Steel three-dimensional framework unit, steel three-dimensional combined framework and application thereof

A steel structure, three-dimensional technology, applied in the application of three-dimensional composite frame of steel structure, in the field of three-dimensional composite frame of steel structure, can solve problems such as difficult adjustment, heavy building structure weight, and aggravated urban road traffic congestion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

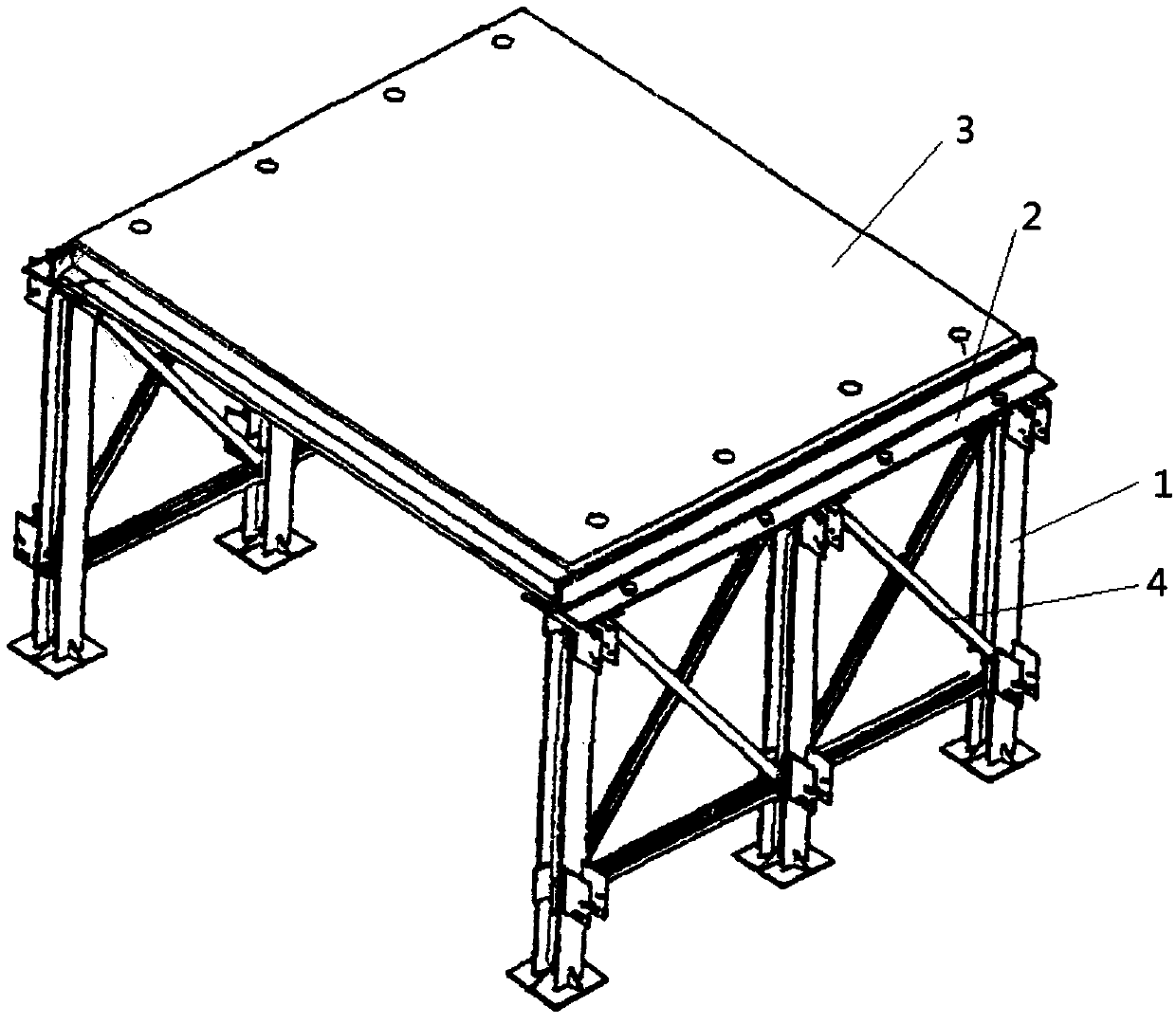

[0097] The three-dimensional frame unit of the steel structure includes a plurality of upright columns and horizontal beams installed on the upper part of the columns, and also includes a steel bridge deck installed on the beams, and the upper end plane of the steel bridge deck is laid with an asphalt concrete road surface. Install tie rods between columns and beams for added strength as required. This embodiment adopts a four-beam and four-column structure.

