Patents

Literature

38results about How to "Realize dust removal" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Coking and slagging robot processing system for high-temperature hearth of coal fired power plant boiler

InactiveCN102175039APrevents dust accumulation inside the systemMove fastTelevision system detailsColor television detailsWater circulationCcd camera

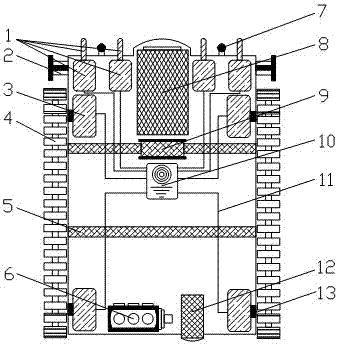

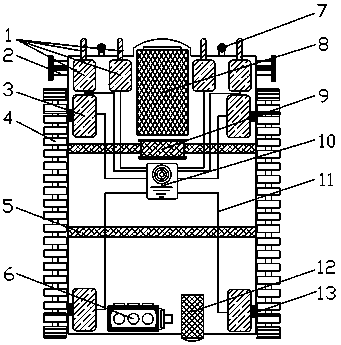

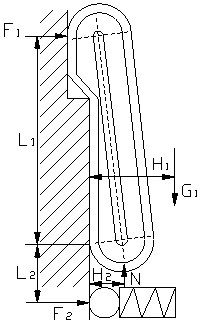

The invention discloses a coking and slagging robot processing system for a high-temperature hearth of a coal fired power plant boiler. A robot body is externally and sequentially provided with an insulation layer, an inner wall, a cooling water interlayer and an outer wall from internal to outside, wherein a short-range nozzle and a long-range nozzle are arranged on the outer wall; the front part of a main CCD (Charge Coupled Device) camera is provided with a high-temperature resistant anti-reflection LOW-E membrane, and the rear part of the main CCD camera is provided with a cooling fan; an inner high-temperature resistant insulation layer, an outer high-temperature resistant insulation layer and a middle vacuum thermal-protective layer are arranged in a visualized imaging system, an inner layer of the inner high-temperature resistant insulation layer is provided with an air forced convection cooling structure, and an outer layer of the outer high-temperature resistant insulation layer is a glass LOW-E membrane coating. The coking and slagging robot processing system can normally operate in a flow field at a temperature ranging from normal temperature to 1200 DEG C, can visually reflect depositing and slagging conditions of the power plant boiler at any time, can also be used for processing the depositing, coking and slagging conditions, can effectively prevent accidents of tube explosion and the like, and can effectively avoid abnormal working conditions such as heat deviation, unstable hydrodynamic force, pulsation among pipes, water circulation stagnation and water backflow, and the like caused by uneven heating of a heat exchanging surface due to depositing, coking and slagging.

Owner:SHANGHAI UNIVERSITY OF ELECTRIC POWER

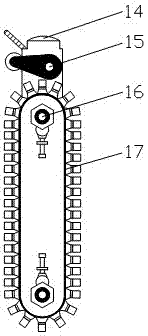

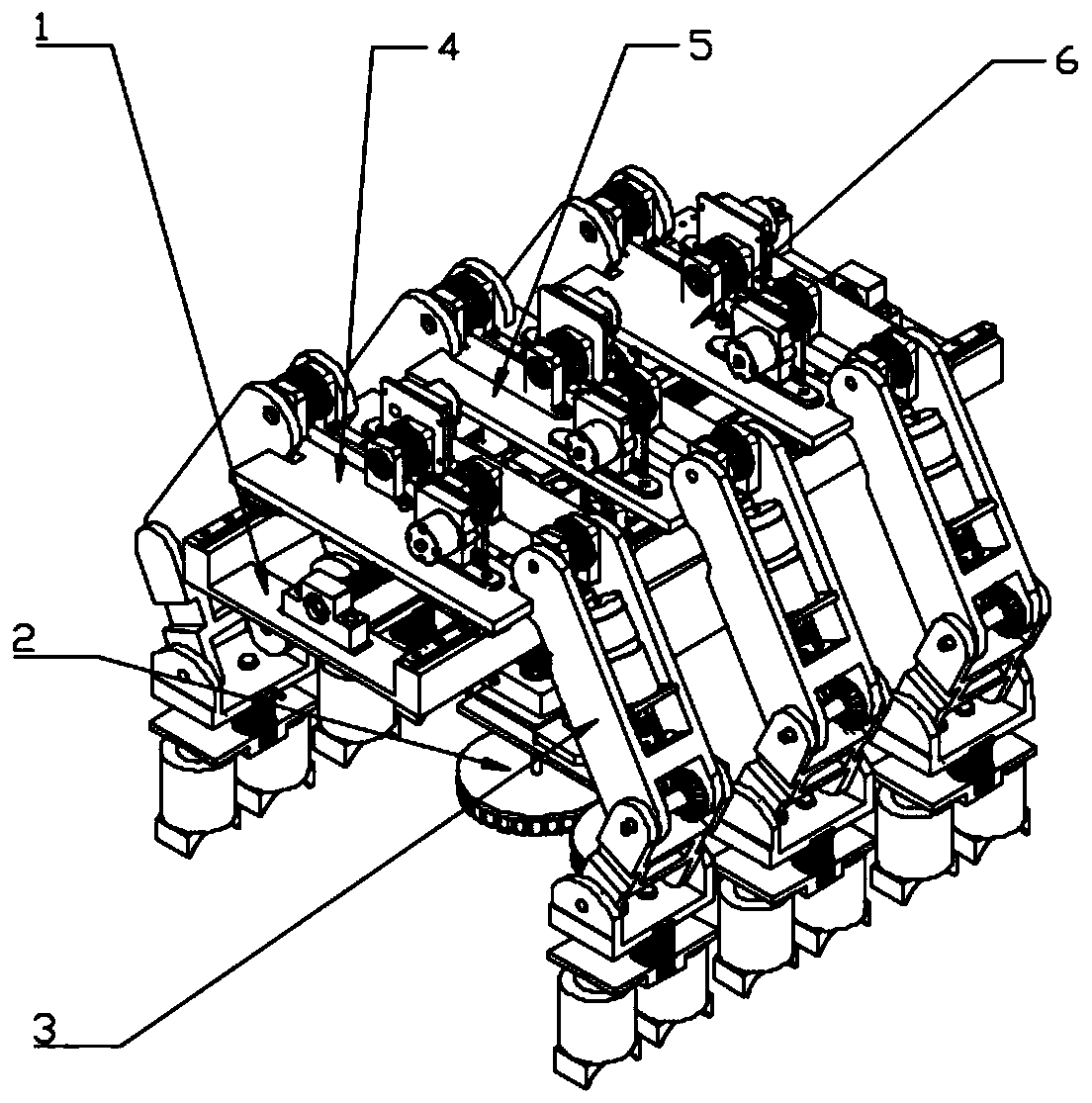

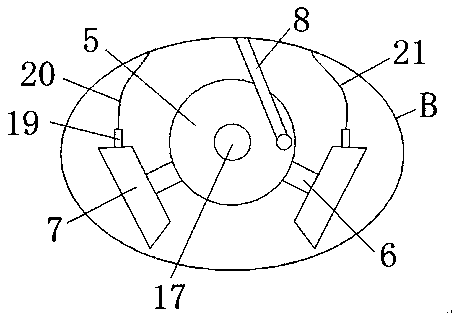

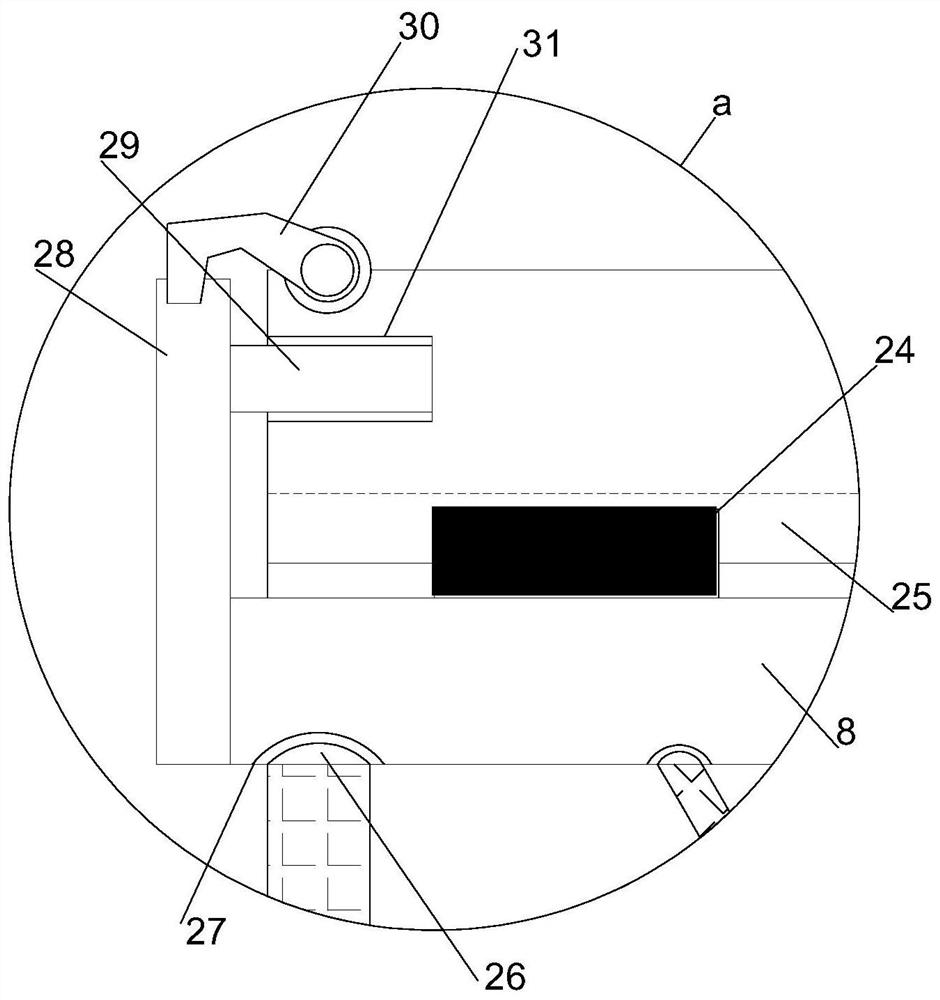

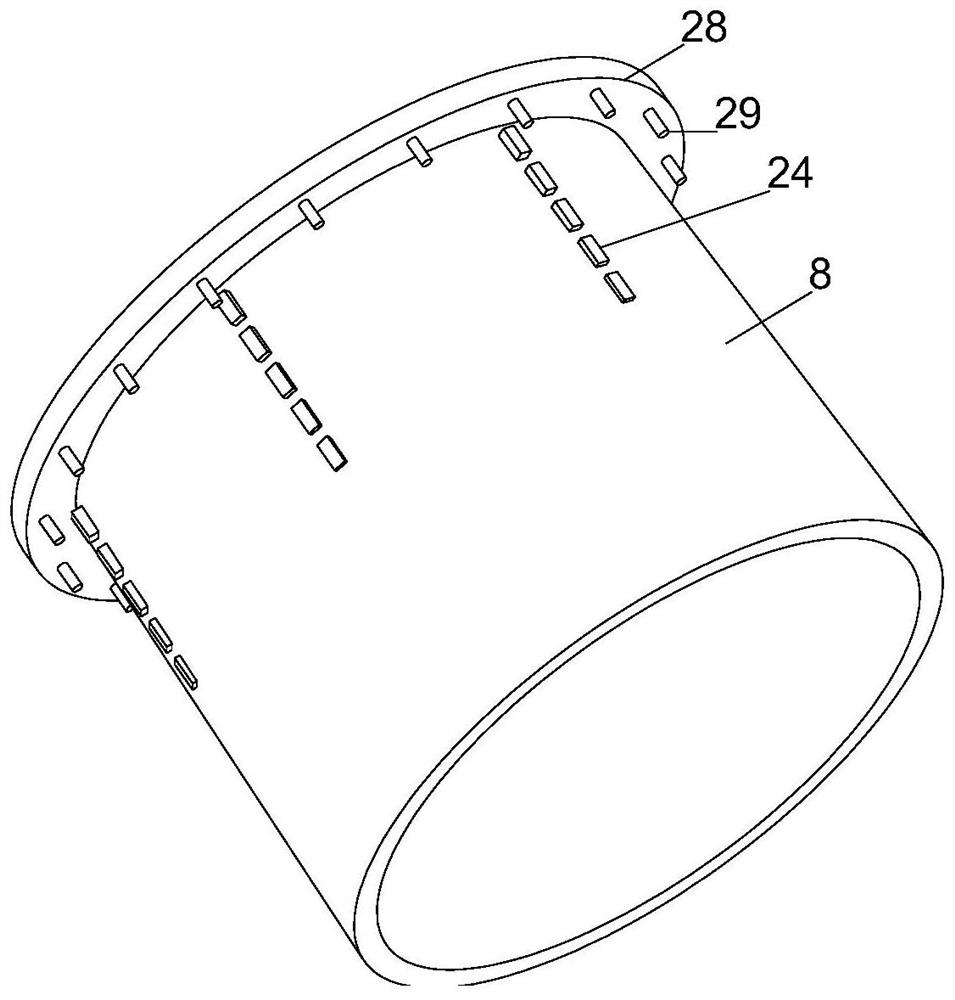

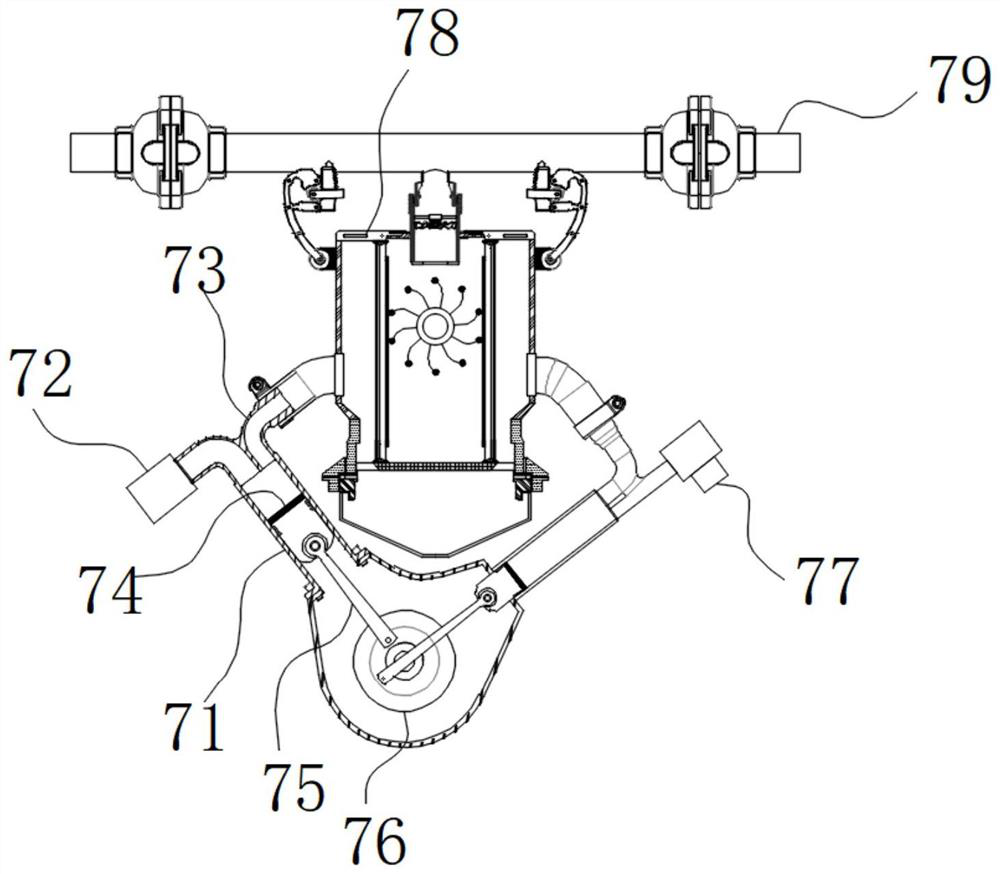

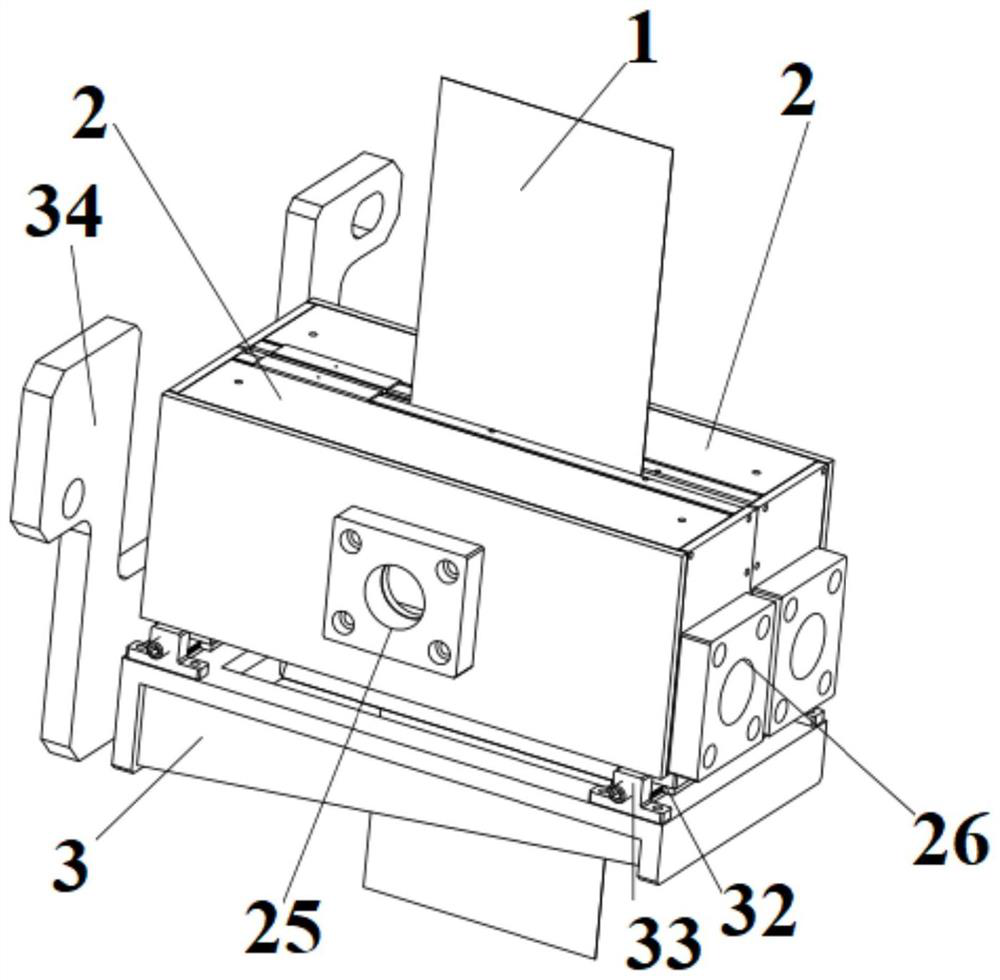

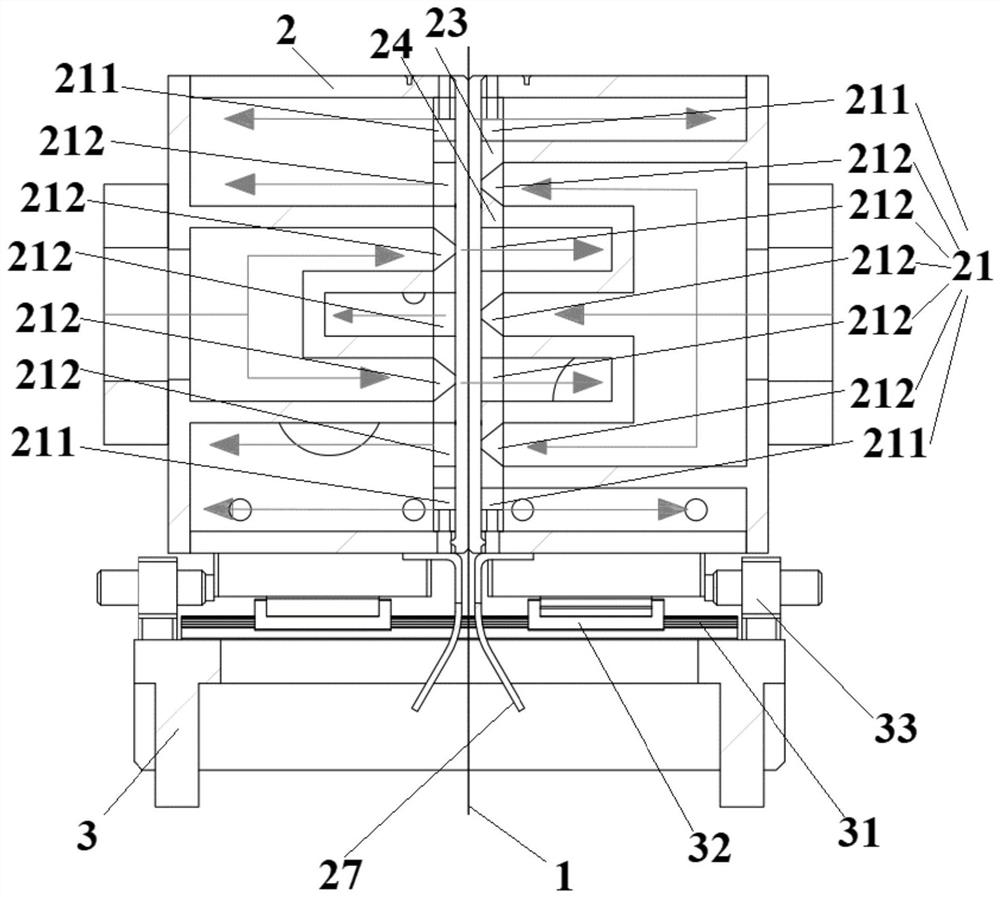

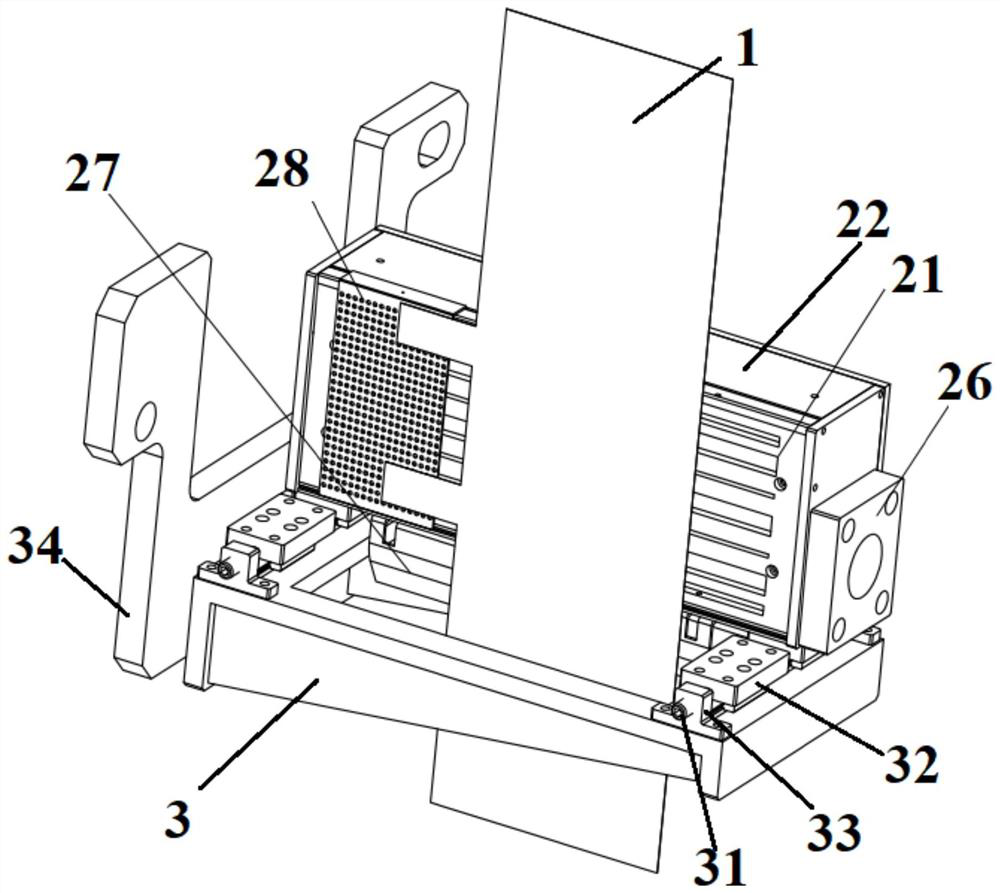

Novel hexapod boiler water wall maintenance robot

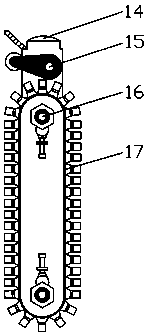

ActiveCN110901785ARealize the adsorption functionRealize the function of overcoming obstaclesVehiclesLow noiseHexapod

The invention provides a novel hexapod boiler water wall maintenance robot. The novel hexapod boiler water wall maintenance robot comprises: a main transmission system for realizing longitudinal linear movement of the robot on a vertical wall surface; a three-degree-of-freedom mechanical leg transverse movement mechanism which is used for realizing an adsorption function, an obstacle crossing function and crossing in different working intervals of the robot; and a maintenance mechanism which achieves the functions of accumulated dust cleaning and camera shooting. The electromagnetic wall-climbing robot is high in load capacity, flexible in movement, high in wall surface adaptive capacity and good in application prospect, almost realizes full coverage of the interior of a boiler without dead angles, and has good application prospect. According to the scheme, low noise, no pollution, low cost and light weight are achieved, and sustainable development of the environment and the society isfacilitated.

