Coal mine safety production tunnel dust removal device

A dust removal device, coal mine safety technology, applied in the direction of safety devices, combined devices, dust prevention, etc., can solve the problems of workers' respiratory tract and lung diseases, dust explosion, low work efficiency, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

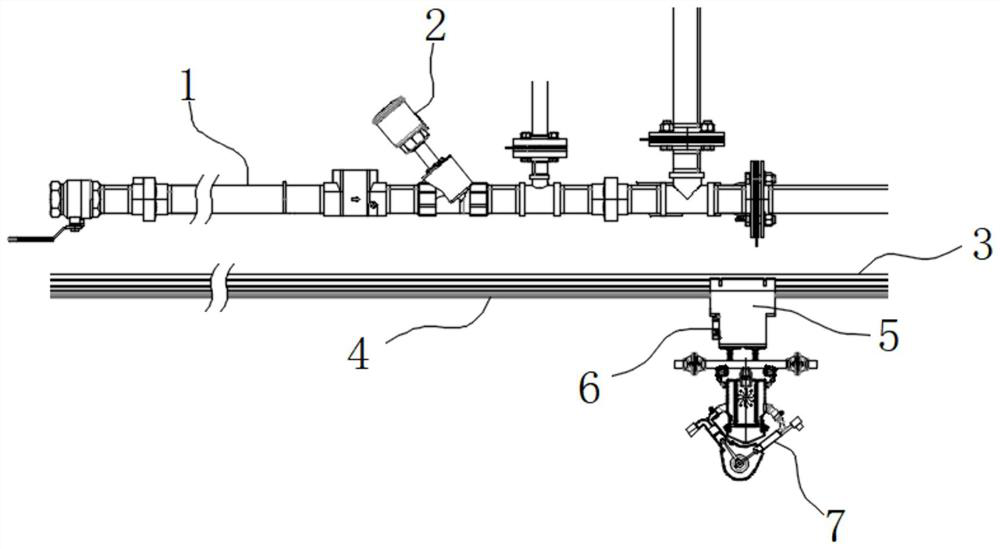

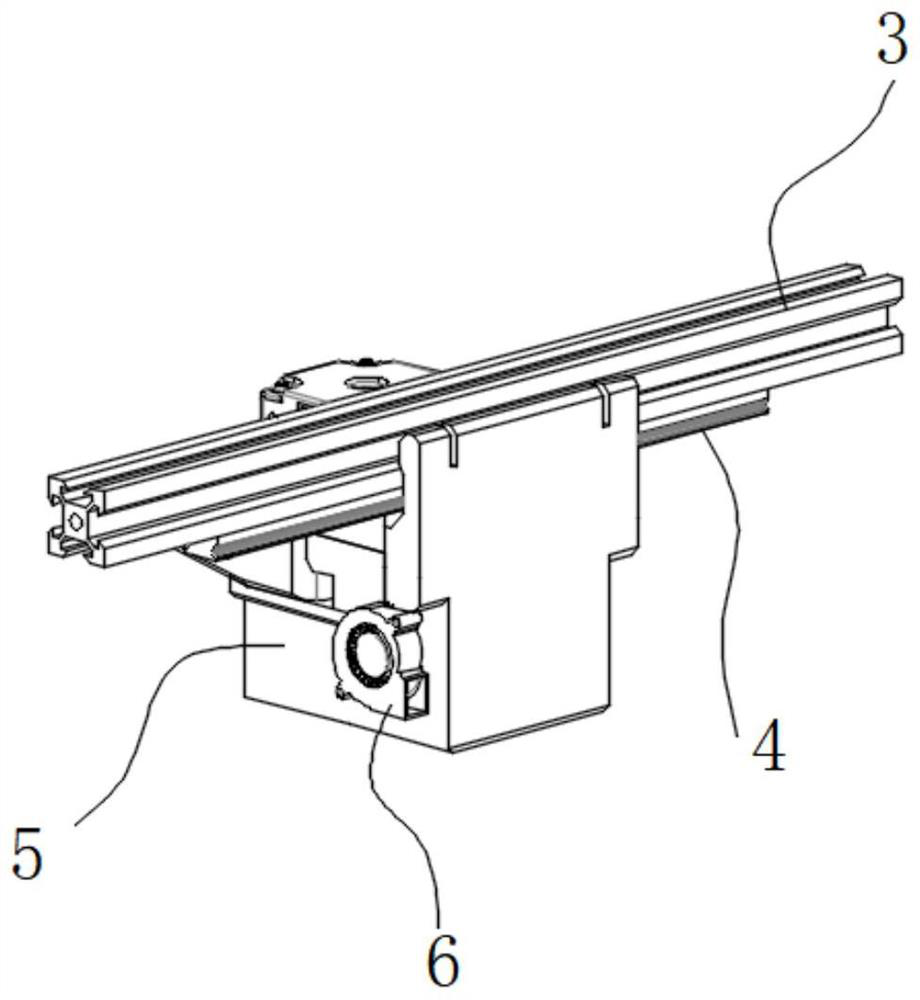

[0039] see Figures 1 to 4 , the present invention provides a coal mine safety production tunnel dust removal device, including:

[0040] The air duct 1 is arranged above the tunnel along the direction of the tunnel, and the air duct 1 is provided with a plurality of air supply heads 2;

