Patents

Literature

44results about How to "Meet mining needs" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Heavy oil aquathermolysis catalytic viscosity reducer and preparation method thereof

The invention provides a heavy oil aquathermolysis catalytic viscosity reducer and a preparation method thereof. The heavy oil aquathermolysis catalytic viscosity reducer comprises o-phenylenediamine, dodecylbenzene sulfonic acid and a transition metal sulfate in a mass mole ratio of 1:0.5-1.5:0.5-1.5. The heavy oil aquathermolysis catalytic viscosity reducer is prepared by the steps of: dissolving dodecylbenzene sulfonic acid in water to obtain a dodecylbenzene sulfonic acid solution with a concentration of 0.5mol / L-1.2mol / L; at 70-110DEG C, adding o-phenylenediamine into the dodecylbenzene sulfonic acid solution to obtain an intermediate product; dissolving the transition metal sulfate in water to obtain a transition metal sulfate solution with a concentration of 0.5mol / L-0.9mol / L; and adding the transition metal sulfate solution into the intermediate product, carrying out reaction at 70DEG C-110DEG C for 2h-4h, and performing vacuum drying to obtain the heavy oil aquathermolysis catalytic viscosity reducer. The heavy oil aquathermolysis catalytic viscosity reducer provided by the invention has better temperature resistance, and can reach more excellent cracking viscosity reducing effect.

Owner:PETROCHINA CO LTD

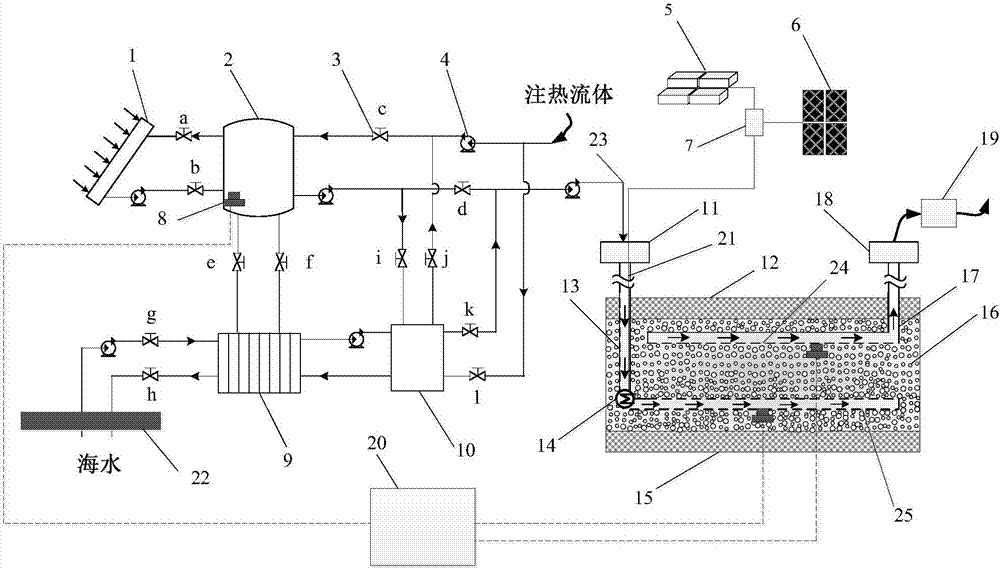

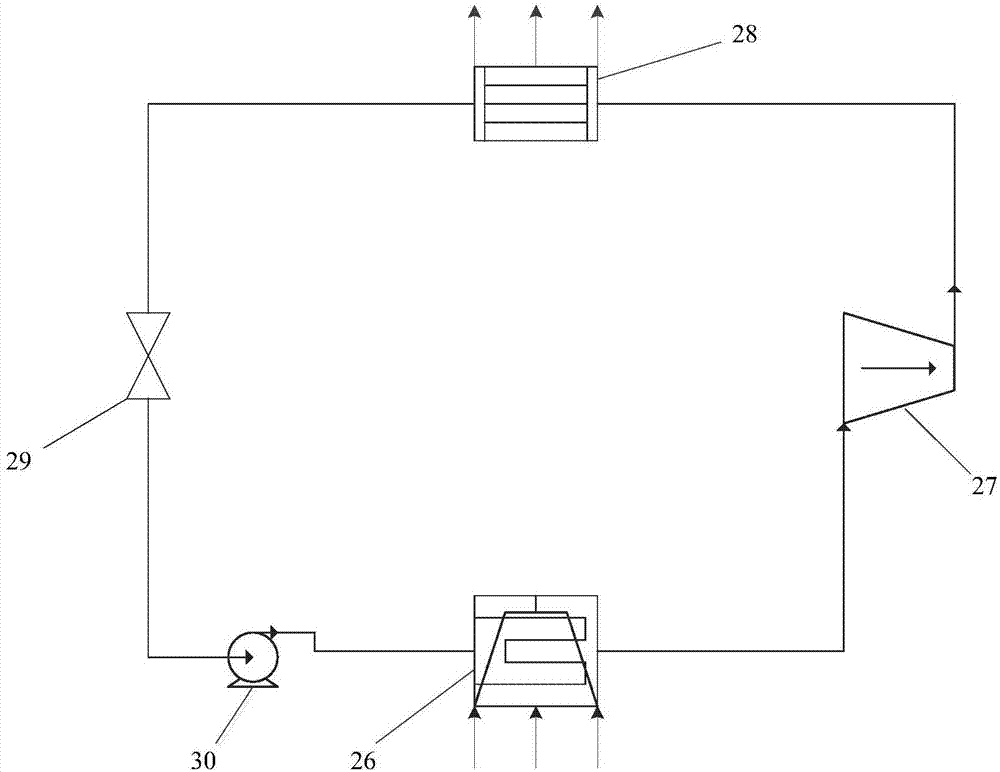

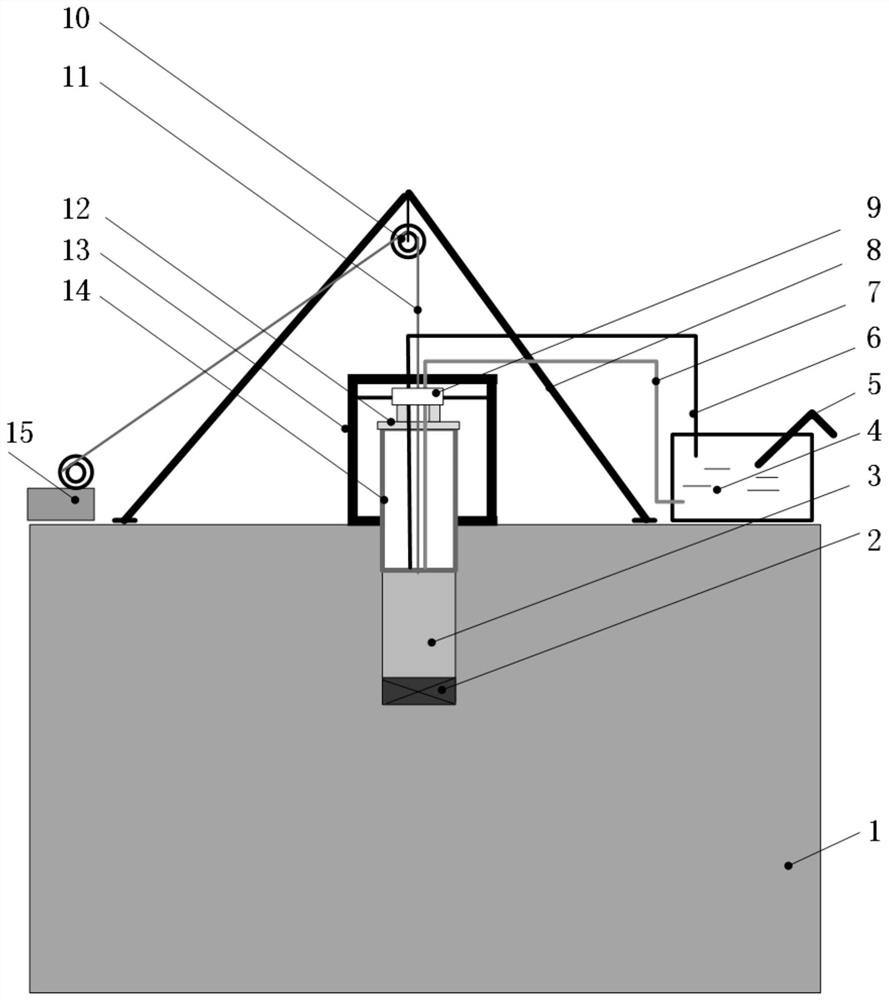

Natural gas hydrate mining device and method based on solar energy and seawater source heat pump combined heat supply technology

ActiveCN108005618AReal-time controlMeet mining needsConstructionsFluid removalWater sourceEngineering

The invention discloses a natural gas hydrate mining device and method based on the solar energy and seawater source heat pump combined heat supply technology. The natural gas hydrate mining method mainly refers to a maritime floating platform, a solar energy heat-collecting unit, a seawater source heat pump unit, a solar energy generating unit, a seabed natural gas hydrate mining unit and a monitoring control unit. According to the method, abundant solar energy and seawater energy in a sea area are utilized to supply heat, and the heat serves as a basic heat source for heat injection method mining of seabed natural gas hydrates; meanwhile, power consumption devices of a compressor, an overheating device, a pump and the like in a system are supplied with the energy through solar energy generating, and thus in the method, the solar energy and the seawater energy are combined to supply the energy for mining the natural gas hydrates; and according to the natural gas hydrate mining method,the reproducible solar energy and seawater energy resources can be utilized to mine the seabed natural gas hydrate resources efficiently, the input cost of the mining heat source is reduced greatly,the process is simple, multiple benefits of the economic benefit, the environmental benefit, the social benefit and the like are achieved, and large-scale commercial mining of the natural gas hydratesis facilitated.

Owner:SOUTH CHINA UNIV OF TECH

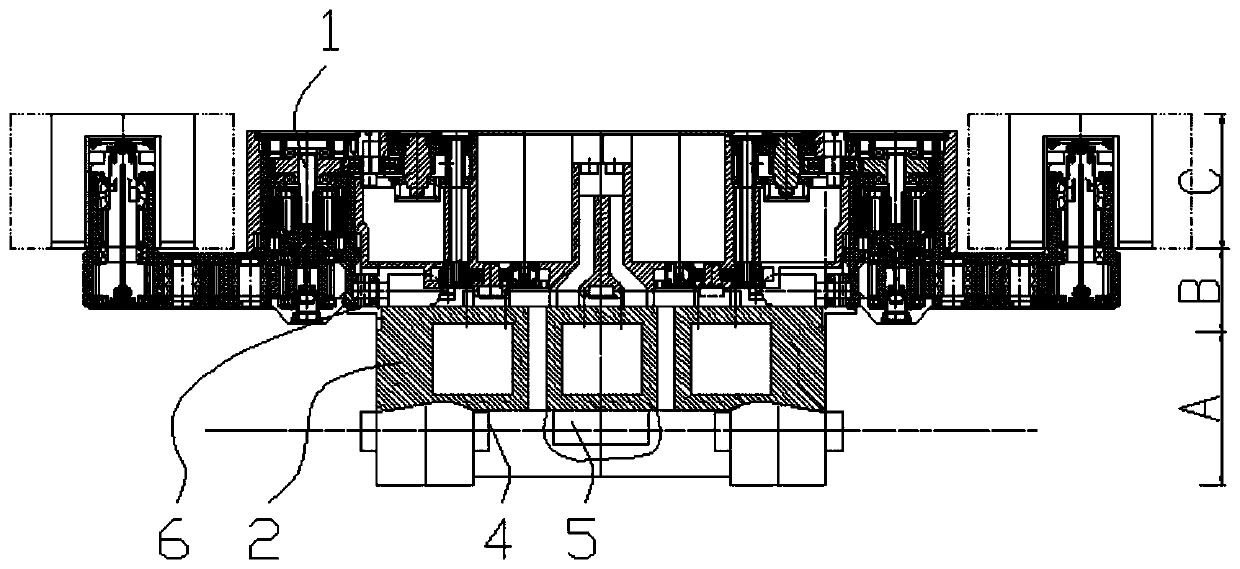

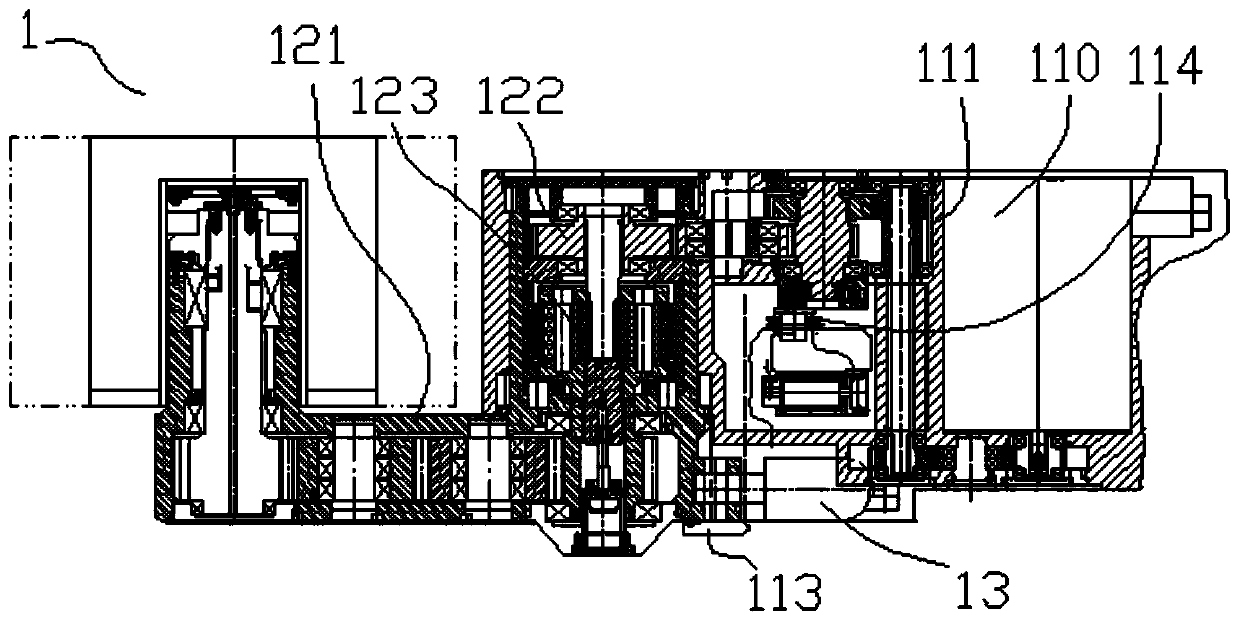

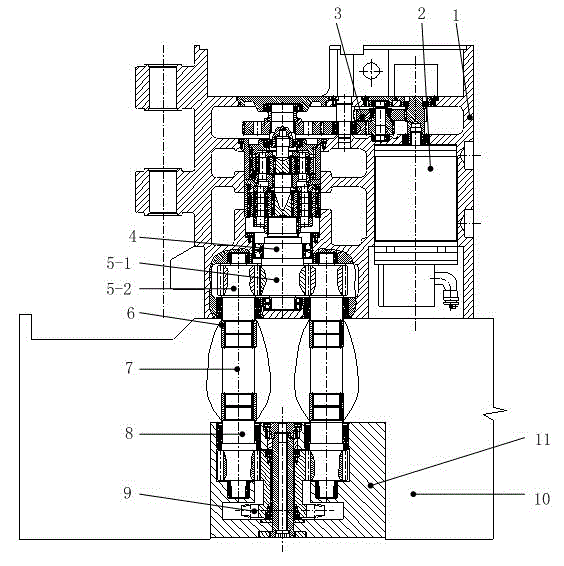

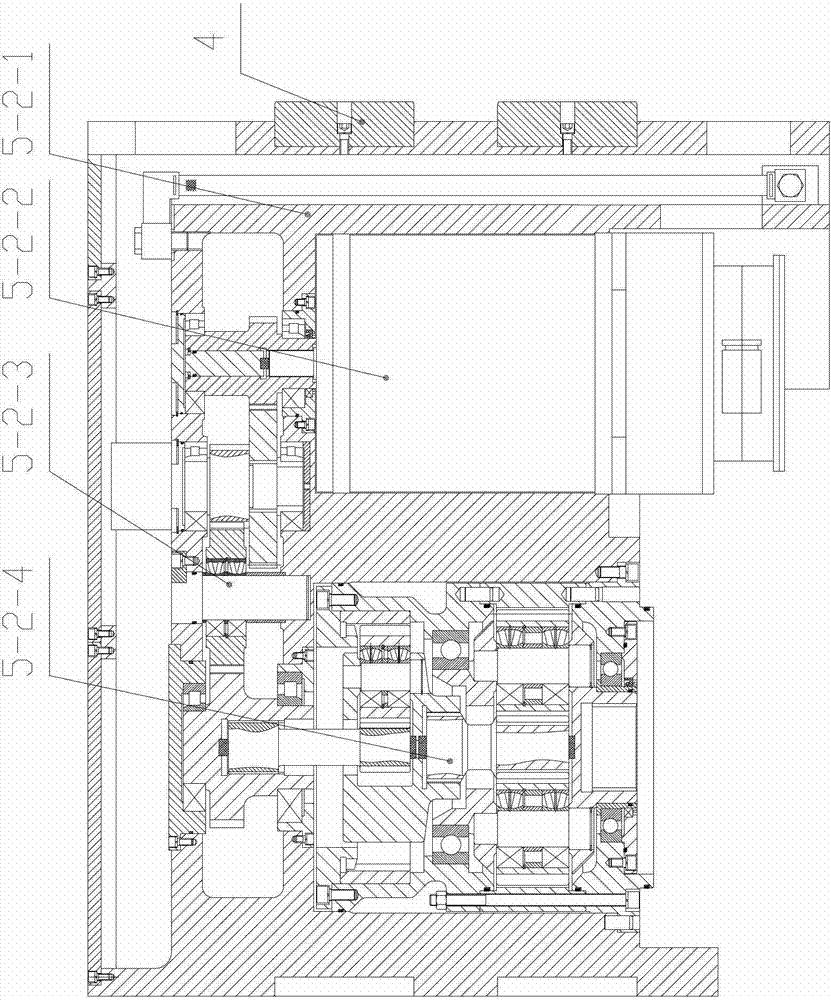

High-temperature-resistant motor applicable to high-temperature electric submersible pump

InactiveCN106160342AHigh working reliabilityReasonable mechanical structureCooling/ventillation arrangementSupports/enclosures/casingsSpiral bladeThrust bearing

The invention discloses a high-temperature-resistant motor applicable to a high-temperature electric submersible pump. A motor shaft is of a hollow structure; one end of the motor shaft stretches to a top housing, and the end part thereof is sealed; the other end of the motor shaft stretches to a tail housing, and an oil inlet is formed in the end part thereof; a supercharging spiral blade and a filter are sequentially arranged at the oil inlet; stabilizing bearings are arranged between adjacent unit rotors; stabilizing bushings and the stabilizing bearings form friction pairs; a thrust bearing is mounted between the top housing and the motor shaft; a static annular plate and a movable annular plate of the thrust bearing form a friction pair; the movable annular plate is fixedly connected with the motor shaft through a flat key; all the friction pairs are lubricated through oil throwing holes in the motor shaft; an oil storage space is formed in the upper part of the movable annular plate of the thrust bearing; the motor shaft is isolated from lubricating oil in the oil storage space through a main shaft spacer bush; a radial supporting bushing is mounted between the tail housing and the motor shaft, and the motor shaft on the upper part of the radial supporting bushing is sleeved with a main shaft protecting tube; an oil returning passage is formed in the housing body of the tail housing; a shading plate is arranged above the oil returning passage, and an annular sedimentation tank is arranged on the tail housing on the outer side of the oil returning passage.