Owner:HARBIN ENG UNIV

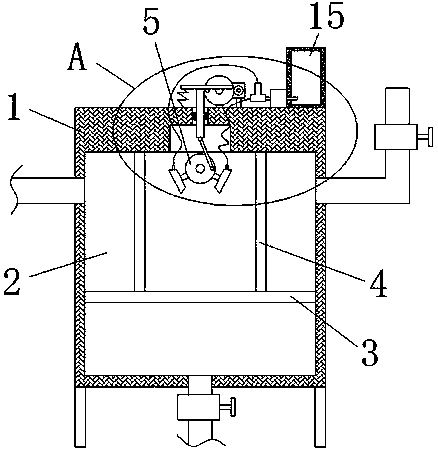

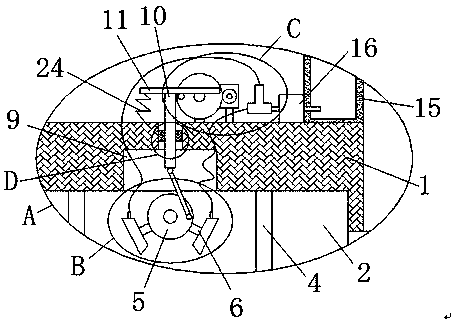

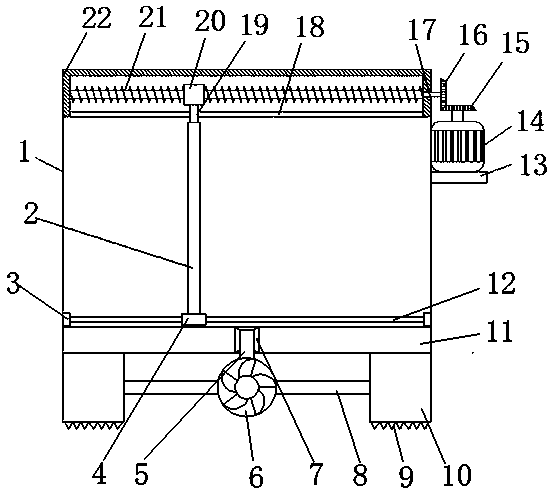

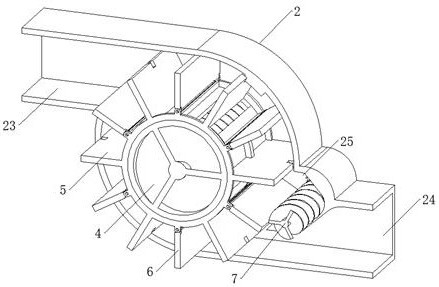

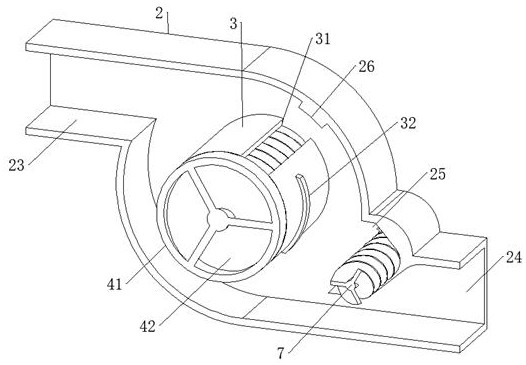

Waste gas treatment device of coating mechanical equipment

ActiveCN108970283ARealize dust removalFully contactedDispersed particle filtrationSpray nozzleMechanical equipment

The invention discloses a waste gas treatment device of coating mechanical equipment. The waste gas treatment device comprises a treatment box, the treatment box is provided with a cavity chamber, a filter plate which is horizontally arranged in fixedly mounted on the side wall of the cavity chamber, a rotary disc is rotatably mounted in the cavity chamber, filter nets fixedly mounted on the sidewall of the cavity chamber are arranged on the two sides of the rotary disc respectively, the bottoms of the filter nets are fixedly connected with the top of the filter plate, two mounting rods whichare symmetrically arranged are fixedly mounted on the outer side of the rotary disc, a spray nozzle is fixedly mounted at the end, away from the rotary disc, of each mounting rod, a traction rod which is obliquely arranged is rotatably arranged on one side of the rotary disc, and the inner wall of the top of the cavity chamber is provided with a groove. The waste gas treatment device is reasonable in design, high in practicality, and simple in structure, the spray nozzles can swing conveniently, and evenly spray clean water onto the filter nets, so that the filter nets remain the wet states all the time, thus dust particles in the waste gas can be conveniently absorbed, and dust removing treatment can be conveniently conducted on the waste gas.

Owner:广东熙霖节能环保工程咨询服务有限公司

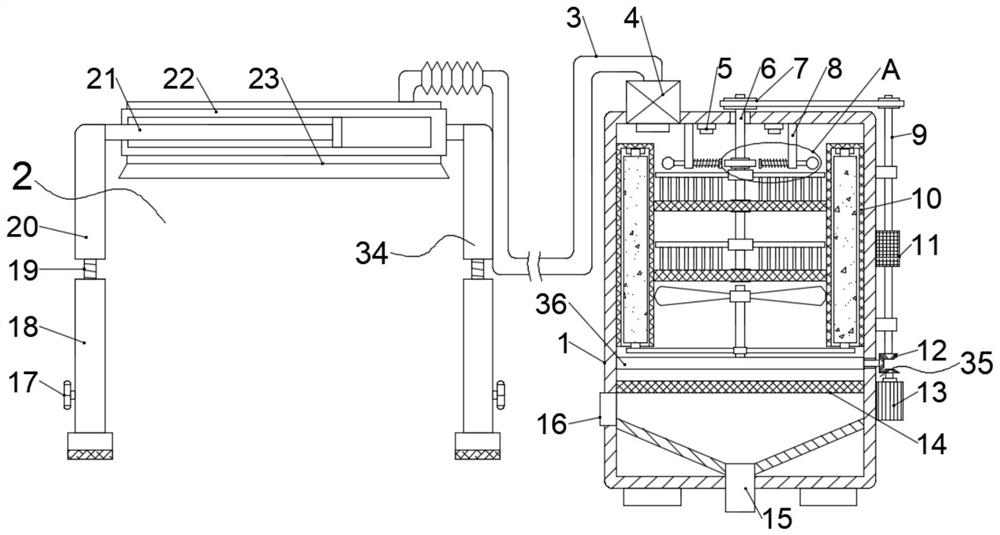

Indoor multifunctional air purifier

ActiveCN104197413ALow priceEasy to replaceCombination devicesLighting and heating apparatusEngineeringAbsorption effect

The invention discloses an indoor multifunctional air purifier which comprises a purifying end and a cleaning end. The purifying end comprises a first air purifying layer used for removing PM2.5, a second air purifying layer used for removing odors in air and a third air purifying layer used for ionization. Each air purifying layer comprises two microporous ceramic plates capable of changing positions, an active carbon plate and a static electricity plate. The cleaning end comprises a miroporous ceramic plate cleaning layer, an active carbon plate cleaning layer and a static electricity plate cleaning layer. The miroporous ceramic plate cleaning layer comprises a first air blowing system, an ultraviolet sterilization lamp, a water spraying system and a rolling brush. The active carbon plate cleaning layer comprises a smoke exhaust hole, a heating system and a fluorescent lamp. The static electricity plate cleaning layer comprises a second air blowing system and a fluorescent lamp. According to the air purifier, the function of purifying air of an original air purifier can be maintained, PM2.5 in the air can be absorbed, a replaceable absorption layer is arranged in the air purifier, and accordingly a good absorption effect is kept for a long time.

Owner:HUNAN CHANGZHONG MACHINERY

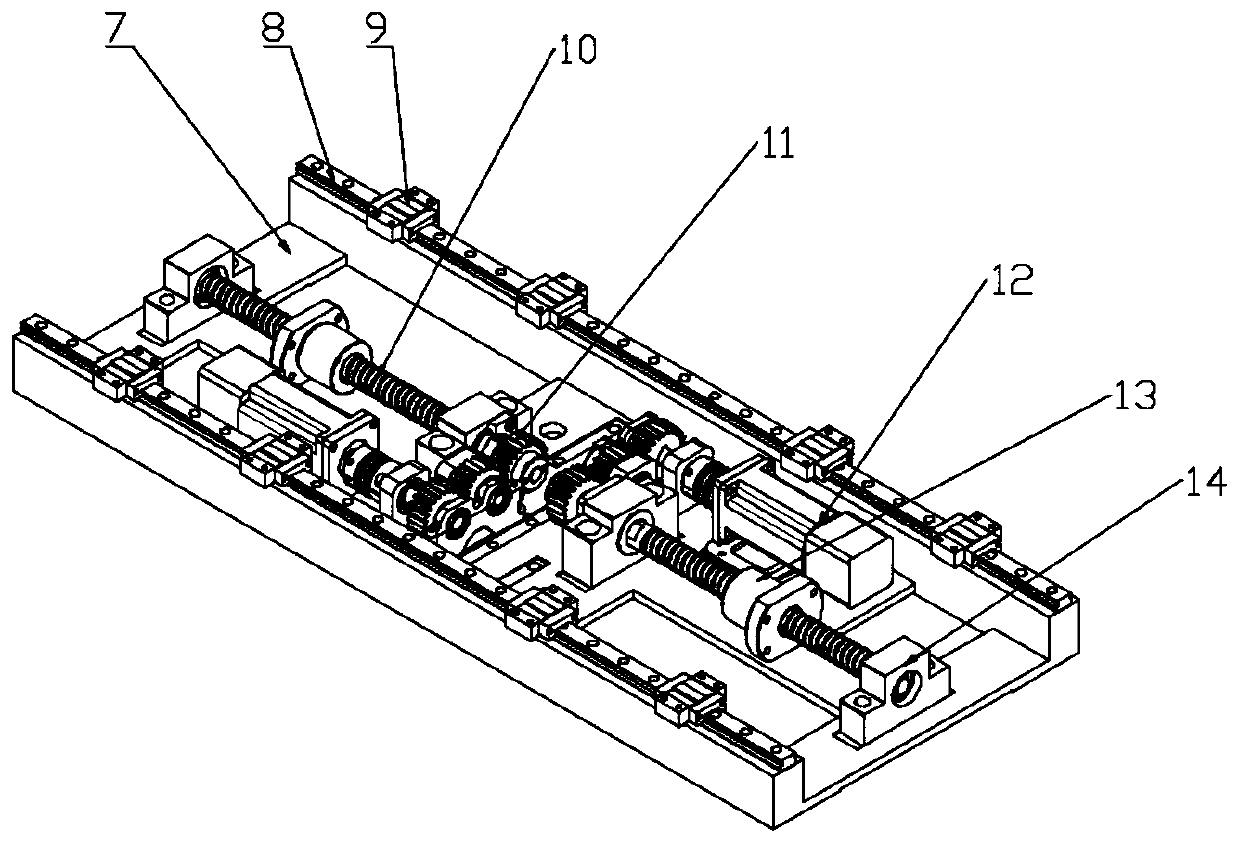

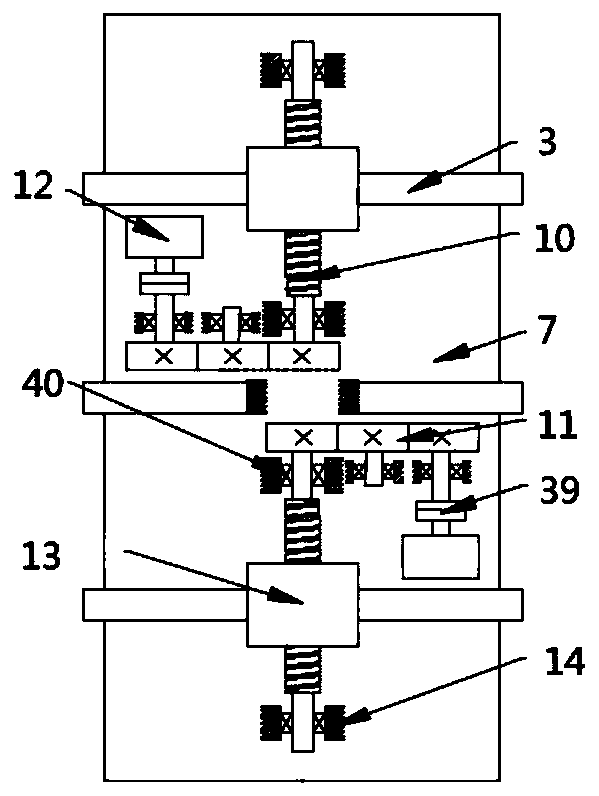

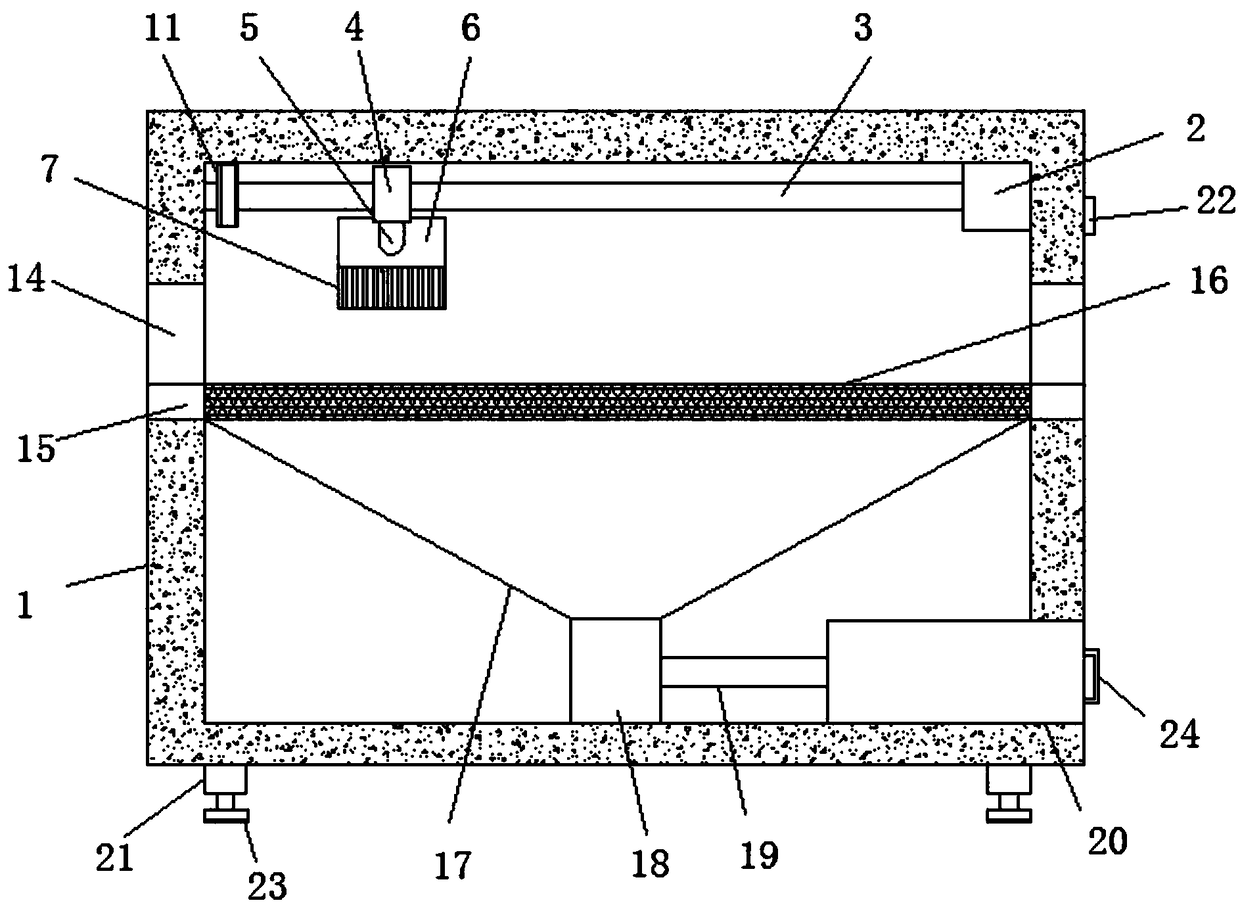

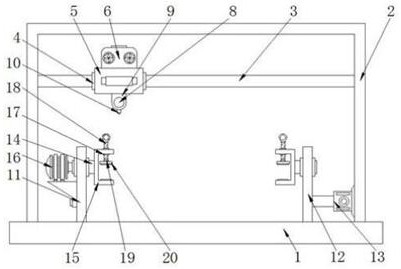

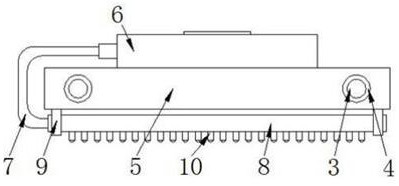

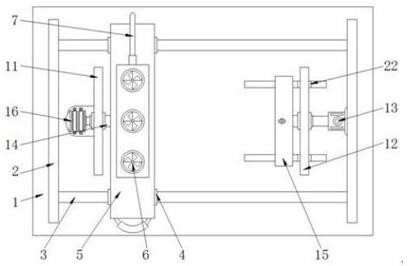

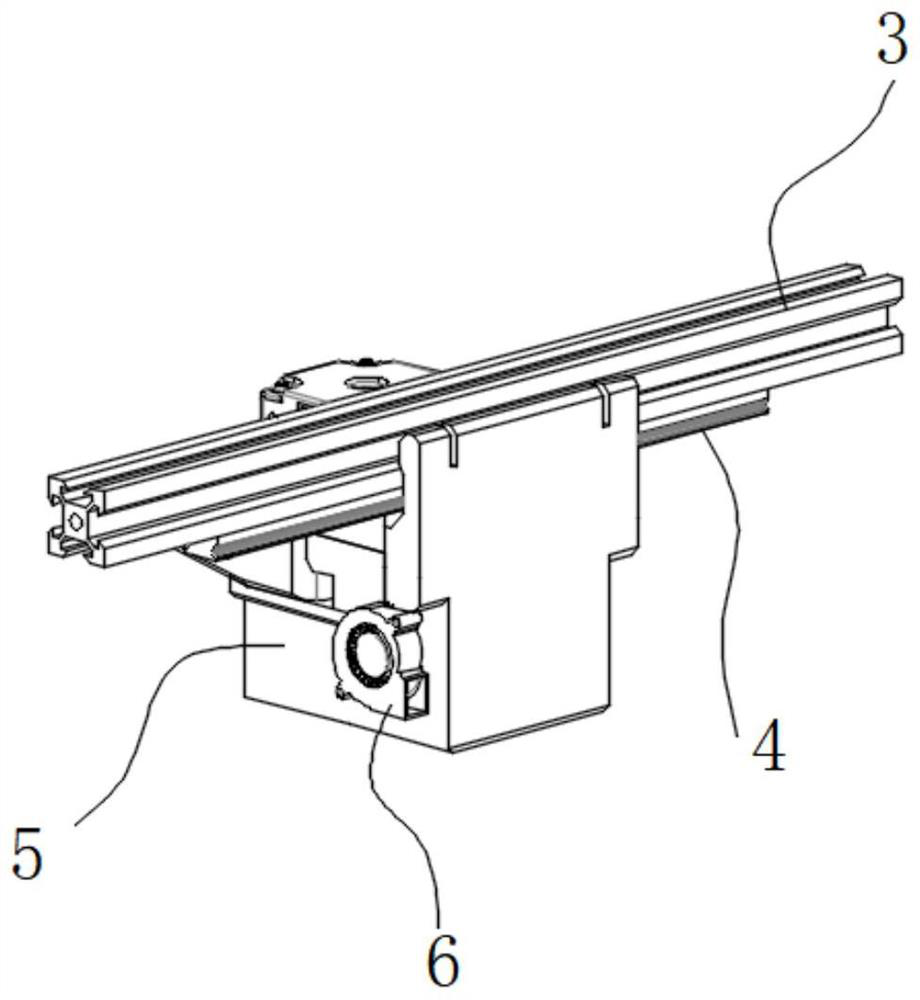

LED display screen dedusting worktable

InactiveCN108772319ARealize dust removalAvoid harmDirt cleaningCleaning using toolsLED displayCoupling

The invention discloses an LED display screen dedusting worktable which comprises a box. A motor is mounted on the inner side of the box; one end of the motor is connected with a first lead screw through a coupling; a first nut is arranged on the first lead screw and connected with a mounting plate through a first connecting rod; a dedusting brush is mounted at the lower end of the mounting plate;the other end of the mounting plate is connected with a second nut through a second connecting rod; one end of the first lead screw is connected with a first transmission wheel, and the first transmission wheel is connected with a second transmission wheel through a synchronous belt; the second transmission wheel is arranged on a second lead screw; a working plate is mounted on the inner side ofthe box, and a plurality of dust sucking openings are formed in the working plate; a funnel groove is formed in the bottom end of the working plate, and a vacuum cleaner is mounted at the bottom of the funnel groove; and one end of the vacuum cleaner is connected with a guiding pipe, and the other end of the guiding pipe is connected with a dust collecting box. The LED display screen dedusting worktable is simple in structure, practical, convenient, and capable of saving the time and labor, and meeting using requirements of people.