[0041] The integrated bin 5 can be movably arranged under the air duct 1, the integrated bin 5 is provided with a dust content detector and a controller, the input end of the dust content detector is connected with the output end of the detection fan 6, and The dust content detector can send detection data to the controller;

[0042] A spray pipe (not shown in the figure), which is laid on one side of the air duct 1, and a plurality of liquid spray heads are arranged on the spray pipe; and

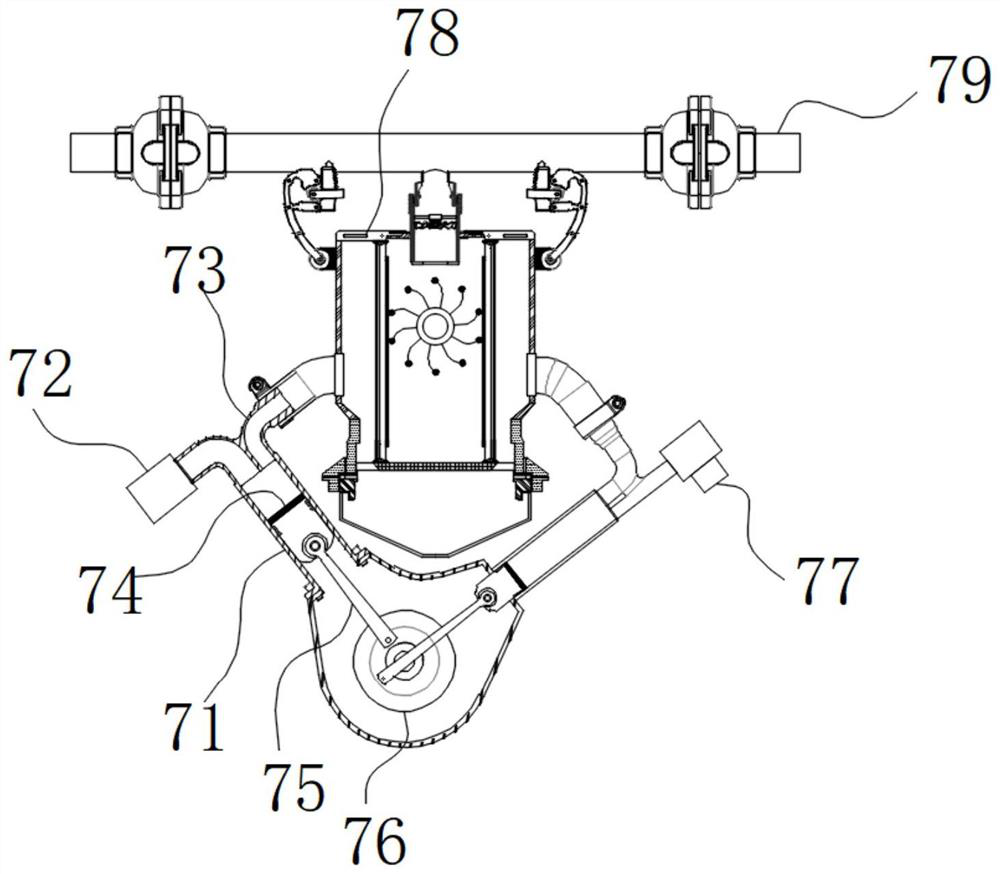

[0043] The dust removal assembly 7 is arranged below the integrated bin 5 and is used to filter and collect the dust in the tunnel air.

[0044] As a preferred embodiment, the controller is configured ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com