Novel dust removal device

A kind of dust removal equipment and new technology, applied in the direction of removing smoke and dust, chemical instruments and methods, cleaning methods and utensils, etc., can solve the problems of reducing dust removal efficiency, inability to facilitate disassembly and replacement, and inability to meet the dust removal effect of a large amount of exhaust gas.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

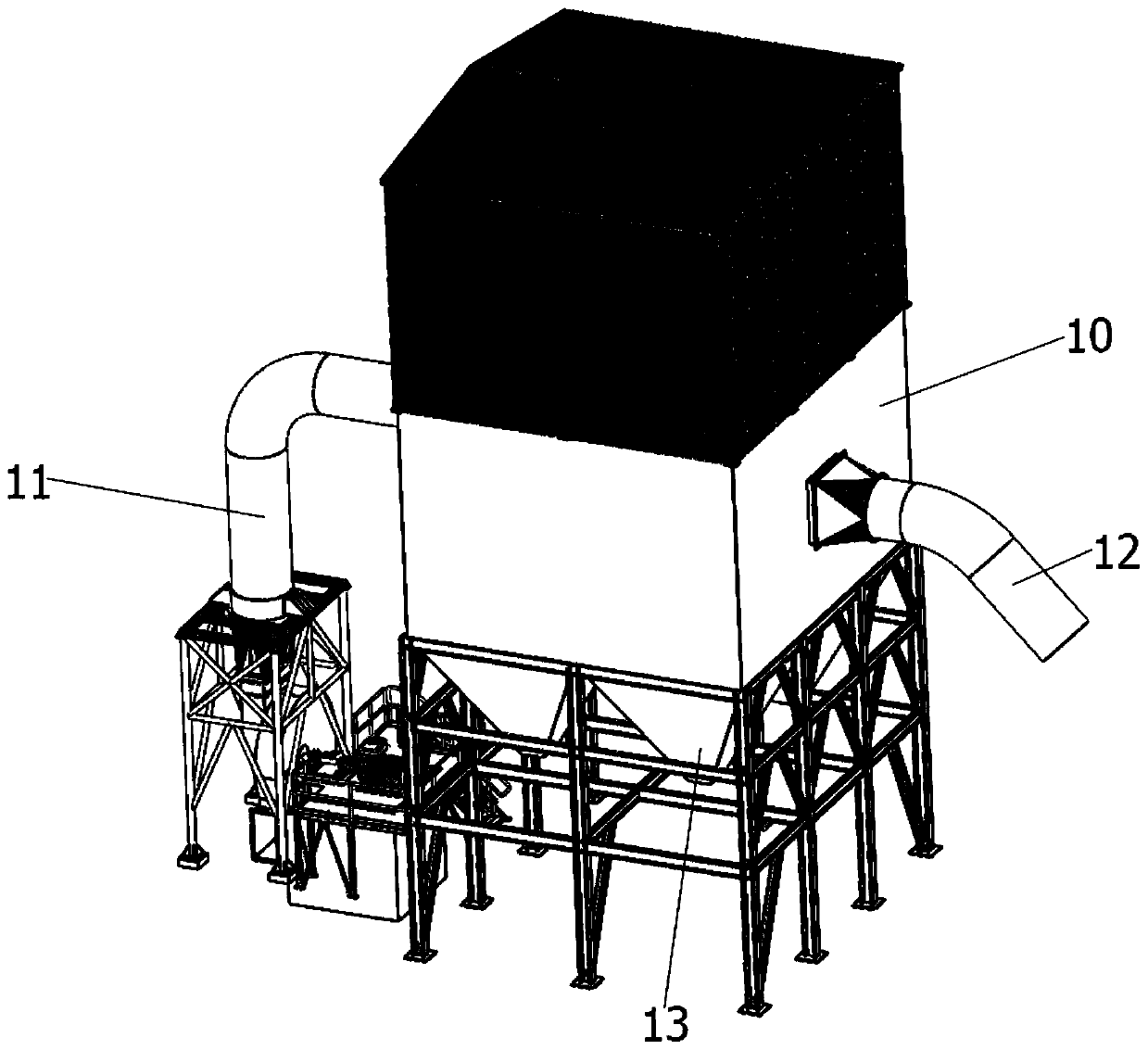

[0017] See Figure 1-2 As shown, the present invention provides a new type of dust removal equipment, including a dust collector 10 and an air intake unit.