Owner:YANYANG LAMP SET TIANCHANG CITY

Dedusting blackboard for junior school students

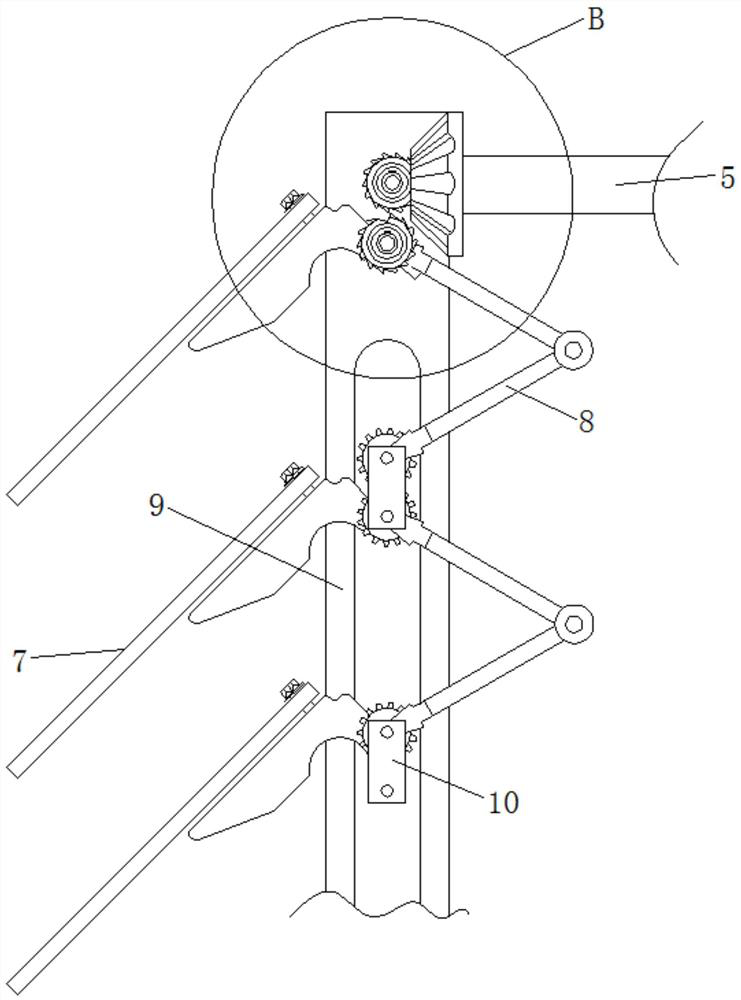

InactiveCN108501582AImprove dust removal effectImprove cleanlinessBoard cleaning devicesWriting boardsEngineeringBevel gear

The invention discloses a dedusting blackboard for junior school students. The dedusting blackboard for junior school students comprises a blackboard body; the top of the right side of the blackboardbody is fixedly connected with a supporting board; the top of the supporting board is fixedly connected with a motor; the output end of the motor is fixedly connected with a first bevel gear; and theleft side of the first bevel gear is engaged with a second bevel gear. Through cooperative use of the blackboard body, a vertical rod, a fixing block, a slide sleeve, a dust suction pipe, a fan, a dust suction head, a dust conveying pipe, a dust removing hole, a dust collection box, a dust falling box, a slide rod, the supporting board, the motor, the first bevel gear, the second bevel gear, a first connection rod, an opening, a second connection rod, a threaded sleeve, a threaded rod, a shell, a first shell, a vertical eraser, a first spring, a cross rod, a second shell, a second spring, a first connection board, a second connection board and a third spring, the problem that existing dedusting blackboards for junior school students are poor in dedusting effect is solved, and the dedustingblackboard for junior school students has the advantage of good dedusting effect.

Owner:孔晓静

Coking and slagging robot processing system for high-temperature hearth of coal fired power plant boiler

InactiveCN102175039BGuaranteed to workHas the ability to visualizeTelevision system detailsColor television detailsInsulation layerEngineering

The invention discloses a coking and slagging robot processing system for a high-temperature hearth of a coal fired power plant boiler. A robot body is externally and sequentially provided with an insulation layer, an inner wall, a cooling water interlayer and an outer wall from internal to outside, wherein a short-range nozzle and a long-range nozzle are arranged on the outer wall; the front part of a main CCD (Charge Coupled Device) camera is provided with a high-temperature resistant anti-reflection LOW-E membrane, and the rear part of the main CCD camera is provided with a cooling fan; an inner high-temperature resistant insulation layer, an outer high-temperature resistant insulation layer and a middle vacuum thermal-protective layer are arranged in a visualized imaging system, an inner layer of the inner high-temperature resistant insulation layer is provided with an air forced convection cooling structure, and an outer layer of the outer high-temperature resistant insulation layer is a glass LOW-E membrane coating. The coking and slagging robot processing system can normally operate in a flow field at a temperature ranging from normal temperature to 1200 DEG C, can visually reflect depositing and slagging conditions of the power plant boiler at any time, can also be used for processing the depositing, coking and slagging conditions, can effectively prevent accidents of tube explosion and the like, and can effectively avoid abnormal working conditions such as heat deviation, unstable hydrodynamic force, pulsation among pipes, water circulation stagnation and water backflow, and the like caused by uneven heating of a heat exchanging surface due to depositing, coking and slagging.

Owner:SHANGHAI UNIVERSITY OF ELECTRIC POWER

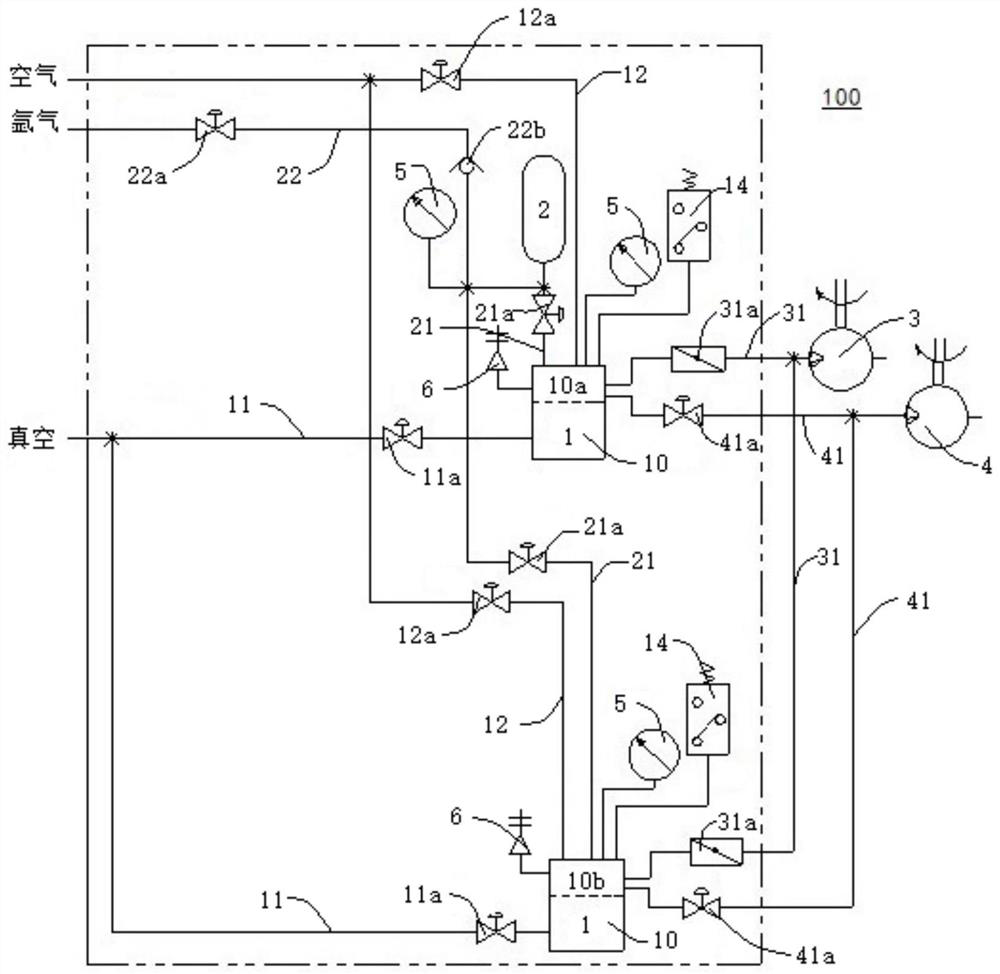

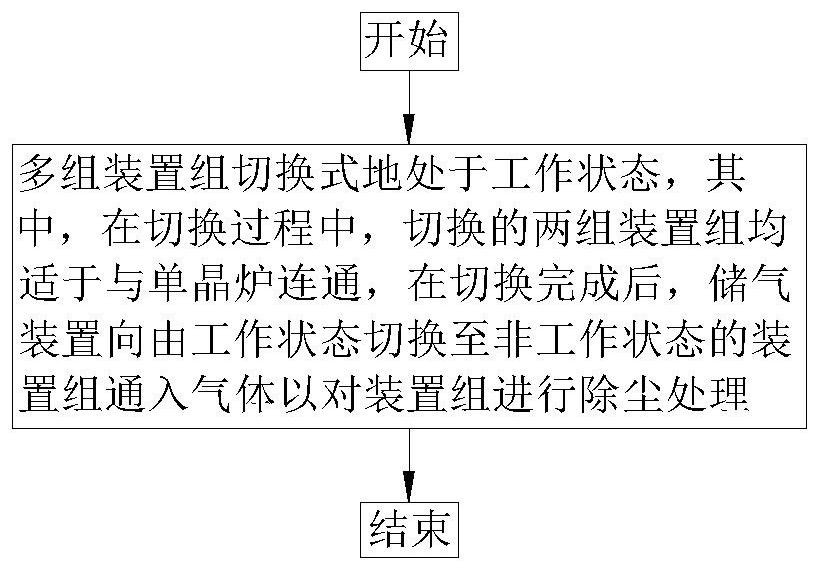

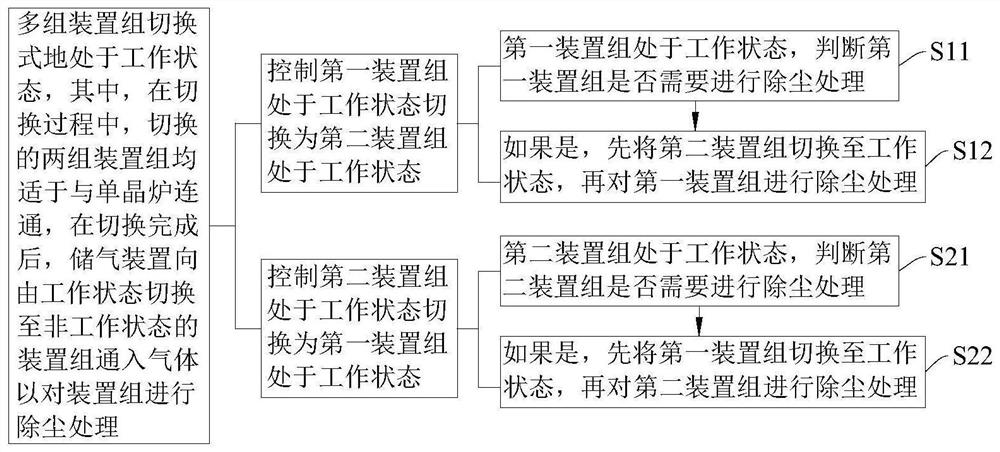

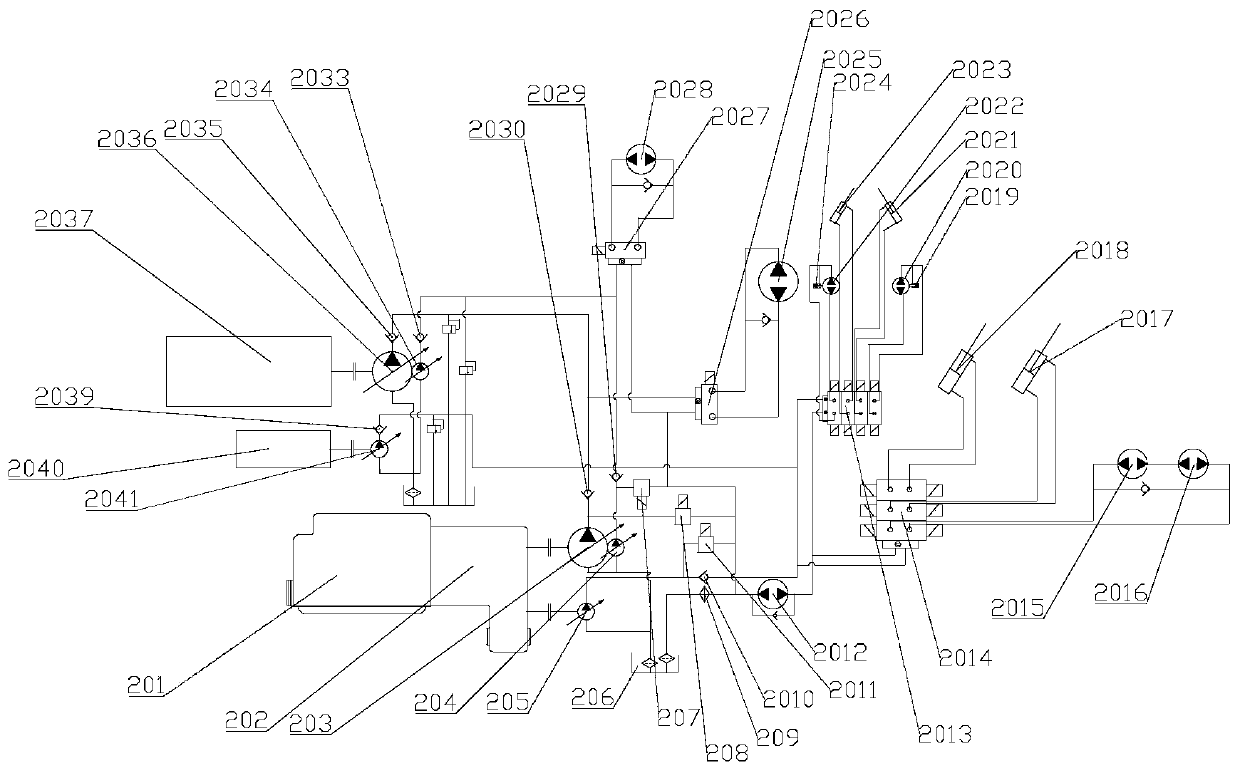

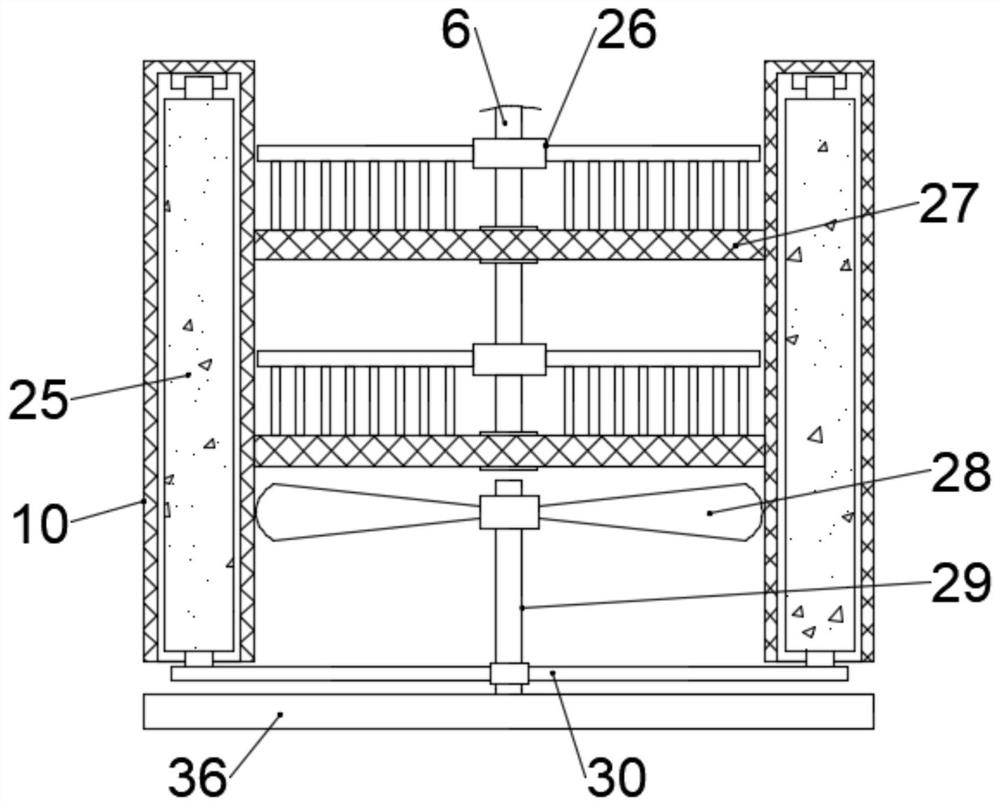

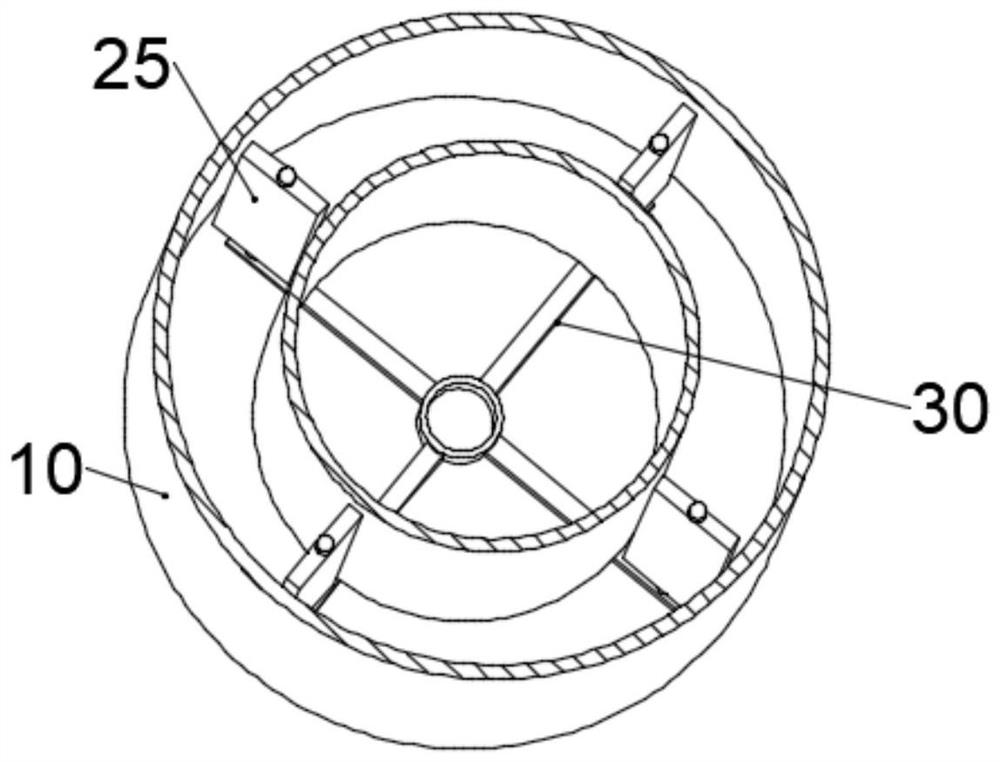

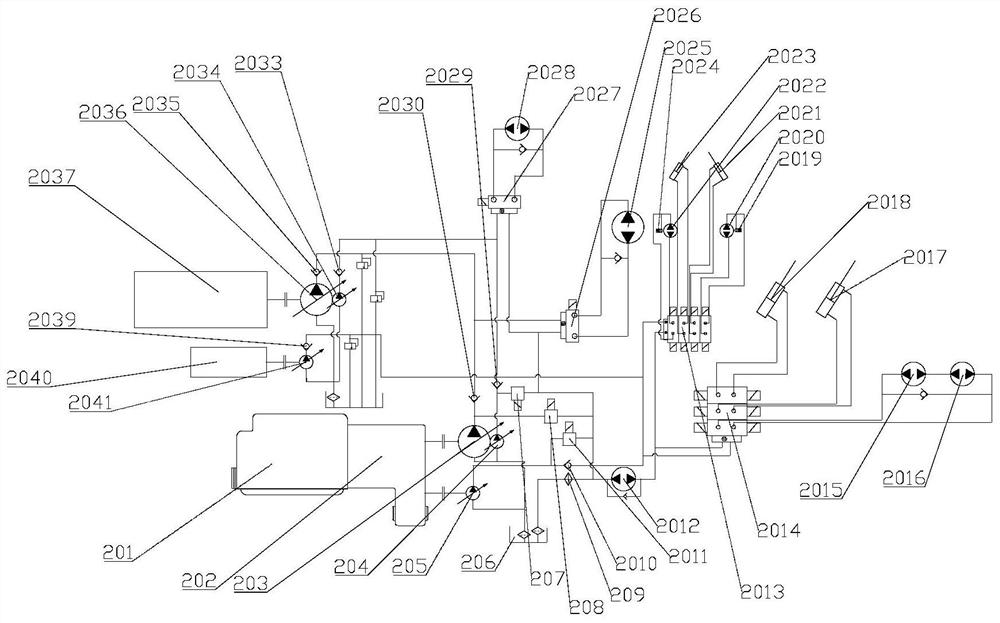

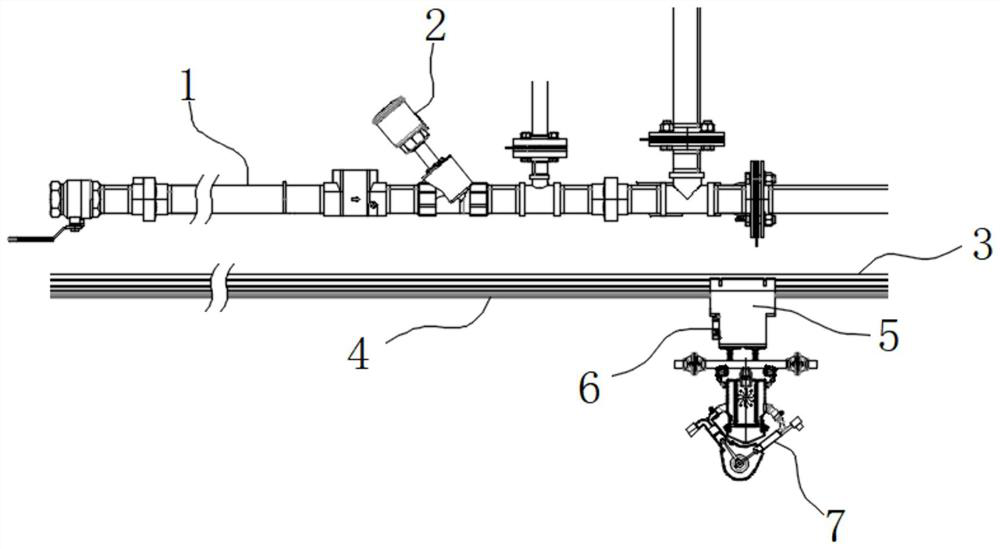

Dedusting and filtering system of single crystal furnace, control method of dedusting and filtering system and single crystal furnace assembly

PendingCN112619306ADoes not affect the crystal growth processEasy to achieve dust removalDispersed particle filtrationTransportation and packagingThermodynamicsFilter system

The invention discloses a dedusting and filtering system of a single crystal furnace. The dedusting and filtering system comprises a plurality of dedusting devices, a gas storage device, a first vacuum device and a second vacuum device, each dedusting device is provided with a first gas inlet pipeline, each first gas inlet pipeline is suitable for communicating with an exhaust port of the single crystal furnace, the gas storage device is provided with a gas outlet pipeline, each dedusting device communicates with the gas storage device through a gas outlet pipeline, a second switch valve is arranged on each gas outlet pipeline, a first vacuum pipeline is arranged on the first vacuum device, each dedusting device communicates with the first vacuum device through the first vacuum pipeline, and a second vacuum pipeline is arranged on the second vacuum device. Each dedusting device communicates with the second vacuum device through the second vacuum pipeline. According to the dedusting and filtering system of the single crystal furnace, dedusting treatment on the dedusting devices is conveniently achieved, the dedusting devices are effectively prevented from being blocked, and the crystal growth process of the single crystal furnace is not affected.

