Dust removal device for rice conveying

A dust removal device, rice technology, applied in the direction of separating solids from solids with airflow, magnetic separation, solid separation, etc., can solve the problems of poor storage efficiency and inability to remove dust, and achieve the effect of improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

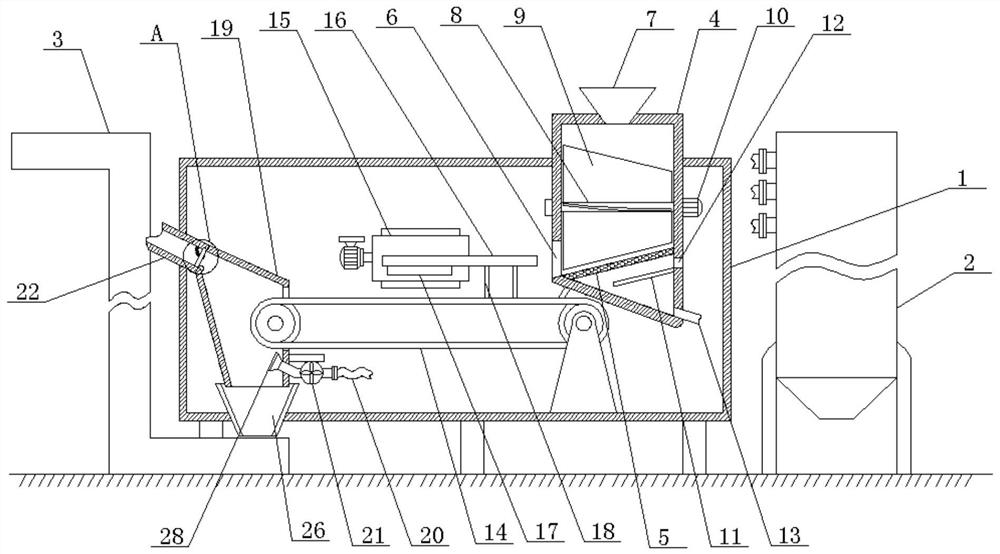

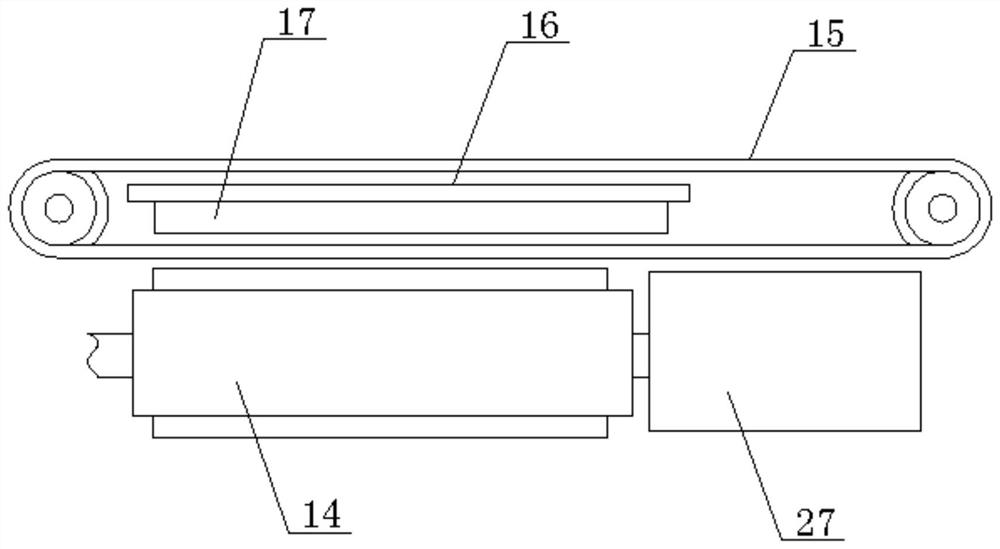

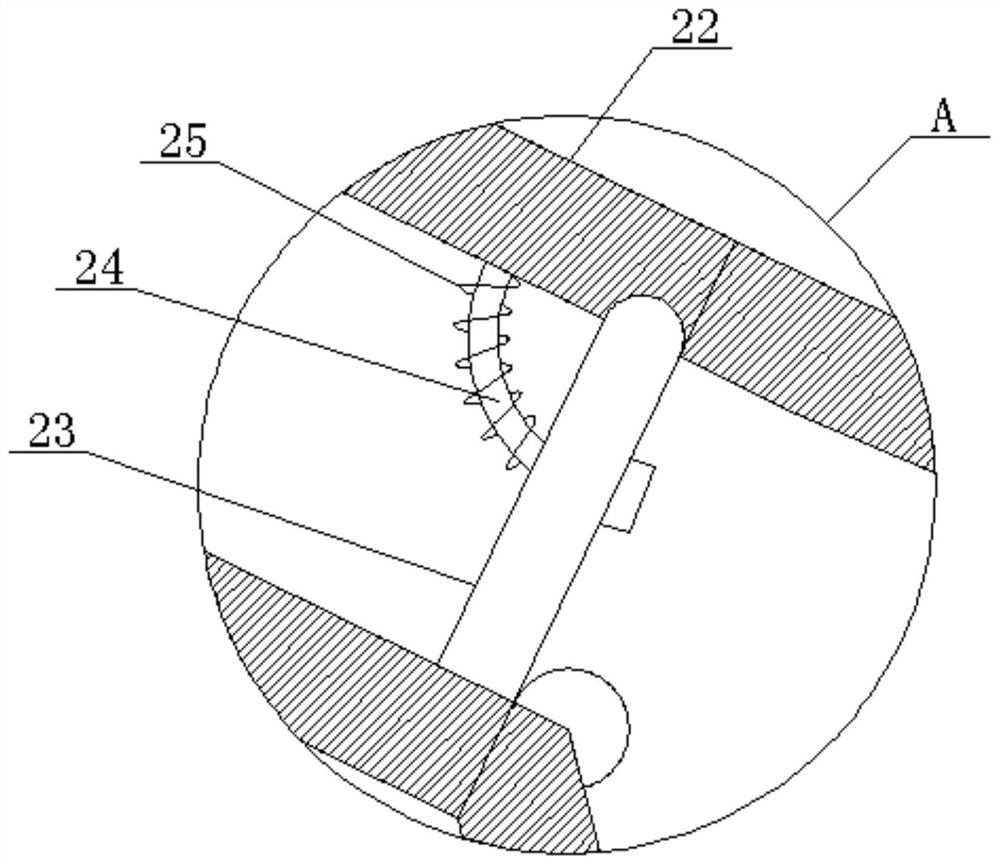

[0024] according to Figure 1-4 A kind of dust removal device for rice conveying shown, comprises dust removal box 1, dust collector 2 and bucket elevator 3, described dust removal box 1 interior is provided with dust filter kettle 4, and described dust filter kettle 4 interior is provided with filter screen 5, The filter screen 5 is arranged at an inclination, which is conducive to rolling the rice on the surface of the filter screen 5, thereby increasing the fluidity of the rice, filtering the dust during the flow, and making the rice drop to the first belt conveyor 14 Among them, one side of the dust filter kettle 4 is located at the inclined bottom of the filter screen 5 and is provided with a discharge port 6, the top of the dust filter kettle 4 is provided with a feed inlet 7, and a rotating shaft 8 is connected between the two sides of the dust filter kettle 4, The surface of the rotating shaft 8 is provided with several stirring blades 9, the stirring blades 9 are set ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com