Owner:TONGYI TECH CO LTD SHENYANG UNIV OF TECH

High efficient short-wall coal-winning machine

The invention relates to a high efficiency short wall coal cutter that includes cut arm, lifting oil cylinder and sliding base frame. The cut arm is made up of cut motor, cut roller and cut reducer. The invention designs the cut arm to portrait swinging, and the cut roller to circular truncated cone. It size of the machine would sharply decrease and the entire structure is small and flexible. It has the advantages of simple structure, light weight, low cost and high efficiency.

Owner:TANGSHAN BRANCH COAL SCI ACAD

Concrete with heat insulation performance

InactiveCN104876485AReduce high temperature heat damageSatisfy thermal insulationSolid waste managementPulverized fuel ashFire resistance

The invention provides concrete with heat insulation performance. The concrete with the heat insulation performance comprises pulverized fuel ash, cement, water, sands, melon seed slices, ceramisites, an early strength agent, a water reducing agent and polypropylene fibers, wherein a weight ratio of the pulverized fuel ash to the cement to the water to the sands to the melon seed slices to the ceramisites to the early strength agent to the water reducing agent to the polypropylene fibers is equal to (10-30):(70-90):(40-50):(150-200):(80-160):(40-120):(3-6):(0.5-2):(0.25-0.45). The concrete with the heat insulation performance provided by the invention has good heat insulation performance and fire resistance, and ensures that the heat preservation and load-bearing requirements for deep mining of mines can be met.

Owner:HUAINAN MINING IND GRP +1

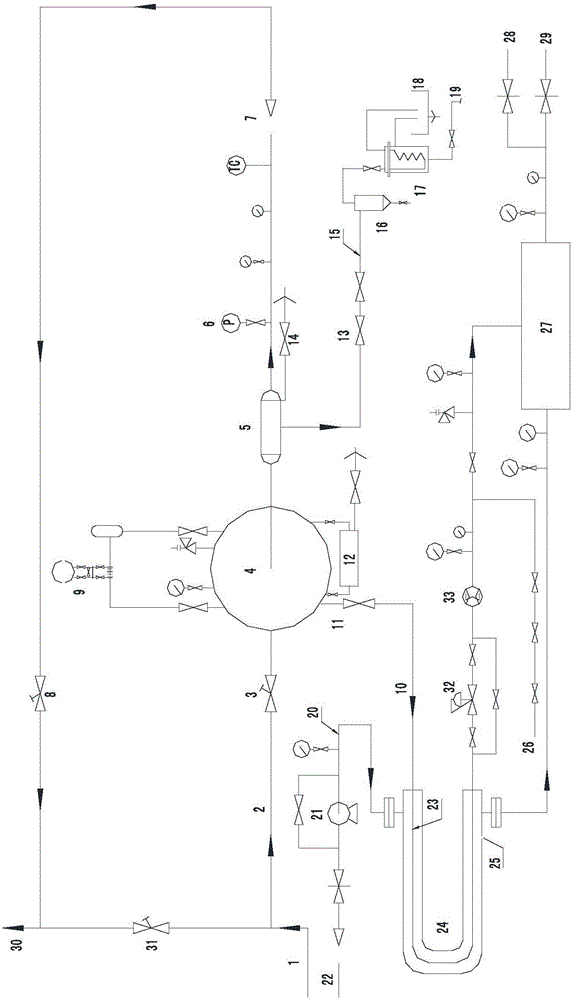

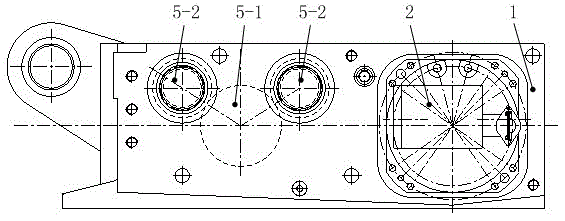

Oil field steam injection boiler steam dryness increasing device

ActiveCN105910088ALess investmentSolve the problem of low drynessFluid removalSteam separation arrangementsOil productionEngineering

The invention discloses an oil field steam injection boiler steam dryness increasing device, and mainly solves the defect of low thickened oil production efficiency due to insufficient dryness of steam provided by a traditional oil field steam injection boiler. The oil field steam injection boiler steam dryness increasing device is characterized in that a steam dryness increasing pipeline (2) includes a boiler steam outlet (1), a high-pressure steam and water separator (4) and a sampling separator (5); boiler steam passes through a high-pressure stop valve A (3) by the boiler steam outlet (1) to enter the high-pressure steam and water separator (4); and high-dryness steam separated by the high-pressure steam and water separator (4) enters the sampling separator (5), and passes through a pressure transducer A (6), a one-way valve (7) and a high-pressure stop valve B (8) in sequence to enter a steam injection pipe network through a steam injection pipe network joint (30). The oil field steam injection boiler steam dryness increasing device can increase the steam dryness by above 95% so as to improve the thickened oil production efficiency.