Owner:徐州晶睿半导体装备科技有限公司

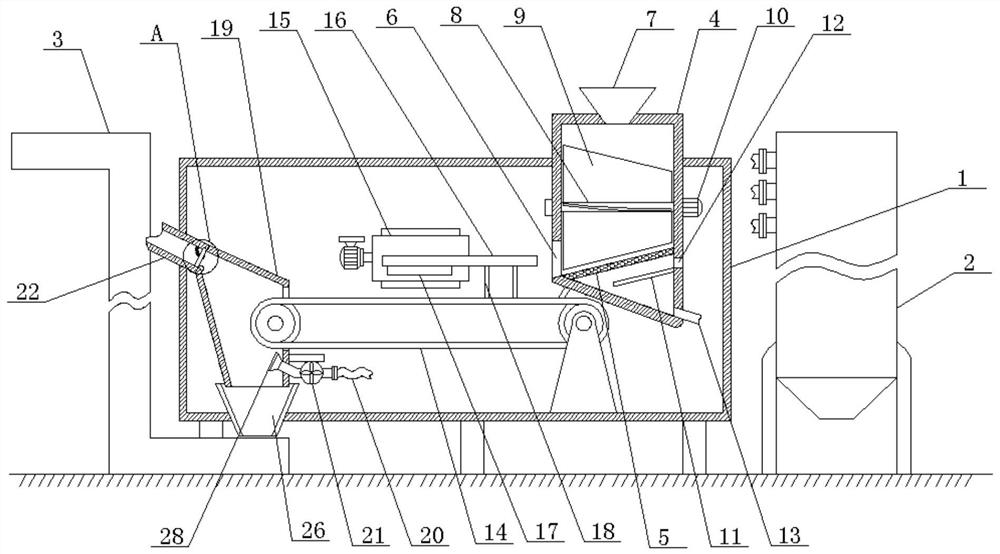

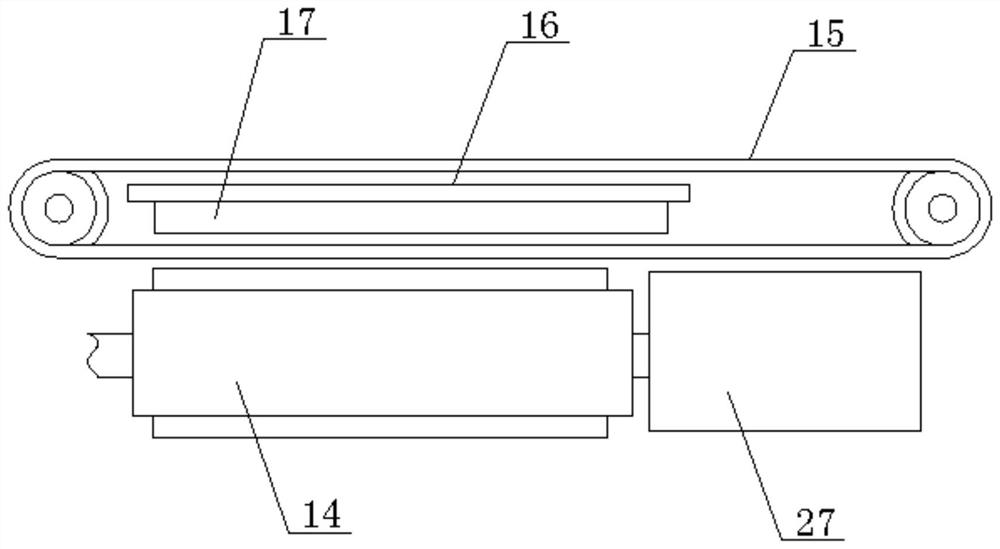

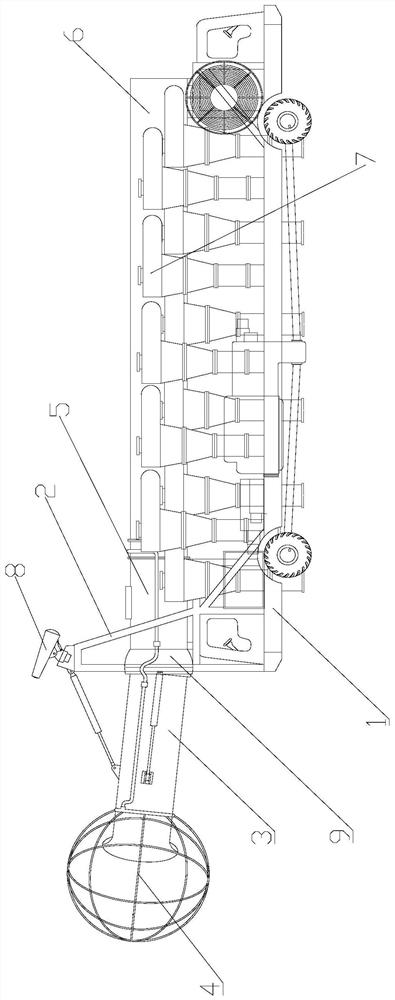

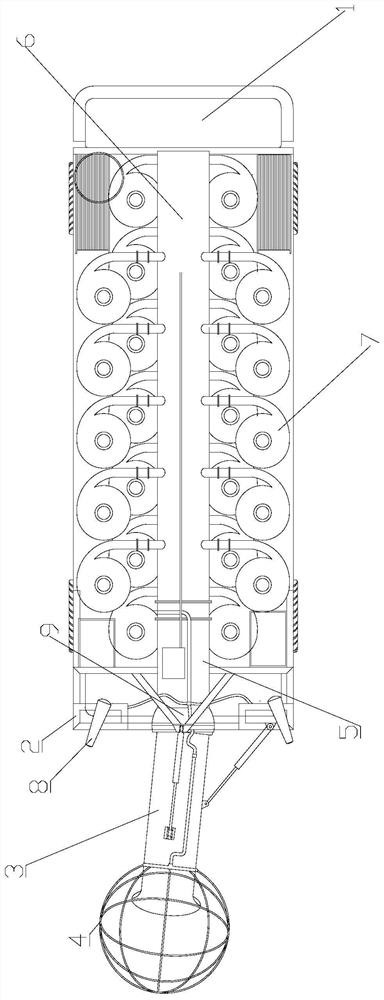

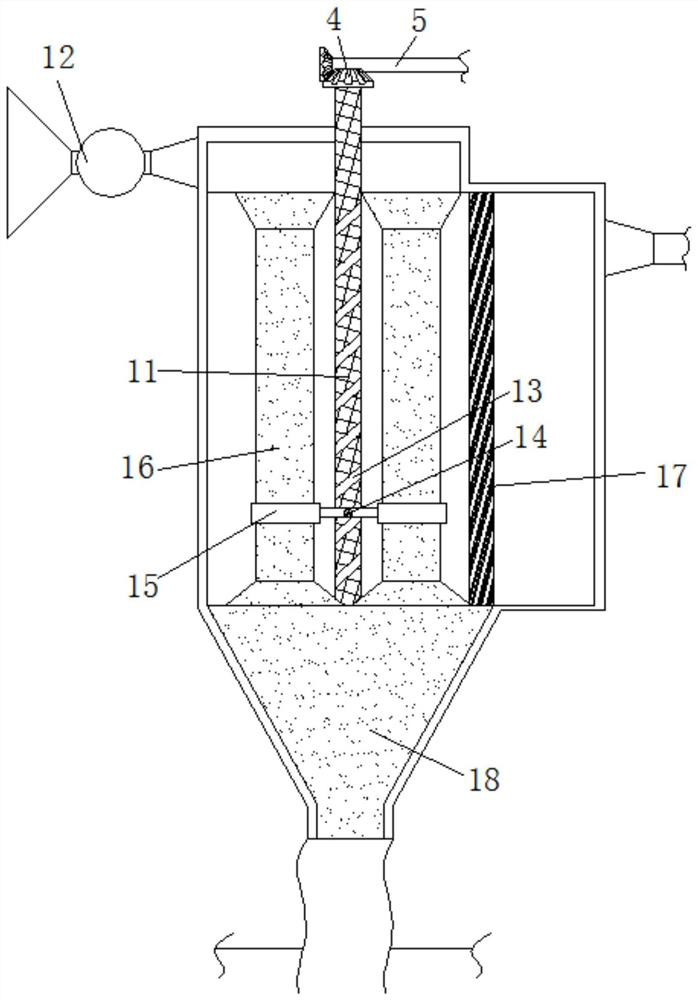

Dust removal device for rice conveying

PendingCN112823919AEasy to cleanRealize dust removalGas current separationMagnetic separationFiltrationAgricultural engineering

The invention discloses a dust removal device for rice conveying. The dust removal device comprises a dust removal box, a dust remover and a bucket elevator, wherein a dust filtration kettle is arranged in the dust removal box, a filter screen is arranged in the dust filtration kettle, the filter screen is obliquely arranged, a discharging port is formed in the position, located at the oblique bottom of the filter screen, of one side of the dust filtration kettle, a feeding port is formed in the top of the dust filtration kettle, and a discharging port is formed in the other side of the dust filtration kettle. A rotating shaft is rotatably connected between two sides of the dust filtering kettle, a plurality of stirring blades are arranged on the surface of the rotating shaft, the stirring blades are arranged in a right trapezoid shape, the inclination angle of the bevel edge of each stirring blade is equal to that of the filter screen, a first belt conveyor is arranged at the bottom of the dust filtering kettle, an iron adsorption device is arranged on the top of the first belt conveyor, and a dust adsorption device is arranged at one end of the first belt conveyor. By arranging the dust filtering kettle, the iron adsorption device and the dust adsorption device, dust and impurities in rice are removed in the conveying process favorably, so that the rice storage efficiency is improved.

Owner:安徽省无为县农兴粮油购销有限公司

Dust removing device special for computer

InactiveCN109877116ARealize dust removalRealize fixed disassemblyFouling preventionElectrostatic cleaningComputer caseEngineering

The invention discloses a dust removing device special for a computer. The dust removing device comprises a main box, a first side cover plate and a second side cover plate, the first side cover plateis fixedly connected with the front surface of the main box through a clamping hole and a fixing screw, and the second side cover plate is fixedly connected to the back surface of the main box through a clamping hole and a fixing screw. The invention relates to the technical field of computer dust removing devices. According to the dust removing device special for the computer, the first side cover plate is fixedly connected with the front surface of the main box through the clamping hole and the fixing screw, the second side cover plate is fixedly connected to the back surface of the main box through the clamping hole and the fixing screw, the top of the main box is fixedly connected with a top cover plate, the bottom of the top cover plate is fixedly connected with a connection base, the dust removing device is integrated onto the main box, the traditional dust removing mode is changed, the dust removing and dust proofing are combined, influences of dust on electric appliance partsare greatly reduced, dust removing processing can be realized without disassembling components inside the main box, and the dust removing device is convenient, quick and efficient to use.

Owner:合肥清若科技有限公司

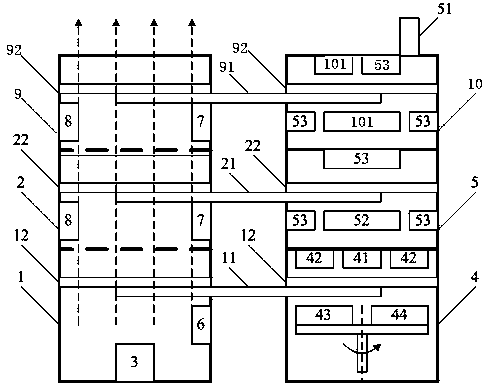

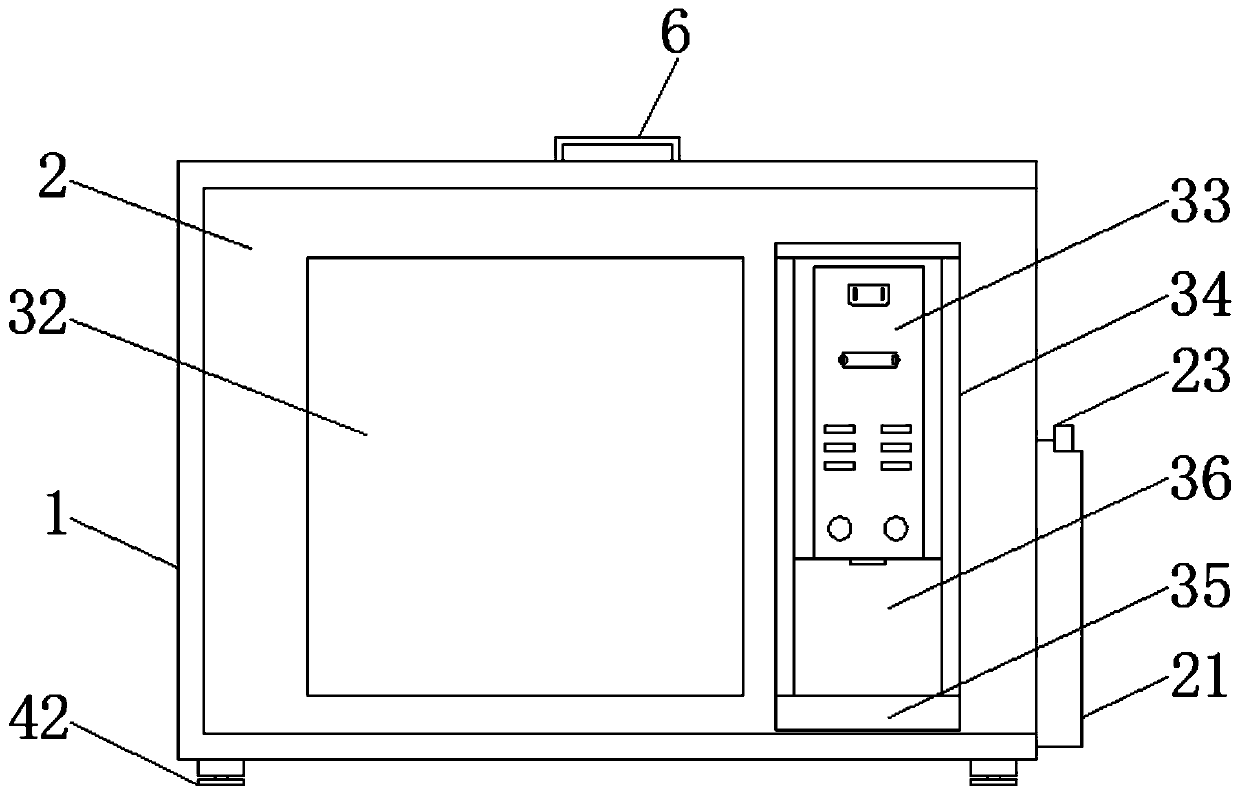

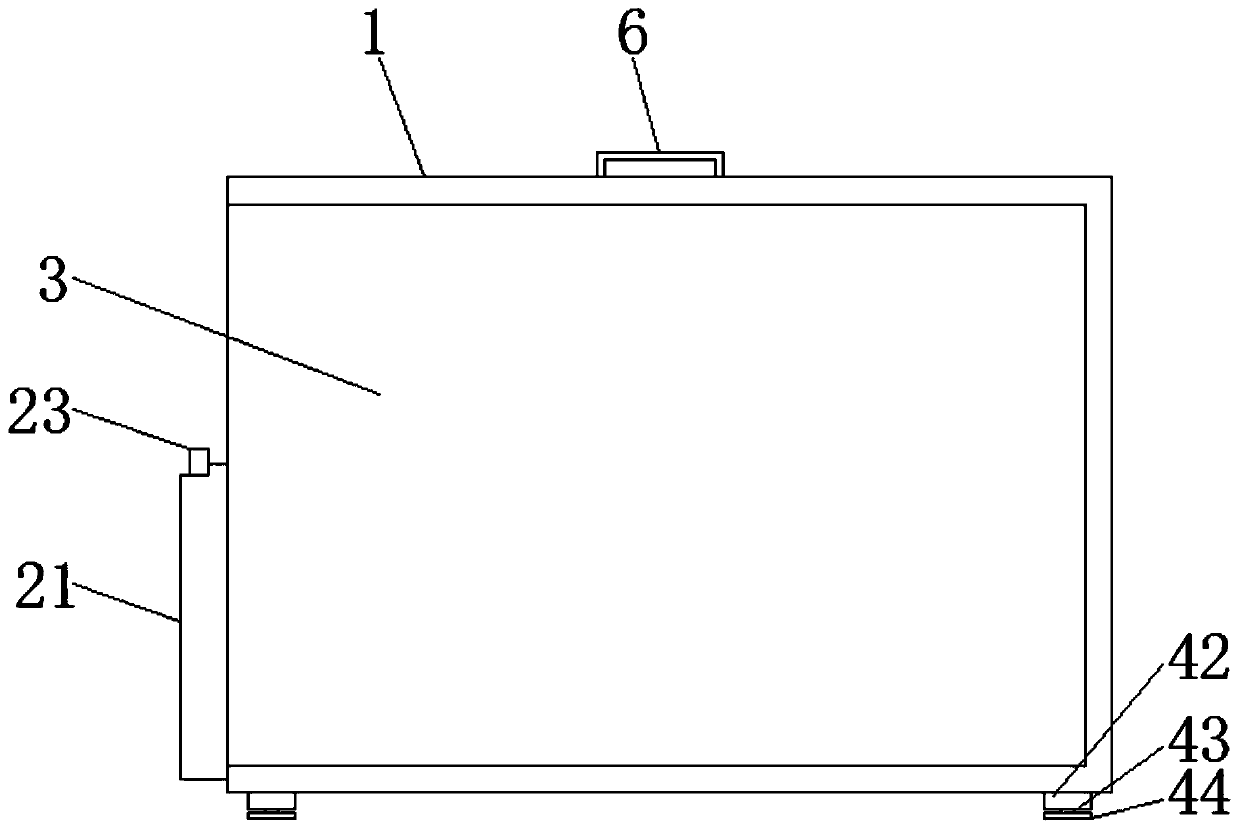

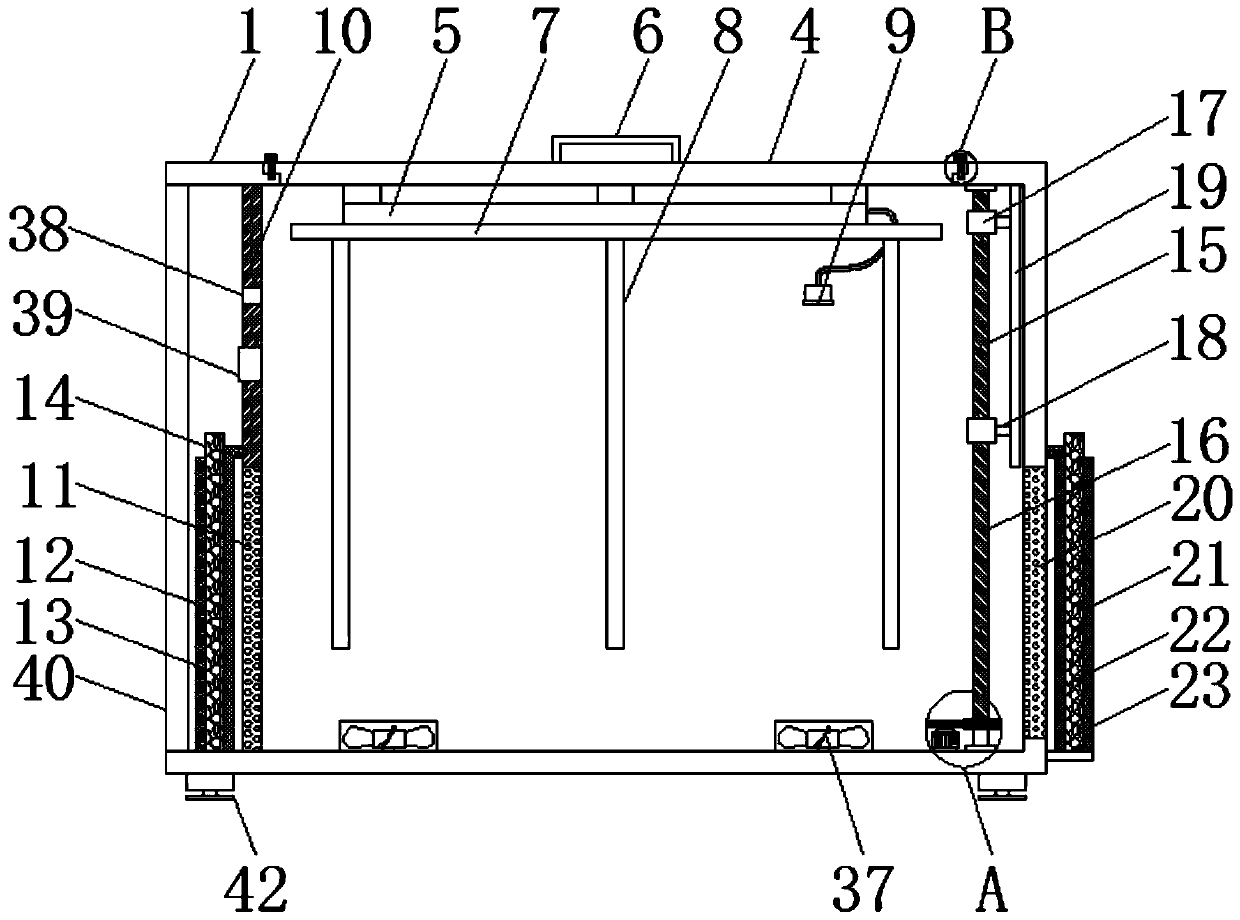

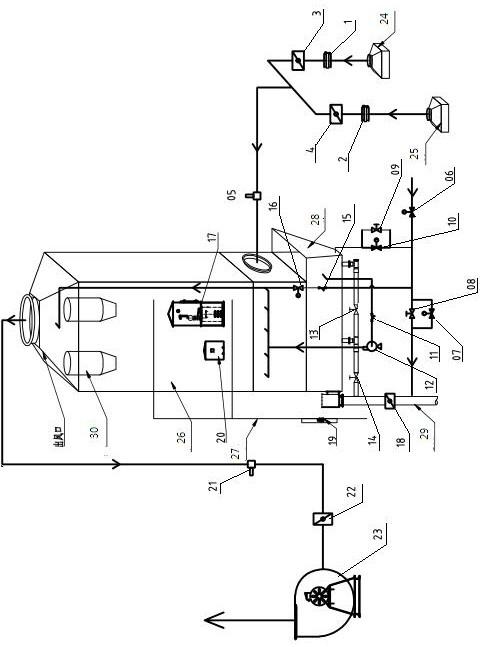

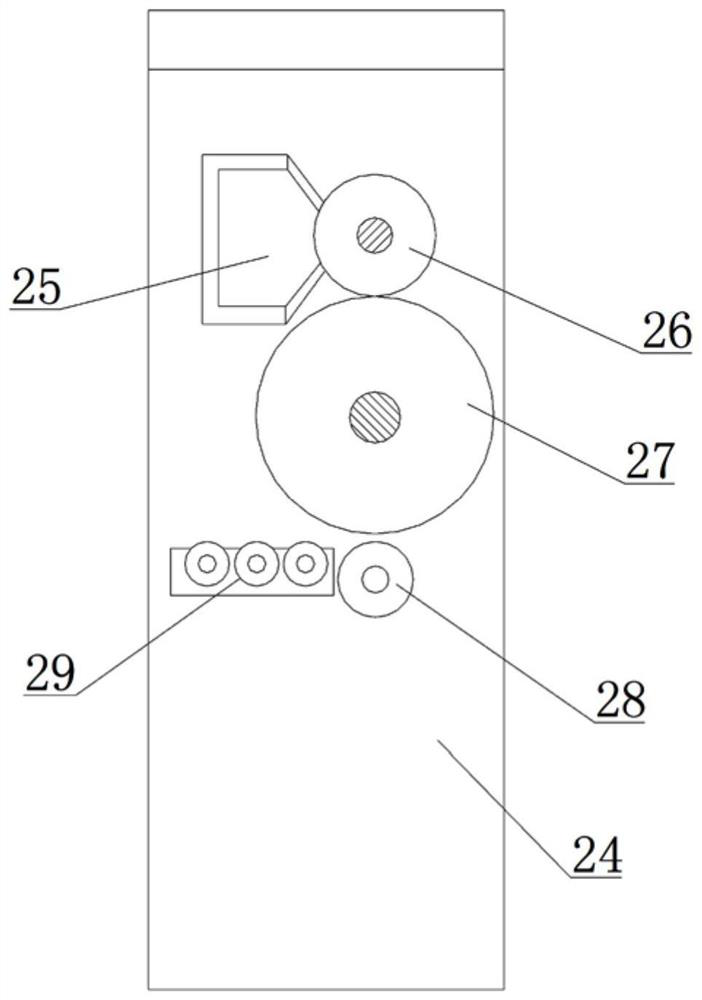

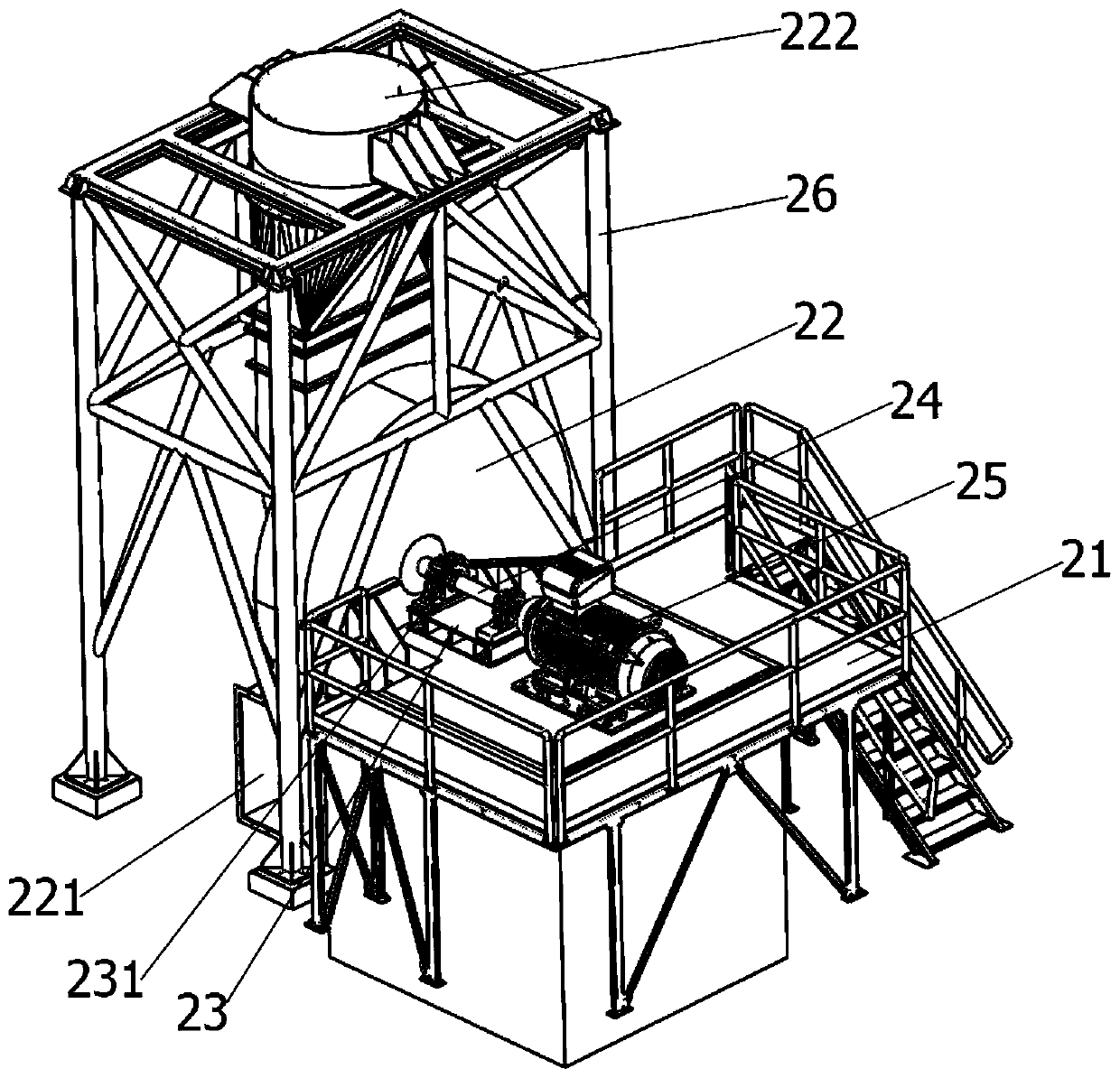

Control system and control method for wet-type electrostatic dust collector of coal conveying system

PendingCN113117891AMeet the protection requirementsDoes not affect dust removal effectExternal electric electrostatic seperatorElectric supply techniquesThermodynamicsControl system

The invention relates to a control system and a control method for a wet-type electrostatic dust collector of a coal conveying system. Existing electrostatic dust collectors mostly adopt a one-supporting-one design on site, that is, a set of complete dust collector control system is only used by one belt, and meanwhile, a traditional wet type electrostatic dust collector can only meet the requirement for on-site dust suppression and cannot feed back on-site conditions in the first time. The control system for the wet type electrostatic dust collector of the coal conveying system comprises a dust collector (26), an induced draft fan (23), a belt air suction cover A (24) and a belt air suction cover B (25), wherein the belt air suction cover A is connected with an A-path belt drawer type filter (1), the belt air suction cover B is connected with a B-path belt drawer type filter (2), the A-path belt drawer type filter is connected with an A-path belt electric butterfly valve (3), and the B-path belt drawer type filter is connected with a B-path belt electric butterfly valve (4). The system and the method are applied to the electrostatic dust collector.