[0018] The two sides of the dust collector 10 are respectively provided with an air inlet pipe 11 and an air exhaust pipe 12, and a purification component is arranged in the dust collector 10, and a discharge port 13 is arranged at the bottom of the dust collector 10, and the waste gas enters into the dust collector 10 through the air inlet pipe 11 to carry After the dust removal treatment, it is discharged from the exhaust pipe 12 to the outside.

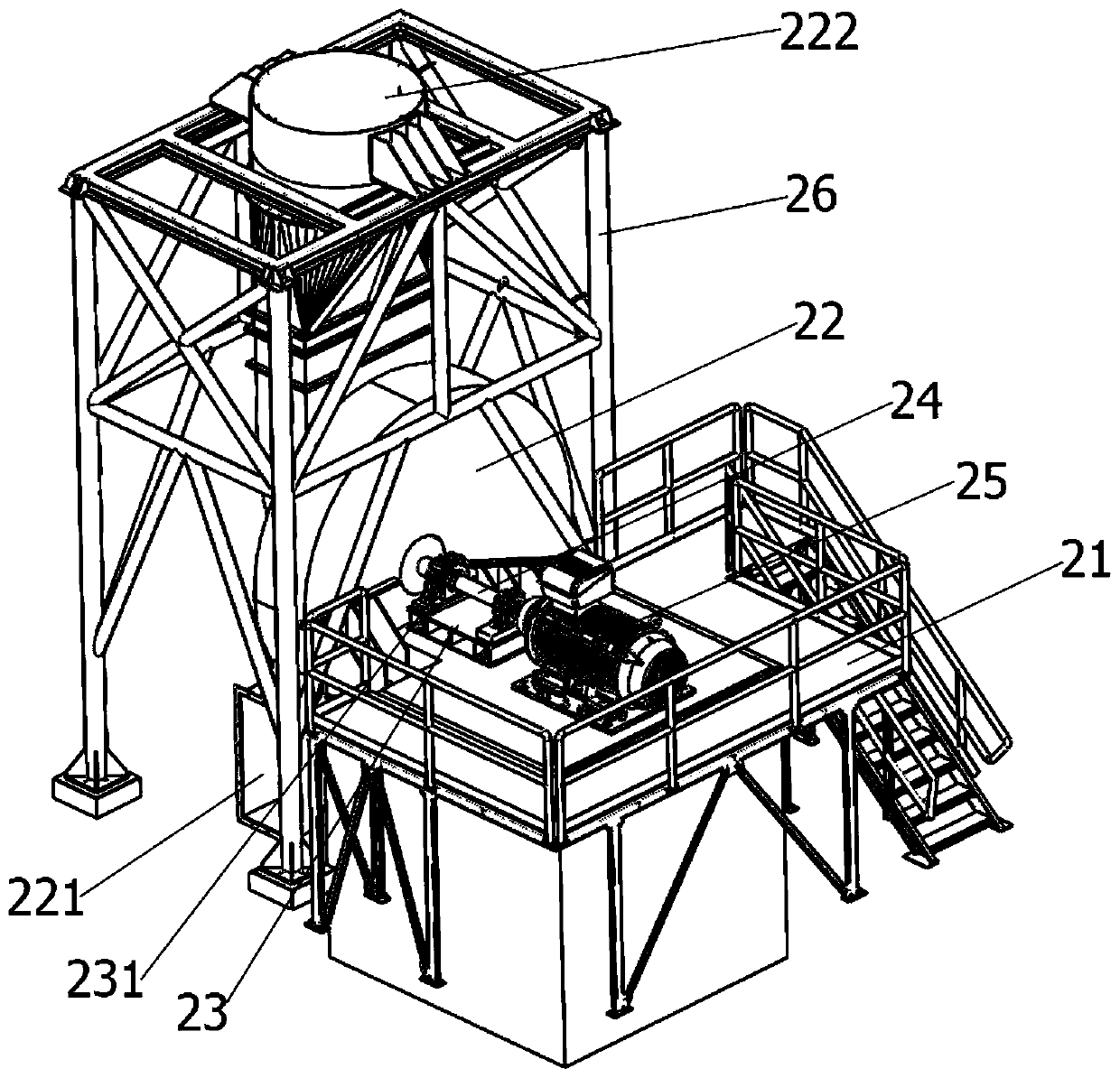

[0019] The air intake unit includes a supporting platform 21 , an air intake fan 22 , a base 23 , a transmission rod 24 and a drive motor 25 . The air intake fan 22 includes an air inlet 221 and an air supply port 222, and the air s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com