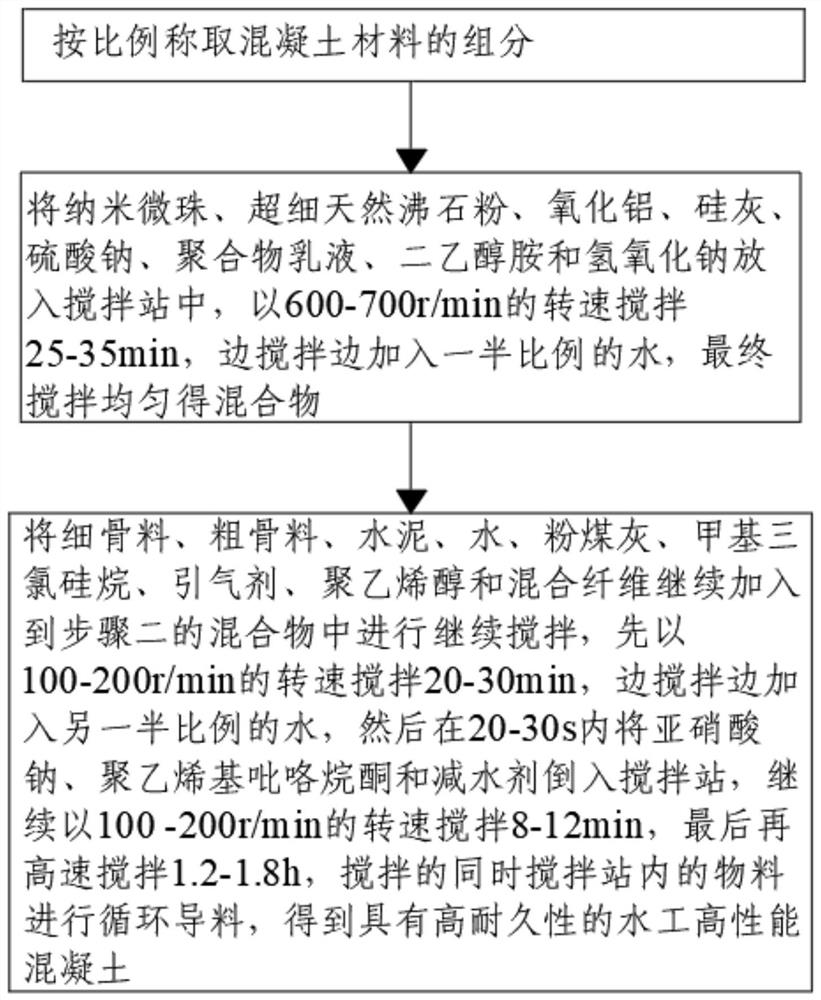

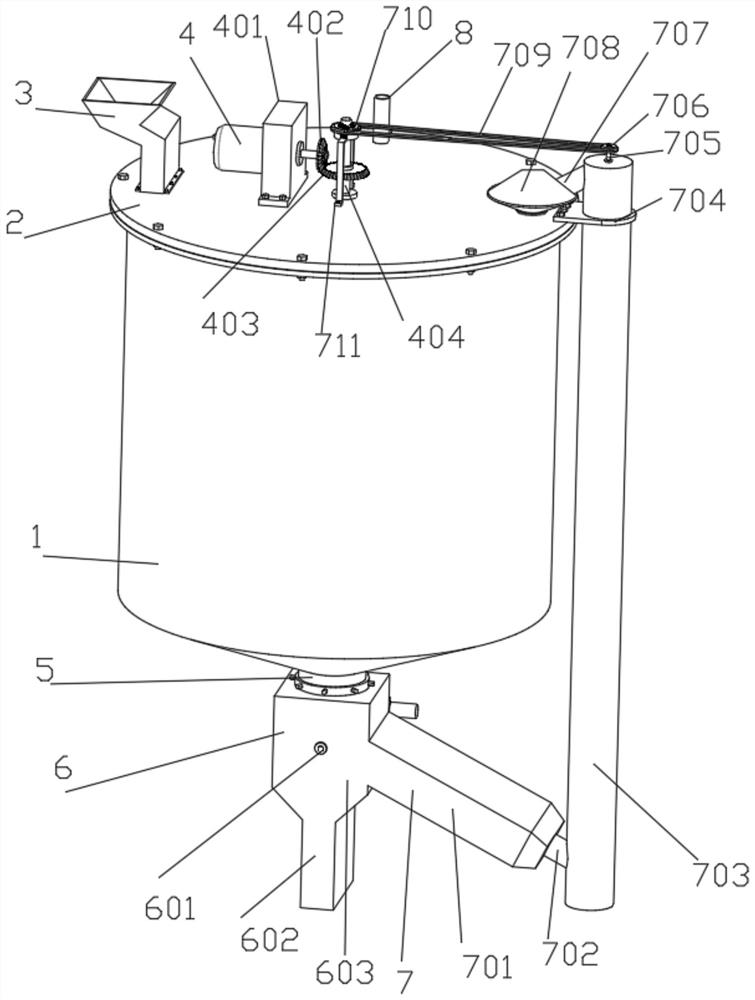

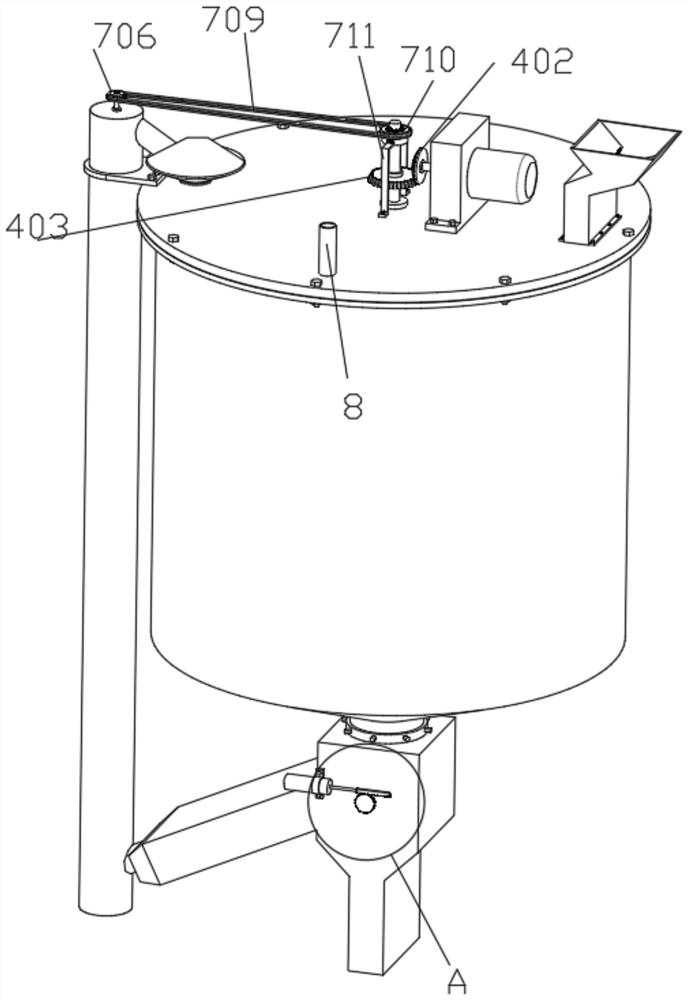

Hydraulic high-performance concrete with high durability as well as preparation process and preparation device thereof

InactiveCN113372051APrevent overflowEasy to handle with dust removalDischarging apparatusCement mixing apparatusFiberPolyvinyl alcohol

The invention discloses hydraulic high-performance concrete with high durability as well as a preparation process and a preparation device thereof, and relates to the technical field of concrete. The hydraulic high-performance concrete with high durability is prepared from the following raw materials in parts by weight: 180 to 240 parts of fine aggregate, 90 to 100 parts of coarse aggregate, 100 to 200 parts of cement, 50 to 120 parts of water, 15 to 35 parts of fly ash, 30 to 80 parts of nano microbeads, 2.5 to 3.7 parts of superfine natural zeolite powder, 10 to 18 parts of aluminum oxide, 5 to 8 parts of silica fume, 2.6 to 4.5 parts of sodium sulfate, 1.3 to 1.8 parts of polymer emulsion, 3.4 to 5.6 parts of diethanol amine, 1.4 to 3.5 parts of sodium hydroxide, 1 to 1.6 parts of methyl trichlorosilane, 2.3 to 3.6 parts of an air entraining agent, 2 to 4 parts of polyvinyl alcohol, 3.5 to 5.6 parts of mixed fibers, 0.3 to 1.2 parts of sodium nitrite, 0.5 to 1.6 parts of polyvinyl pyrrolidone and 1.8 to 2.3 parts of a water reducing agent. The hydraulic high-performance concrete with high durability has a filling effect and a water reducing effect, so that the hydraulic high-performance concrete with high durability has high durability and is beneficial to long-time use, meanwhile, the processing efficiency is improved, and rapid production is facilitated.