Owner:GUANGDONG DATANG INT CHAOZHOU POWER GENERATION

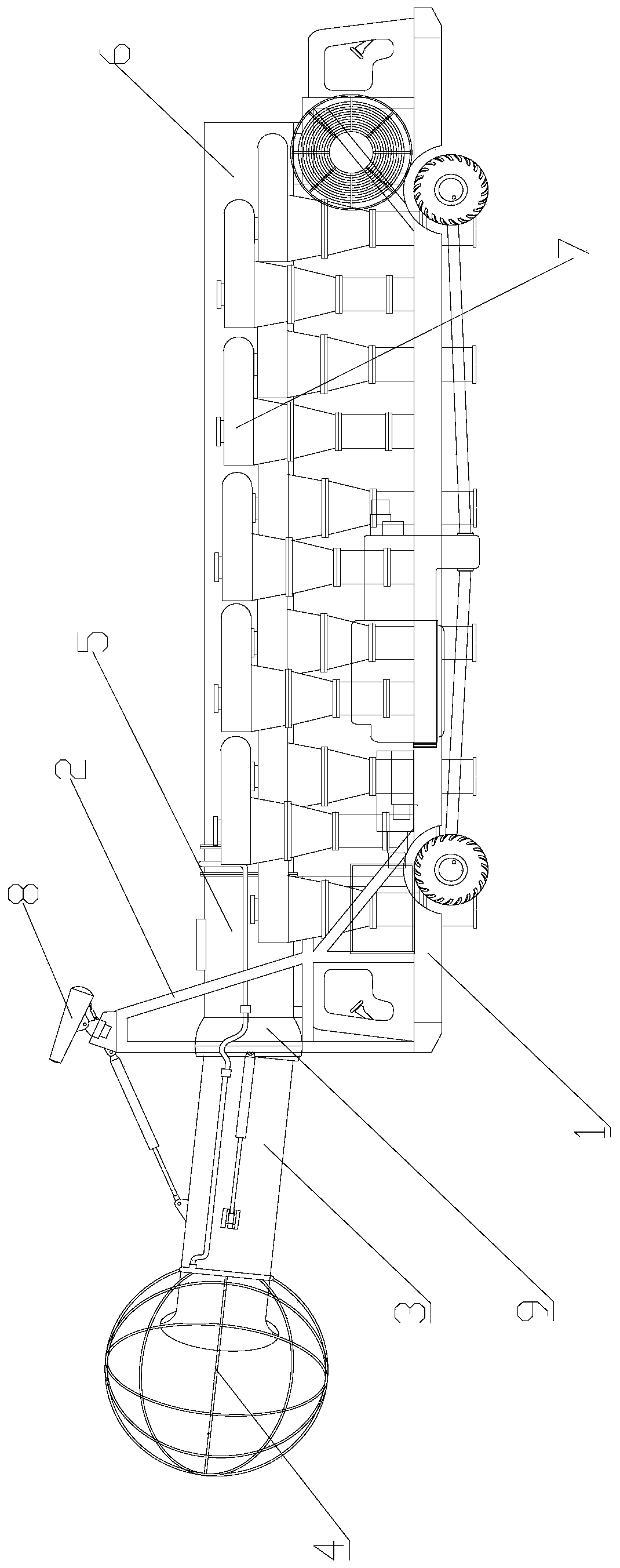

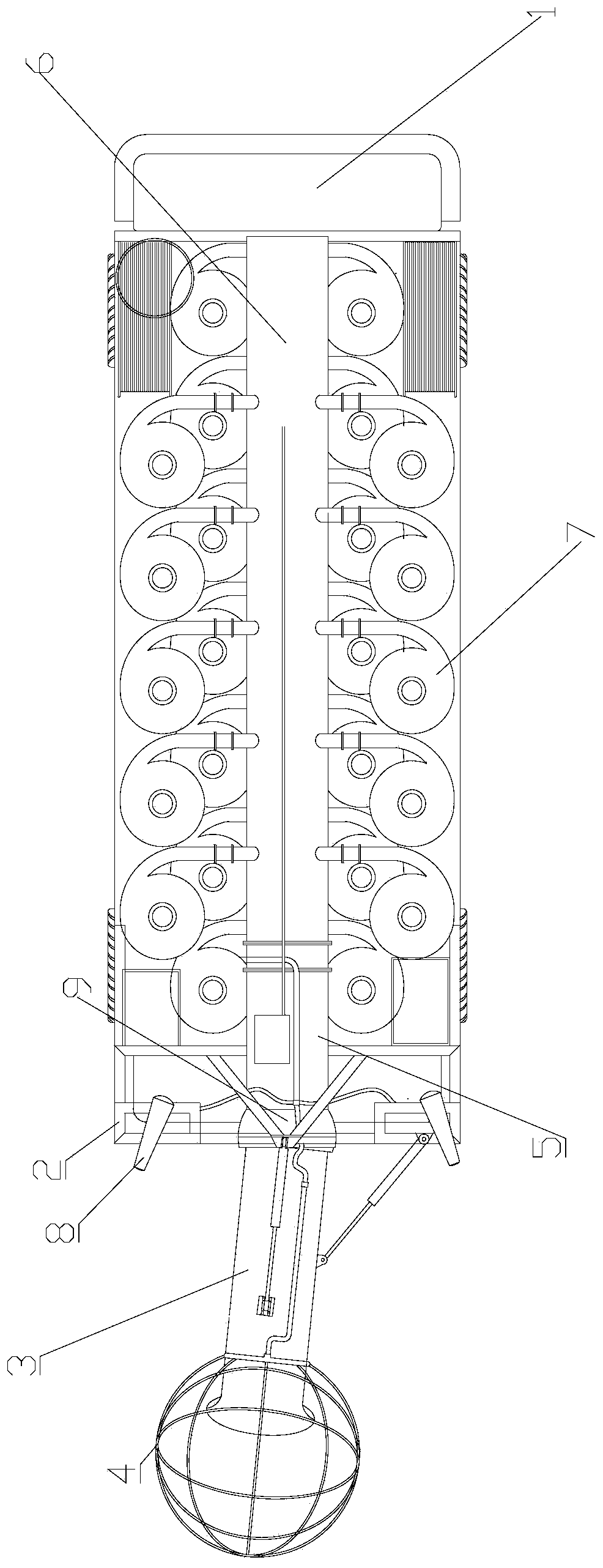

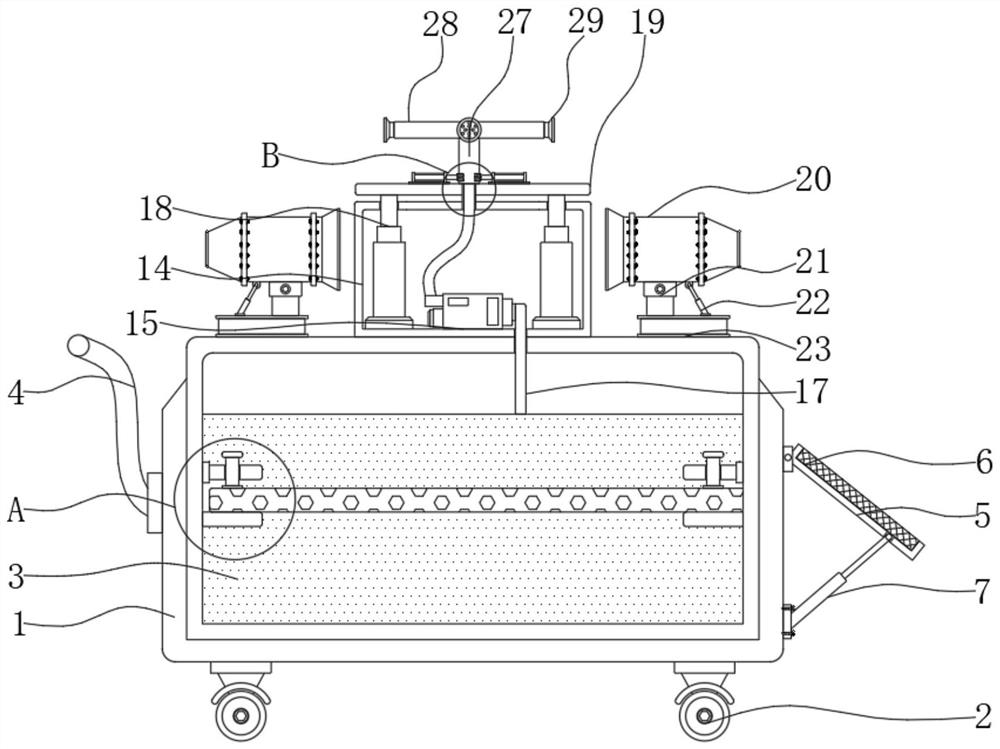

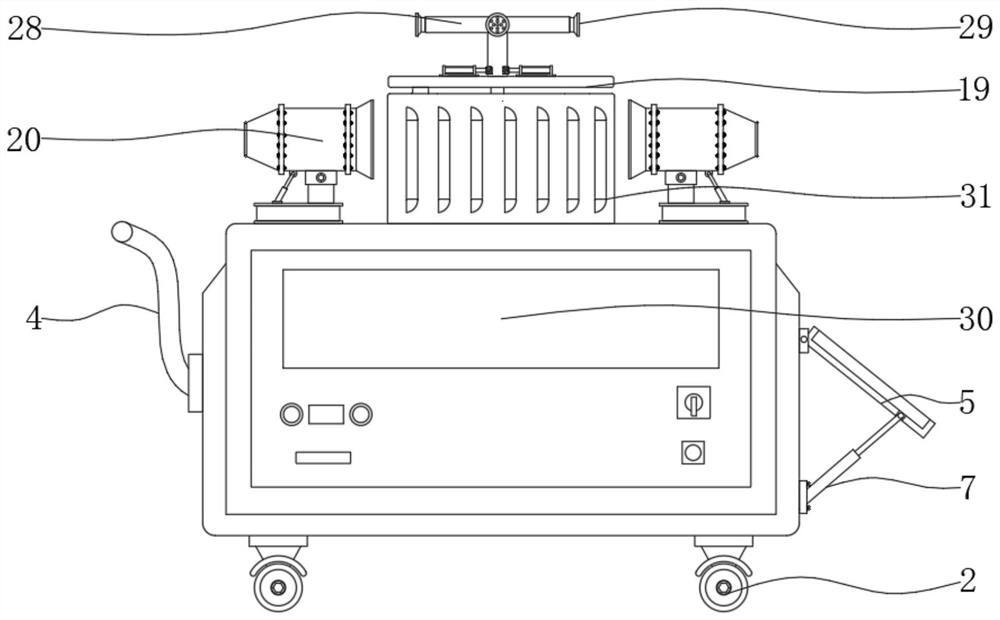

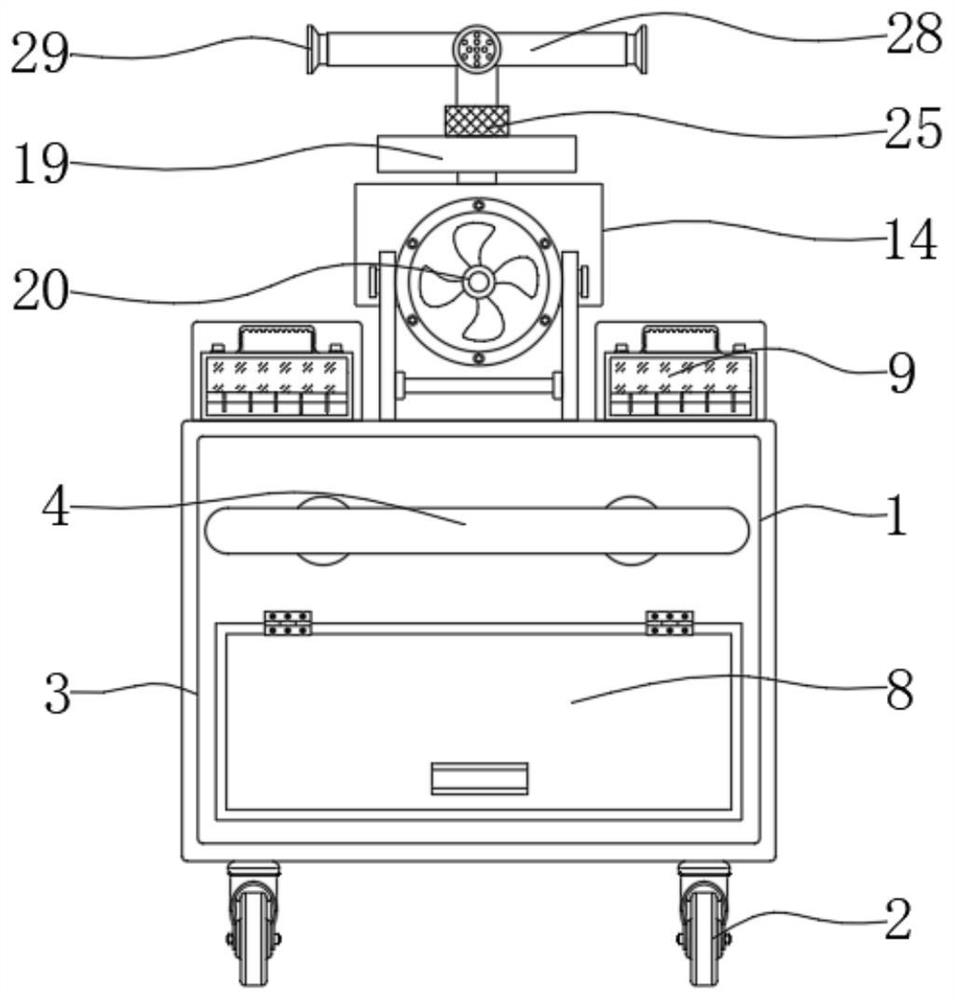

Movable dust removal equipment without filter element

ActiveCN110552734AImprove cleanlinessAvoid cloggingDust removalFire preventionFilter elementWaste management

The invention discloses movable dust removal equipment without the filter element. The movable dust removal equipment without the filter element comprises a base plate, a gas storage main pipe, a fan,a swirler set, an air inlet main pipe, a water supply device and a spraying device; a walking structure is arranged on the base plate; one end of the air inlet main pipe is connected with an air inlet of the fan; one end of the gas storage main pipe is connected with an air outlet of the fan, and the other end of the air storage main pipe is closed; the swirler set comprises a plurality of swirler, the inlet of each swirler is in communication with the gas storage main pipe through an extension pipe, and the lower outlet is downwards arranged; and the water supply device is connected with thespraying device through a pipeline with a water pump and is used for supplying water to the spraying device.

Owner:贾开兴

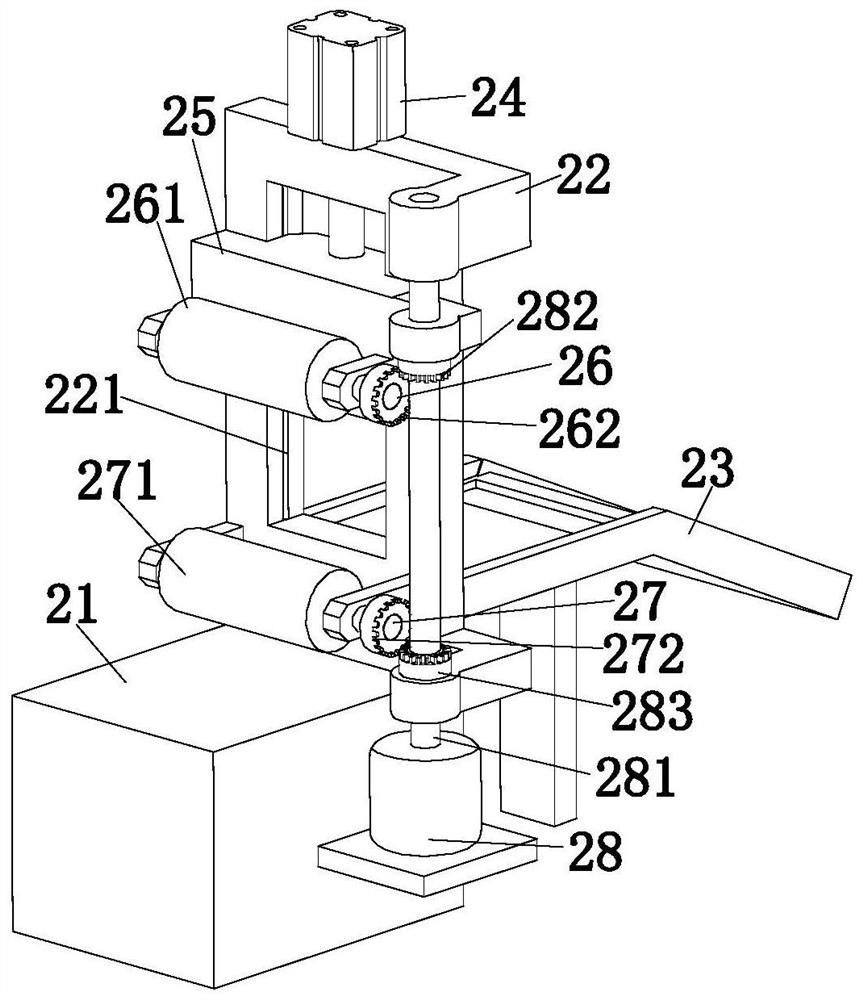

Product performance detection device for integrally molded inductor production and detection method thereof

PendingCN113866512ARealize dust removalRealize automatic feeding processResistance/reactance/impedenceMeasurement instrument housingInductorMechanical engineering

The invention discloses a product performance detection device for integrally molded inductor production and a detection method thereof. The product performance detection device comprises a base, an L-shaped plate is fixedly connected to the upper end of the base, a detection driving mechanism is installed on the L-shaped plate, a guide groove is formed in the upper end of the base, and a sliding groove opposite to the bottom of the guide groove is formed in the bottom of the base; the sliding groove communicates with the guide groove through a discharging groove and a moving groove, and four supporting rods are fixedly connected to the base. The invention further discloses a detection method of the product performance detection device for production of the integrally-molded inductors, and the method comprises the following steps: S1, placing the integrally-molded inductors in a material frame in a stacked manner, and then starting an electric telescopic rod. According to the invention, the electric telescopic rod works, automatic feeding can be conducted on inductors, meanwhile, automatic taking can be achieved, manual participation is not needed, the labor amount of workers is greatly reduced, meanwhile, manual contact is not needed, and pollution to the inductors is reduced.

