Control system and control method for wet-type electrostatic dust collector of coal conveying system

A wet electrostatic and coal conveying system technology, applied in the direction of external electrostatic separator, electrostatic separation, power supply technology, etc., can solve the problems of dust temperature change without real-time monitoring and feedback, usable area occupation, increased workload, etc., to achieve Avoid the further expansion of the explosion, improve safety, and ensure the effect of safe transmission

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

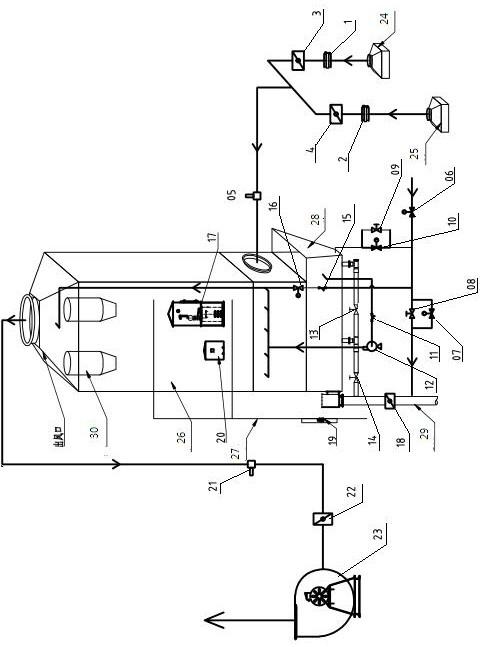

[0021] A control system for a wet electrostatic precipitator of a coal conveying system, comprising: a dust collector 26, an induced draft fan 23, an A-belt suction hood 24 and a B-belt suction hood 25, the A-belt suction hood and the A-way belt The drawer filter 1 is connected, the B belt suction hood is connected to the B belt drawer filter 2, and the A belt drawer filter is connected to the A belt electric butterfly valve 3, so The B-way belt drawer filter is connected to the B-way belt electric butterfly valve 4, the A-way belt electric butterfly valve and the B-way belt electric butterfly valve are respectively connected to the inlet temperature sensor 5, and the inlet temperature sensor is connected to the The inlet of the dust collector is connected, the air outlet of the dust collector is connected to the outlet temperature sensor 21, the outlet temperature sensor is connected to the manual air regulating valve 22, and the manual air regulating valve is connected to the...

Embodiment 2

[0023] According to the wet electrostatic precipitator control system of the coal conveying system described in Embodiment 1, the described dust collector is connected with the water tank 28, and the described water tank is respectively connected with the ash hopper flushing manual valve 9, the ash hopper flushing electromagnetic valve 10 and the emulsification pump for filtering The emulsification pump filter is connected to the emulsification pump 12, the No. 1 blowdown manual valve 13 and the No. 2 blowdown manual valve 14 are installed between the water tank and the ash fall pipe 29, and the ash fall pipe It is connected with the ash unloading valve 18.

Embodiment 3

[0025] According to the coal handling system wet electrostatic precipitator control system described in embodiment 1 or 2, the ash falling pipe is respectively connected with the ash flushing manual valve 7 and the ash flushing solenoid valve 8, and the ash flushing manual valve and the ash flushing manual valve The ash flushing solenoid valve is connected to the water inlet manual valve 6, the nozzle of the ash falling pipe is connected to the dust collector, and a ladder 27 is installed on the outside of the dust collector, and a ladder 27 is installed on the ladder. The security forms a switch 19 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com