Owner:灌南县水利建筑工程有限公司 +1

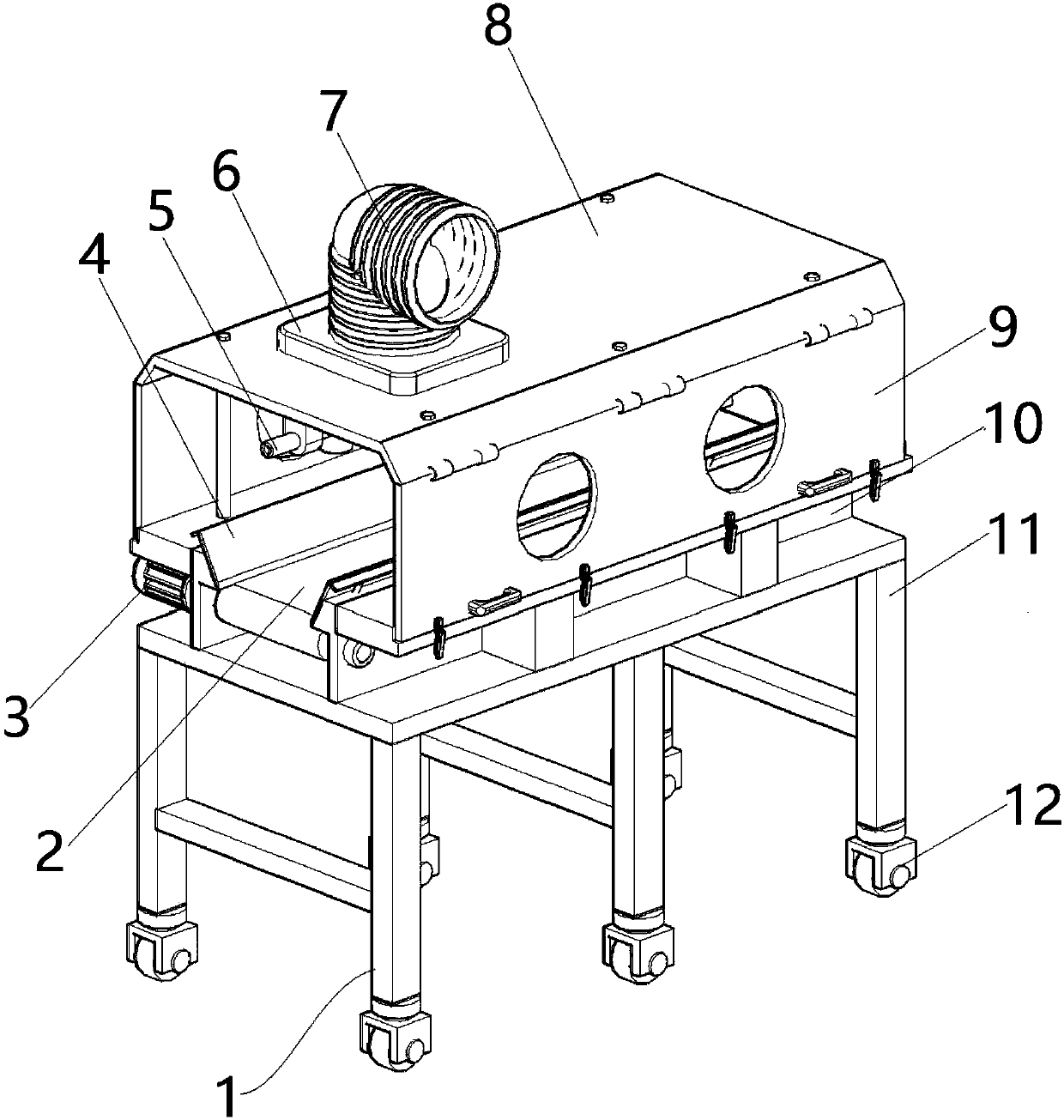

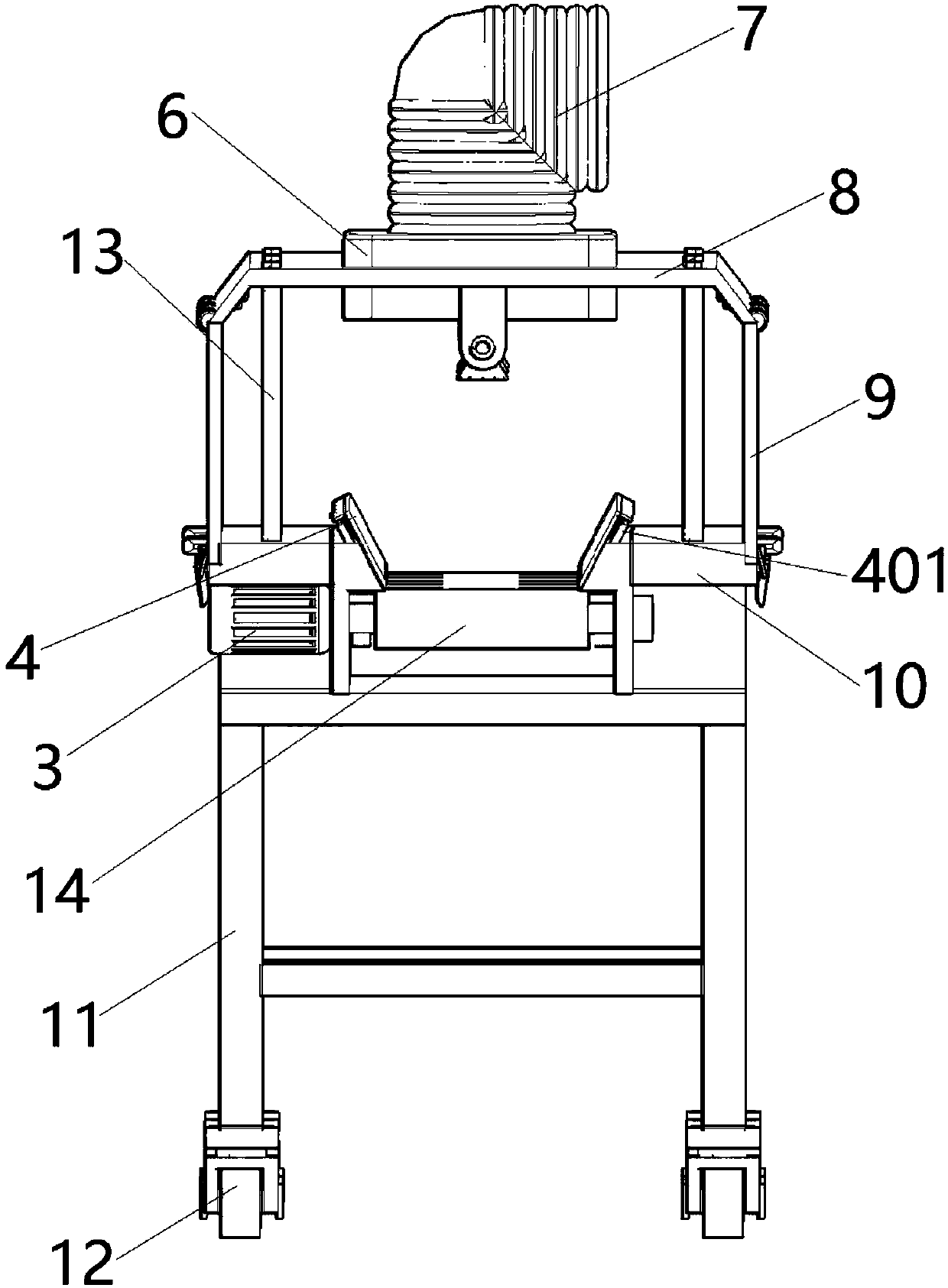

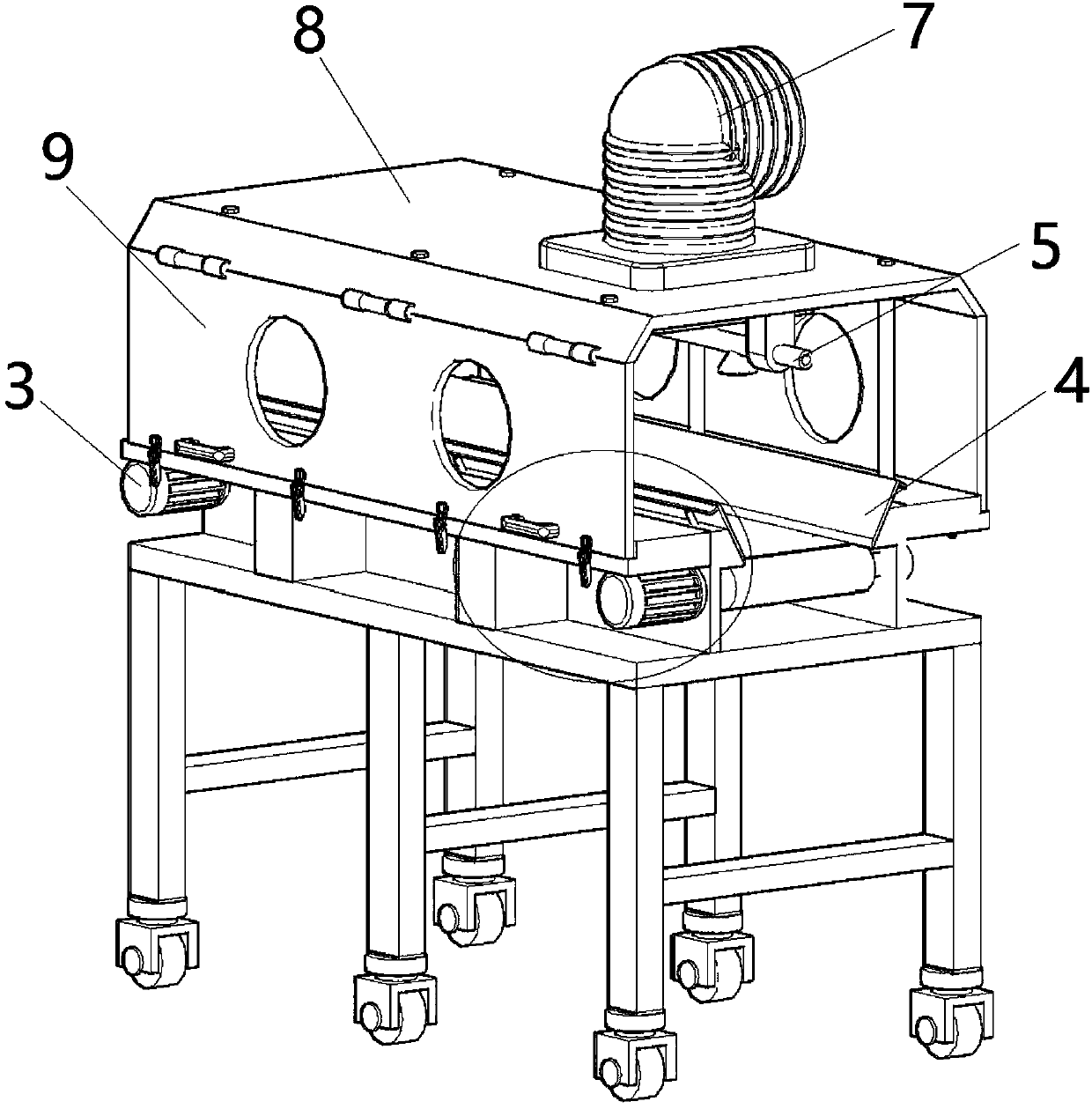

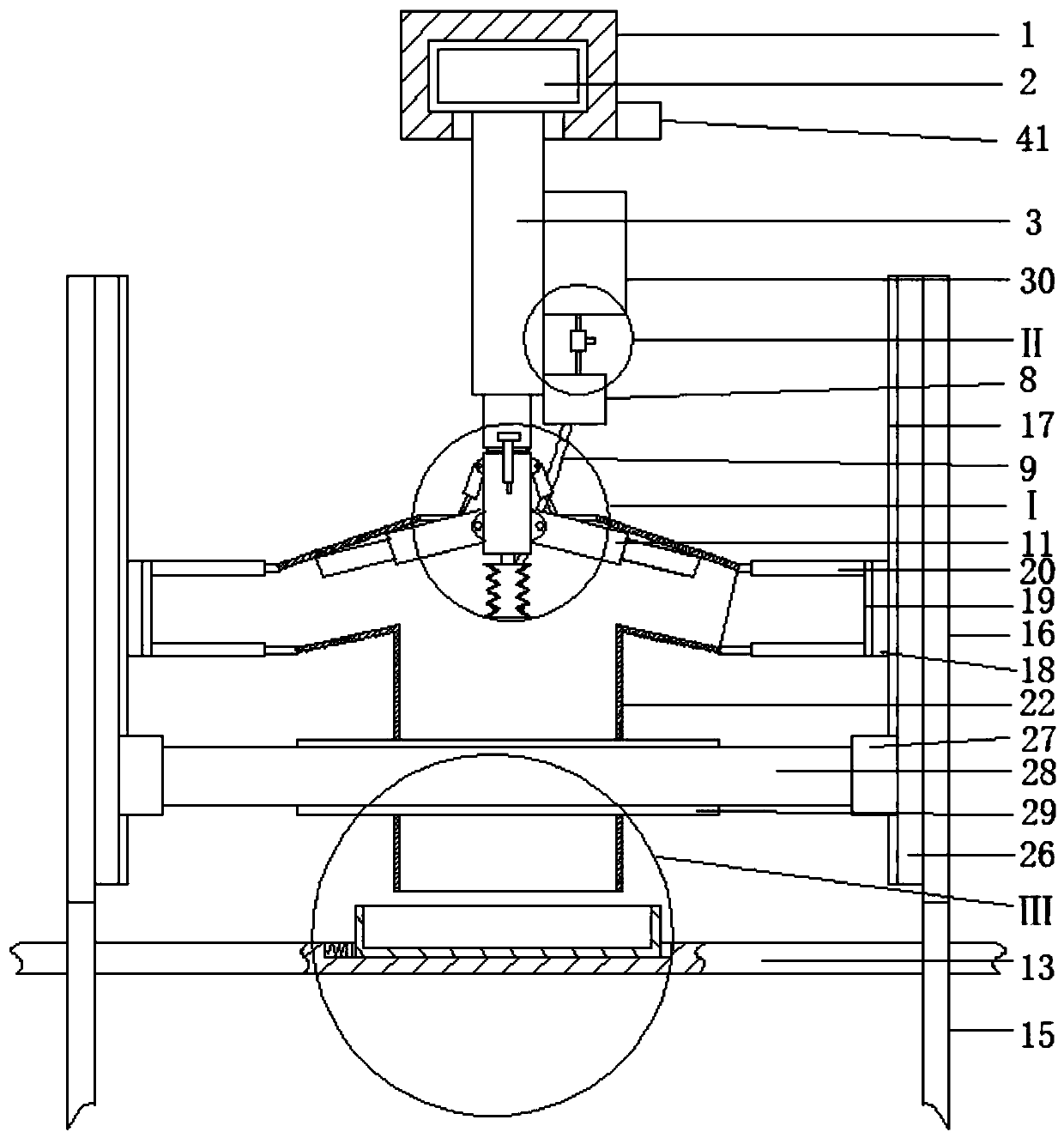

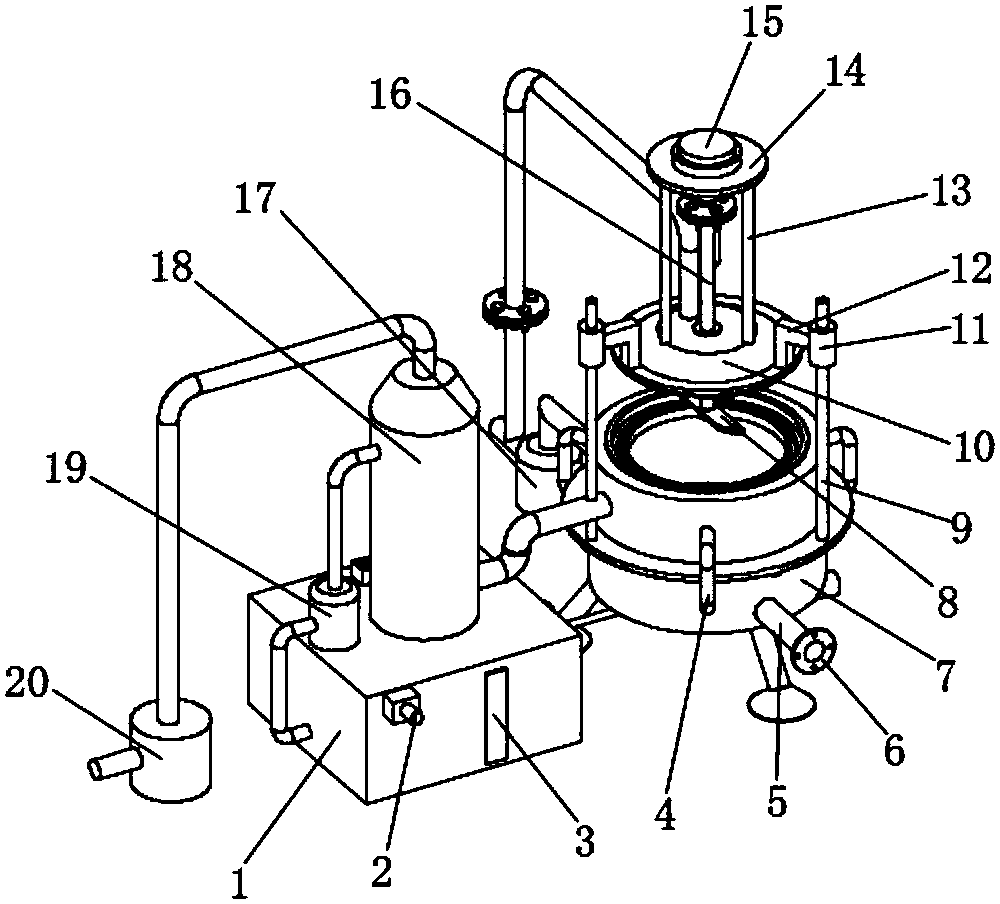

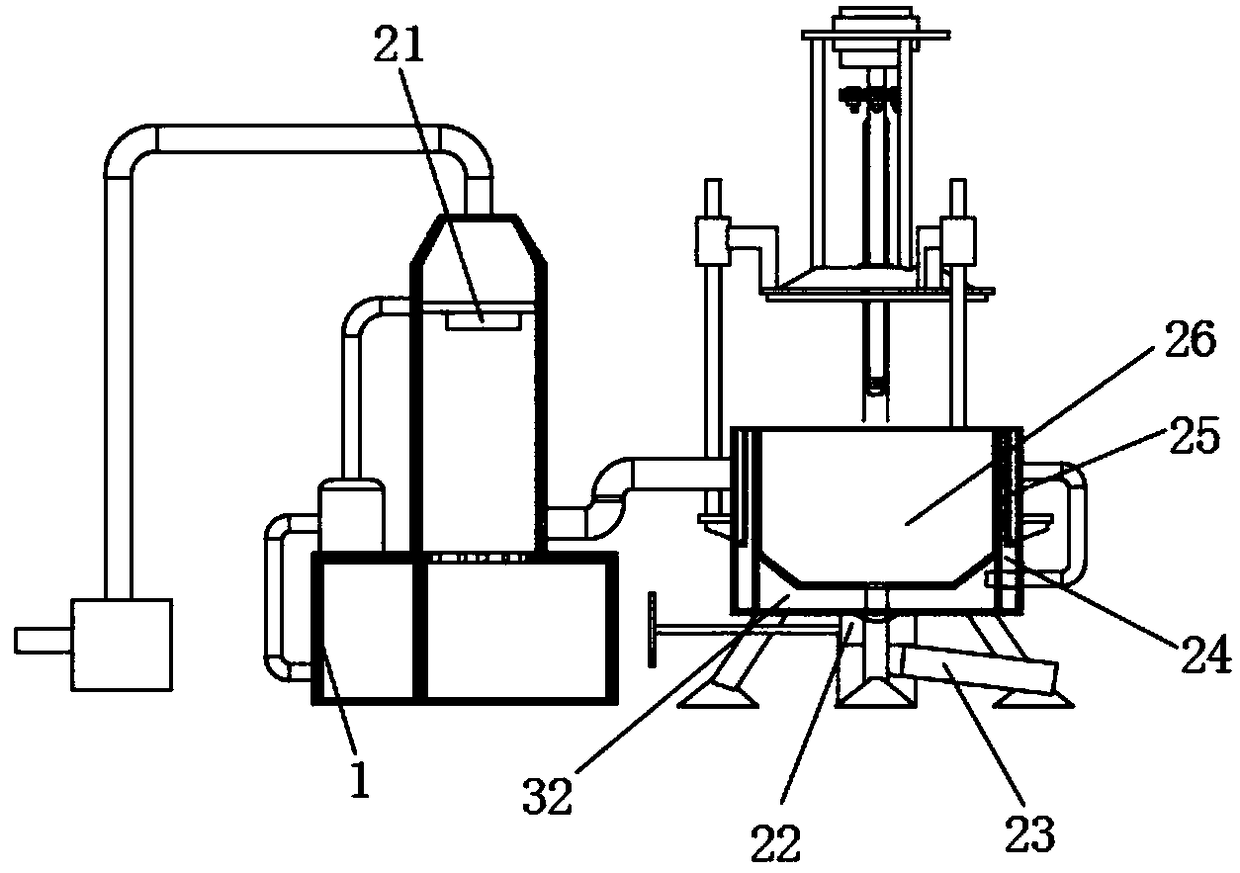

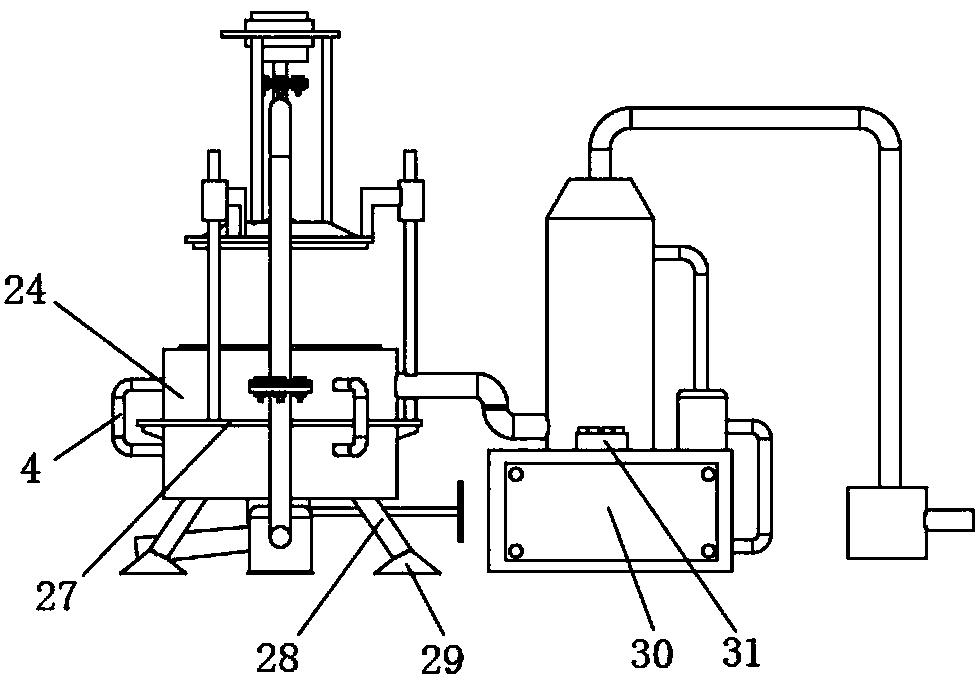