Owner:浙江富尔科技有限公司

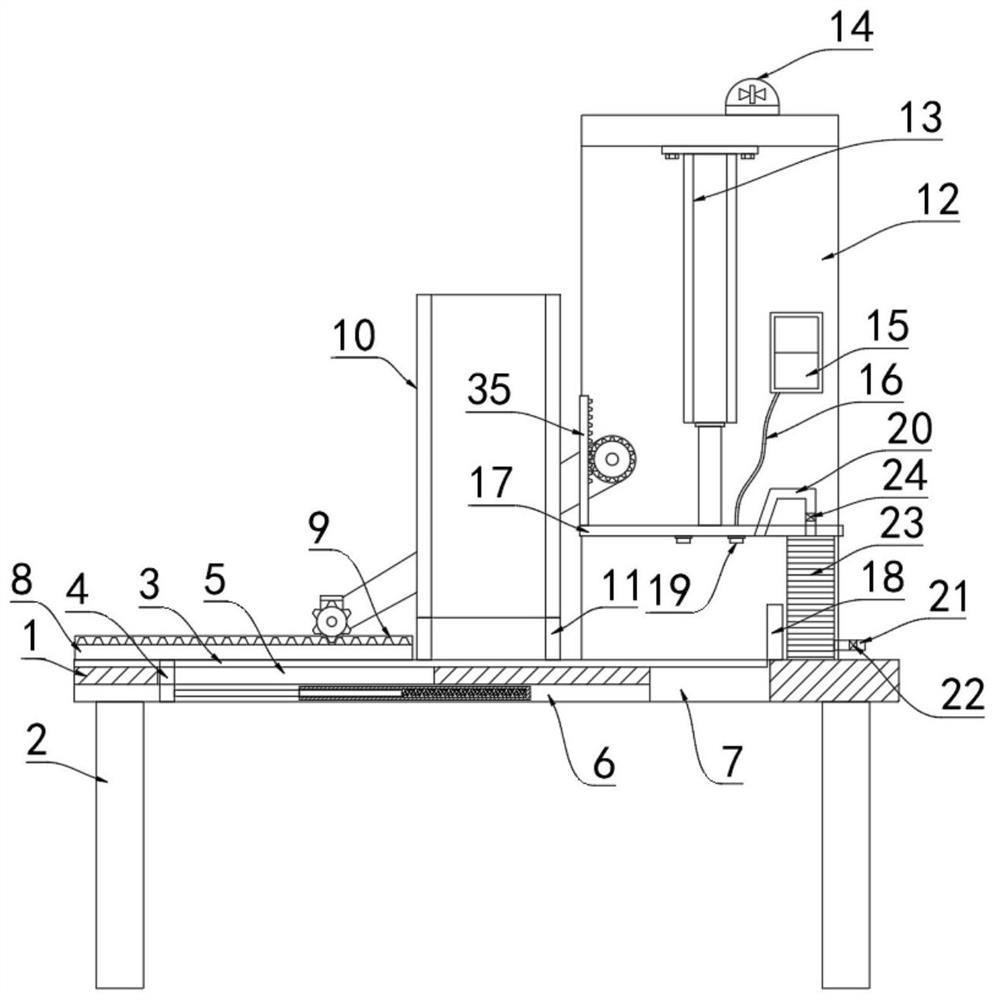

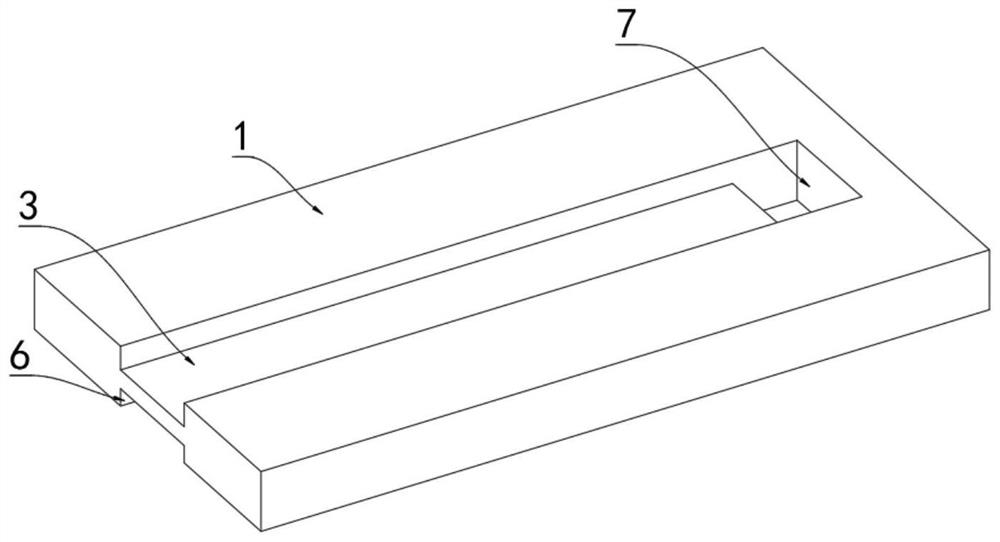

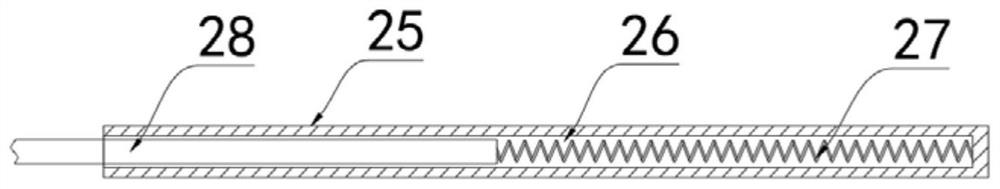

Waste recovery device for plastic pipe machining

InactiveCN112873631ARealize recycling operationsAchieve recyclingUsing liquid separation agentPlastic recyclingDust controlProcess engineering

The invention discloses a waste recovery device for plastic pipe machining, and belongs to the technical field of recovery devices. The waste recovery device comprises a workbench, a conveying assembly, a sliding assembly, a lifting assembly, a cutting assembly, a grinding assembly and a dust removal assembly, wherein the workbench is arranged horizontally and the top of the workbench is provided with a feed port, the conveying assembly is arranged at the front end of the workbench and fixedly connected with the workbench, the sliding assembly is arranged on the workbench and is in sliding fit with the workbench, the lifting assembly is fixedly connected to the sliding assembly, the cutting assembly is fixedly connected to the lifting assembly, the grinding assembly is arranged below the feeding port and fixedly connected with the workbench, the dust removal assembly is arranged at the bottom of the workbench, and the dust removal end of the dust removal assembly penetrates through the workbench and extends to the position above the feeding port. The waste recovery device can be conveniently used, the using effect of the recovery device can be improved, and practicability is achieved.

Owner:刘斌

Intelligent welding device for computer hardware machining

InactiveCN114211186AFlipImprove clamping stabilityWelding/cutting auxillary devicesAuxillary welding devicesComputer hardwareElectric machinery

The invention discloses an intelligent welding device for computer hardware machining, and belongs to the technical field of computer hardware machining. The intelligent welding device comprises a base plate, a frame is welded to the upper surface of the base plate, a sliding rod is fixedly installed on the inner side wall of the frame, the outer surface of the sliding rod is sleeved with a sliding sleeve, and the sliding sleeve is clamped to the left side face of a supporting plate; by arranging the mounting plate a, the mounting plate b, the rotating shaft a, the U-shaped locking seat and the locking plate, the electric push rod extends or contracts to drive the mounting plate b to move left and right, so that the distance between the mounting plate a and the mounting plate b is adjusted, and clamping and dust removing operation on different main plates is met; the threaded column rotates to drive the locking plate to move downwards to be matched with the U-shaped locking seat to clamp and fix the mainboard, the clamping stability is good, the driving motor drives the rotating shaft a to rotate, the mainboard is driven to rotate through the U-shaped locking seat, overturning of the mainboard is achieved without releasing fixation, the working efficiency is improved, and use is convenient.

Owner:金乡县恒业商贸有限公司

Automatic dust removal system for belt conveying

PendingCN114261719AImprove processing effectImprove practicalityDispersed particle filtrationCleaningPhysicsEngineering

The invention is suitable for the technical field related to dust removal, and provides a belt conveying automatic dust removal system which comprises a box body and an exhaust pipe arranged on the box body. The dust suction mechanism is connected with the box body and is used for sucking dust and guiding the dust into the box body; the dust treatment mechanism is positioned in the box body; wherein the dust treatment assembly comprises a first filter plate, an adsorption assembly, a second rotating shaft and a guide fan, the adsorption assembly comprises an adsorption frame and an adsorption plate arranged in the adsorption frame, the second rotating shaft is mounted in the box body through a mounting plate, the guide fan is arranged on the second rotating shaft, and the first filter plate is arranged on the first filter plate. The first filter plate is connected with the adsorption frame, the adsorption plate is connected with the second rotating shaft through a linkage rod, and the material conveying device is innovative in structure and can be conveniently used in material conveying in a dry conveying environment.

Owner:安徽特旭矿山设备科技有限公司

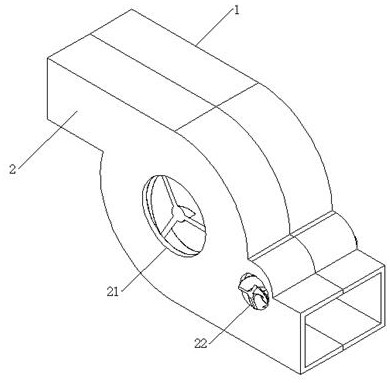

Cylindrical flow guide type environment-friendly dust removal device

InactiveCN112023543ALarge adjustment rangeRealize dust removalDispersed particle filtrationTransportation and packagingDust controlStructural engineering

The invention relates to the field of environment-friendly dust removal, and concretely relates to a cylindrical flow guide type environment-friendly dust removal device. The device comprises a horizontally-arranged supporting mounting cylinder, a plurality of fixed mounting rings are arranged on the outer side of the right end of the supporting mounting cylinder at equal angles, and an arc-surface dust screen is arranged at the right end of the supporting mounting cylinder. An active flow guide cylinder is horizontally arranged in the middle of the right half section of the supporting mounting cylinder, a direction guide and flow guide cylinder is horizontally arranged in the middle of the left end of the active flow guide cylinder, a direction guide mounting cylinder is horizontally arranged on the left half section of the supporting mounting cylinder, and a cambered surface reducing flow guide cylinder is horizontally arranged in the direction guide mounting cylinder. By means of the structure of the active flow guide structure and the split flow guide structure, the flow and the flow speed of the device have a large adjustment range, multi-stage adjustment dust removal operation is achieved in cooperation with adjustment of flow guide, the maintainability of the device is remarkably improved through the direction guide mounting structure and the interchangeability replacement structure, and it is guaranteed that the device can stably operate for a long time.

Owner:陈克建

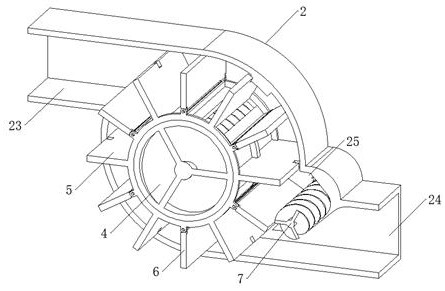

Ventilation equipment with cleaning function

ActiveCN113483427AReduce dust contentImprove collection effectMechanical apparatusLighting and heating apparatusDust controlEngineering

The invention discloses ventilation equipment with a cleaning function, and relates to the technical field of ventilation equipment. The ventilation equipment comprises a first shell and a second shell, the first shell and the second shell are mutually spliced to form a ventilation channel, a columnar cavity is formed in the middle of the formed ventilation channel, and an air outlet and an air inlet formed in the ventilation channel are distributed in the tangential direction of the columnar cavity; a first dust outlet and a second dust outlet which communicate with the ventilation channel are formed in the side surface of the second shell, a communicating pipe is mounted on the end surface of the inner side of the first dust outlet, the communicating pipe is sleeved with a rotating wheel, and a plurality of dust collecting parts are mounted on the rotating wheel; a dust discharging groove extends from the inner side of the second dust outlet and communicates with the columnar cavity, and a second rotating part is mounted in the dust discharging groove. The mounted rotating wheel is pushed by air to rotate, part of the air enters the rotating wheel and the columnar cavity and then stands, sand and dust in the air fall onto a flat plate of the rotating wheel under the action of gravity, the sand and dust rotate along with the flat plate until the sand and dust rotate to the dust discharging groove, and dust removal is completed.

Owner:南通专用风机有限公司

No filter element mobile dust removal equipment

ActiveCN110552734BImprove cleanlinessAvoid cloggingDust removalFire preventionDust controlFilter element

The invention discloses a mobile dedusting device without a filter element. The mobile dedusting device without a filter element includes a chassis, a main gas storage pipe, a fan, a cyclone group, a main air inlet pipe, a water supply device, and a spray device; the chassis There is a walking structure on the top; one end of the air inlet main pipe is connected to the air inlet of the fan; the fan is fixed on the chassis through a bracket; one end of the air storage main pipe is connected to the air outlet of the fan, and the other end is closed The cyclone group includes several cyclones, the inlet of each cyclone communicates with the gas storage main pipe through the extension pipe, and the lower outlet is set downward; the water supply device is connected with the spraying device through a pipeline with a water pump, For supplying water to spray installations.

Owner:贾开兴

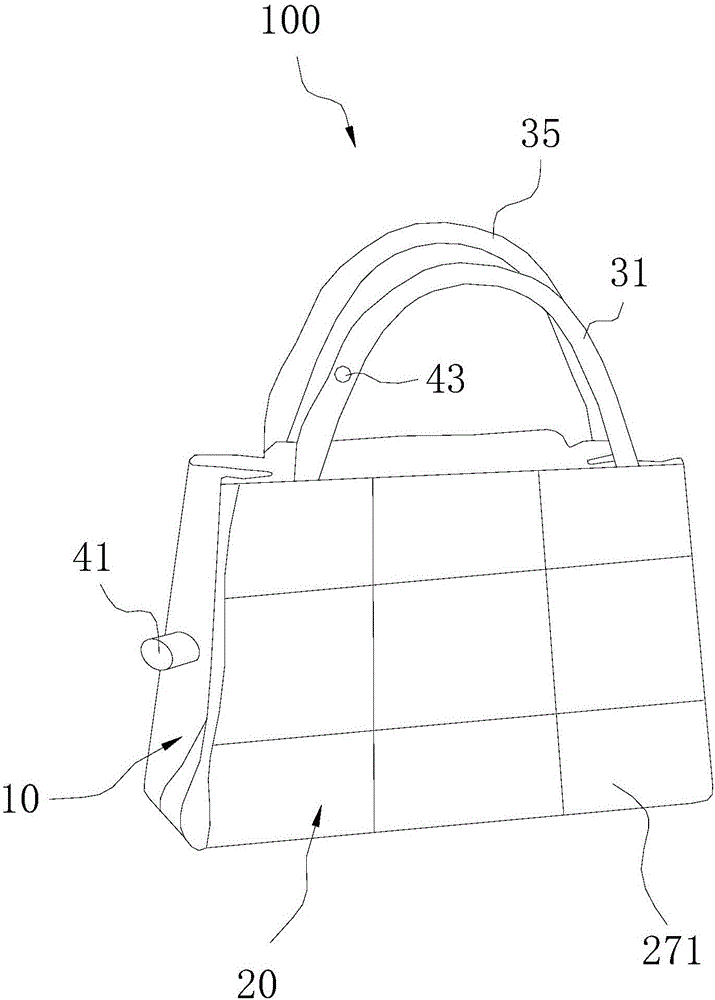

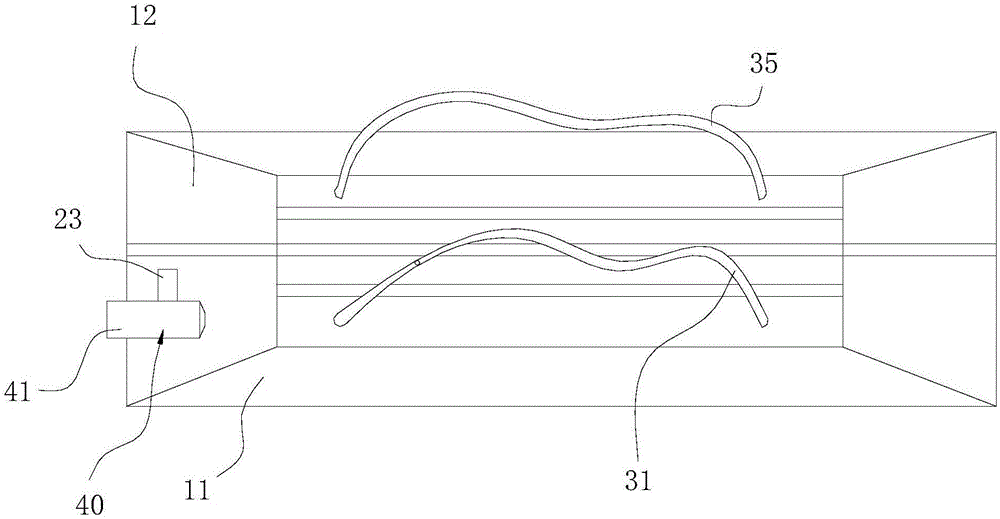

Backpack

InactiveCN106108310AEasy to carryNot easy to forgetTelevision system detailsPursesEngineeringElectrical and Electronics engineering

The invention relates to a backpack. The backpack comprises an accommodating piece, a display assembly, a first shoulder strap and a second shoulder strap, an illuminating assembly and a dust removal assembly, wherein the accommodating piece comprises a first accommodating body and a second accommodating body which are arranged side by side; the display assembly comprises a power supply as well as a camera, a central controller and a plurality of display screens which are electrically connected to the power supply; the first shoulder strap is connected to the first accommodating body and the second shoulder strap is connected to the second accommodating body; the illuminating assembly comprises a lamp holder, a button and a cable; the dust removal assembly comprises an air blowing component, a ventilation soft hose and a dust removal head; a first accommodating cavity is formed in the first accommodating body; the air blowing component is arranged at the bottom of the first accommodating cavity; the dust removal head is clamped on the sidewall of the first accommodating cavity; and the air blowing component and the dust removal head are connected to two ends of the ventilation soft hose. The backpack can achieve an illuminating function, and dust in the backpack can be removed.