[0098] The four beams of the common unit form a rectangle, the four columns are located at the four corners of the rectangle, the rectangular steel bridge deck is installed on the beams, and the steel bridge deck is located on the horizontal plane.

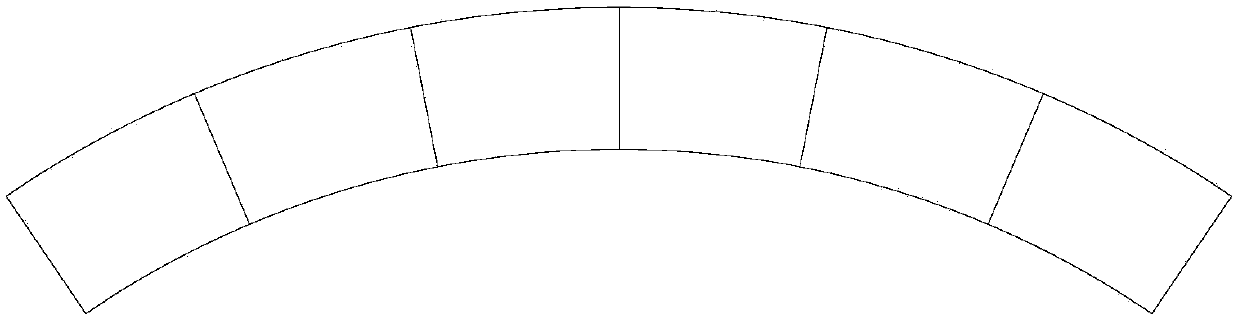

[0099] The steel bridge deck of the straight curve unit has two straight lines and two arcs in the direction of the top view. Four columns are located on the four corners of the steel bridge deck. The four beams connect the columns on the upper part of the columns as Instal...

Embodiment 2

[0105] The three-dimensional composite frame of steel structure in this embodiment is applied to parking spaces and driveways.

[0106] On both sides of the urban motorway (lane adjacent to the sidewalk), a section of steel structure three-dimensional composite frame is set up, the upper floor is open to traffic, and the lower floor is for parking. The upper layer can be used as a special lane for buses and cars, and a parking spot is set up at a distance (such as 1000 meters), equipped with elevators and pedestrian ladders for passengers to get on and off. There is a parking space below the driveway.

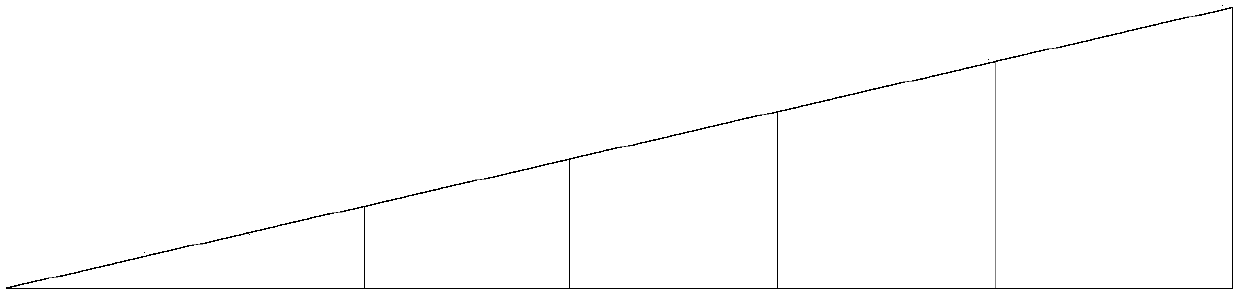

[0107] The three-dimensional composite frame of the steel structure is built by ordinary units and straight ramp units. After the common units are connected, the steel bridge decks form a horizontal road surface together. After the straight ramp units are connected, the steel bridge decks form a straight slope road surface together. The front and rear sides of a level road. A s...

Embodiment 3

[0110] The three-dimensional composite frame of steel structure in this embodiment is applied to parking spaces and driveways.

[0111] A two-lane steel structure three-dimensional composite frame is set in the middle of the urban motorway. The upper layer can be used as a special lane for buses and cars, and a parking spot is set up at a distance (such as 1000 meters), equipped with elevators and pedestrian ladders for passengers to get on and off. There is a parking space on the lower level.

[0112] The three-dimensional composite frame of the steel structure is built by ordinary units and straight ramp units. After the common units are connected, the steel bridge decks form a horizontal road surface together. After the straight ramp units are connected, the steel bridge decks form a straight slope road surface together. The front and rear sides of a level road. A steel structure three-dimensional frame unit with a large span is erected on the outside of the two steel str...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com