Novel hexapod boiler water wall maintenance robot

A water-cooled wall and robot technology, applied in the field of hexapod bionic robots, can solve the problems of low safety, low efficiency, backward detection technology, etc., and achieve the effect of low noise and high reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

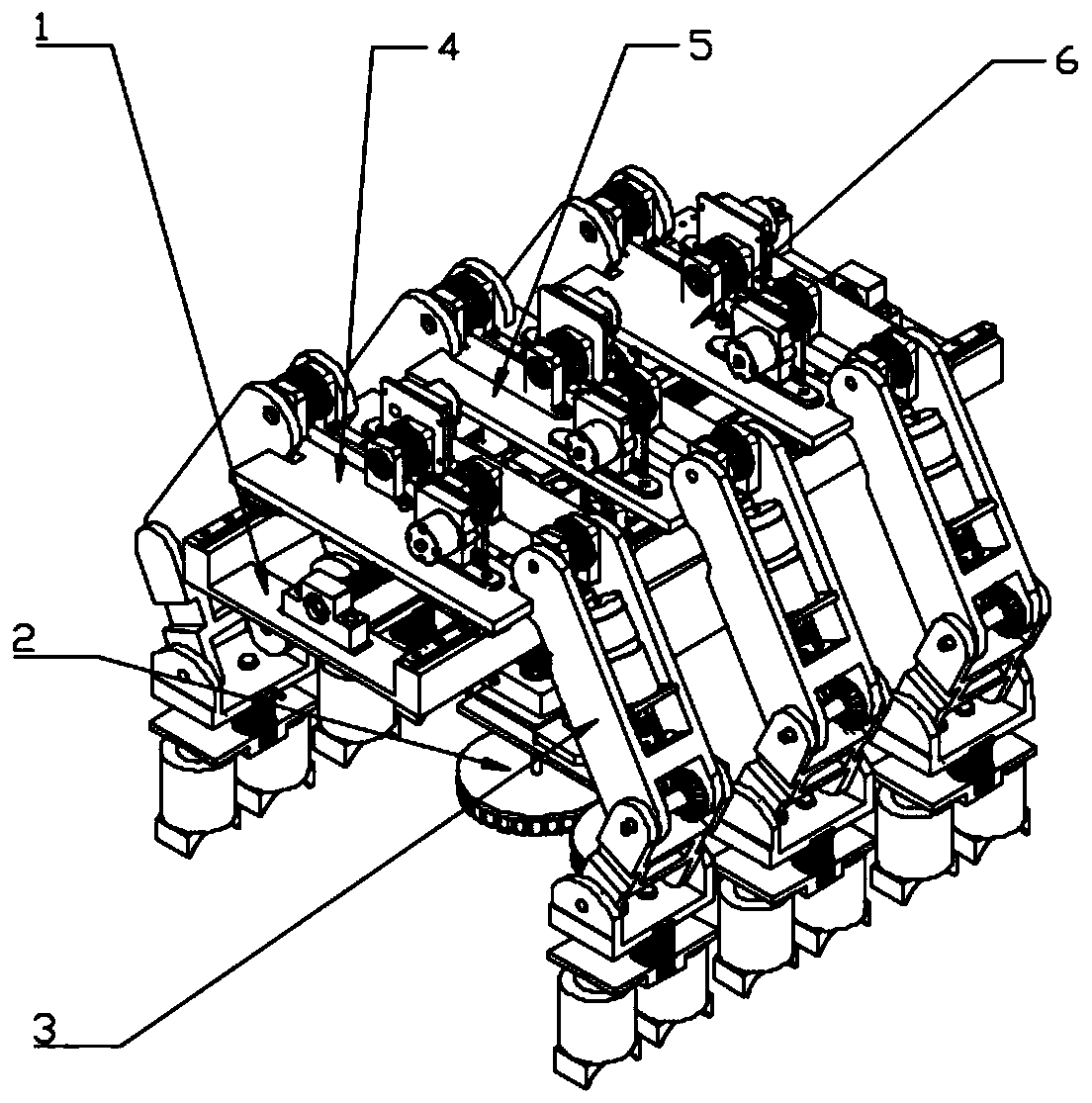

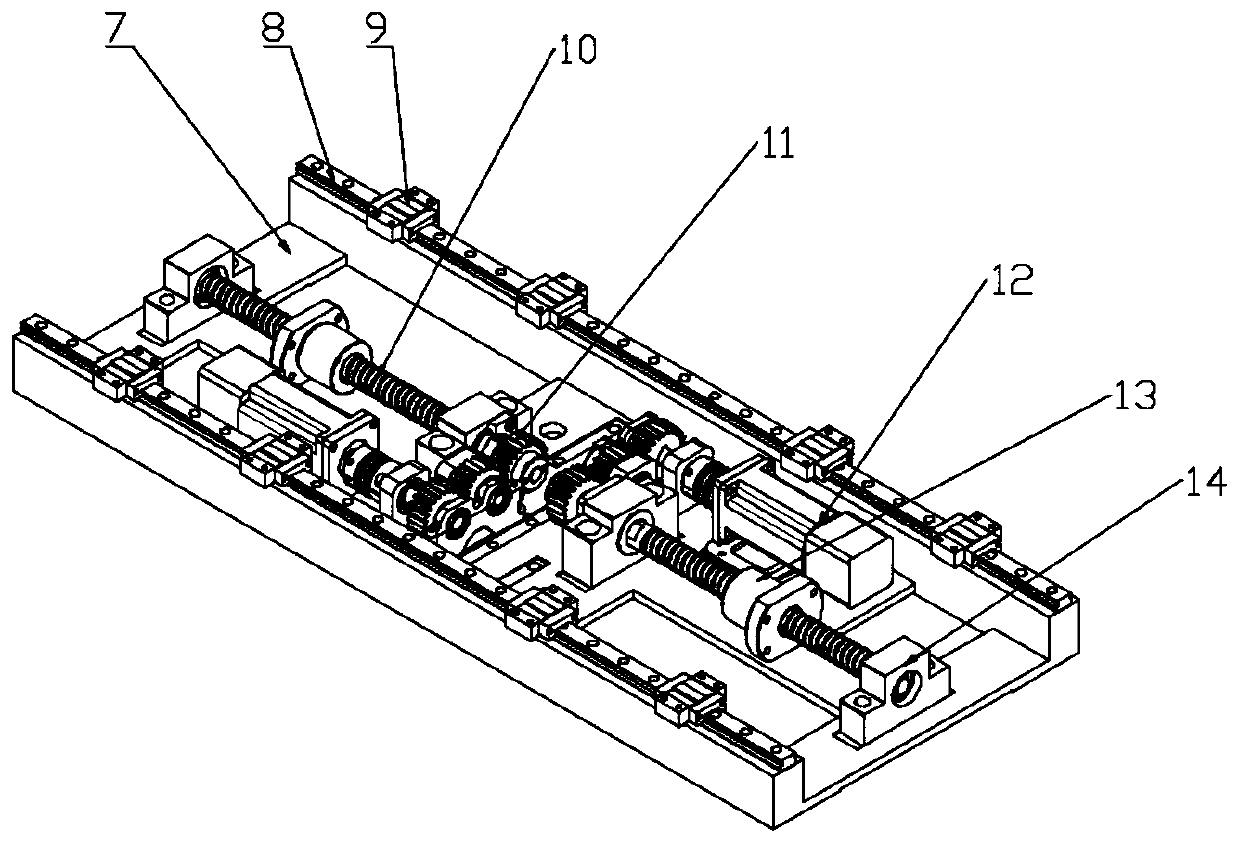

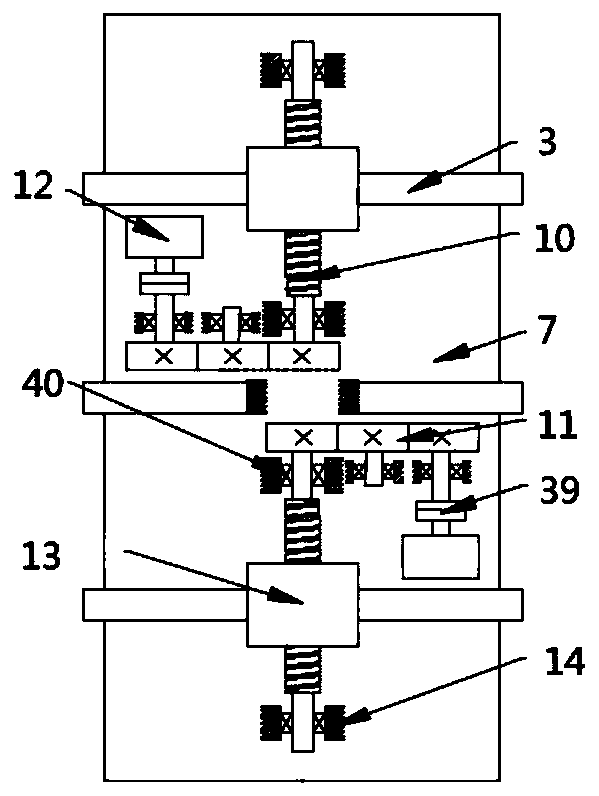

[0032] The purpose of the present invention is to solve the maintenance problem of the boiler water wall, and it is designed for the working environment of the boiler water wall with an ambient temperature of 40-60°, a bare pipe diameter of 50-70 mm, a bare pipe pitch of 70-90 mm, and a boiler inlet hole diameter of 450 mm or more. A new type of hexapod wall-climbing robot is realized by adopting the following technologies: A new type of hexapod boiler water-cooled wall maintenance wall-climbing robot provided by the present invention includes a mobile platform for the main body of the robot, six symmetrically arranged mechanical legs, and an inspection and cleaning mechanism with rolling brushes composition. Two sets of symmetrical mobile platforms and one set of fixed platforms are installed on the robot body. The mobile platform is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com