Owner:惠州市大隆科技有限公司

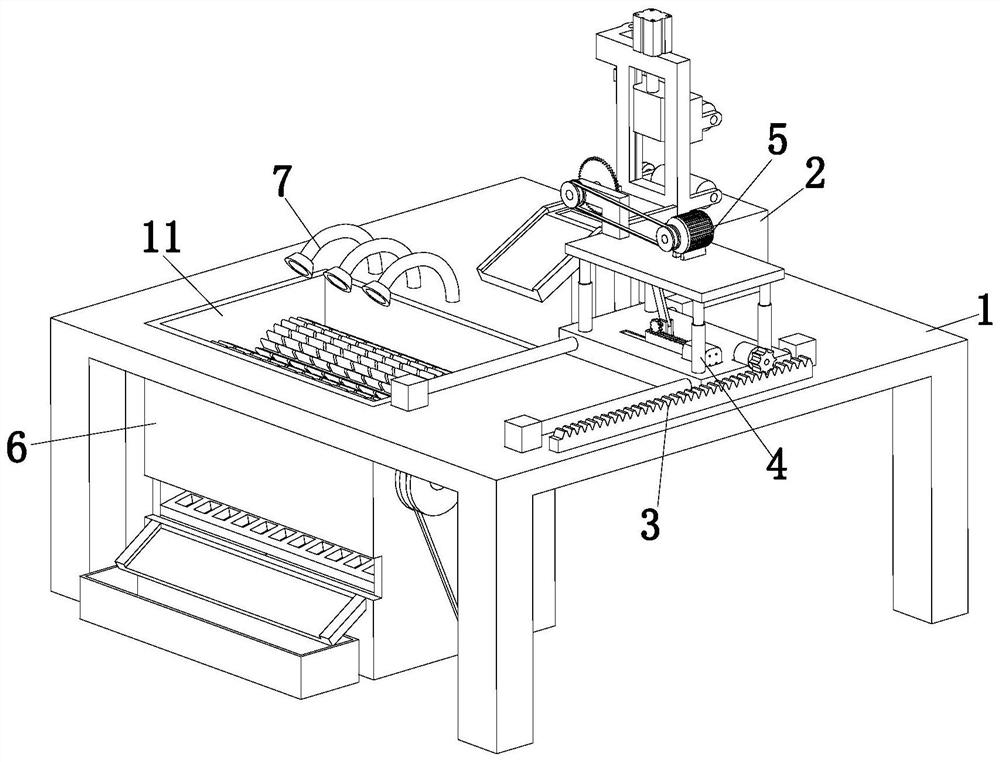

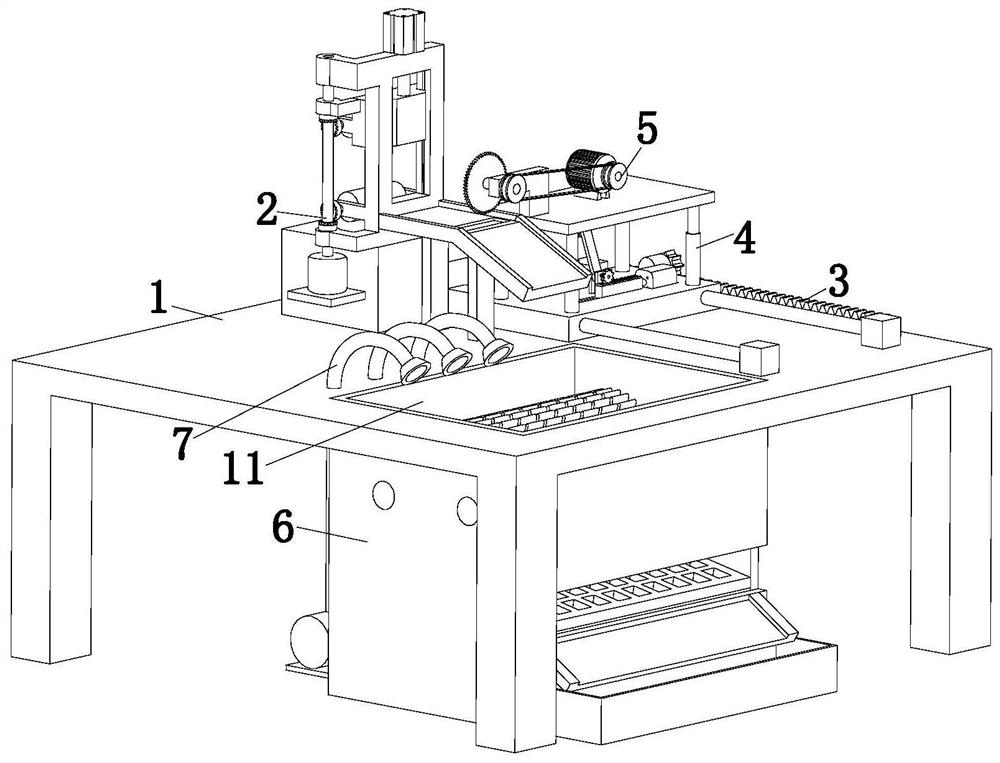

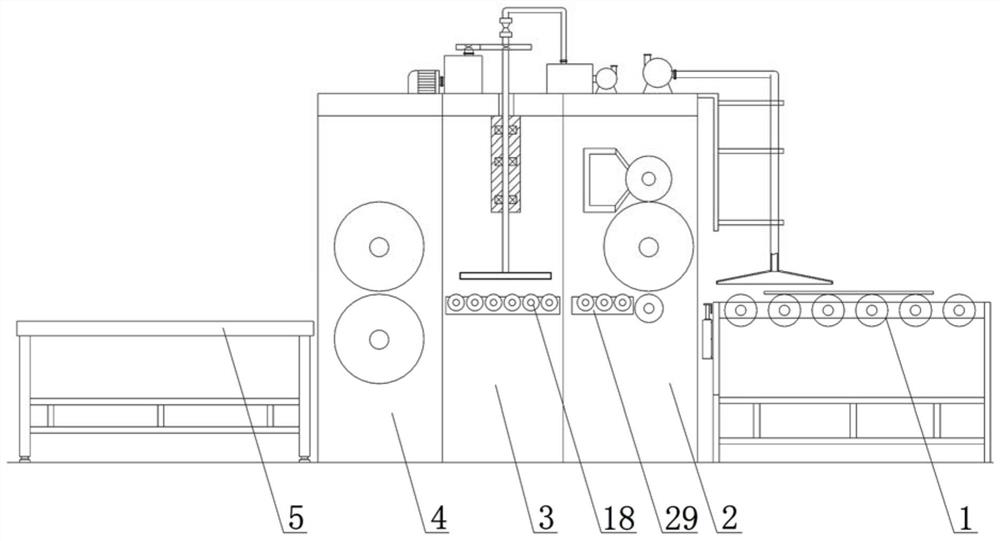

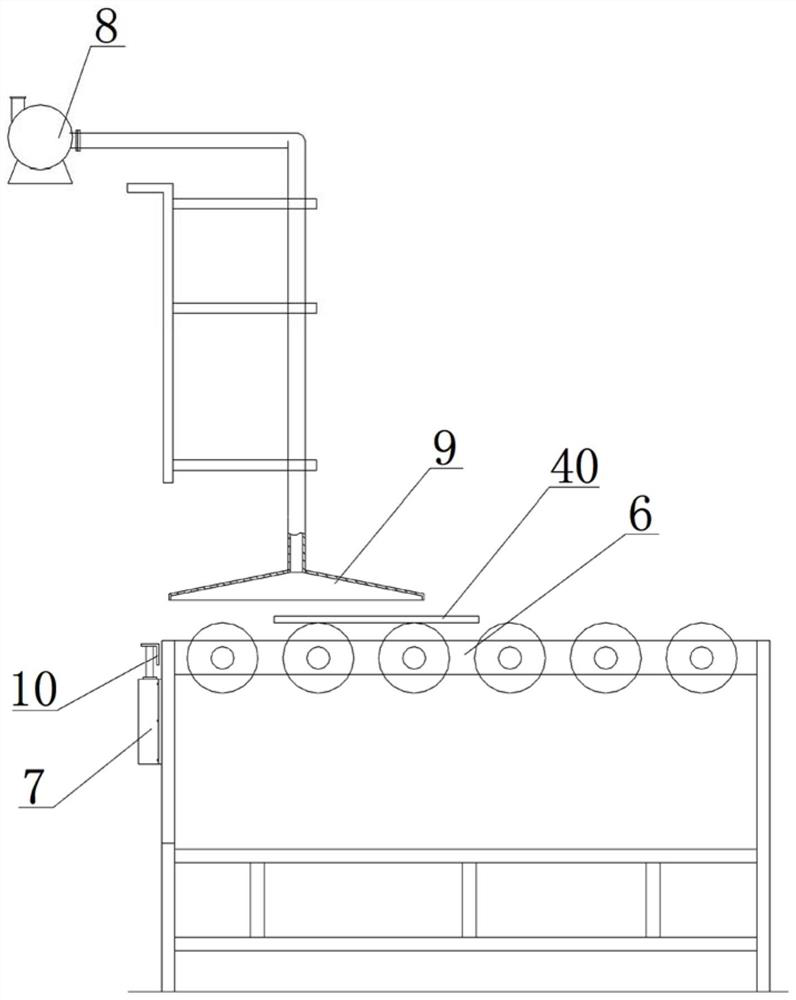

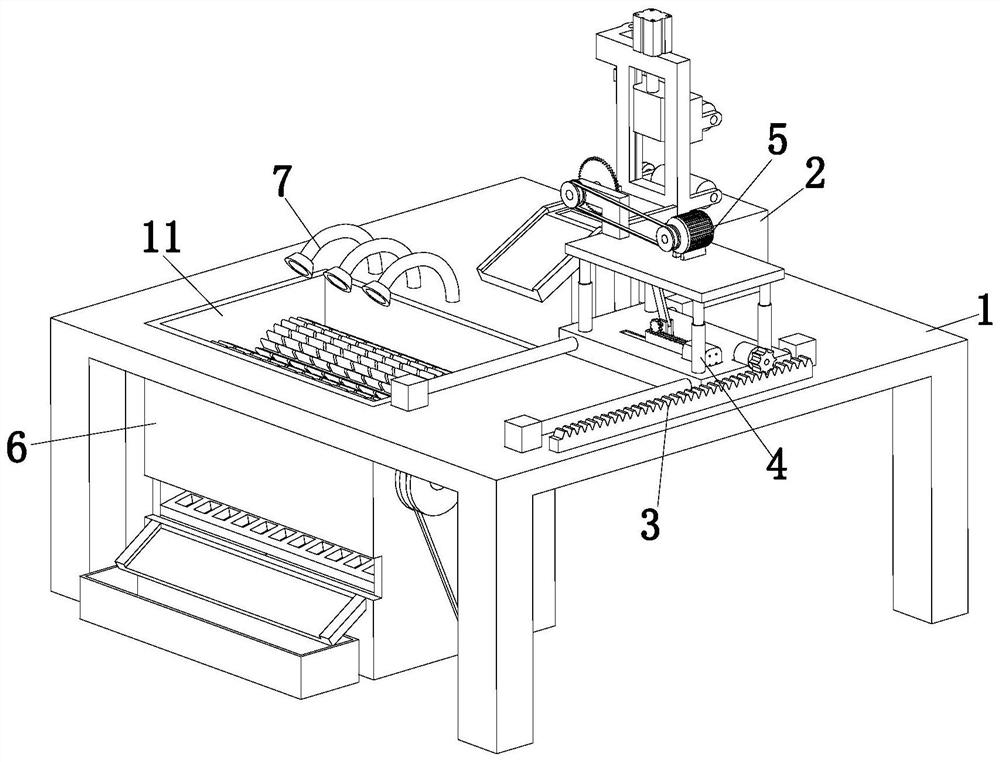

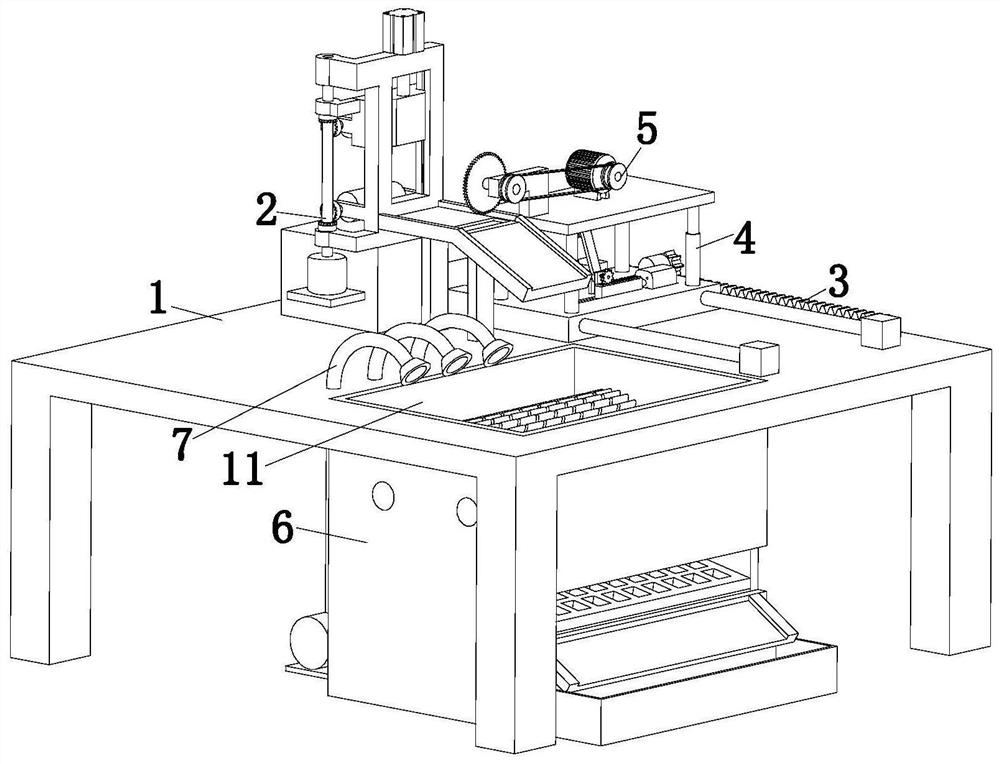

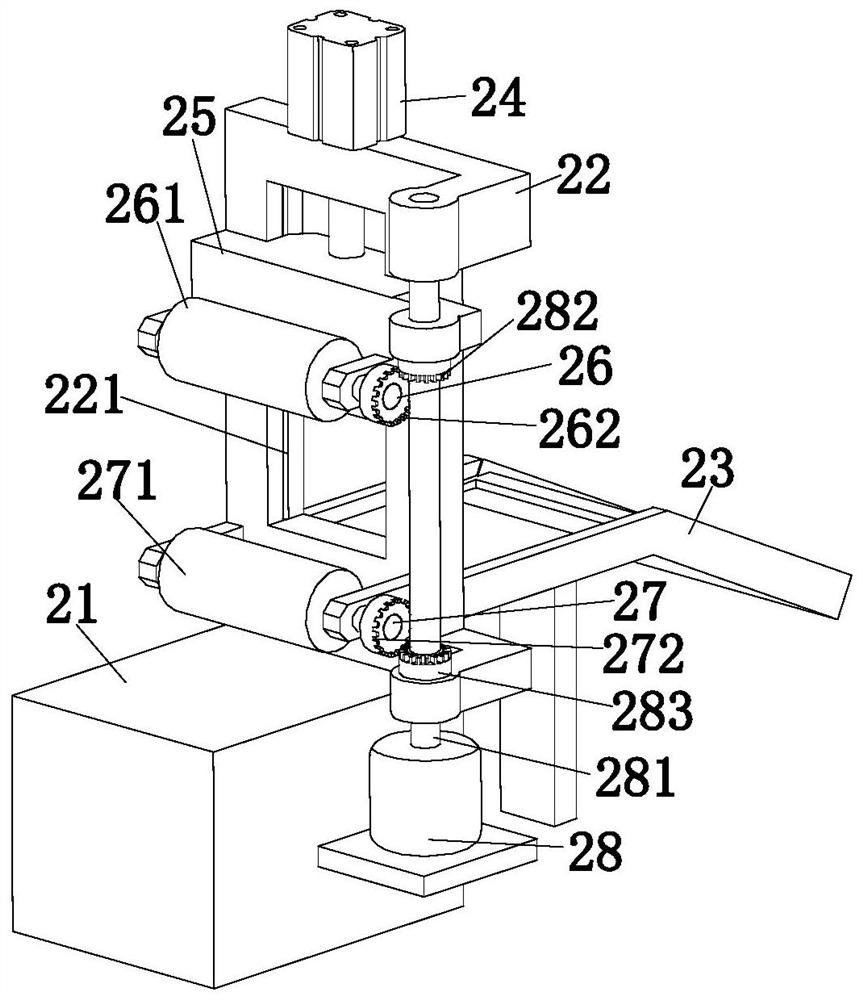

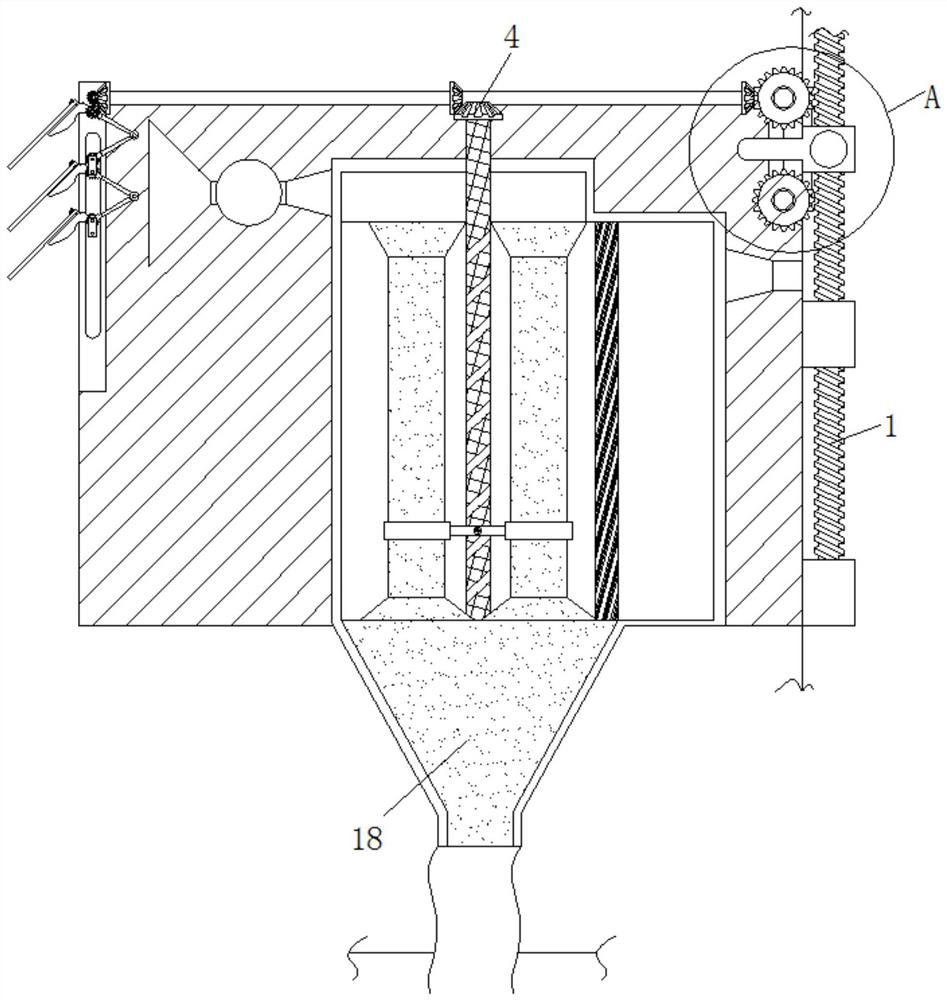

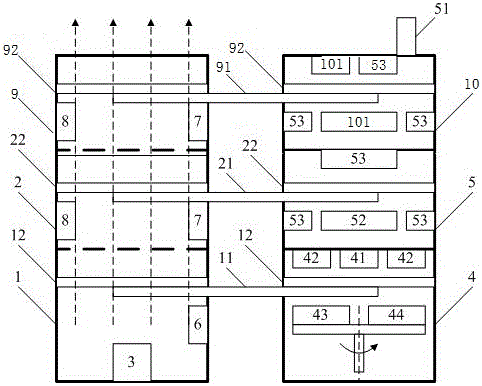

Fully automatic high-speed intelligent printing slotting die-cutting machine and its working method

ActiveCN113043731BRealize dust removalQuality assuranceCylinder pressesPlaten pressesCardboardEngineering

The invention discloses a fully automatic high-speed intelligent printing slotting die-cutting machine, which includes a paper feeding device, a printing device, a drying device, a slotting device and a collecting platform arranged in sequence from right to left, and the paper feeding device includes an input roller table device, lifting cylinder, blower and wind cover, the lifting cylinder is fixed at the left end of the frame of the input roller table device, a baffle is fixed on the piston rod of the lifting cylinder, the wind cover is arranged directly above the input roller table device, and the blower The air outlet of the air outlet is connected to the top port of the wind hood through the pipe; the drying device includes the second frame, the power unit, the air outlet pipe, the air heater and the induced draft fan, and the air outlet pipe is rotatably installed on the top of the second frame , one end of the air outlet pipe extends downwards in the second frame and a turntable is fixed on the extension end. The beneficial effects of the invention are: compact structure, improved printing quality, improved corrugated cardboard production efficiency, and the ability to change the distance between two grooves and the size of the groove width.

Owner:中山市德裕机械有限公司

Novel dust removal device

InactiveCN111545547ARunning Power AdjustmentEasy to change and adjustDirt cleaningImpellerDust control

The invention provides a novel dust removal device comprising a dust remover and a gas inlet unit. An air inlet pipe and an exhaust pipe are arranged on the two sides of the dust remover correspondingly. A purification assembly is arranged in the dust remover. Material discharge ports are arranged at the bottom of the dust remover. The gas inlet unit comprises a supporting table, a gas inlet draught fan, a base, a transmission rod and a drive motor. The gas inlet draught fan comprises an air inlet and an air sending port. The air sending port is connected with the air inlet pipe through a pipeline. The drive motor and the base are fixedly arranged on a supporting table. The output end of the drive motor is connected with the transmission rod. A rotation base is arranged on the base. The transmission rod is arranged in the rotation base in a penetrating manner. The end portion of the transmission rod is connected to the drive end of the gas inlet draught fan. An impeller in the gas inlet draught fan is driven to rotate through rotation of the transmission rod, and in this way, mold selection and replacement can be conveniently conducted on the drive motor on the supporting table andadjustment of the operation power of the gas inlet draught fan can be achieved through connection and assembly of the transmission rod so that dust removal treatment of large-flow waste gas can be achieved and operators can conveniently conduct replacement and adjustment.

Owner:青岛铭宏智能装备科技有限公司

A ventilation device with cleaning function

ActiveCN113483427BReduce dust contentImprove collection effectMechanical apparatusLighting and heating apparatusDust controlStructural engineering

The invention discloses a ventilating device with a cleaning function and relates to the technical field of ventilating devices. The present invention includes shell one and shell two, and shell one and shell two are spliced together to form a ventilation channel, wherein, the middle part of the formed ventilation channel is a columnar cavity, and the air outlet and air inlet provided in the ventilation channel are all along the columnar shape. The distribution of the tangential direction of the cavity; the side of the second shell is opened with the dust outlet 1 and the dust outlet 2, which are connected with the ventilation channel. There are several dust-collecting parts installed on the runner; a dust discharge groove is extended on the inner side of the second dust outlet, and the dust discharge groove is connected with the columnar cavity, and the second rotating part is installed in the dust discharge groove. The invention pushes the installed runner to rotate through air, and after part of the air enters the runner and the columnar cavity, the air is left still, and the sand and dust in the air fall on the flat plate of the runner under the action of gravity, and the sand and dust follow the rotation of the flat plate until it rotates to the exhaust. At the dust tank, dust removal is completed.

Owner:南通专用风机有限公司

Waste recovery equipment for plastic pipe processing

InactiveCN112873630ARealize recycling operationsAchieve recyclingUsing liquid separation agentPlastic recyclingDust controlProcess engineering

The invention discloses waste recovery equipment for plastic pipe processing, and belongs to the technical field of recovery devices. The waste recovery equipment comprises a workbench, a conveying assembly, a sliding assembly, a lifting assembly, a cutting assembly, a grinding assembly and a dust removal assembly, wherein the workbench is placed horizontally, a feeding port is formed in the top of the workbench, the conveying assembly is arranged at the front end of the workbench and fixedly connected with the workbench, the sliding assembly is arranged on the workbench and is in sliding fit with the workbench, the lifting assembly is fixedly connected to the sliding assembly, the cutting assembly is fixedly connected to the lifting assembly, the grinding assembly is arranged below the feeding port and fixedly connected with the workbench, the dust removal assembly is arranged at the bottom of the workbench, and the dust removal end of the dust removal assembly penetrates through the workbench and extends to the position above the feeding port. The waste recovery equipment can be conveniently used, and the using effect of the waste recovery equipment can be improved.

Owner:刘斌

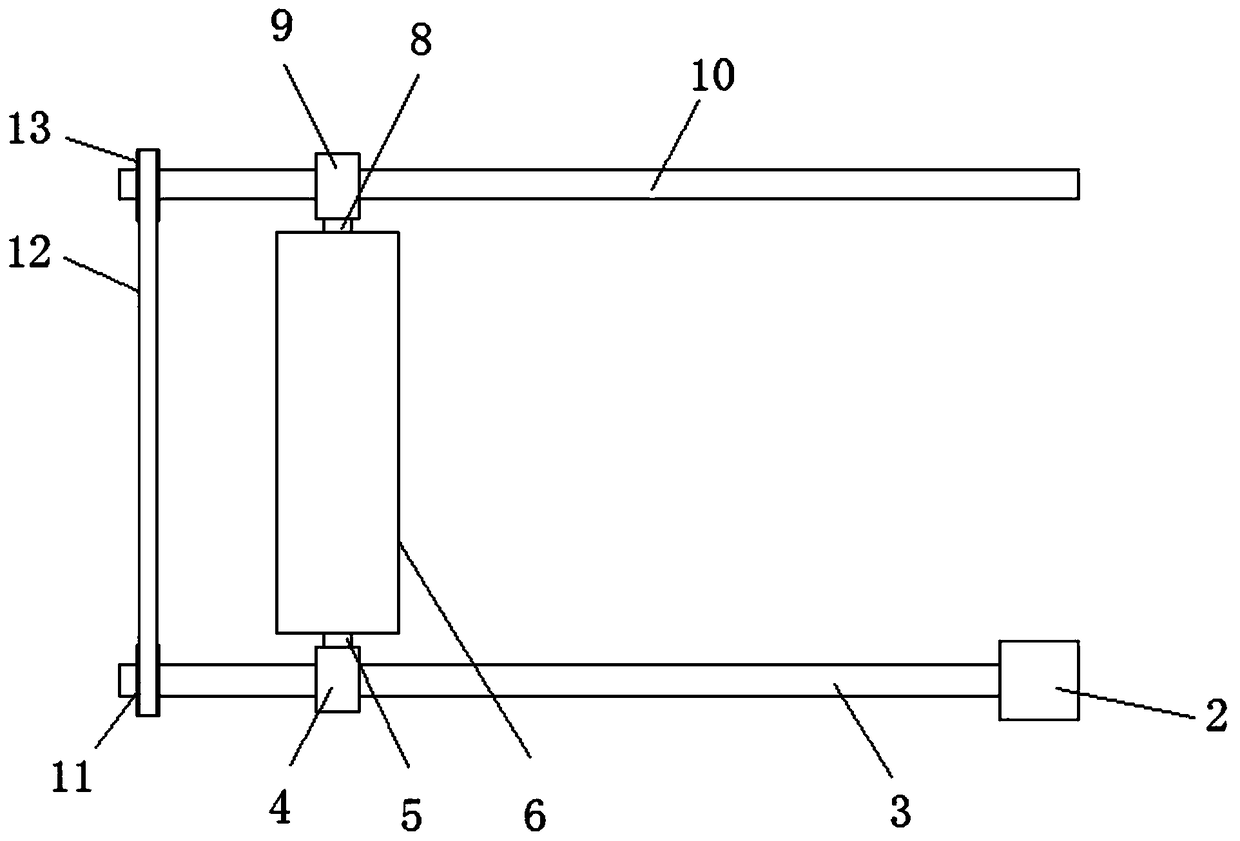

Computer dedusting device capable of moving in mainframe box

InactiveCN112077078AEasy to operateReduce manual labor intensityDispersed particle filtrationTransportation and packagingRatchetElectrical and Electronics engineering

The invention relates to the technical field of computer hardware equipment, and discloses a computer dedusting device capable of moving in a mainframe box. The computer dedusting device capable of moving in the mainframe box comprises a screw, wherein a first connection block is connected with the outer side of the screw through threads, a first gear is rotatably connected with the outer side ofthe first connection block, a first bevel gear is meshed with the outer side of the first gear, a first connecting shaft is rotatably connected with the interior of the first bevel gear, a first ratchet wheel is meshed with the outer side of the first bevel gear, and a first exhaust fan is rotatably connected with the outer side of the first ratchet wheel. According to the computer dedusting device capable of moving in the mainframe box, through connection between the screw and the first exhaust fan, dedusting treatment is conducted on most areas, the problems that in order to dedust computermainframe boxes in the prior art, computers need to be manually disassembled generally, and parts in the computers need to be cleaned are solved, operation is simple, the manual labor intensity is low, the practicability is high, and blocking of heat emission holes is avoided, so that the service life of a computer is greatly prolonged.

Owner:湖州南浔吾心信息技术有限公司

Environment-friendly spraying dust removal device for chemical raw material preparation

PendingCN112892127AReduce power generation costsReduce pollutionUsing liquid separation agentFiltration circuitsProcess engineeringEnvironmental geology

The invention discloses an environment-friendly spraying dust removal device for chemical raw material preparation, and relates to the technical field of chemical raw material preparation, in particular to an environment-friendly spraying dust removal device for chemical raw material preparation, which comprises a fixed seat and a filter screen, a steering wheel is welded below the fixed seat, and a water tank is fixedly connected above the fixed seat; a handle is fixedly connected to the left side of the fixing seat, a groove is movably connected to the right side of the fixing seat, a photovoltaic panel is connected to the interior of the groove in a clamped mode, a supporting rod is fixedly connected to the lower portion of the groove, a movable door is arranged below the handle, and a storage battery is arranged above the handle. According to the environment-friendly spraying dust removal device for chemical raw material preparation, in the using process, dust removal treatment can be conducted on suspended particles with different gravities, the spraying angle can be changed, and spraying can be conducted on all parts of a dust removal area; besides, solar energy is utilized for power generation, on one hand, the power generation cost cannot be wasted, and on the other hand, the pollution to the environment is reduced.

