A large-format micro-hole high-speed drilling system

A large-format, micro-hole technology, used in welding equipment, laser welding equipment, metal processing equipment, etc., can solve the problems of poor control of fine processing and poor control of laser beam modulation trajectory, and achieve rich spatial trajectory modulation motion, Improve efficiency and drilling quality, improve the effect of scanning processing format

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

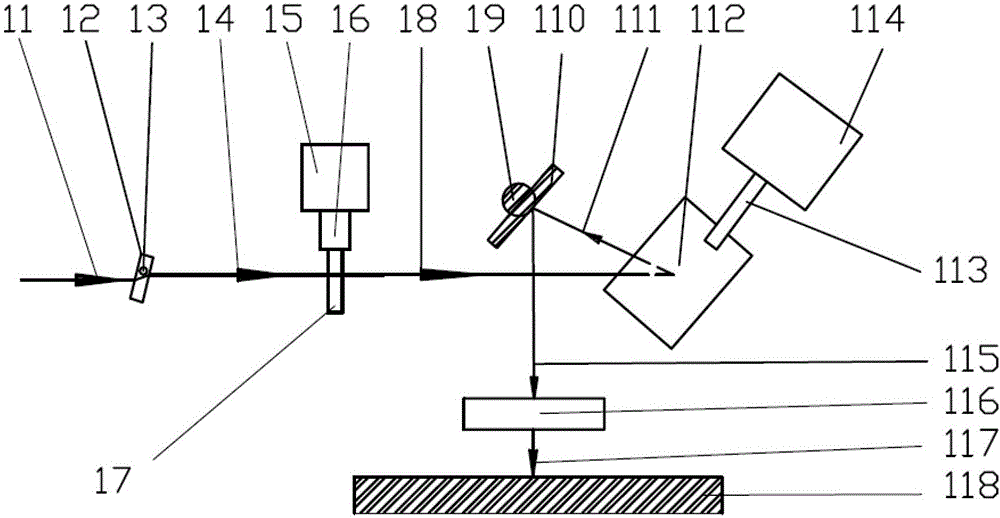

[0042] figure 1 It is a schematic diagram of the structure of the device for laser drilling of stainless steel sheets. The device includes a beam spatial modulation module and a galvanometer scanning flat-field focusing module. Wherein the beam spatial modulation module comprises a first quartz plate glass 12 and a second quartz plate glass 17, the first quartz plate glass 12 is installed on the motor spindle 13 of the first motor (not shown in the figure), the second A quartz plate glass 17 is mounted on the motor spindle 16 of the second motor 15 . The first quartz plate glass 12 and the second quartz plate glass 17 can swing around the motor spindle. The galvanometer scanning flat-field focusing module includes a scanning galvanometer and a scanning flat-field focusing mirror. The scanning flat-field focusing mirror is a telecentric focusing mirror 116, and the scanning vibrating mirror includes a first reflecting mirror 112 and a second reflecting mirror 110, and the fir...

Embodiment 2

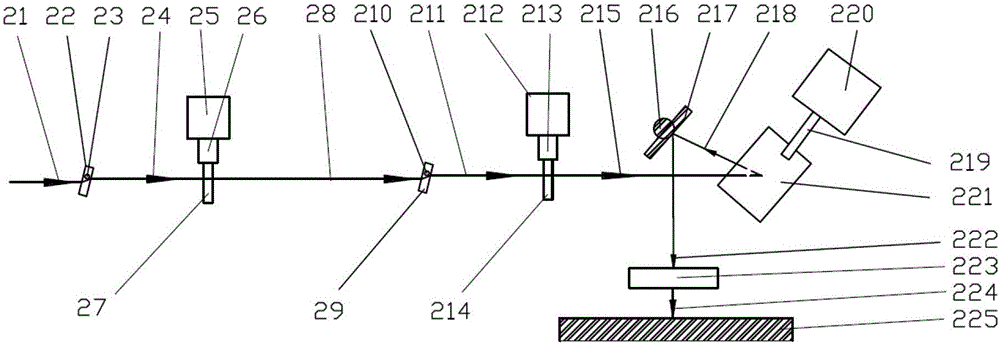

[0055] figure 2Schematic diagram of the device structure for ceramic laser drilling, by figure 2 It can be seen that, on the basis of Embodiment 1, this embodiment adds two flat optical elements and two motors for controlling the oscillation of the flat optical elements. The device includes a beam spatial modulation module and a galvanometer scanning flat-field focusing module. Wherein the beam spatial modulation module comprises a first quartz plate glass 22, a second quartz plate glass 27, a third quartz plate glass 29 and a fourth quartz plate glass 214, and the first quartz plate glass 22 is installed on the first swing axis 23 , can swing around the first swing shaft 23, and the first swing shaft 23 is the motor main shaft of the first motor (not shown in the figure). The second quartz plate glass 27 is installed on the second swing shaft 26 and can swing around the second swing shaft 26 , and the second swing shaft 26 is the motor main shaft of the second motor 25 . ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| power | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| wavelength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com