Owner:BC P INC CHINA NAT PETROLEUM CORP +1

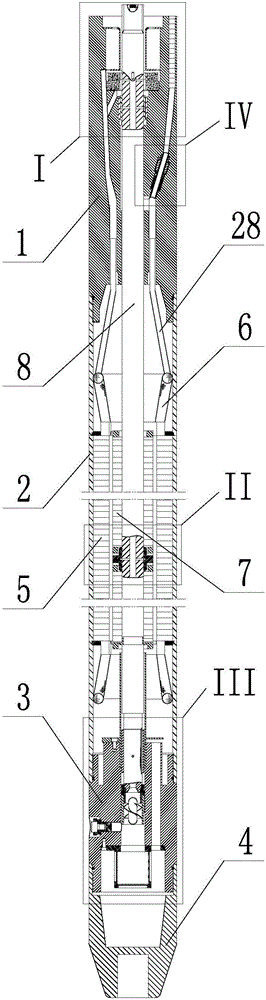

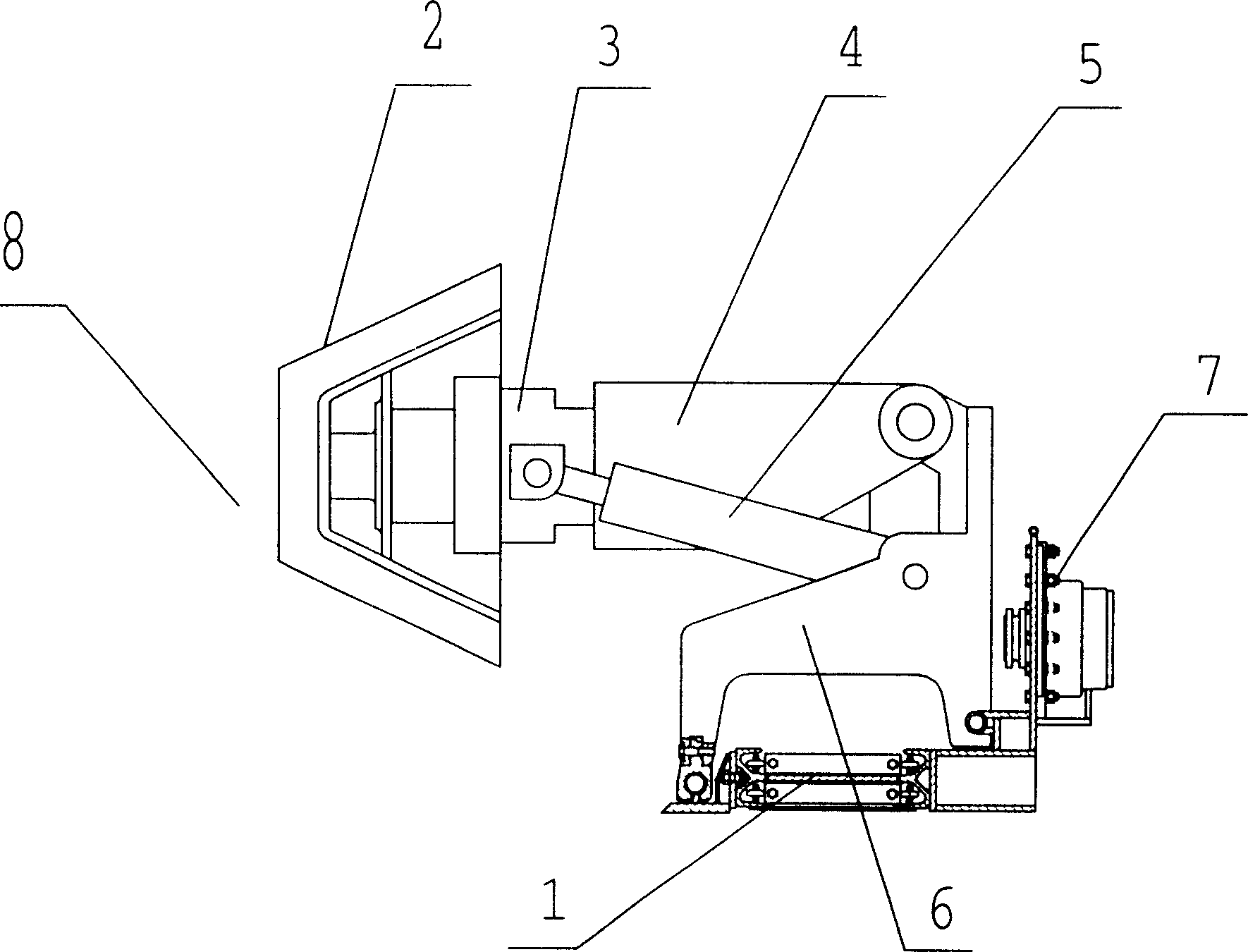

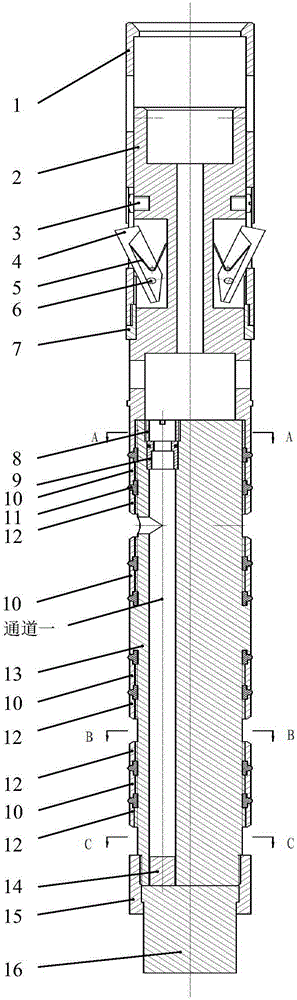

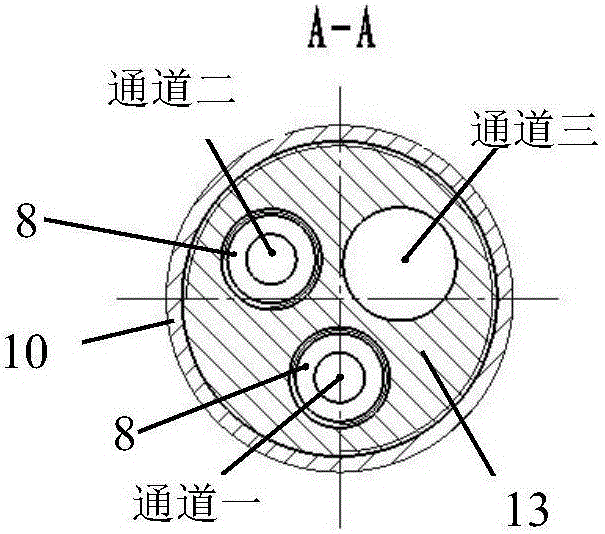

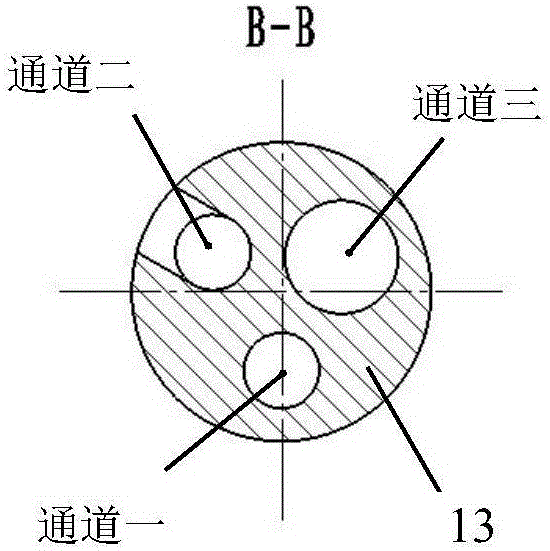

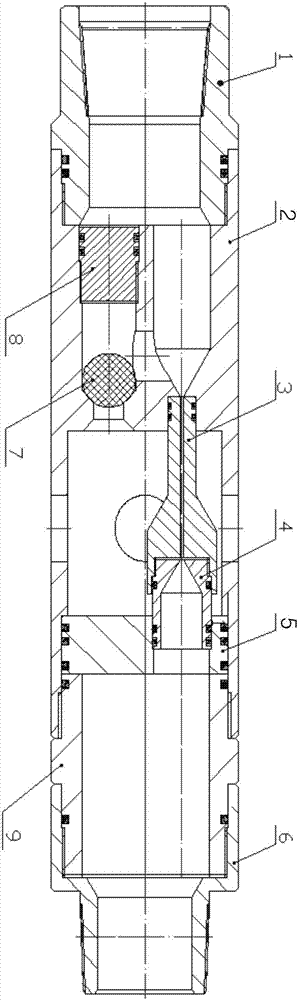

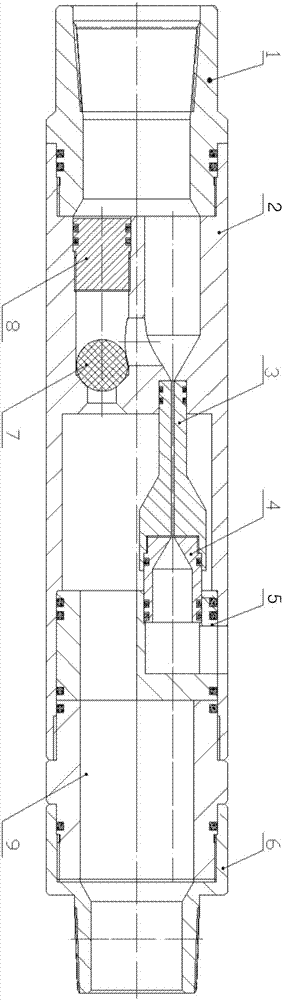

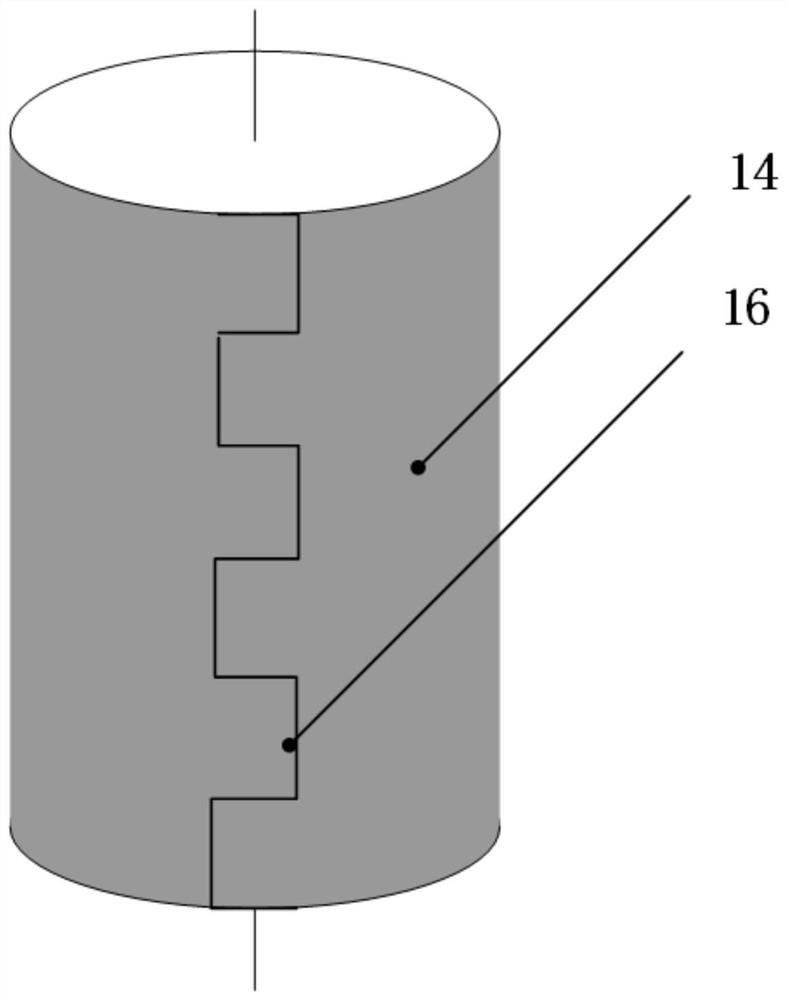

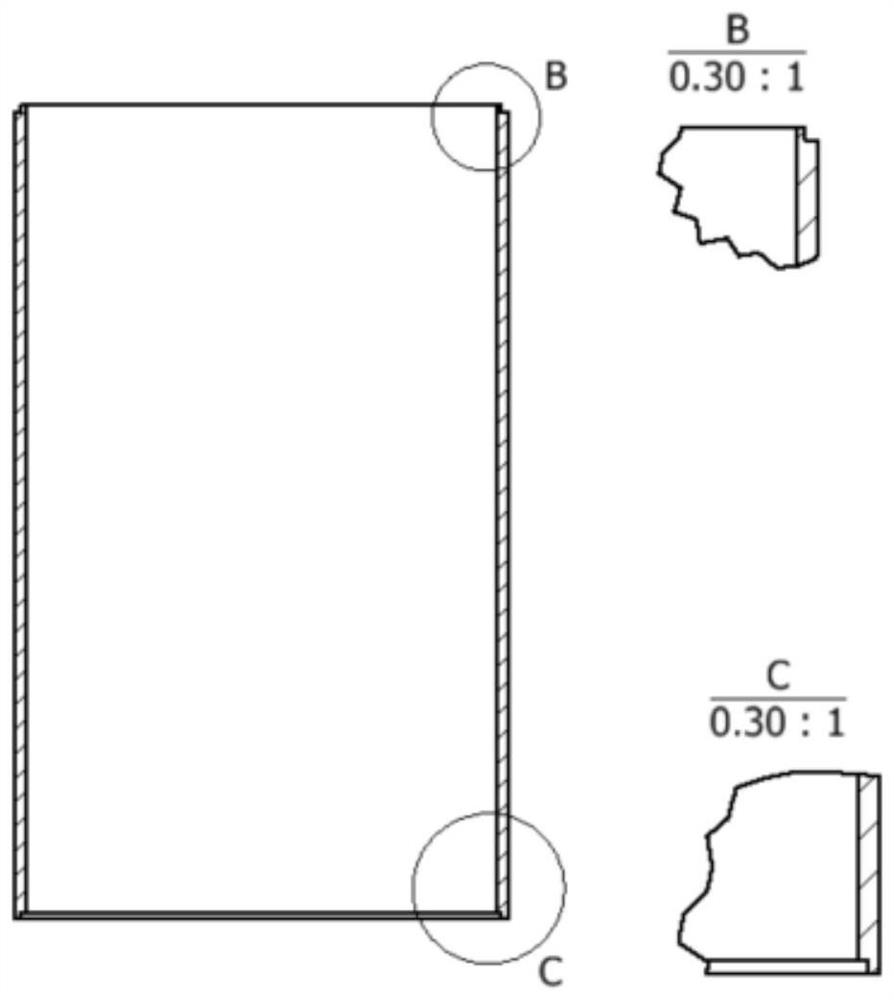

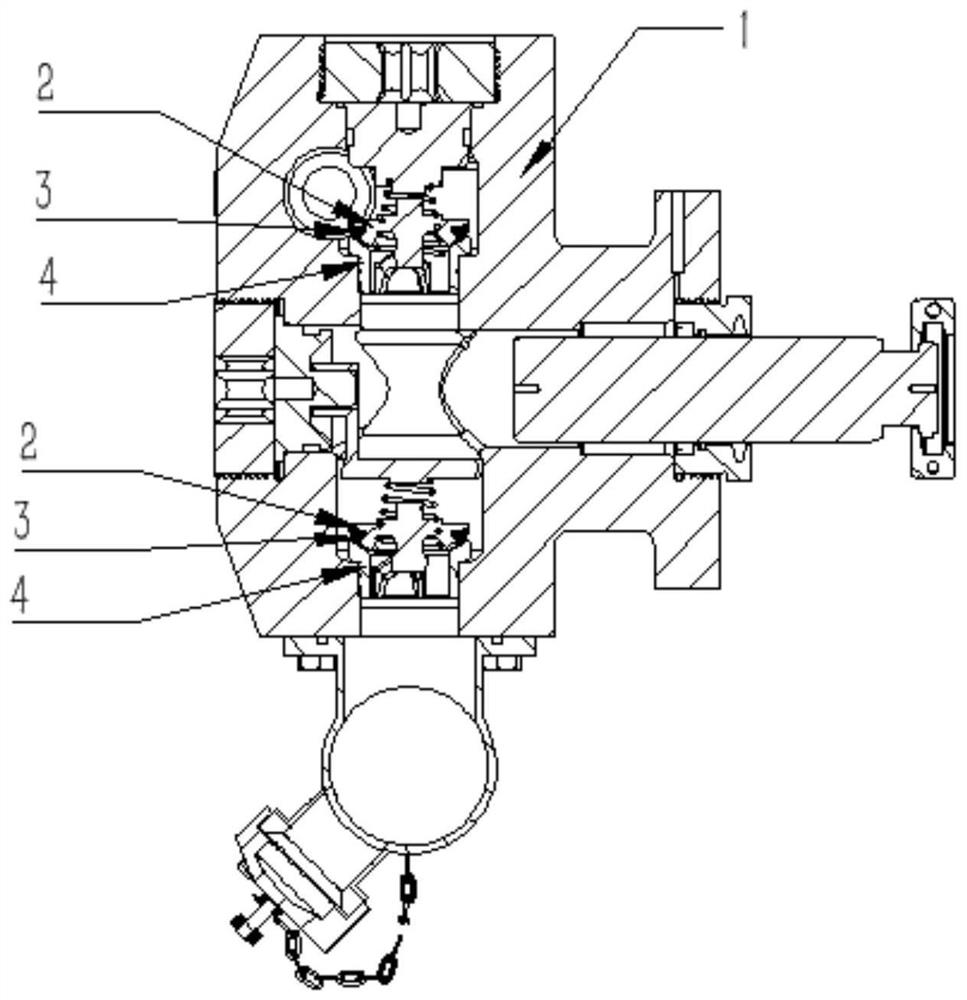

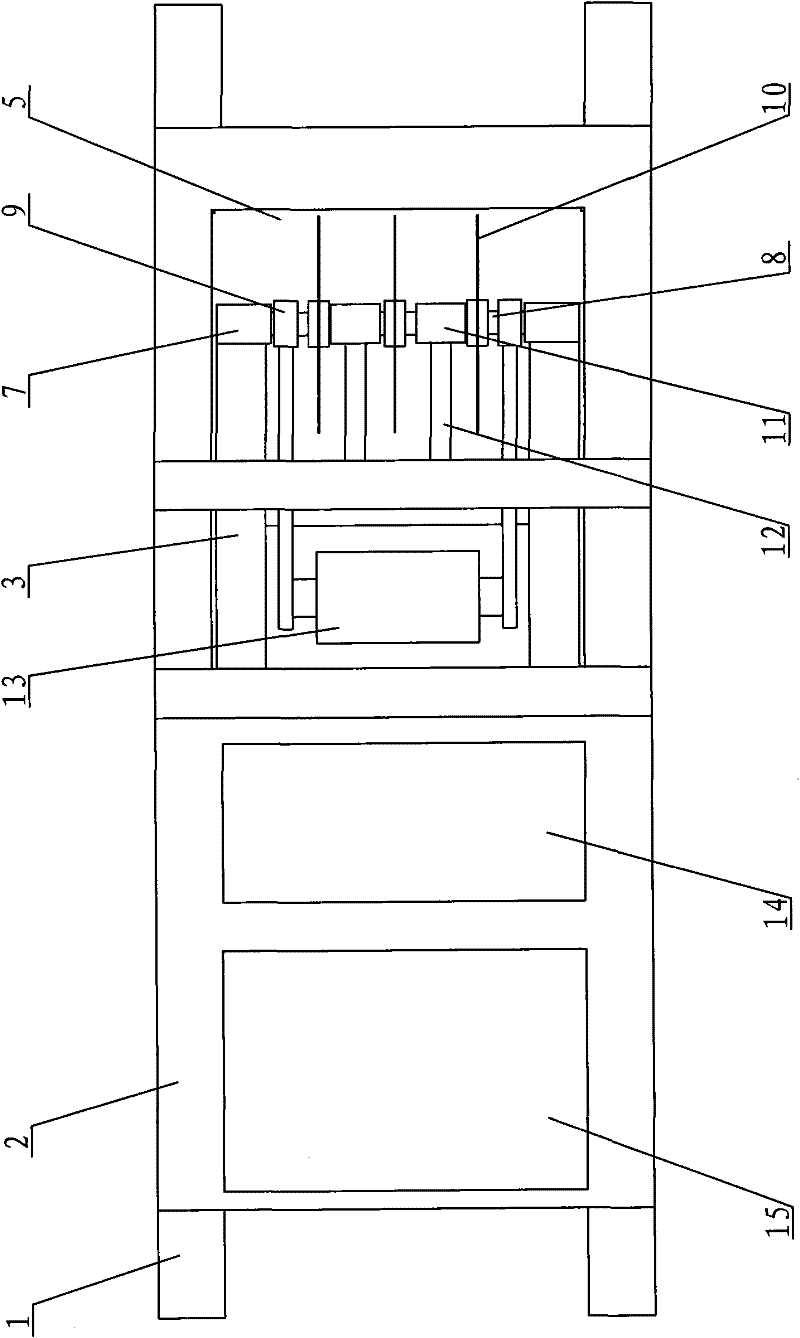

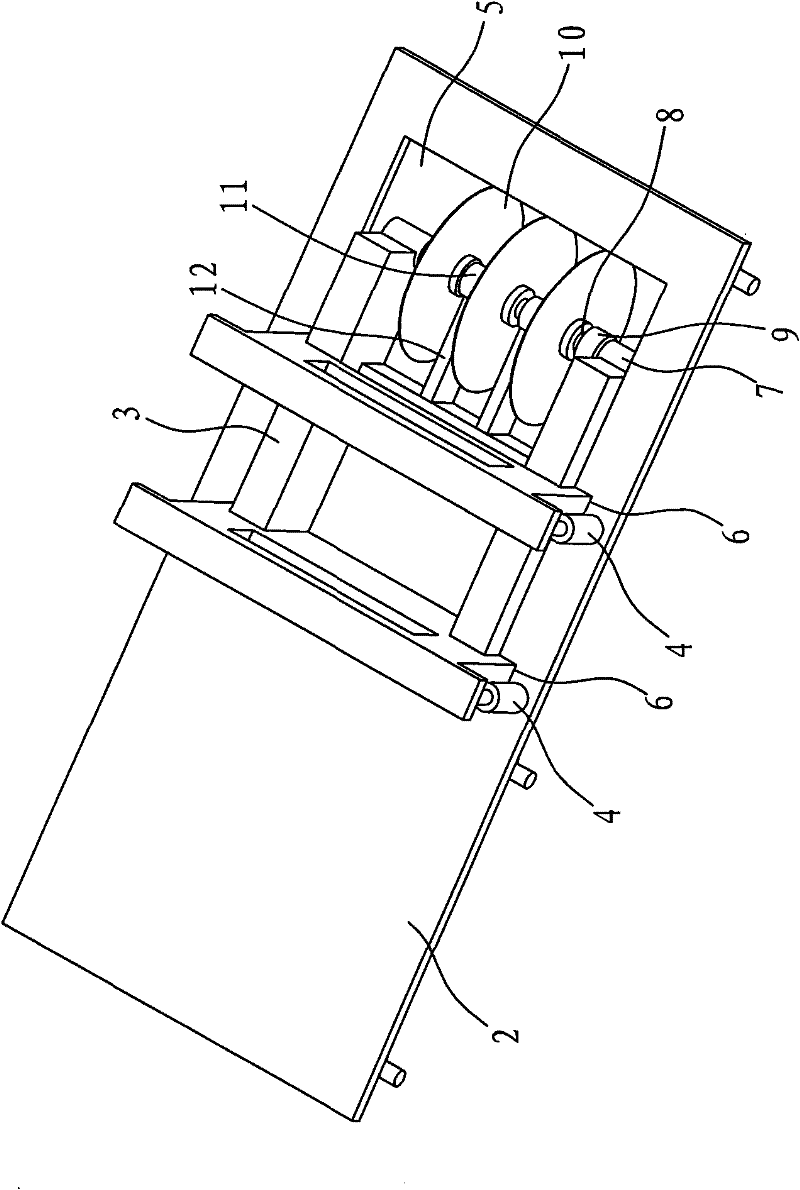

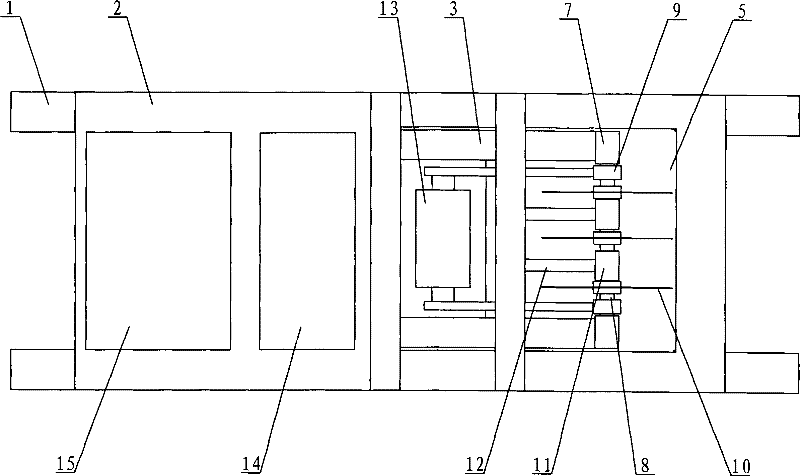

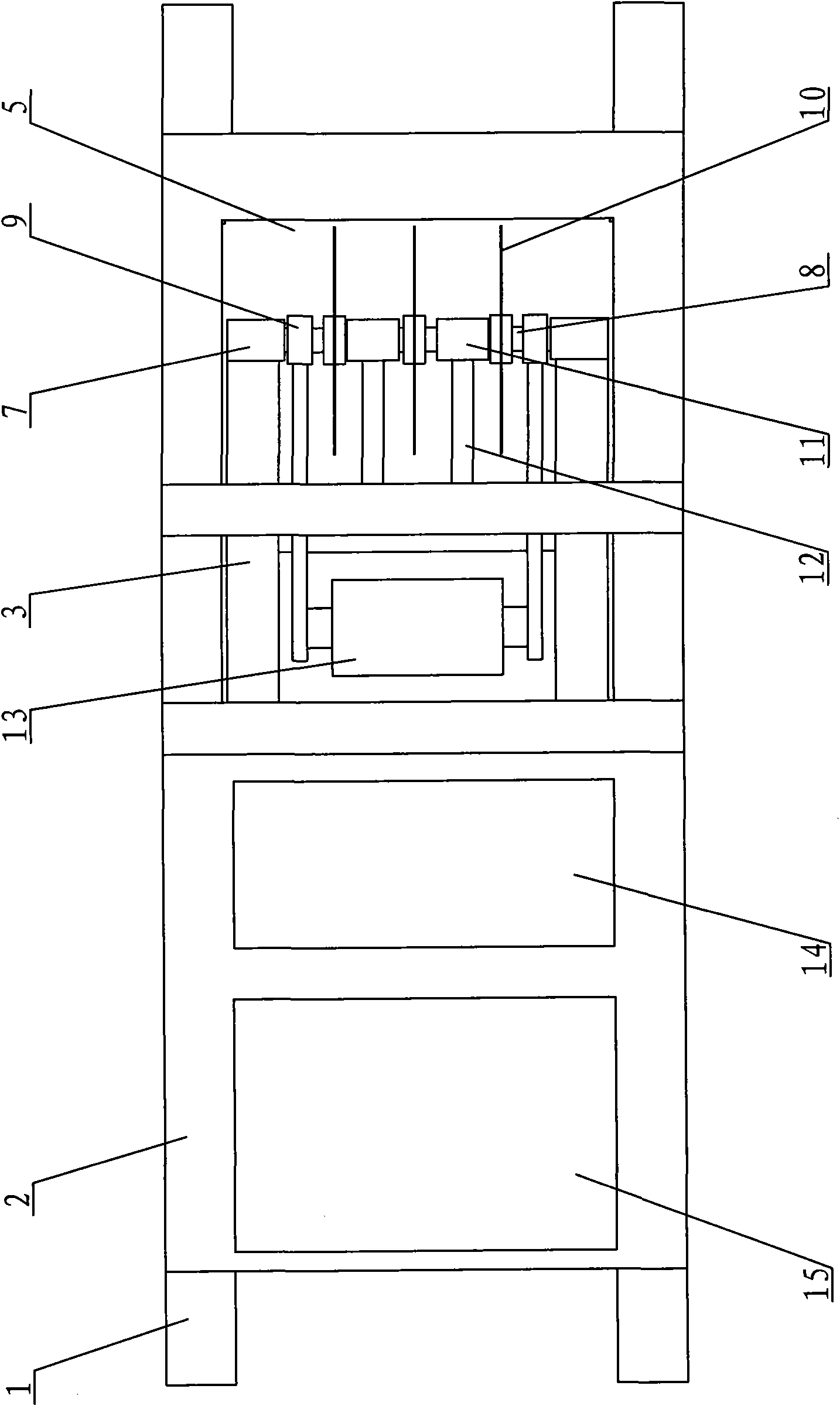

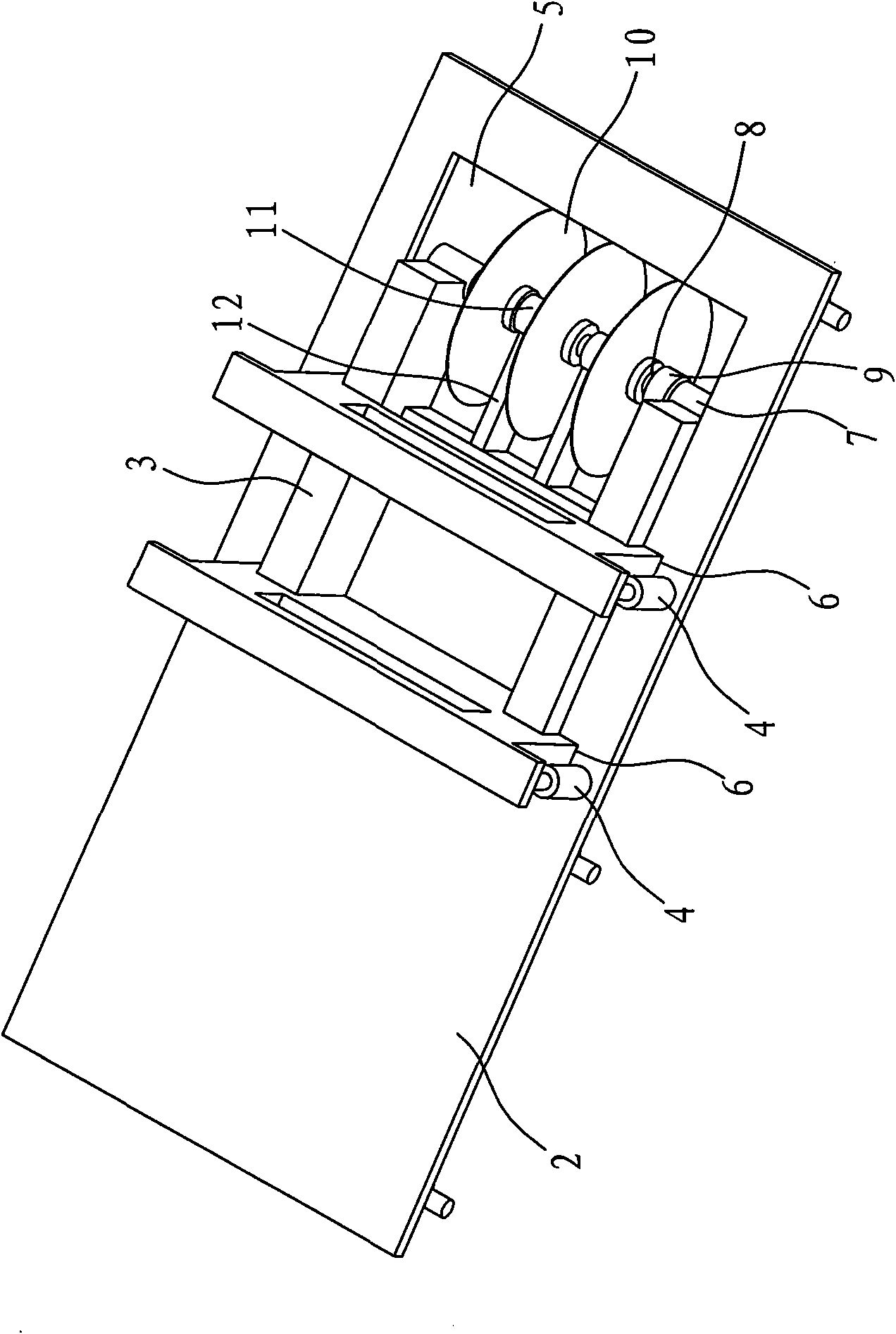

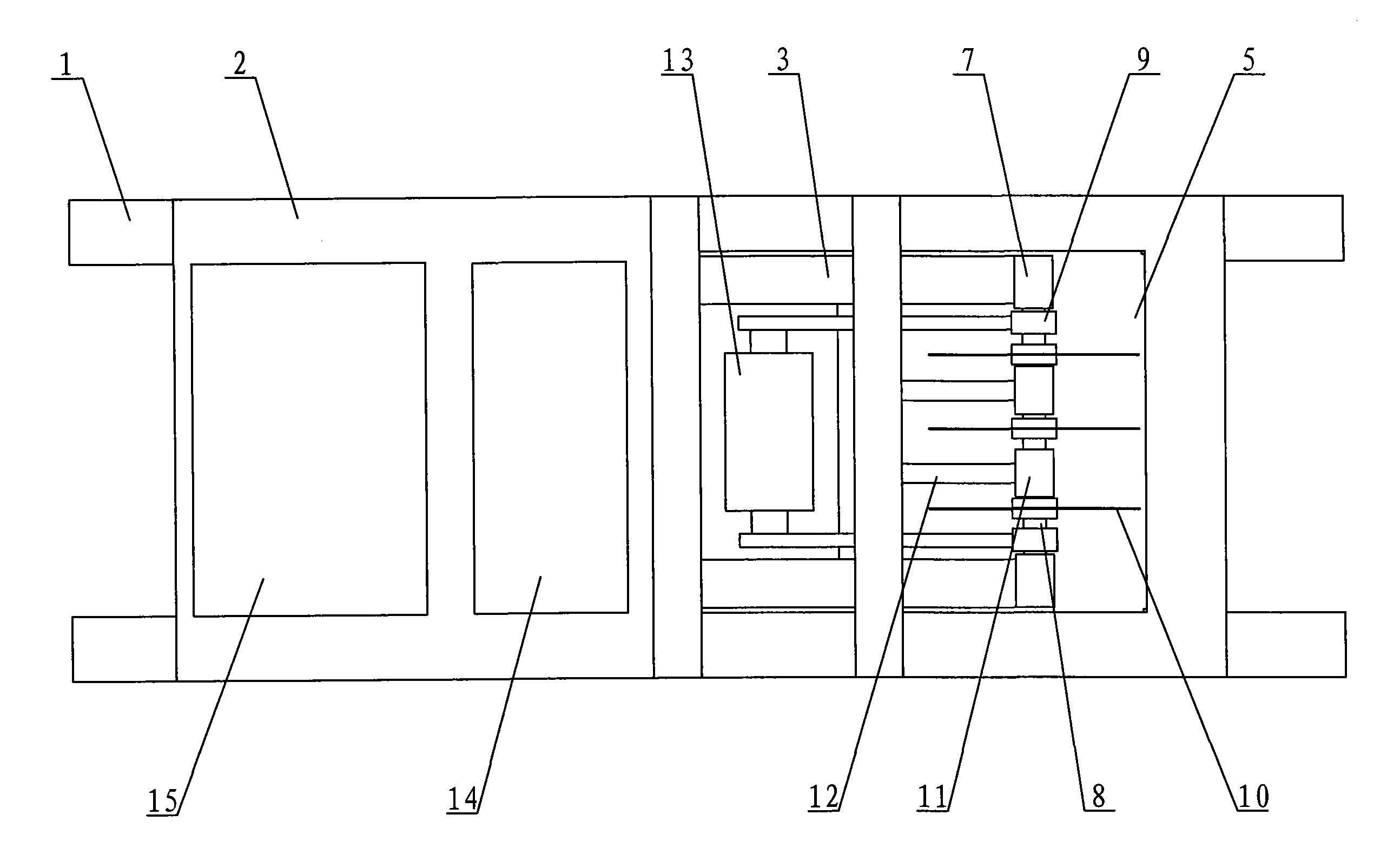

Gas well storage type integrated layered production allocation pressure gauge

ActiveCN105888650ASimple structureAvoid interlayer interferenceSurveyFluid removalOil productionProcess engineering

The invention relates to the technical field of oil production engineering, and belongs to a gas well storage type integrated layered production allocation pressure gauge, which solves the problem in the prior art that long-term pressure monitoring and productivity allocation during a dynamic production process of two gas producing zones cannot be realized at the same time. The gas well storage type integrated layering and production allocating pressure gauge is formed by a salvaging connector (1), a positioning main body (2), anti-rotation pins (3), positioning scissors (4), torsion springs (5), scissor pins (6), regulating sleeves (7), a pressing cap (8), an air faucet (9), regulating rings (10), sealing packings (11), pressing rings (12), a production allocation main body (13), a sensor (14), a back-up nut (15) and a pressure gauge cabin (16). The gas well storage type integrated layered production allocation pressure gauge disclosed by the invention has the advantages that the structure is simple and reliable, static and dynamic production of two kinds of gas producing zones and long-term monitoring on pressure in a shaft can be realized at the same time, and the like.

Owner:PETROCHINA CO LTD +1

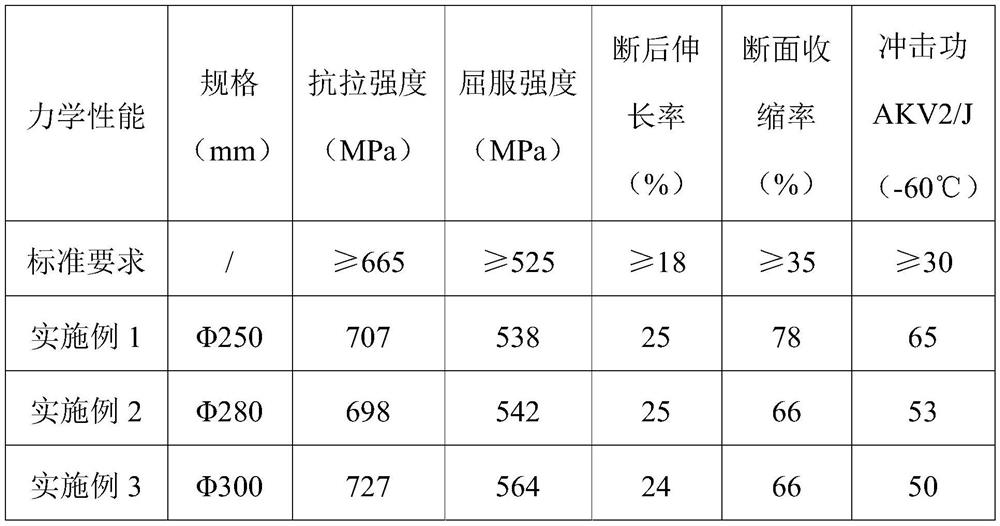

Steel for petroleum valve body and preparation method thereof

PendingCN113025901APromotes precipitation strengtheningPromote fine grain strengtheningTemperature control deviceWork heating devicesElectric furnacesImpact toughness

The invention discloses steel for a petroleum valve body and a preparation method thereof. The steel comprises C, Si, Mn, P, S, Cr, Mo, Ni, 0.01-0.02% of Nb, 0.01-0.02% of V, Al, Cu, Ti, As, Sn, Sb, Pb, Bi, H, O, N, Fe and inevitable impurities. The preparation method comprises the steps of electric furnace smelting, LF refining, VD vacuum treatment, continuous casting and rolling. By adding V and Nb microalloying elements, precipitation strengthening and fine grain strengthening are promoted, the strength and toughness of the material are improved, especially the low-temperature impact toughness is improved, and smelting, continuous casting and rolling process parameters are controlled in the preparation process, so that the steel has high purity, compact structure and good mechanical performance, and the requirement of deep sea oil exploitation is met.