Owner:蔡颖佳

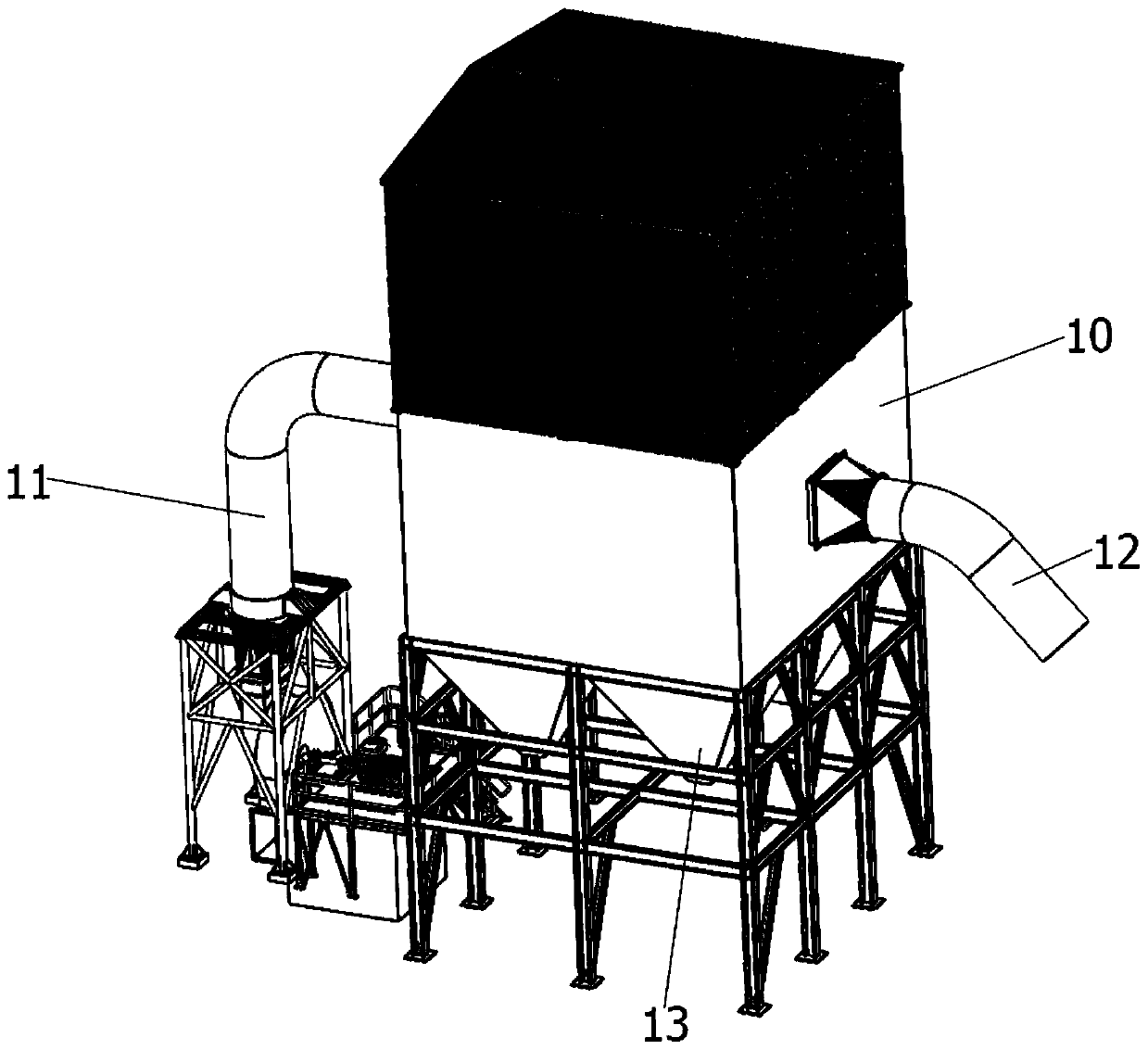

Coal mine safety production tunnel dust removal device

ActiveCN114682039AAchieve protectionRealize the effect of spray dust reductionHuman health protectionCombination devicesMining engineeringDust control

The invention discloses a coal mine safety production tunnel dust removal device which comprises an air pipe arranged above a tunnel along the trend of the tunnel and provided with a plurality of air supply heads; the integration bin is movably arranged below the air pipe, a dust content detector and a controller are arranged in the integration bin, the input end of the dust content detector is connected with the output end of the detection fan, and the dust content detector can send detection data to the controller; the spraying pipe is laid on one side of the air pipe, and a plurality of liquid spraying heads are arranged on the spraying pipe; and the dust removal assembly is arranged below the integration bin and used for filtering and collecting dust in the tunnel air.

Owner:SHENYANG LIGONG UNIV

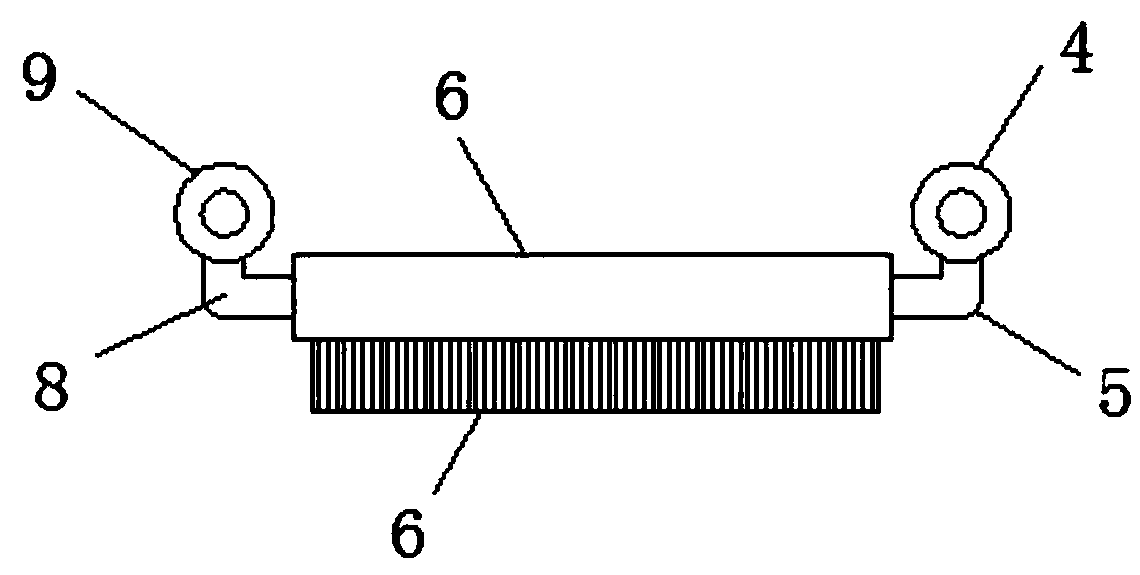

Coiled material dust removal device

ActiveCN113477618ARealize dust removalPrevent getting involvedDirt cleaningCleaning using gasesParticle flowDust control

The invention provides a coiled material dust removal device which comprises two oppositely-arranged air blowing heads. A coiled material penetrates through the space between the two air blowing heads, a plurality of opposite air openings are formed in the opposite surfaces of the air blowing heads in the length direction of the coiled material, and the two air blowing heads provide airflow for the air openings to enable the coiled material to vibrate. The coiled material dust removal device has the advantages that the coiled material is driven to vibrate only through different airflow directions among the air openings, so that particles leave the coiled material, then the particles flow along with the airflow under the action of the airflow to leave the range of the coiled material, dust removal operation of the coiled material is achieved, only the airflow needs to be provided in the process, actions of components such as pistons are not needed, vibration and noise of the dust removal device are reduced, and the comfort level of workers is improved.

Owner:HEFEI GUOXUAN HIGH TECH POWER ENERGY

A kind of indoor multifunctional air purifier

ActiveCN104197413BLow priceEasy to replaceCombination devicesLighting and heating apparatusEngineeringAbsorption effect

The invention discloses an indoor multifunctional air purifier which comprises a purifying end and a cleaning end. The purifying end comprises a first air purifying layer used for removing PM2.5, a second air purifying layer used for removing odors in air and a third air purifying layer used for ionization. Each air purifying layer comprises two microporous ceramic plates capable of changing positions, an active carbon plate and a static electricity plate. The cleaning end comprises a miroporous ceramic plate cleaning layer, an active carbon plate cleaning layer and a static electricity plate cleaning layer. The miroporous ceramic plate cleaning layer comprises a first air blowing system, an ultraviolet sterilization lamp, a water spraying system and a rolling brush. The active carbon plate cleaning layer comprises a smoke exhaust hole, a heating system and a fluorescent lamp. The static electricity plate cleaning layer comprises a second air blowing system and a fluorescent lamp. According to the air purifier, the function of purifying air of an original air purifier can be maintained, PM2.5 in the air can be absorbed, a replaceable absorption layer is arranged in the air purifier, and accordingly a good absorption effect is kept for a long time.

Owner:HUNAN CHANGZHONG MACHINERY

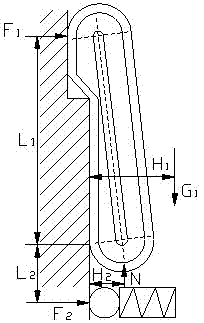

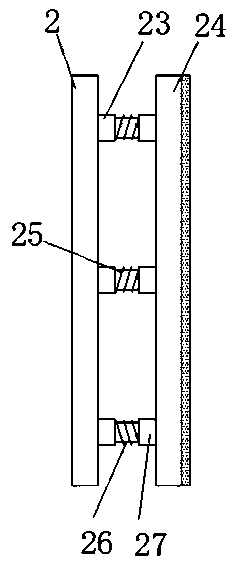

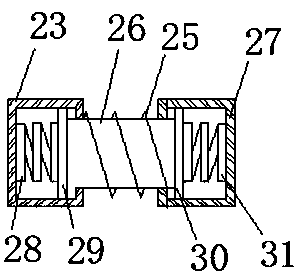

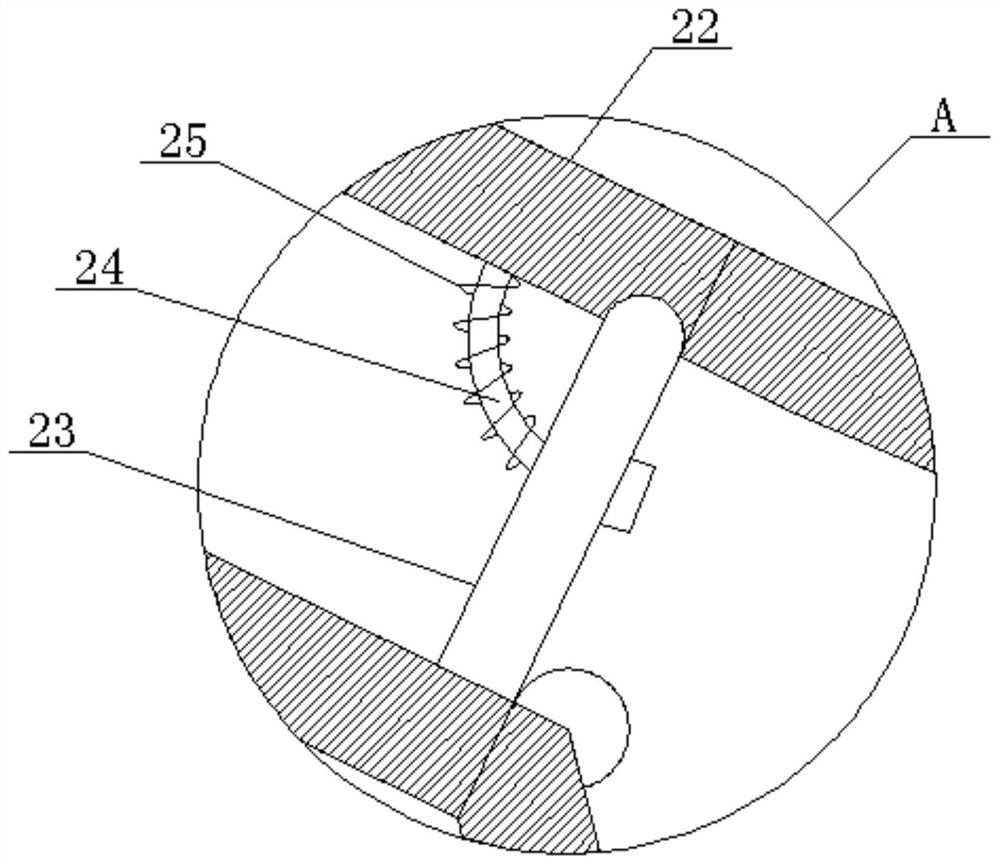

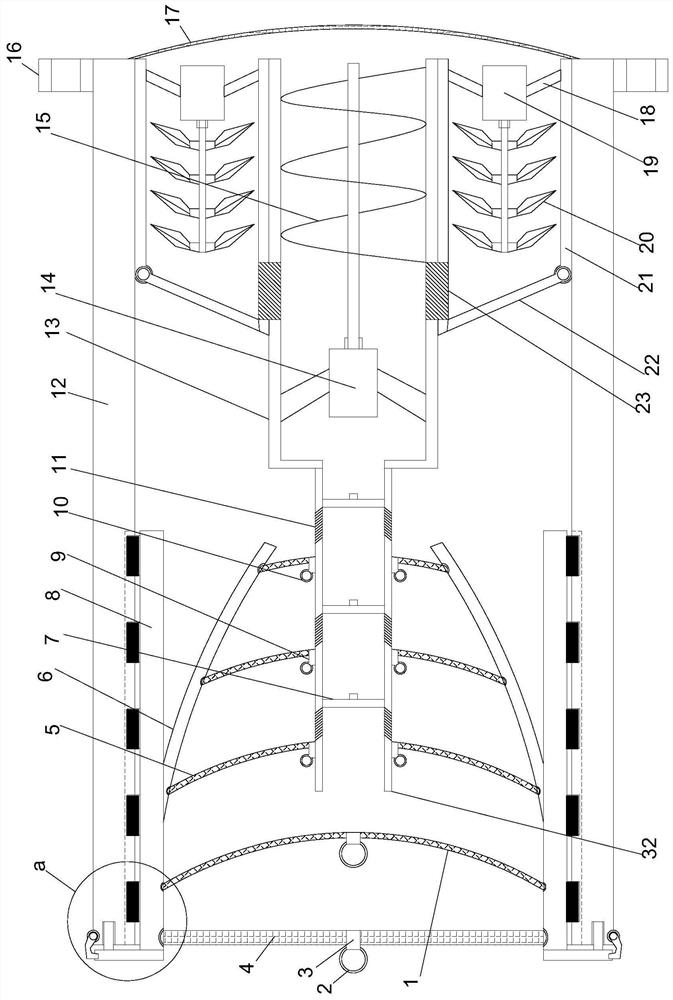

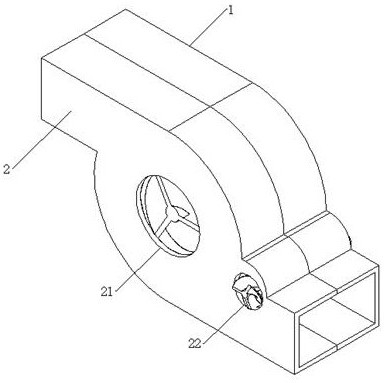

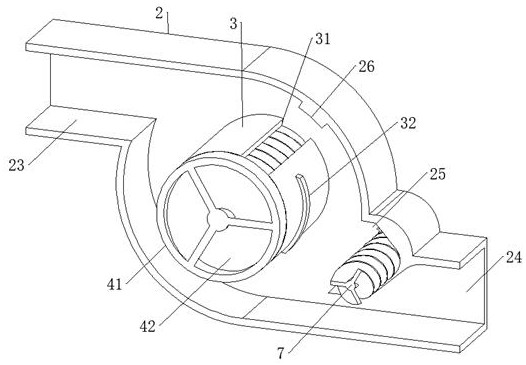

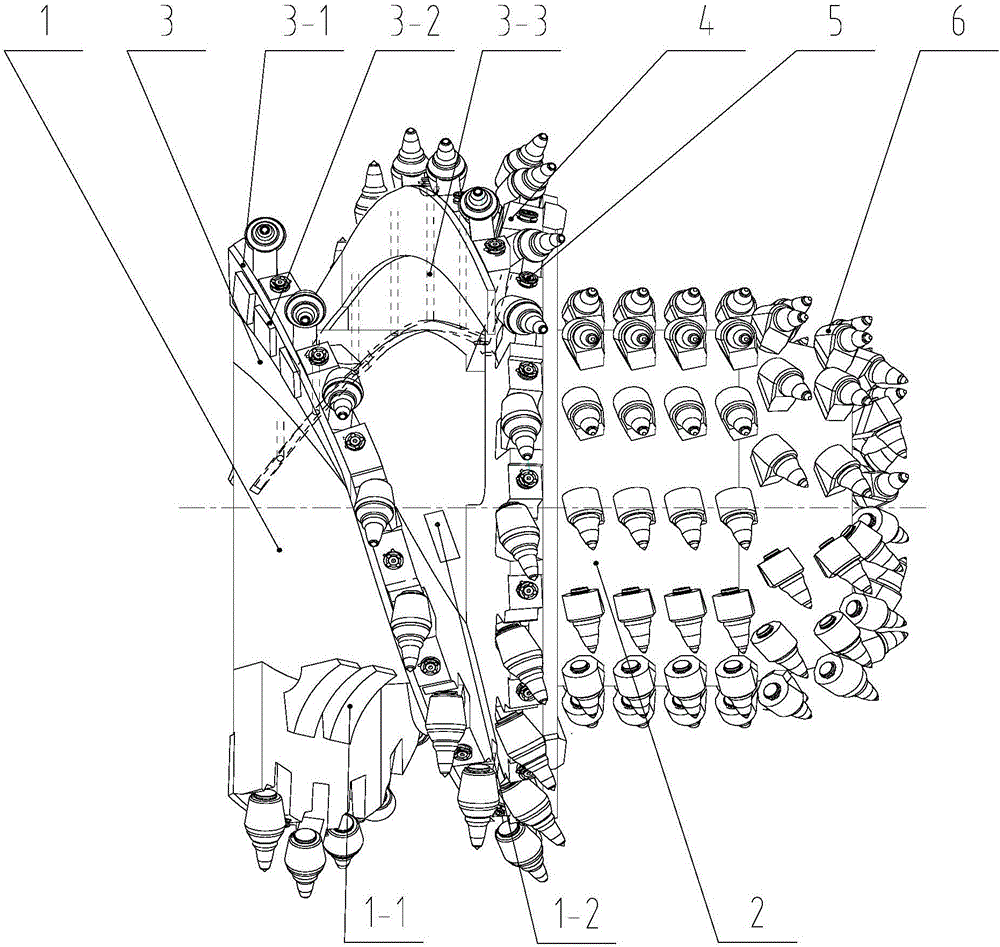

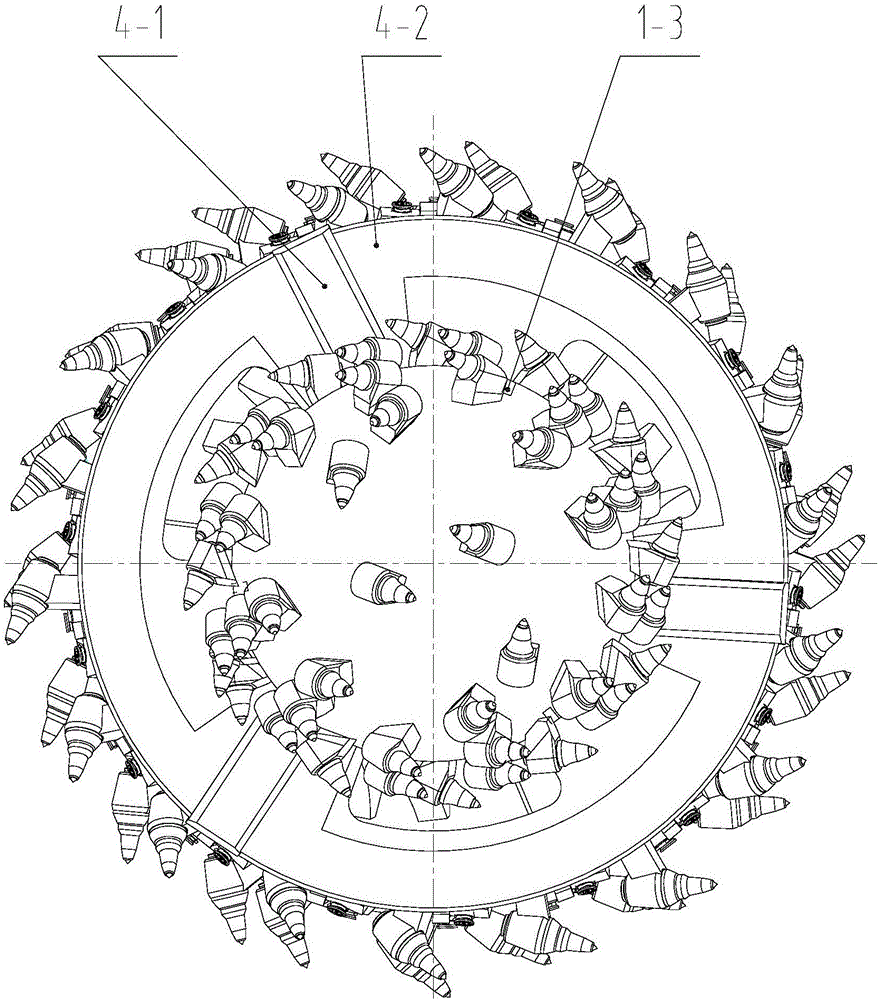

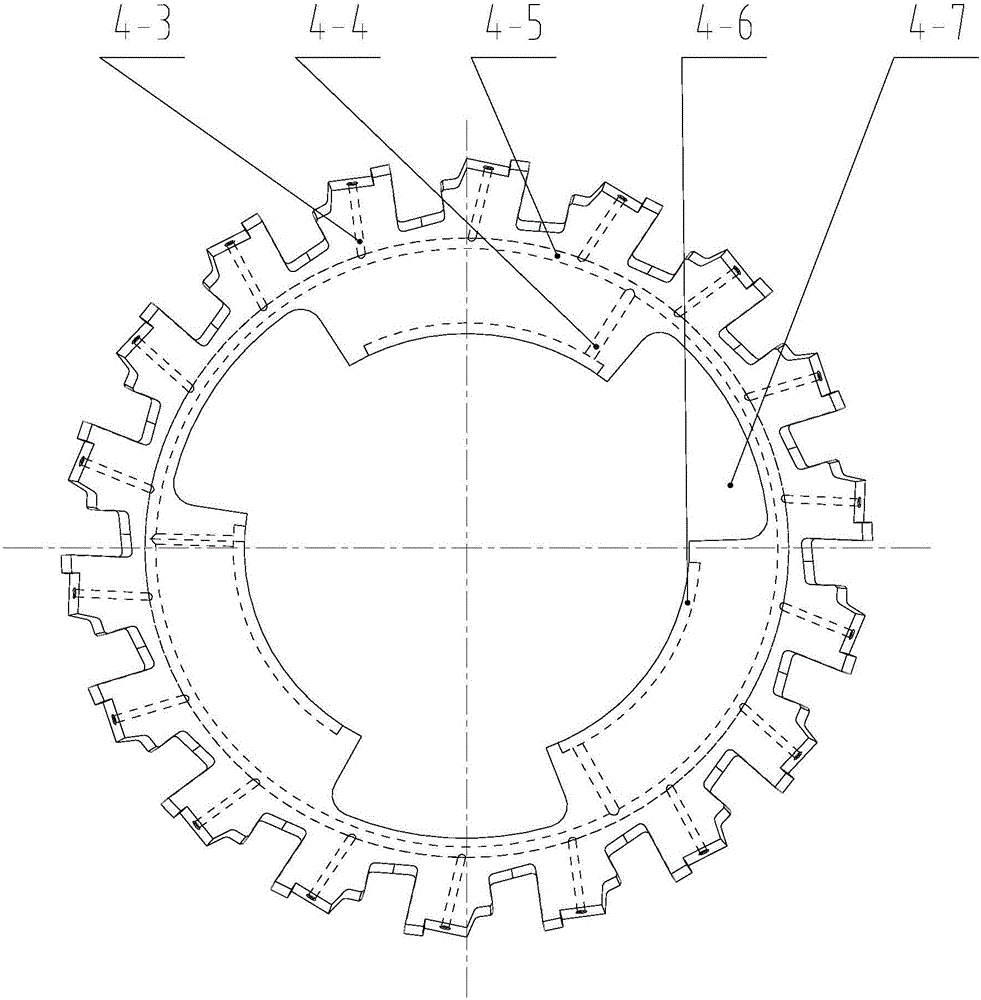

Deep Well High Stress Coal Rock Ladder Roller

ActiveCN104712334BGuaranteed water supplyMeet mining needsSlitting machinesCutting machinesMotor driveSpiral blade

Disclosed is a deep-well high-stress coal rock stepped drum, comprising a rear cylinder hub (1), a front cylinder hub (2), a spiral blade (3), an end plate (4), nozzles (5) and pick-shaped cutters (6). The end plate (4) is arranged at the joint of the rear cylinder hub (1) and the front cylinder hub (2), the spiral blade (3) connected to the end plate (4) is arranged on the rear cylinder hub (1), a plurality of pick-shaped cutters (6) and nozzles (5) are distributed on the outer edge of the spiral blade (3) and the end plate (4) at intervals, and the pick-shaped cutters (6) in spiral arrangement are fixed on the front cylinder hub (2); and the end plate (4) is provided with an annular water delivery channel (4-5), and is provided with a nozzle water delivery channel (4-3), a wheel hub water delivery channel (4-4) and an end plate blade water delivery channel (4-6) which are in communication with the annular water delivery channel (4-5). With the drum, the mechanical mining problem of deep-well high-stress coal rock is solved, and deep-well high-stress coal rock cutting efficiency is increased in the case that explosion-proof motor power is not greatly increased. The structure uses an explosion-proof motor drive, such that underground explosion-proof requirements can be satisfied, and the shearer drum has a simple and compact structure.

Owner:江苏中矿汇弘科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com