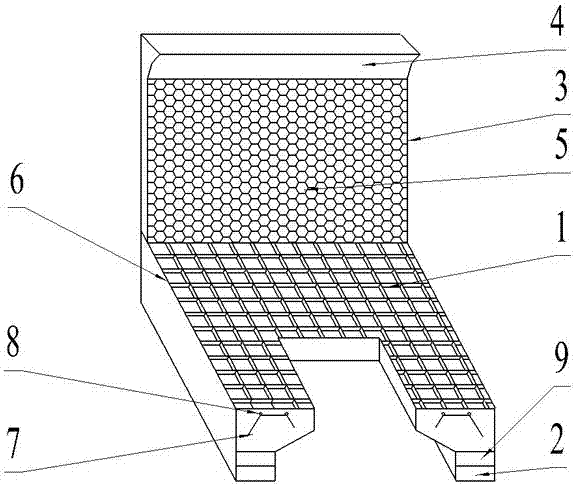

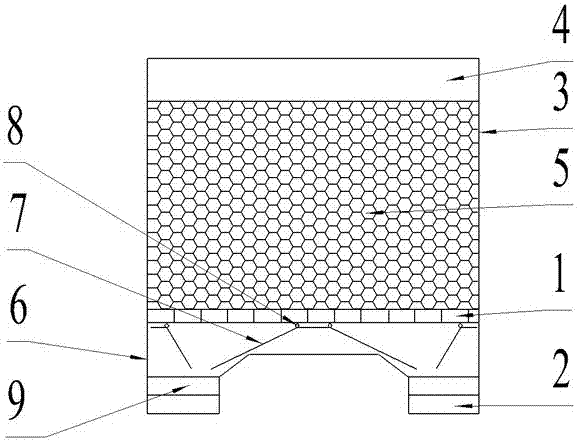

Washing type grinding dedusting equipment

PendingCN107030611AReduce pollutionImprove air qualityGrinding/polishing safety devicesWater storageDust control

The invention discloses washing type grinding dedusting equipment which comprises a hollowed-out grinding platform and a dedusting device. The equipment is characterized in that the dedusting device comprises a vertical dedusting unit located on the back of the grinding platform and a horizontal dedusting unit located under the grinding platform; the vertical dedusting unit and the horizontal dedusting unit are each internally provided with a spray system; communicating water storage grooves are formed in the bottoms of the vertical dedusting unit and the horizontal dedusting unit; and water pumps are further arranged at one sides of the water storage grooves, water inlets of the water pumps are connected with the water storage grooves, and water outlets of the water pumps are connected with the spray systems. The vertical dedusting unit and the horizontal dedusting unit are used for treating waste residues and dust in the vertical direction and the horizontal direction correspondingly, air pollution in an artificial environment is obviously reduced, water is recycled at the same time, and water resources are saved.