Owner:JIANGSU LIANFENG ENERGY EQUIP

Delayed cross-linked polymer system

The invention relates to the technical field of in-situ leaching uranium mining, in particular to the technical field of a fluid control system for plugging high-permeability channels or plugging part of high-permeability layers in the in-situ leaching uranium mining process so as to control a leaching agent solution and leaching range, reduce reagent consumption and improve the uranium recovery rate. The invention also relates to a delayed cross-linking depth profile control in oil exploitation and provides a delayed cross-linked polymer system. The delayed cross-linked polymer system comprises high-molecular-weight polyacrylamide, a phenolic aldehyde cross-linking agent and a crosslinking delayer. By adjusting the adding amount of the crosslinking delayer, the crosslinking time can be controlled to reach the effects of meeting the required injection amount and widening a leaching control range. By adopting a crosslinking delayer adding mode, the delayed cross-linked polymer system is low in cost, simple to prepare, low initial viscosity, adjustable in gelling time and high in gelling strength.

Owner:BEIJING RESEARCH INSTITUTE OF CHEMICAL ENGINEERING AND METALLURGY

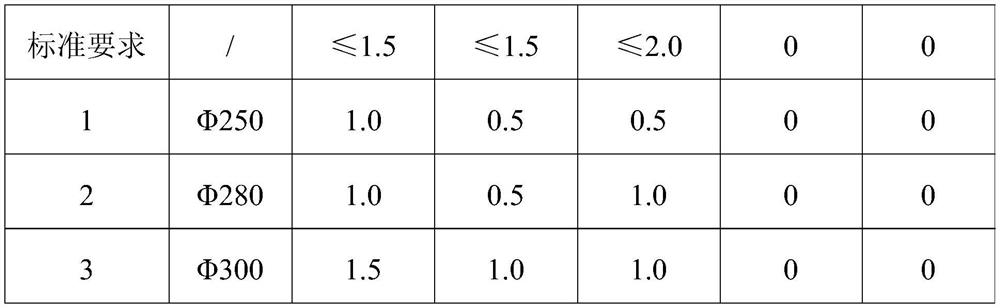

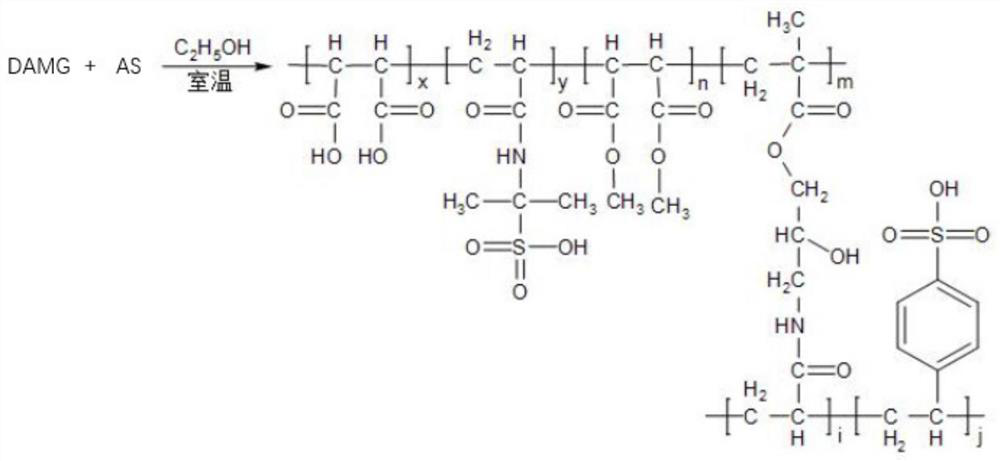

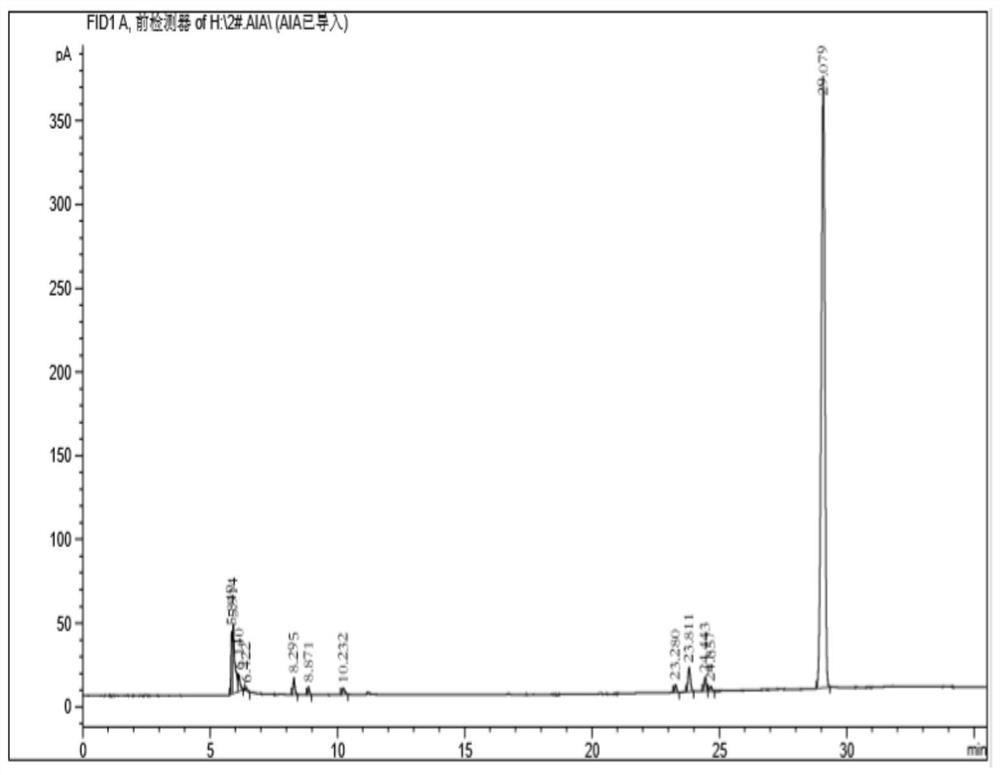

High-molecular polymer oil displacement surfactant for oil field and preparation method of high-molecular polymer oil displacement surfactant

ActiveCN111808594AImprove development efficiencyImprove performanceDrilling compositionMeth-Active agent

The invention discloses a high-molecular polymer oil displacement surfactant for an oil field and a preparation method of the high-molecular polymer oil displacement surfactant and belongs to the technical field of oil field development. The high-molecular polymer oil displacement surfactant is prepared from a DMAG quaternary polymer and an AS polymer; the DMAG quaternary polymer is composed of areaction monomer, an initiator and distilled water; the reaction monomer is composed of dimethyl maleate, maleic anhydride, 2-acrylamide-2-methylpropanesulfonic acid and dehydrated glyceryl methacrylate; the initiator is azodiisopropylimidazoline acid salt; the AS polymer is polymerized in distilled water by taking acrylamide and vinylbenzene sulfonic acid as reaction monomers, 2,2'-Azobis[2-(2-imidazolin-2-yl)propane] dihydrochloride(AIBI) as an initiator and mercaptoethylamine sulfonate as a chain transfer agent. The prepared oil displacement surfactant and crude oil form emulsion, the viscosity of the crude oil can be effectively reduced, remaining oil in stratum gaps can be effectively exploited, and the exploitation requirement of an oil field for thick oil and pore remaining oil is met.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

