Tubular separating machine

A separator, tubular technology, applied in liquid separation, separation methods, chemical instruments and methods, etc., can solve the problems of small adjustment range, inability to separate, poor separation effect, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

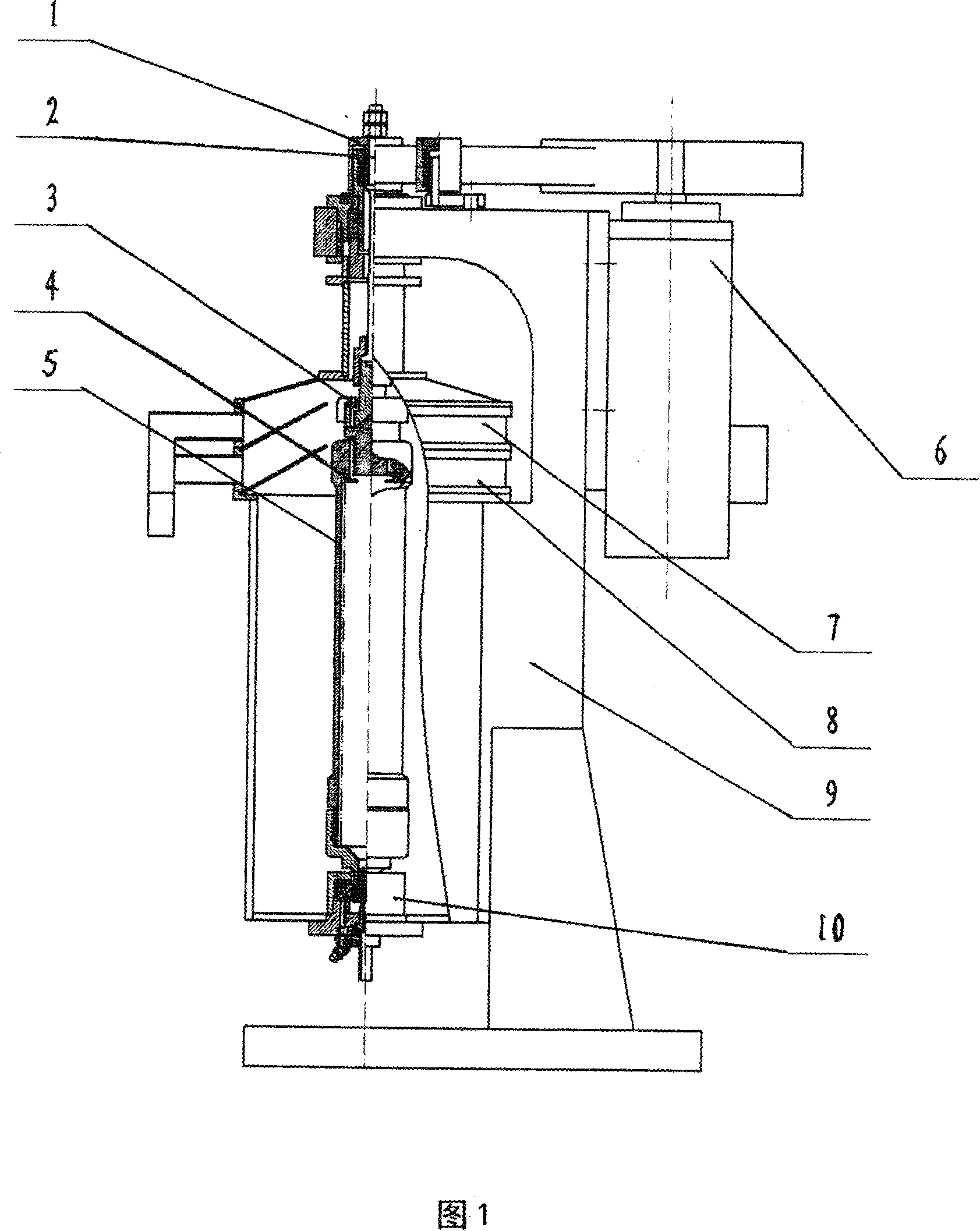

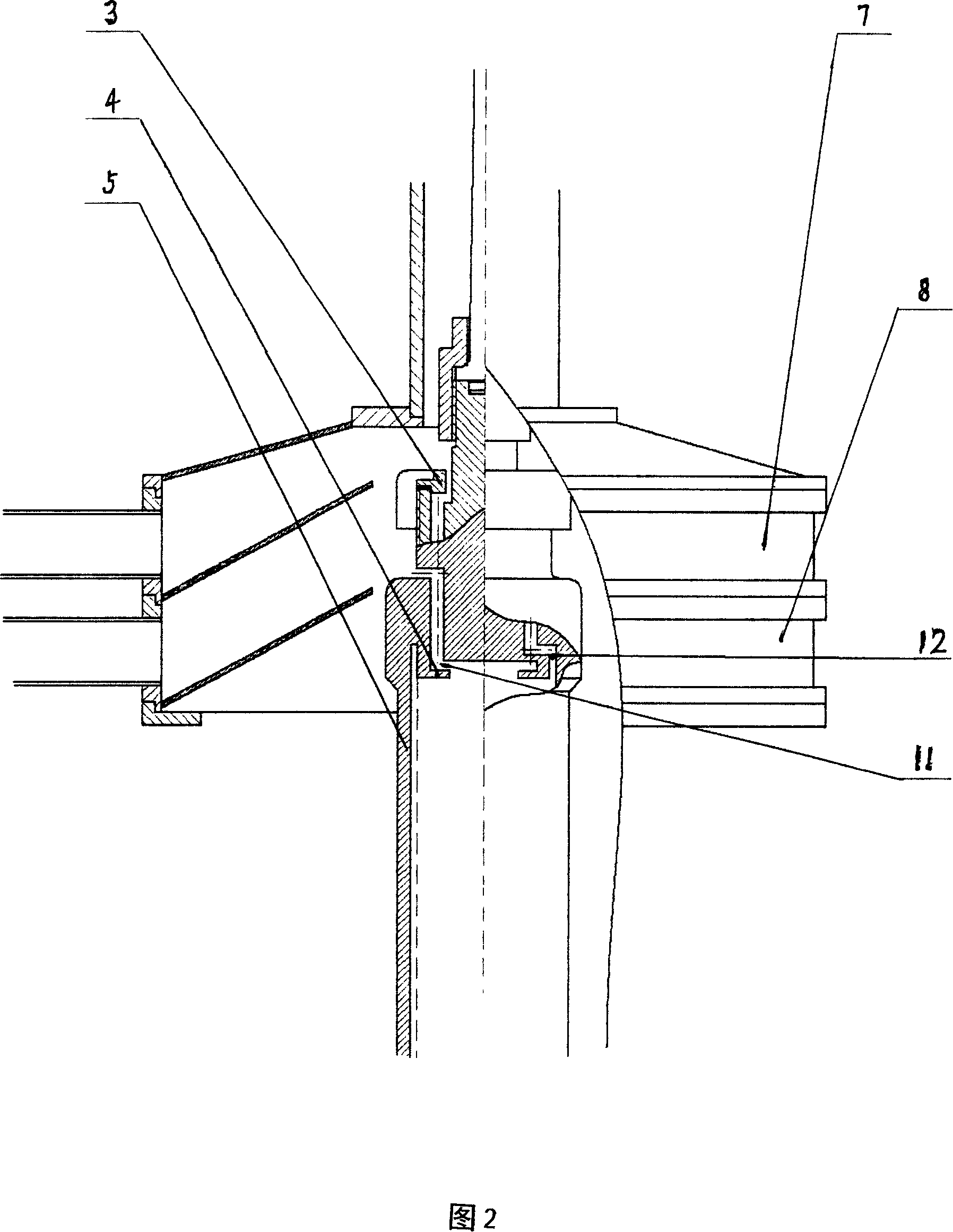

[0009] With reference to Fig. 1, 2, on fuselage 9 motor 6 is housed, and the fuselage bottom is equipped with liquid-inlet bearing degree 10, and fuselage top is fixed with high-speed pulley seat, and bearing outer ring is fixed on the high-speed pulley seat, flexible main shaft 2 and The inner ring of the bearing is fixed and connected with the high-speed pulley. The high-speed pulley is connected with the motor pulley by a belt. The drum 5 is fixed on the main shaft through the connection cap of the main shaft. The drum includes the drum body, and the bottom shaft cover is connected to the drum body through threads. The lower end is connected, the separation head is welded on the upper end of the drum body, there is a light phase liquid isolation ring 4 in the lower part of the separation head, a heavy phase liquid channel 12 is located outside the light phase liquid isolation ring, and a heavy phase liquid adjustment ring 3 is located at the outlet of the heavy phase liquid c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com