Owner:李军

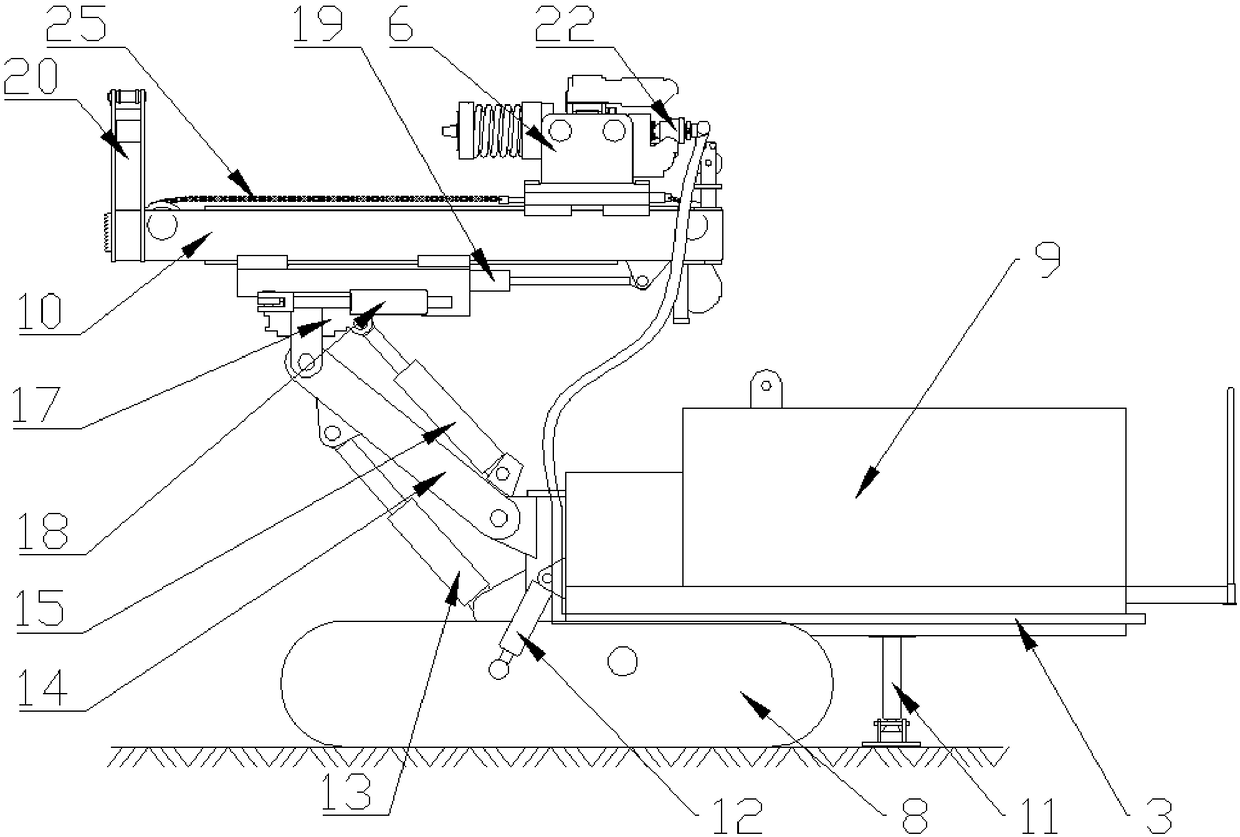

Down-the-hole drill with dustproof function and use method thereof

ActiveCN109057702AWith dust removal functionCompact structureConstructionsReciprocating drilling machinesAir pumpHigh pressure water

The invention belongs to the technical field of rock drilling, and particularly relates to a down-the-hole drill with a dustproof function and a use method thereof. The down-the-hole drill comprises adust removal mechanism, the dust removal mechanism comprises a high-pressure water pump and a high-pressure water pipe, one end of the high-pressure water pipe is connected with the high-pressure water pump, the other end of the high-pressure water pipe is communicated to a high-pressure air pipe through a tee joint, and the high-pressure air pipe is connected with a manual switching valve whichis arranged between the tee joint and a high-pressure air pump. According to the down-the-hole drill with the dustproof function and the use method thereof, by arranging the dust removal mechanism, the down-the-hole drill has a dust removal function, and dust removal equipment does not need to be independently added; secondly, the high-pressure water pipe is communicated to the high-pressure air pipe, and the original structure of the down-the-hole drill is utilized for aiding dust removal work, so that the down-the-hole drill is compact in overall structure and small in occupied space.

Owner:SINOHYDRO FOUND ENG

Coal mine transformer cooling system and cooling method

PendingCN110415932AEasy to ventilate and dissipate heatWith dustproof functionTransformers/inductances coolingTransformerEngineering

The invention discloses a coal mine transformer cooling system and a cooling method; the cooling system comprises a base, an electric telescopic rod, a water pump and a cooler, wherein a dustproof bottom plate is clamped and connected in the lower end of the base, and the upper end of the base is clamped and connected with a cover plate; the left end and the right end of the base are fixedly connected with a supporting frame; a spiral rod is welded and connected to the inner wall of the supporting frame; electric telescopic rods are fixedly installed on the upper side and the lower side of thespiral rod; a rotating piece is welded to the outer surface of a rotating block; the electric telescopic rods are connected to the end face, away from the base, of the rotating block through a sliding rail in a sliding mode; a cooling box is arranged on the lower end surface of the inside of the base; and the water pump and the cooler are fixedly connected to the left end and the right end of thecooling pipe respectively through bolts. According to the coal mine transformer cooling system, the dustproof function is achieved, and meanwhile, the coal mine transformer can be subjected to ventilation and heat dissipation; and in addition, water cooling heat dissipation is combined, so that sufficient heat dissipation is facilitated, and the coal mine transformer cooling system is convenientto use.