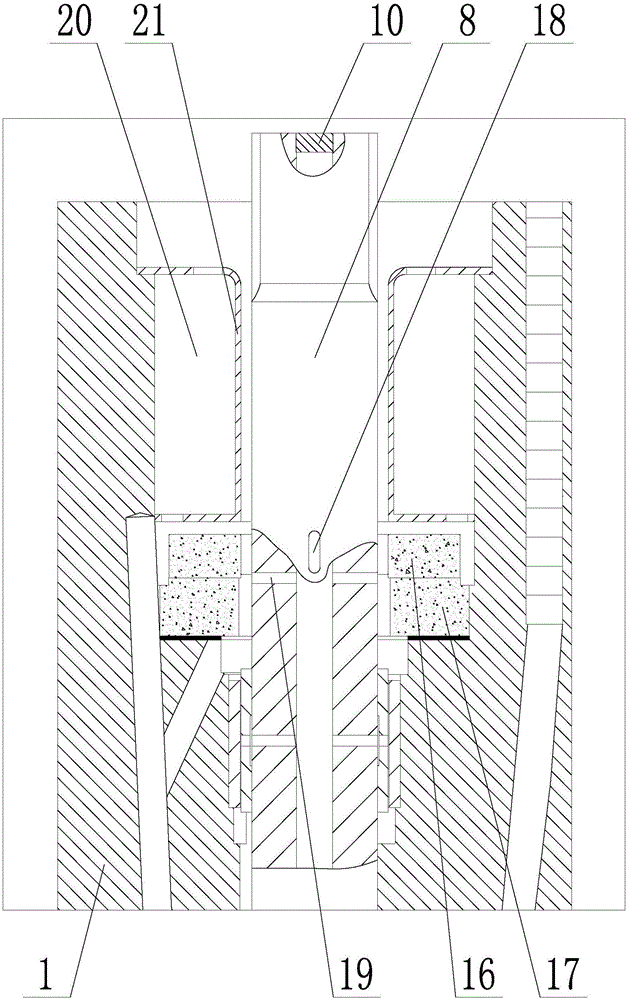

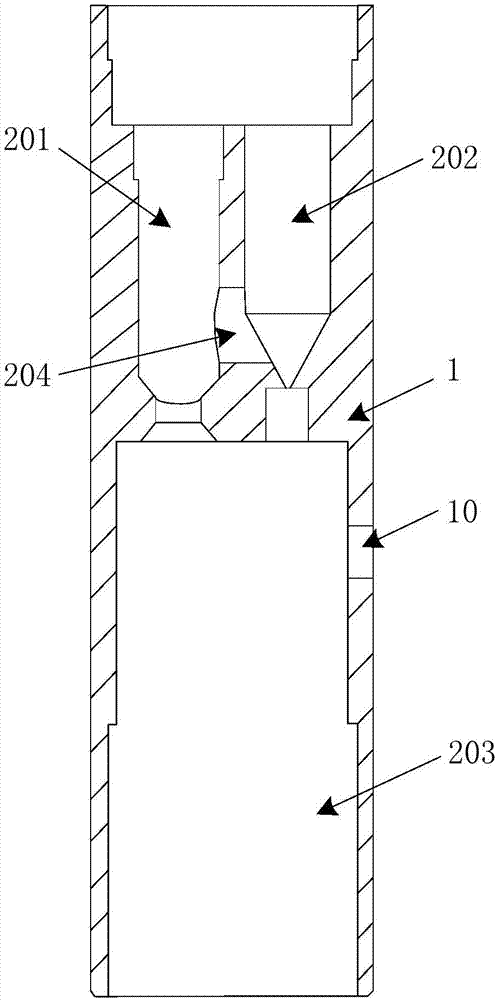

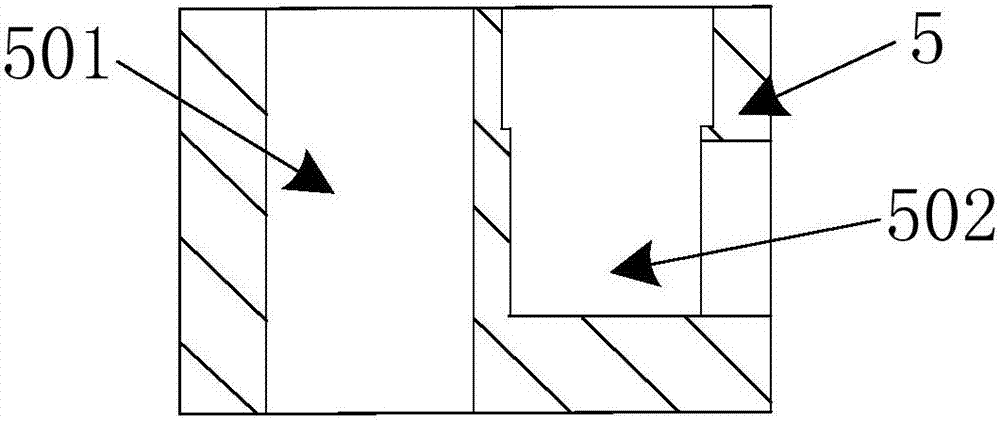

Upper layer low pressure and negative pressure separate mining device

PendingCN107420075AImprove passabilityMeet mining needsFluid removalWell/borehole valve arrangementsSpray nozzleBall valve

The invention discloses an upper layer low pressure and negative pressure separate mining device. The upper layer low pressure and negative pressure separate mining device comprises a main body, a pipework, a spraying nozzle, a pressing cap, a ball valve and a valve seat; a first eccentric through hole and a second eccentric through hole which are formed in the top face of the main body communicate with a central through hole formed in the bottom face of the main body; the valve seat and the ball valve are plugged at the end of the top end of the first eccentric through hole and the communicating position of the first eccentric through hole and the central through hole, and a communicating hole between the first eccentric through hole and the second eccentric through hole is located above the ball valve; the pipework is mounted in the second eccentric through hole in a plugging mode, and a central hole channel of the pipework communicates with the second eccentric through hole; the inner diameter of the bottom end of the pipework is increased and provided with the spraying nozzle, so that the central hole channel of the pipework communicates with the central hole channel of the spraying nozzle; the pressing cap is arranged below a flow hole formed in the inner wall of the main body, and the central axis of a third eccentric through hole formed in the center of the pressing cap overlaps with that of the second eccentric through hole, so that the spraying nozzle is located on the inner side of the top end of the third eccentric through hole; and the upper layer low pressure and negative pressure separate mining device solves the problem that the differential pressure between layers results in backward flowing from a high pressure layer to a lower pressure layer in the multi-layer mining process, and the joint mining of multiple layers is achieved.

Owner:CNPC BOHAI DRILLING ENG

Data mining system

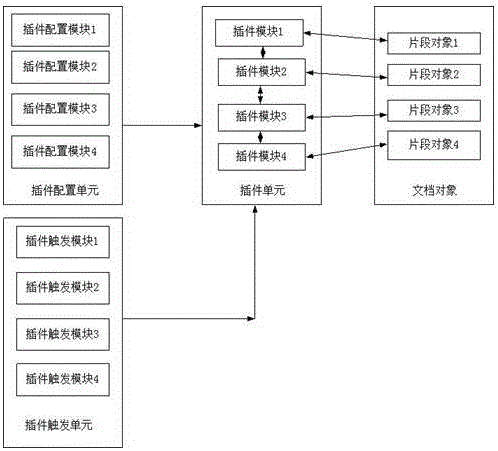

InactiveCN106096032AMeet mining needsProgram loading/initiatingSpecial data processing applicationsData treatmentComputer science

The invention relates to a data mining system. The data mining system comprises a plug-in unit, a plug-in configuration unit and a plug-in trigger unit, wherein the plug-in unit comprises a plurality of plug-ins capable of transferring data processing results to each other, a document object is processed with different methods respectively, and the preset-mode data processing results are correspondingly formed; the plug-in configuration unit comprises a plurality of plug-in configuration modules, and the multiple plug-in configuration modules correspond to a plurality of plug-in modules respectively, and are used for configuring the selected plug-ins according to selected instructions when the system is started; the plug-in trigger unit comprises a plurality of plug-in trigger modules, and the multiple plug-in trigger modules correspond to the multiple plug-in modules respectively, and used for triggering the corresponding plug-in modules according to trigger conditions to start the document object for processing. The plug-in configuration unit provides a plug-in loading list, and is used for allowing a user to select the corresponding plug-in modules for configuration from the plug-in loading list. The data mining system meets the complex and multiple mining requirements.

Owner:HYLANDA INFORMATION TECH

Auxiliary decision-making method and device based on medical record, electronic equipment and storage medium

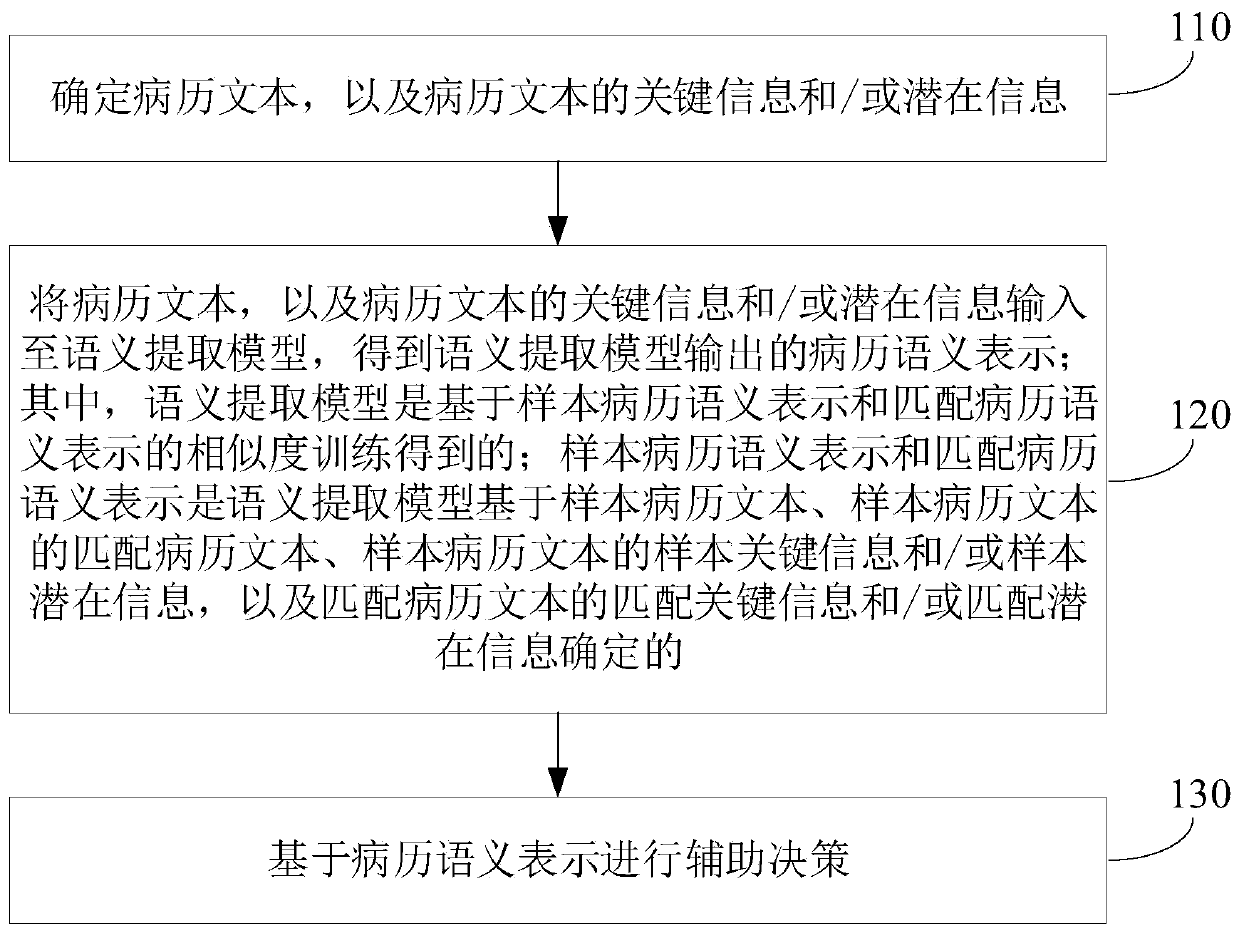

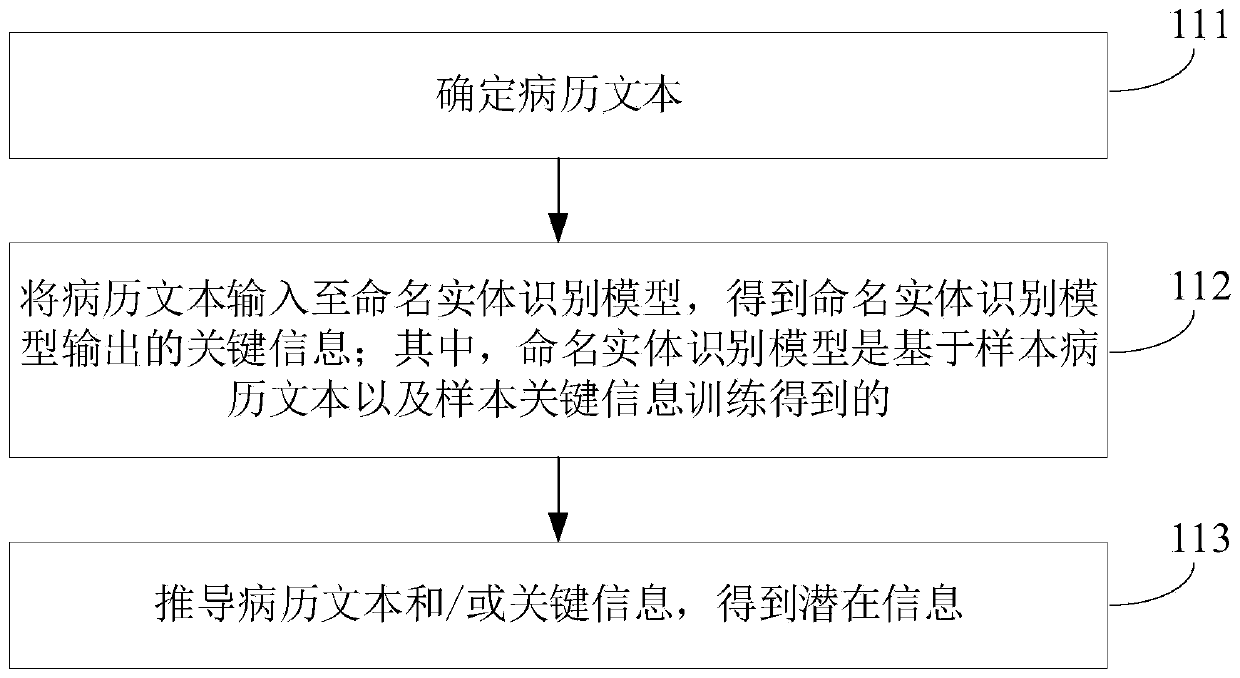

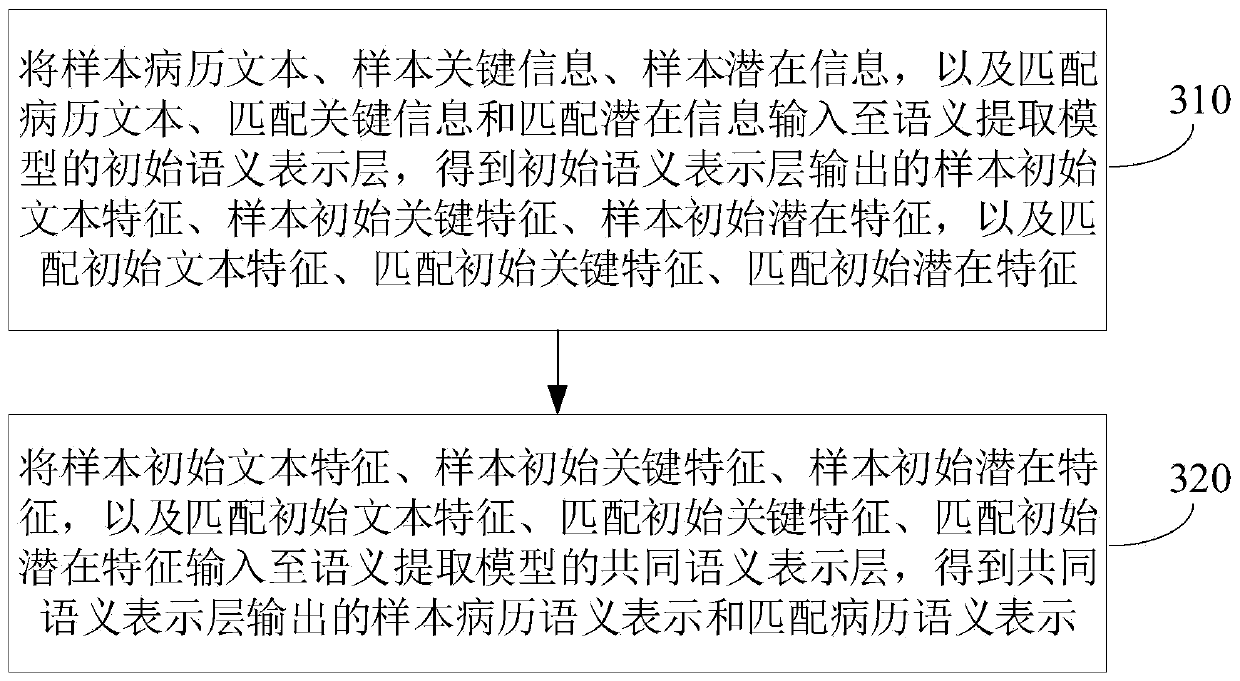

ActiveCN111259111ARefined reflectionMeet mining needsMedical data miningText database queryingMedical recordSemantic representation

The embodiment of the invention provides an auxiliary decision-making method and device based on a medical record, electronic equipment and a storage medium. The method comprises the steps of determining a medical record text and key information and / or potential information of the medical record text; inputting the medical record text and the key information and / or potential information of the medical record text into a semantic extraction model to obtain medical record semantic representation output by the semantic extraction model; performing auxiliary decision making based on the medical record semantic representation, wherein the semantic extraction model is obtained on the basis of similarity training of sample medical record semantic representation and matched medical record semanticrepresentation; the sample medical record semantic representation and the matched medical record semantic representation are determined by the semantic extraction model based on the sample medical record text, the matched medical record text, the sample key information and / or the sample potential information of the sample medical record text and the matched key information and / or the matched potential information. According to the method and device, the electronic equipment and the storage medium provided by the embodiment of the invention, the accuracy and reliability of auxiliary decision making are improved.

