Coking and slagging robot processing system for high-temperature hearth of coal fired power plant boiler

A technology for coal-fired power plants and disposal systems, which is applied in the fields of mechanical design and manufacturing, heat transfer, optics, and signal transmission to achieve fast moving speed, increase availability, and increase power generation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

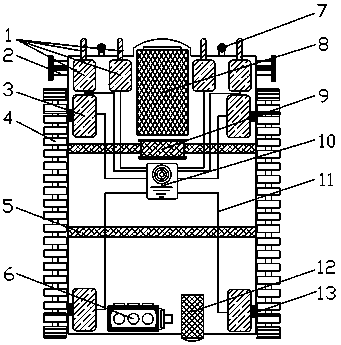

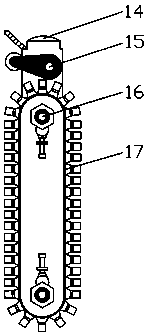

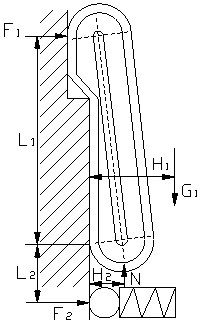

[0028] Such as figure 1 , shown in 2, the coal-fired power plant boiler high-temperature furnace coking slagging robot disposal system of the present invention includes a robot body, a slagging cleaning device, a visual imaging system, a signal receiving control system, and a cooling system.

[0029] In addition to the characteristics of general robots, robots also need to have their own characteristics. The robot is 0.8m long, 0.6m wide and 0.38m high. It includes slag knocking motor 1, grinding stick 2, drive motor 3, magnetic track 4, support rod 5, gas distribution box 6, steel brush 7, main CCD camera 8, main CCD camera cooling fan 9, signal receiving controller 10, Wire 11, auxiliary CCD camera 12, transmission shaft 13, high temperature resistant LOW-E film 14, grinding roller drive shaft 15, external thermocouple 16, transmission chain 17.

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com