Owner:盐城奇林电气有限公司

Energy-saving and emission-reducing wastewater circulating dust-settling device for building construction

PendingCN114146518AAchieve recyclingAchieving processing powerTransportation and packagingUsing liquid separation agentWastewaterChemical agent

The invention discloses a building construction energy conservation and emission reduction wastewater circulation dust fall device which comprises an outer box, one side of the interior of the outer box is fixedly connected with a treatment box, the upper surface of the outer box is provided with a first feeding port and a second feeding port, the first feeding port penetrates through the upper end of the treatment box, and the second feeding port penetrates through the lower end of the treatment box. A feeding pipe is fixedly connected to the lower end of the second feeding port, a shell is fixedly connected to the surface of one side of the feeding pipe, a sliding groove is formed in the other side of the interior of the outer box, a motor box is fixedly connected to one end of the interior of the sliding groove, a second motor is arranged in the motor box, and a lead screw is in transmission connection to one end of the second motor; according to the waste water treatment device disclosed by the invention, through the arrangement of the treatment box, a chemical agent for harmless treatment of waste water is poured into the treatment box through a feeding pipe and then is sprayed into air through an atomization spray head, dust in the air is subjected to dust falling treatment, and thus recycling of the waste water is realized.

Owner:CHINA CONSTR FIFTH ENG DIV CORP LTD

Animal husbandry feed crushing device for

PendingCN112547199AEasy to crushIncrease jitterSievingFeeding-stuffAnimal scienceAgricultural science

The invention discloses an animal husbandry feed crushing device which comprises a machine body and a crushing device body fixedly mounted in the machine body, wherein a filter plate which is mountedon the inner wall of the machine body in a sliding mode is arranged below the crushing device body, two shaking devices are fixedly mounted below the filter plate, a feed returning device is fixedly installed on the side face of the machine body, a motor is fixedly installed on the side face of the machine body, the output end of the motor is connected with a rotating shaft, and each shaking device comprises a middle rod. When the animal husbandry feed crushing device is used, feed can be conveniently crushed through the arranged crushing device body, the shaking devices are arranged to conveniently shake the filter plate, and the feed which does not meet the requirements is conveniently screened out, and then conveyed back to a feeding opening again through the feed returning device to befurther crushed; and the motor rotates to drive the rotating shaft to rotate at the same time, so that cams are driven to rotate, and meanwhile, circular wheels are driven to move up and down.

Owner:张金英

Multifunctional gas integrated sensor

PendingCN112461994AGood cooling effectGood dust treatmentGas analyser construction detailsPhysicsSensor field

The invention belongs to the field of sensors, particularly relates to a multifunctional gas integrated sensor, and aims at solving the problems that an existing gas integrated sensor is poor in heatdissipation performance, external dust easily enters the sensor in the heat dissipation process, and the service life of the gas integrated sensor is seriously affected. Themultifunctional gas integrated sensor in the following scheme comprises a sensor main body, a base is fixedly connected to the bottom of the sensor body, side boxes are fixedly connected to the two sides of the sensor body, a sealing plate is slidably and hermetically mounted in each side box, an upper plate is fixedly connected to the top of each sealing plate, first air holes are formed in the sides, away from each other,of the two side boxes, and first one-way valves are fixedly connected into the first air holes. And a first dustproof plate is fixedly connected in the first air hole. The sensor main body is good inheat dissipation effect, dustproof processing is well carried out in the heat dissipation process, and the indicator lamp can flicker intermittently during heat dissipation to remind that heat dissipation is carried out normally.

Owner:GUANGXI POWER GRID ELECTRIC POWER RES INST

Clothes disinfection and sterilization device for textile industry

InactiveCN112618748AEasy to operateAccelerate the speed of disinfection and sterilizationLavatory sanitoryHeatProcess engineeringIndustrial engineering

The invention discloses a clothes disinfection and sterilization device for the textile industry, and belongs to the field of textile processing. The clothes disinfection and sterilization device comprises a disinfection and sterilization box, wherein a screw rod is movably connected to the bottom of the side surface of the disinfection and sterilization box in a sleeving manner; and a forward and reverse motor is fixedly connected to one end of the screw rod. According to the clothes disinfection and sterilization device for the textile industry, through the arrangement of the disinfection and sterilization box, the screw rod, the forward and reverse motor, a moving block, a positioning rod, a placing plate, a liquid storage box, a liquid conveying pipe, a liquid conveying pump, a liquid conveying sleeve, a spray head, an ultraviolet lamp and a heating plate, a plurality of working procedures of alcohol disinfection and sterilization, high-temperature sterilization, ultraviolet sterilization and the like can be integrated together, so that the problem that the operation is tedious because clothes to be treated need to be manually transferred to corresponding working procedure equipment in sequence in the prior art is solved, the labor amount of production workers can be reduced, the clothes disinfection and sterilization speed is also increased, the working efficiency of clothes disinfection and sterilization is improved, and besides, the cost of clothes disinfection and sterilization is reduced.

Owner:杜宇尘

Standing air conditioner for office

InactiveCN108917030APlace stableEasy to moveMechanical apparatusLighting and heating apparatusEngineeringMobile phone

The invention discloses a standing air conditioner for office. The standing air conditioner comprises a fixing seat, supports are connected to the bottom end of the fixing seat, universal wheels are mounted on inner sides of the supports, and a hydraulic telescopic rod is connected to the top end of each universal wheel and positioned at the top of the fixing seat. A hydraulic oil cylinder is arranged in the middle of the top end of the fixing seat, and supporting blocks are connected to edges of the top end of the fixing seat. The standing air conditioner can be placed and moved convenientlyand stably and can be connected with an external media device to play music, so that functions of the air conditioner are increased; in addition, convenience in charging of a mobile phone is achieved,indoor illumination can be conveniently realized under the condition of power failure, an air inlet of air inlet window blinds can be filtered, influences on utilization effects due to dust enteringthe air conditioner are prevented, corners of the air conditioner can be protected from bump damages, and dustproof treatment of the front surface of the air conditioner can be realized when the air conditioner is not used.

Owner:陈文志

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com