Owner:讯飞医疗科技股份有限公司

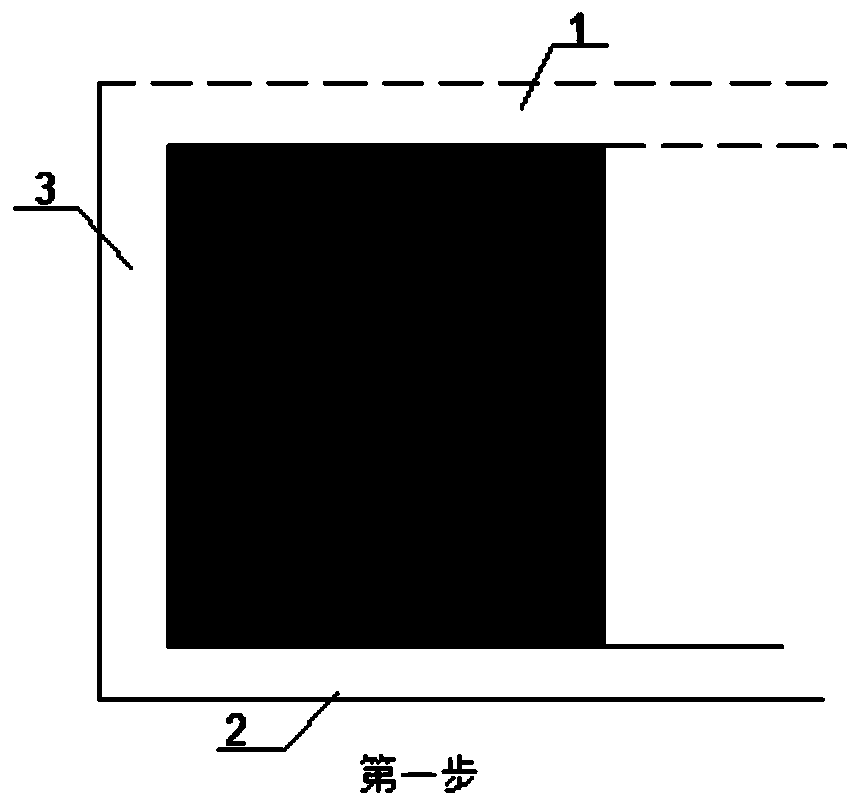

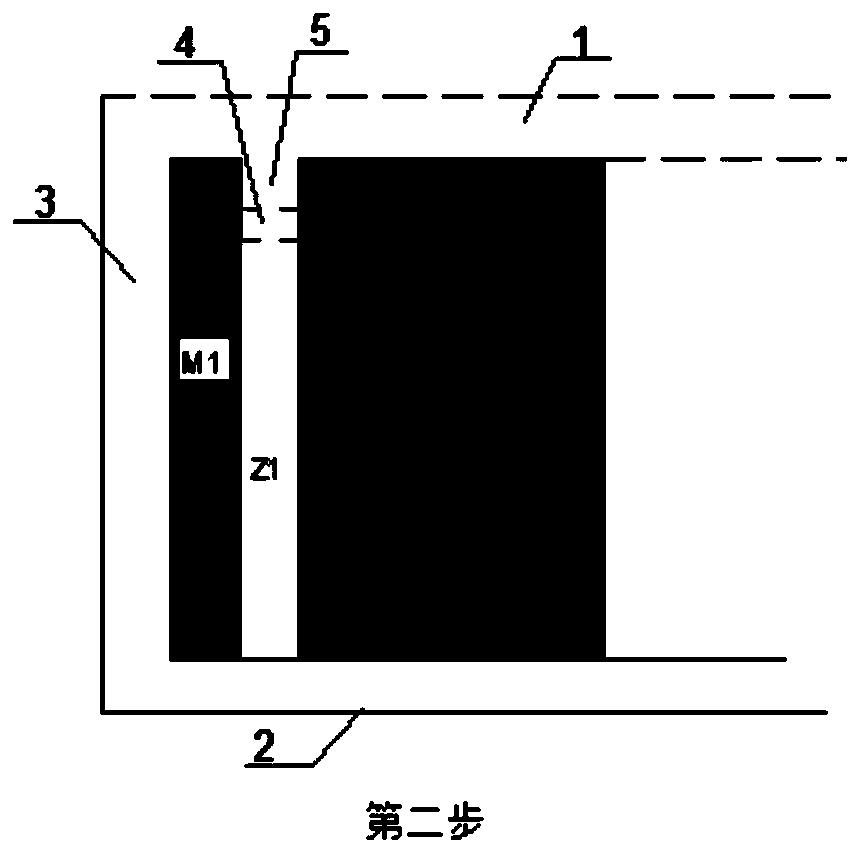

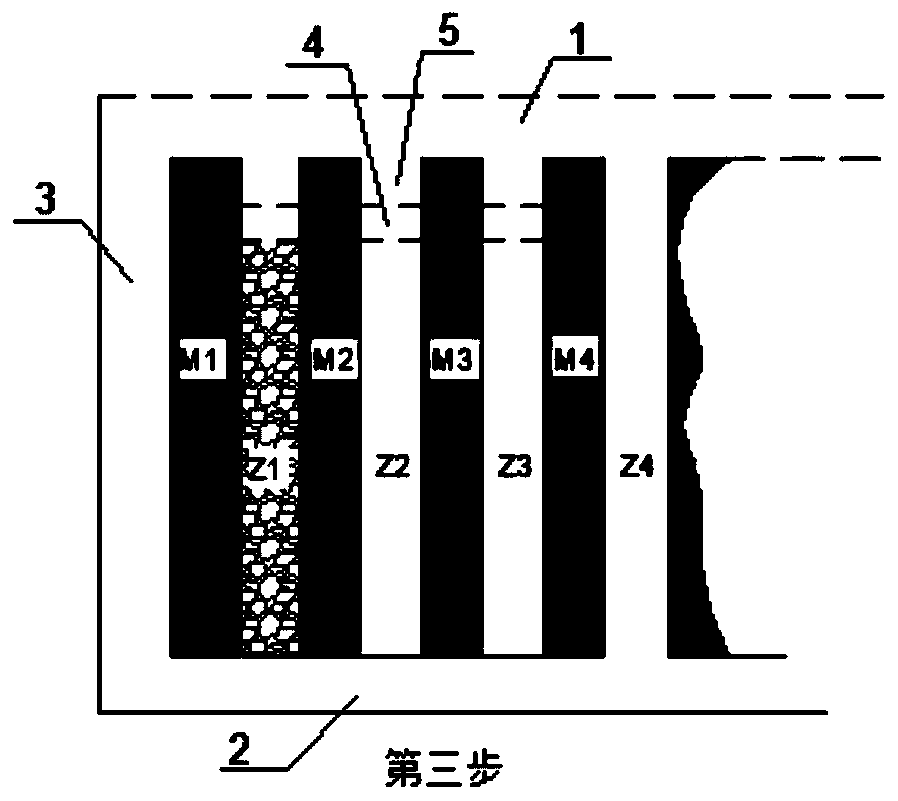

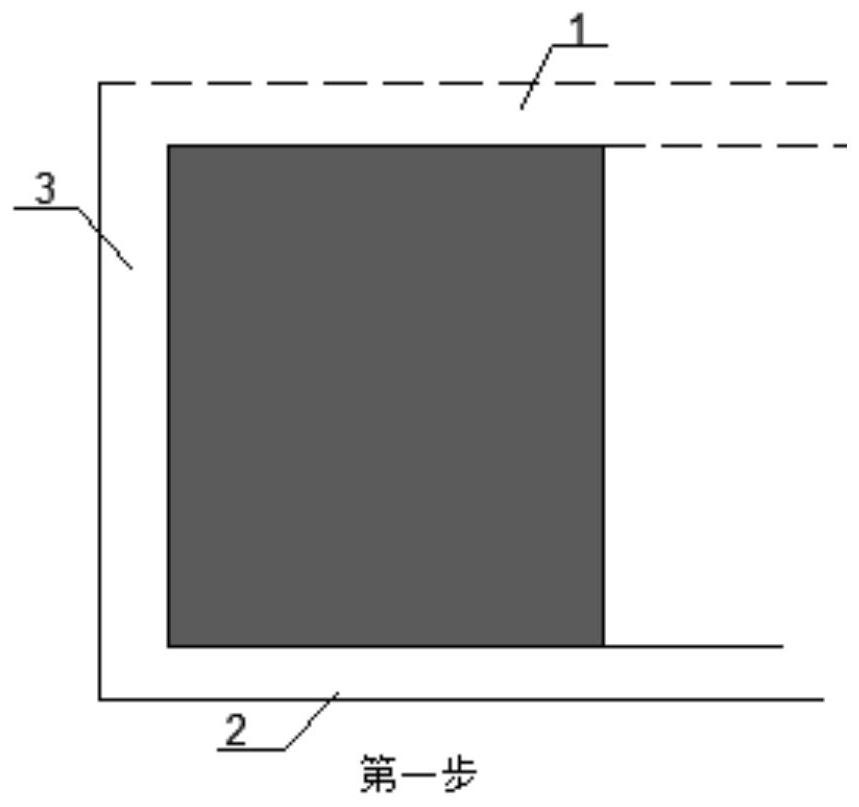

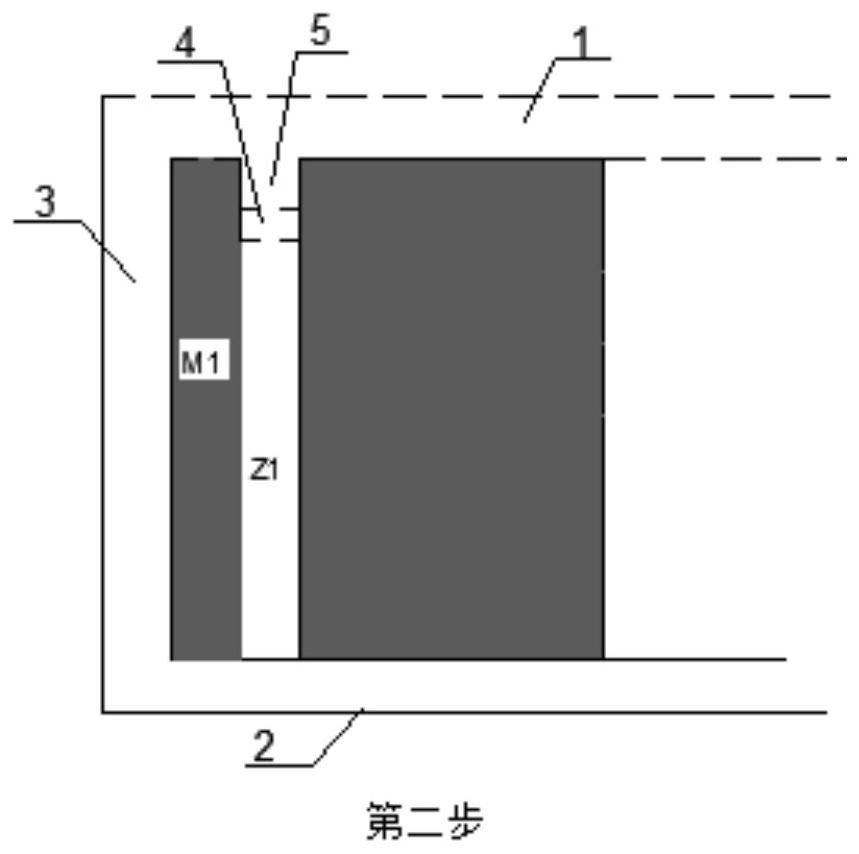

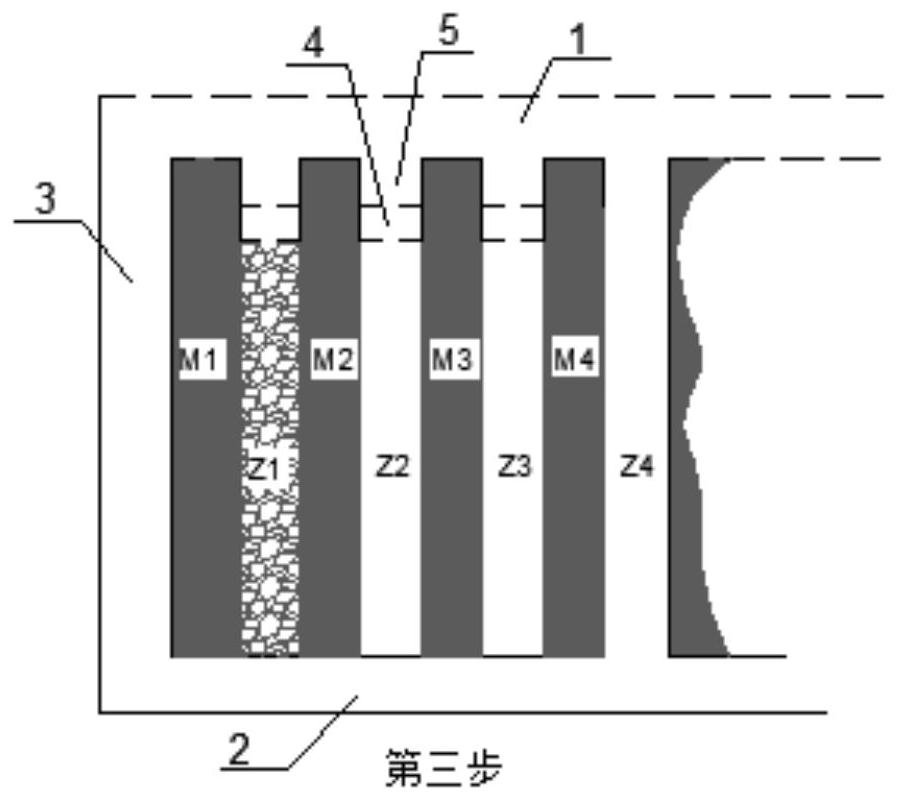

Centralized filling roadway layering stepping mining and filling "three under" mining method for approximately horizontal superhigh seam

ActiveCN110145308AEasy to transportGuaranteed stabilityUnderground miningSurface miningMining engineeringCoal pillar

The invention provides a centralized filling roadway layering stepping mining and filling "three under" mining method for an approximately horizontal superhigh seam, and relates to the mining method technology field. The approximately horizontal superhigh seam is first divided into multiple mining layers, and the centralized filling roadway layering stepping mining and filling "three under" miningmethod for the approximately horizontal superhigh seam specially includes steps: A, arranging a centralized filling roadway along a coal seam roof, arranging a transport gate road along a coal seam floor, and opening a cutting hole at a dip angle of 5-7 degrees on a boundary of a working face; B, by arranging a centralized filling inclined roadway, a filling chamber and the centralized filling roadway in communicating mode, forming a transport gate road-cutting hole-centralized filling inclined roadway-filling chamber-centralized filling roadway air return system; C, alternately arranging a plurality of branch roadways Z and a plurality of coal pillars M at the lowest mining layer along the cutting hole, completing mining of the branch roadways Z first, and filling the branch roadways Z;D, mining the coal pillars M after completing filling of the roadways Z, and filling the coal pillar areas, a transport roadway and the transport gate road; E, repeating the steps from A to D, and completing mining of all the mining layers. The centralized filling roadway layering stepping mining and filling "three under" mining method for the approximately horizontal superhigh seam achieves filling and mining of the approximately horizontal superhigh seam, and is safe and efficient.

Owner:山东威斯特矿山工程科技股份有限公司

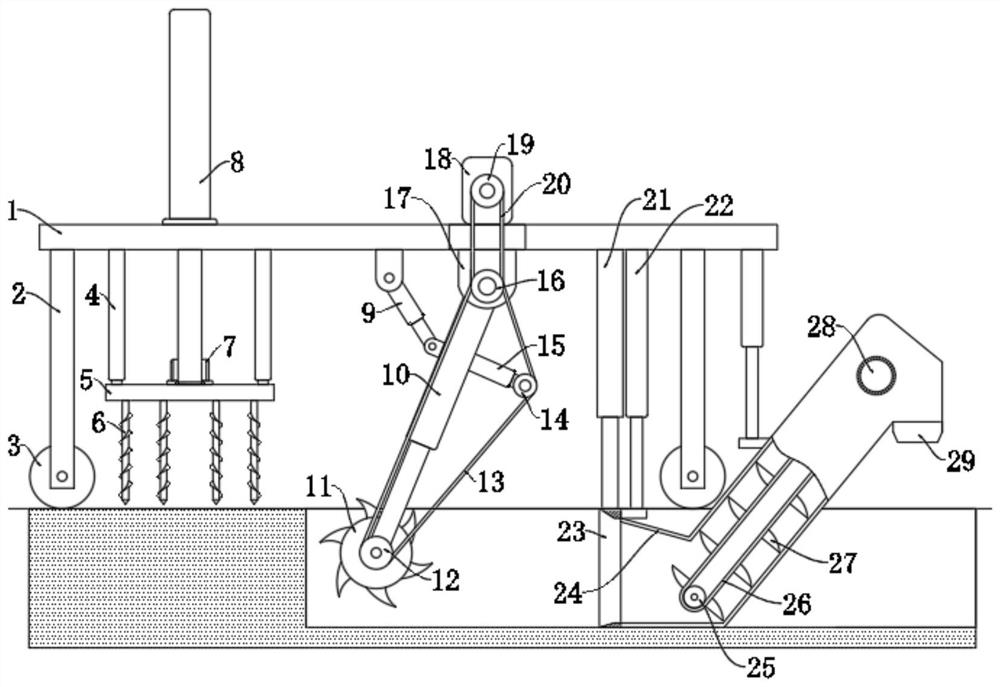

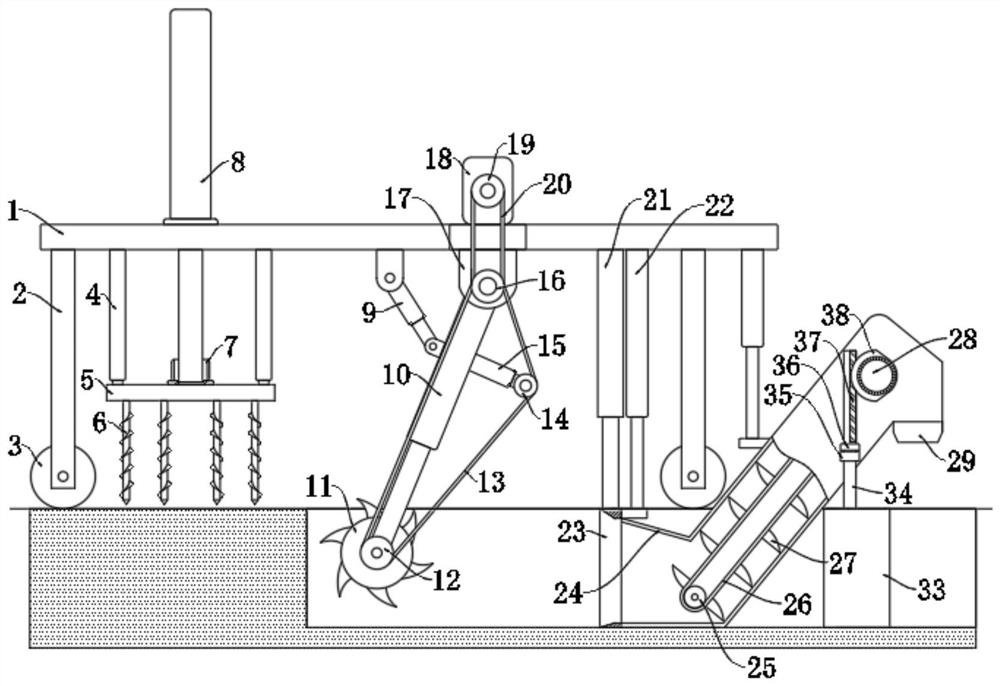

Ground ditch excavating equipment for construction site

The invention discloses ground ditch excavating equipment for a construction site. The equipment comprises a top frame, wherein supporting legs are arranged at the four corners of the lower end of thetop frame, moving wheels are installed at the bottoms of the supporting legs, an mounting disc is arranged below the front portion of the top frame, two symmetrical first guiding telescopic rods arefixedly connected to the upper end of the mounting disc, the other ends of the first guide telescopic rods are fixedly connected to the lower side of the top frame, two first lifting oil cylinders arearranged at the upper end of the top frame, the telescopic ends of the two first lifting oil cylinders downwards penetrate through the top frame and are fixedly connected to the mounting disc, a mounting groove is formed in the upper end of the mounting disc, a soil loosening mechanism is arranged in the mounting groove, a connecting base is fixedly connected to the lower side of the middle of the top frame, and an excavating mechanism is arranged on the connecting base. According to the ground ditch excavating equipment for the construction site, by arranging the soil loosening mechanism, the excavating difficulty is reduced, the excavating efficiency is improved, excavated soil can be lifted out of a ditch in time, and the inner wall of the excavated ditch is compacted.

Owner:廖冬花

Short-span thin coal seam coal mining machine

PendingCN111425196ARealize the arrangementReduce the height of the fuselageToothed gearingsDriving meansThermodynamicsGear wheel

The invention relates to a short-span thin coal seam coal mining machine. The coal mining machine comprises a cutting system, a machine body, a guide sliding shoe, a dragging connecting device and a supporting sliding shoe; the root of a motor-free rocker arm of the cutting system is rotationally supported in a standing shell of a non-swing transmission part, and large and medium size parts such as a cutting motor, a large gear and a planetary mechanism of the cutting system do not change positions along with swing of the rocker arm; the standing shell is fixed to the machine body and locatedin front of the machine body, and the standing shell and the machine body form a basic frame of the coal mining machine; and the guide sliding shoe and the supporting sliding shoe are both installed on the basic frame, the guide sliding shoe and the supporting sliding shoe support the rear portion and the middle portion of the basic frame from the lower portion respectively, and the machine body is in floating connection with a dragging chain of a scraper conveyor through the dragging connecting device. According to the short-span thin coal seam coal mining machine, the structural arrangementproblem of the short-machine-body high-power thin coal seam coal mining machine for the ultra-thin or thin coal seam working face with the complex conditions of low mining height, high coal rock hardness and the like can be solved.

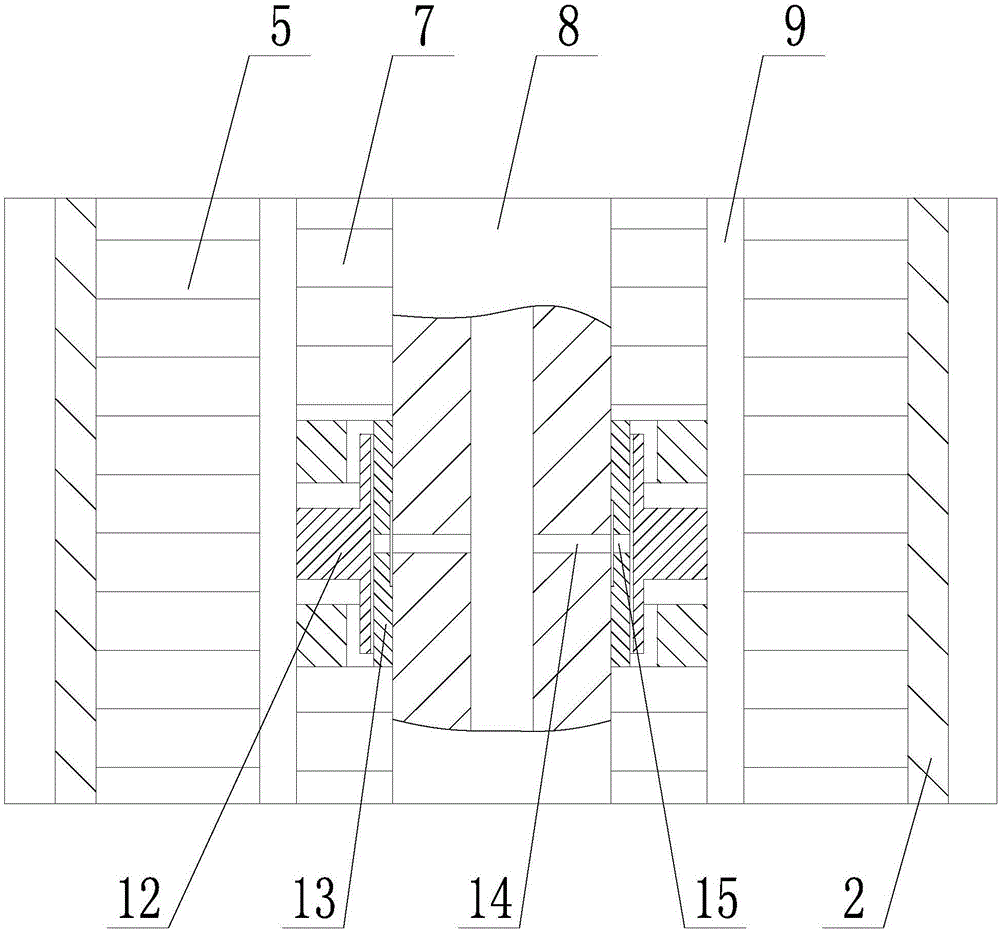

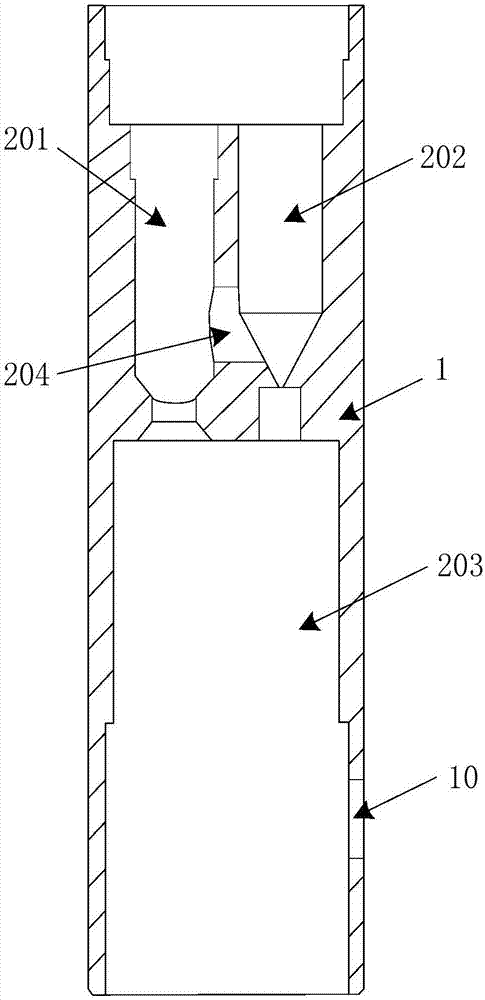

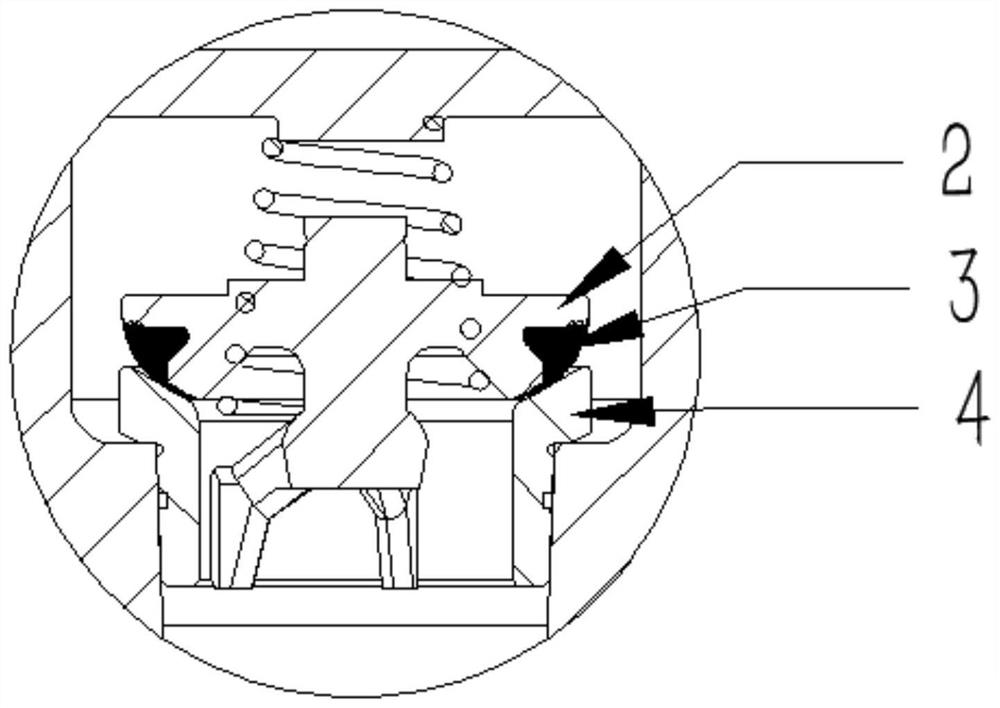

Upper layer high-pressure negative-pressure separated exploiting device

PendingCN107165606ASolving conflicts between layersImprove passabilityFluid removalWell/borehole valve arrangementsSpray nozzleEngineering

The invention discloses an upper layer high-pressure negative-pressure separated exploiting device. The upper layer high-pressure negative-pressure separated exploiting device comprises a main body, a valve seat, a ball valve, a throat pipe and a pressing cap, wherein a first eccentric through hole and a second eccentric through hole are formed in the top surface of the main body, a central through hole is formed in the bottom surface of the main body, and the first eccentric through hole and the second eccentric through hole communicate with the central through hole; the valve seat and the ball vale are arranged at the end of the top end of the first eccentric through hole and the communicating part between the first eccentric through hole and the central through hole correspondingly, a communicating hole formed in the portion between the first eccentric through hole and the second eccentric through hole is formed above the ball valve; the throat pipe is installed at the bottom of the second eccentric through hole in an inserted mode, the inner diameter of the bottom end of the throat pipe is increased, and the bottom end of the throat pipe is provided with a spraying nozzle, and thus a central hole channel of the throat pipe, the second eccentric trough hole and a central hole channel are connected sequentially; the pressing cap is arranged on the inner wall of the lower side of the main body, a third eccentric through hole and a fourth eccentric through hole are formed in the top surface of the pressing cap, and the fourth eccentric through hole communicates with an overflowing hole which is formed in the side wall of the lower side of the main body. According to the upper layer high-pressure negative-pressure separated exploiting device, the through capability of fluid in the low pressure area is maximally improved, the application range of interlayer pressure differences of tools is enlarged, and the exploiting efficiency is greatly improved.

Owner:CNPC BOHAI DRILLING ENG

Portable water injection type rotary excavating equipment for tower footing pile hole construction in mountainous and hilly areas

PendingCN111894449AMeet mining needsCompact structureDrilling rodsBorehole drivesWater sourceReduction drive

The invention provides portable water injection type rotary excavating equipment for tower footing pile hole construction in mountainous and hilly areas. The equipment comprises a first machine base,a rotary excavating feeding module, a rotary excavating direction adjusting module, a rotary excavating module and a mud-water separation system which are all fixed on the ground; the rotary excavating feeding module comprises an axial telescoping jacking mechanism, a jacking block, and a jacking tube; the rotary excavating direction adjusting module comprises a second machine base, and an axial telescopic adjusting jacking mechanism and an adjusting positioning plate which are both arranged in the second machine base and used for adjusting the rotary excavating feeding direction; the rotary excavating module comprises a third machine base, and a driving motor, a speed reducer and a cutter disc which are all mounted on the third machine base; and the mud-water separation system comprises awater source, a separation tank, a sediment pump and a connecting pipeline, wherein the water source and the separation tank are located on the ground, and the sediment pump and the connecting pipeline are arranged on the adjusting positioning plate in the second machine base. The equipment has the advantages of compact and simple structure, convenient disassembly and assembly, small size and light weight, and is convenient to transport in the mountainous and hilly areas.

Owner:成蜀电力集团有限公司

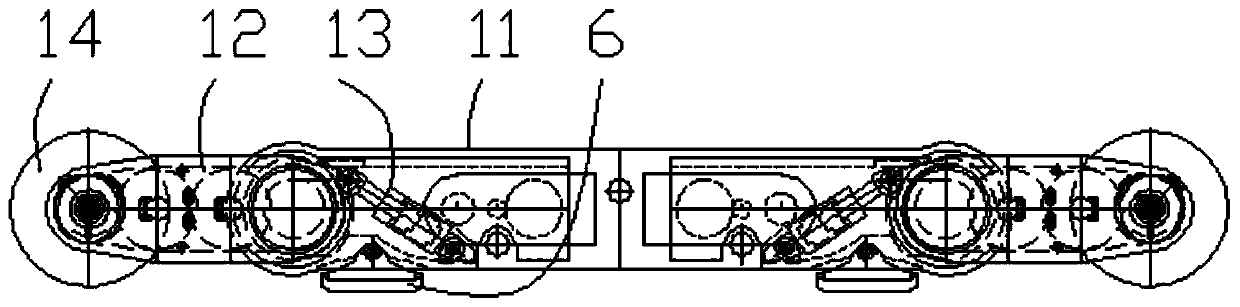

Dragging part of torque shunting thin coal layer mining machine

InactiveCN102889080BMeet mining needsImprove mining efficiencyPropulsionElectric machineTransmitted power

The invention discloses a dragging part of a torque shunting thin coal layer mining machine. The dragging part comprises a dragging shell, a dragging motor, a dragging speed reduction box, a torque shunting gear transmission mechanism, a gap bridge, a traveling shell, a torque shunting gear transmission mechanism and a traveling wheel. When the dragging part of the torque shunting thin coal layer mining machine works, the output shaft of the traction motor transmits power to the dragging speed reduction box and then transmits the power to the traveling wheel through a multi-stage cylindrical gear and a planetary gear after being subjected to transmission speed reduction; the traveling wheel is meshed with a pin row arranged on an emptying side; and due to the rotation of the traveling wheel, the thin coal layer mining machine can travel. The dragging part is driven by the motor, can meet a requirement on underwell explosion prevention and is simple and compact in overall structure; through the arrangement of torque shunting gear transmission mechanism and gap bridge, the coal passing space is enlarged; a coal layer with the height of 0.65 to 1.3 meters can be mined; a demand for mining the underwell thin coal layer can be met; and the mining efficiency of the underwell thin coal layer and the coal resource production capacity can be improved.

Owner:CHINA UNIV OF MINING & TECH

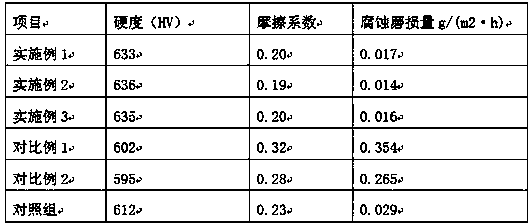

Method for prolonging service life of oil extraction pump for oil field

PendingCN111394760AHigh thermodynamic stabilityNot prone to electrochemical corrosionJewelleryOil fieldElectroplating

The invention relates to the technical field of performance research of pumps, and discloses a method for prolonging the service life of an oil extraction pump for an oil field. Prepared electroplating liquid is electro-deposited onto a pump body to-be-plated piece of the oil extraction pump through an electroplating method to form a dense electroplated coating with the thickness being 17.0-19.0 microns, immersion and flushing of corrosive media can be borne for a long term, and excellent chemical resistance and corrosion resistance are achieved; meanwhile, the prepared coating is hard, the surface friction coefficient is low, scaling is inhibited, and the defect that an existing protection coating cannot solve the problem of stress cracking corrosion caused by the corrosive media of the oil field is overcome; and the binding performance of the coating and a pump body can further be enhanced while the corrosion resistance of the coating is improved, defects such as blistering and falling are avoided, and high actual application value is achieved.

Owner:ANHUI LUYUAN PUMP&VALVE CO LTD

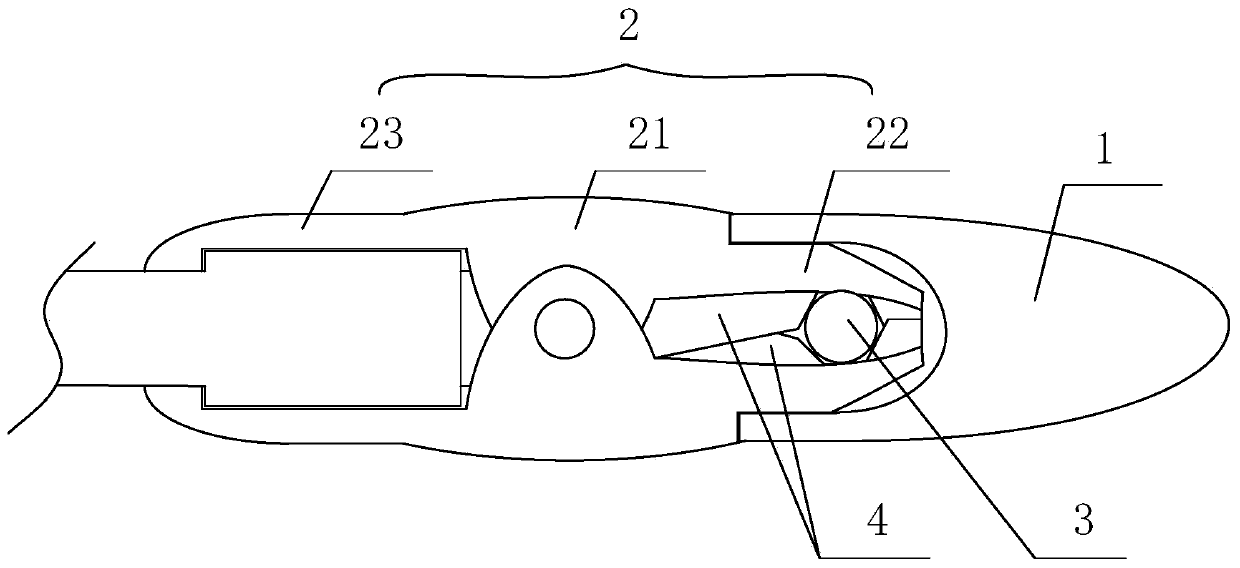

A stable bucket tooth for an excavator

InactiveCN106638760BAchieve fixationEasy to insertSoil-shifting machines/dredgersEngineeringExcavator

The invention discloses a stable type bucket tooth of an excavator. The problem that a pin shaft of a conventional bucket tooth is simple and convenient to insert but extremely inconvenient to withdraw is solved. The stable type bucket tooth disclosed by the invention comprises a tooth seat (2), a tooth tip (1) with pin shaft holes, and a pin shaft (3) connected with the tooth tip (1) and the tooth seat (2) through the pin shaft holes. The stable type bucket tooth is characterized in that a plugging connecting fitting (5) is arranged at one of the pin shaft holes in the tooth tip (1), a slot diameter end (6) is arranged at one end away from the plugging connecting fitting (5), of the pin shaft (3), and a protruding spring fitting (7) matched with the slot diameter end (6) is arranged on the tooth tip (1). The stable type bucket tooth disclosed by the invention has the advantages of being stable in connection, simple in structure, convenient to disassemble and the like.

Owner:永平县建达鑫鑫合金铸造有限公司

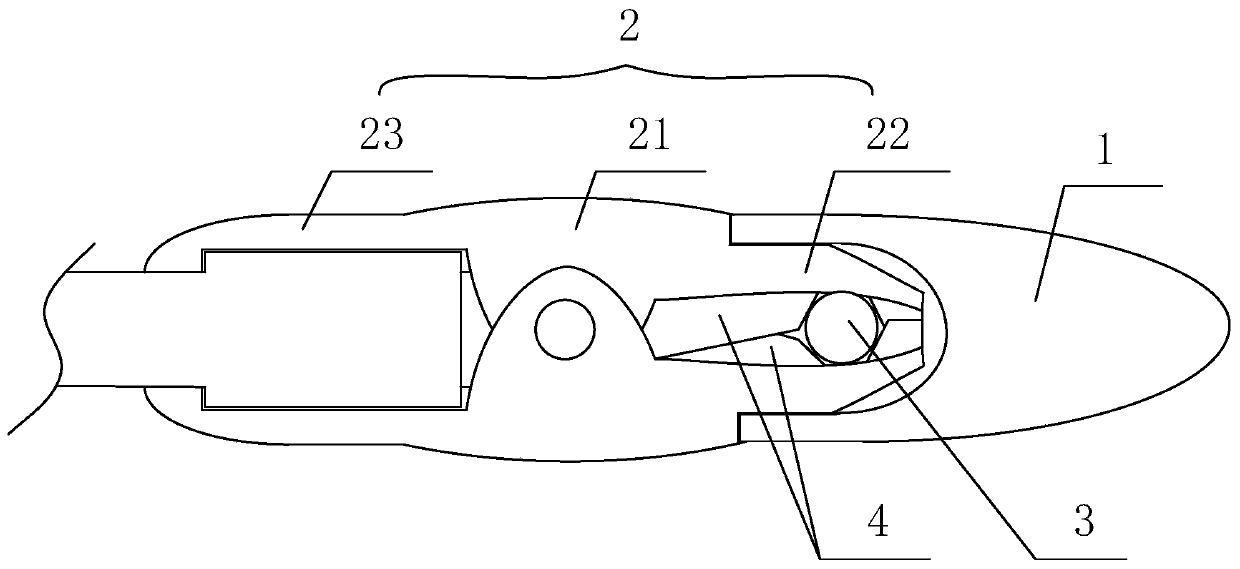

An easy-to-replace bucket tooth installation device

InactiveCN106638761BAchieve separationRealize the assemblySoil-shifting machines/dredgersEngineeringExcavator

The invention discloses a bucket tooth mounting device convenient to change, and solves the problem that existing structure bucket teeth are very inconvenient to change. The bucket tooth mounting device comprises a tooth holder (2), a tip (1) having a pinhole, and a pin (3) connecting the tip (1) and the tooth holder (2) through the pinhole, and is characterized in that the tooth holder (2) comprises a middle hinging portion (21), a tooth end connection portion (22) connected with the tip (1), and a tail connection portion (23) connected with an excavator bucket through the middle hinging portion (21). The bucket tooth mounting device has the advantages of good convenience in separating and assembly operations, good connection stability, simple structure and the like.

Owner:永平县建达鑫鑫合金铸造有限公司

Manufacturing process method of valve seat for fracturing pump

InactiveCN112025059AUniform hardnessImprove product qualityPlasma welding apparatusWelding/cutting media/materialsShale gasProcess engineering

The invention provides a manufacturing process method of a valve seat for a fracturing pump. The method comprises the specific steps of forming a concave notch in the surface area of a valve seat blank, performing surfacing on high-strength alloy powder into the concave notch in a plasma surfacing mode to make the alloy powder melted, mixed, diffused and solidified, and performing self-excited cooling after welding to obtain a high-performance alloy layer of the valve seat for the fracturing pump. According to the method, a plasma surfacing process is adopted to replace a traditional carburizing treatment process, the problems that the depth of a carburized layer is low and the hardness sharply decreases along with the depth of the carburized layer in the carburizing process are avoided, the high-hardness depth of the valve seat can reach 2-3 mm, and the hardness is uniform and will not decrease along with surface abrasion. Therefore, the product quality of the valve seat is improved,the product service life of the valve seat is prolonged, the frequency of replacement or maintenance of the fracturing pump is reduced, the labor intensity of workers is reduced, the product reliability is improved, shutdown or pump stop caused by failure in the operation process is avoided, and the shale gas exploitation requirement is better met.

Owner:江苏艾福泰克能源装备有限公司

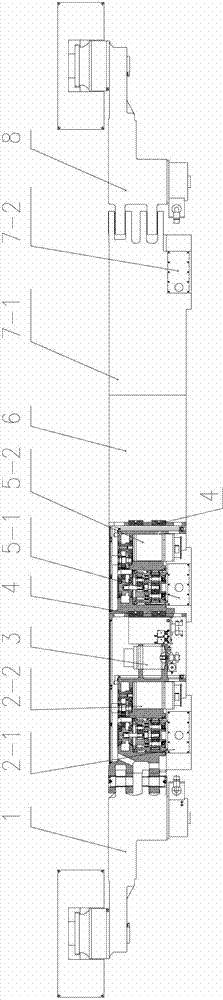

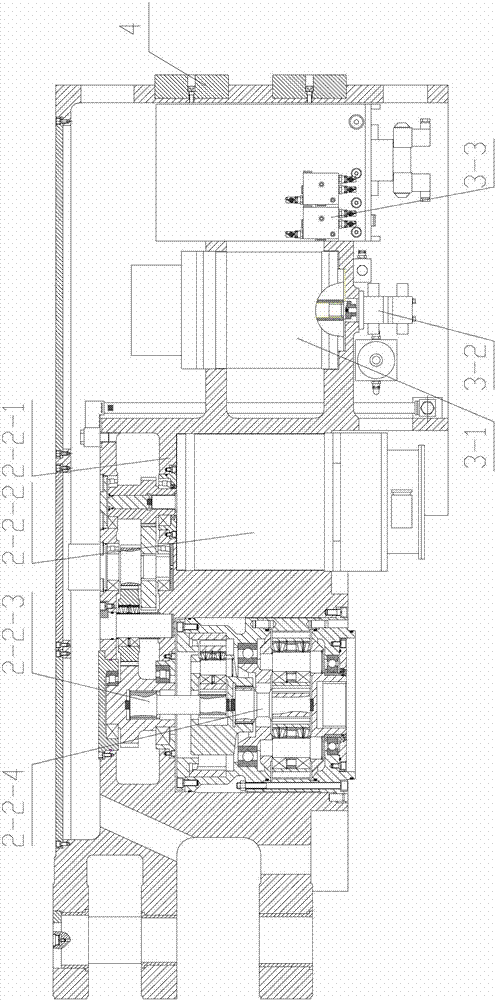

Multi-point driving electric traction coal mining machine

InactiveCN103174416BSolve the problem of mechanized miningMeet mining needsDriving meansPropulsionElectricityEngineering

The invention discloses a multi-point driving electric traction coal mining machine which comprises a left cutting part, an electric control cabinet and a right cutting part, wherein a left traction part is arranged between the left cutting part and the electric control cabinet; a right traction part is arranged between the right cutting part and the electric control cabinet; the left traction part comprises a first fixed box and a second fixed box; the right end of the second fixed box is connected with the electric control cabinet; the left end of the second fixed box is connected with the right end of the first fixed box; the bottom of the second fixed box is connected with a second travelling box; the left end of the first fixed box is connected with the left cutting part; the bottom of the first fixed box is connected with a first travelling box; the right traction part comprises a third fixed box; the left end of the third fixed box is connected with the electric control cabinet; the right end of the third fixed box is connected with the right cutting part; the bottom of the third fixed box is connected with a third travelling box; and the third fixed box and the first fixed box have the same structures and are arranged in a symmetrical way. The coal mining machine is driven by a plurality of points at the same time, meets the mining demands of a down-hole steeply inclined coal seam, and improves the mining efficiency of the down-hole steeply inclined coal seam.

Owner:CHINA UNIV OF MINING & TECH

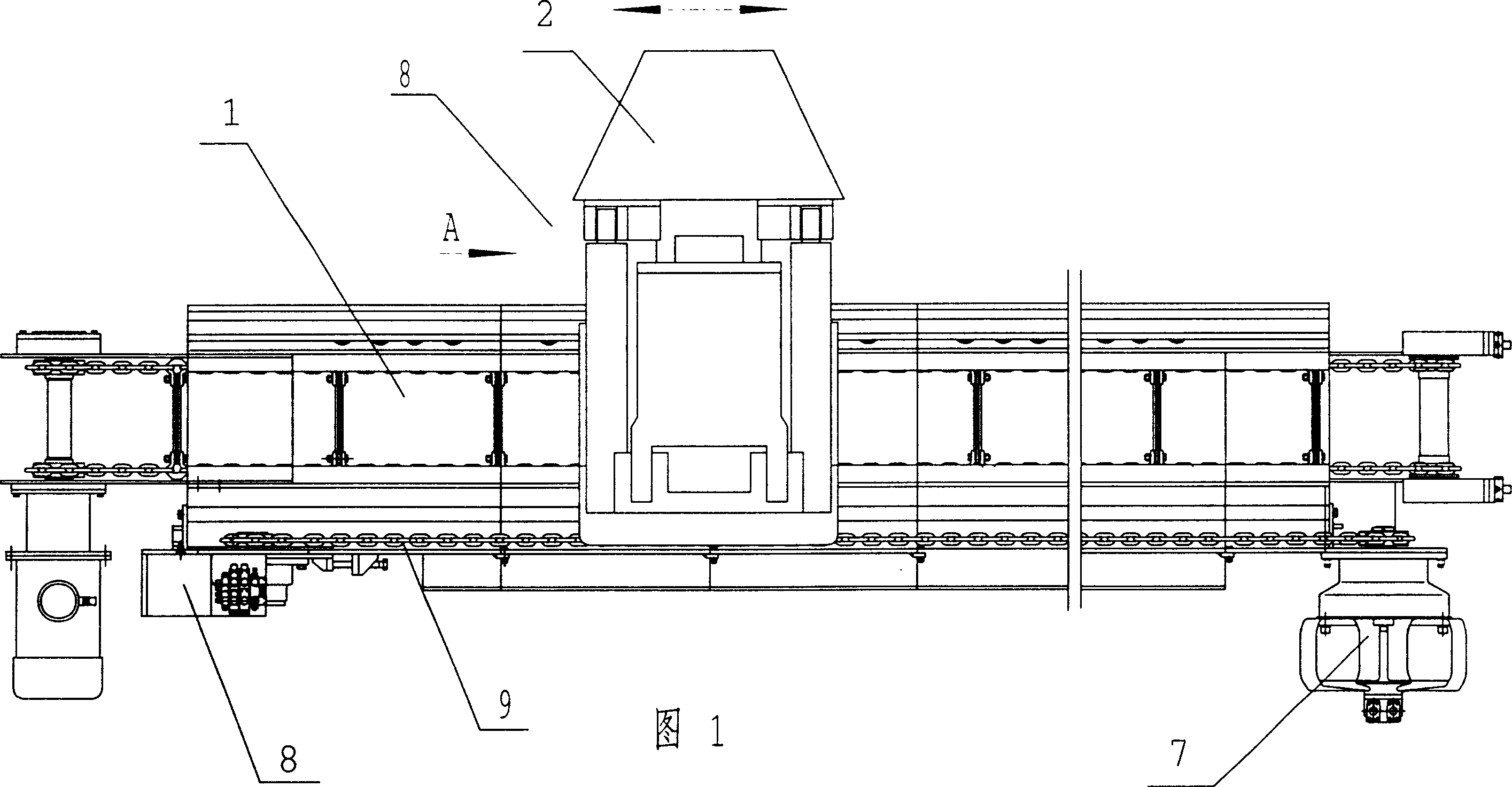

Multi-blade saw mine quarrying machine

InactiveCN101769153BMeet mining requirementsReduce manufacturing costOpen-pit miningCircular discHydraulic ram

The invention relates to a multi-blade saw mine quarrying machine comprising a track and a walking frame, wherein the walking frame walks along the track, the back part of the walking frame is provided with a hydraulic system and a pushing motor, the front part of the walking frame is provided with a working port in which a movable frame is placed, the movable frame is supported on the walking frame by a hydraulic ram, the back part of the movable frame is provided with a working motor, the front end of the movable frame is horizontally connected with a rotating shaft through a bearing brush,a pair of driven pulleys are symmetrically arranged on the rotating shaft, the driven pulleys are connected with driving pulleys of the working motor through pulley sleeves, and more than one disc saw blade is arranged on the rotating shaft at intervals. The quarrying machine has the advantages of compact structure, stability, safe use, integral moulding of mining, no need of secondary processing, low mining and processing cost and wide range of application, and can realize the synchronous mining of multi-channel stone and the control of the specifications of the stone through regulating the walking speed of the walking frame, the height of the movable frame and the distance among a plurality of disc saw blades.

Owner:徐玉贞

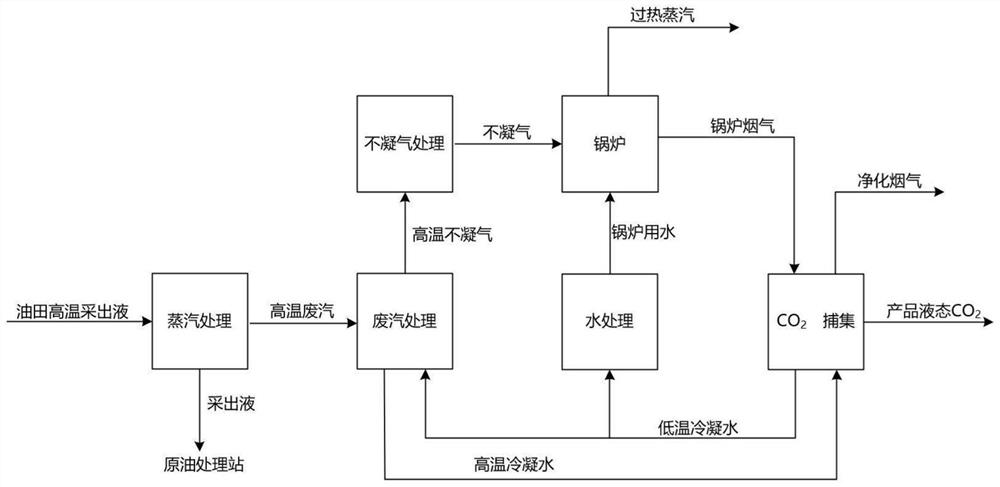

Green low-carbon development system and method for thickened oil

PendingCN114482927AReduce wasteTroubleshoot unusable heat balancesDispersed particle separationFluid removalHeat balanceWater processing

The invention discloses a green low-carbon development system and method for thickened oil, and relates to the technical field of thickened oil development, and the system comprises a waste steam treatment module, a non-condensable gas treatment module, a water treatment module, a CO2 capture module, a boiler and a steam treatment module. Middle-grade waste heat obtained in the oil field high-temperature waste steam treatment process is used as a heat source needed for CO2 capture, flammable non-condensable gas obtained in the high-temperature waste steam treatment process is used for partially replacing boiler fuel, condensate water obtained in the high-temperature waste steam treatment process is used as boiler feed water, waste heat resources are reasonably utilized, and the CO2 capture effect is improved. According to the invention, waste of heat energy is reduced, the heat balance problem that a large amount of waste heat cannot be utilized in the oil extraction process is partially solved, resource utilization of medium-grade waste heat, non-condensable gas and condensed water in high-temperature produced liquid of an oil field can be realized, high-quality superheated steam and liquid CO2 can be provided for production of the oil field, and near-zero emission of CO2 of the whole system is realized at the same time; therefore, green and low-carbon development of the thickened oil is realized.

Owner:西安本清化学技术有限公司 +1

A kind of thick oil hydrothermal cracking catalytic viscosity reducer and preparation method thereof

Owner:PETROCHINA CO LTD

Multi-blade saw mine quarrying machine

InactiveCN101769153AMeet mining requirementsReduce manufacturing costOpen-pit miningCircular discHydraulic ram

The invention relates to a multi-blade saw mine quarrying machine comprising a track and a walking frame, wherein the walking frame walks along the track, the back part of the walking frame is provided with a hydraulic system and a pushing motor, the front part of the walking frame is provided with a working port in which a movable frame is placed, the movable frame is supported on the walking frame by a hydraulic ram, the back part of the movable frame is provided with a working motor, the front end of the movable frame is horizontally connected with a rotating shaft through a bearing brush, a pair of driven pulleys are symmetrically arranged on the rotating shaft, the driven pulleys are connected with driving pulleys of the working motor through pulley sleeves, and more than one disc saw blade is arranged on the rotating shaft at intervals. The quarrying machine has the advantages of compact structure, stability, safe use, integral moulding of mining, no need of secondary processing, low mining and processing cost and wide range of application, and can realize the synchronous mining of multi-channel stone and the control of the specifications of the stone through regulating the walking speed of the walking frame, the height of the movable frame and the distance among a plurality of disc saw blades.

Owner:徐玉贞

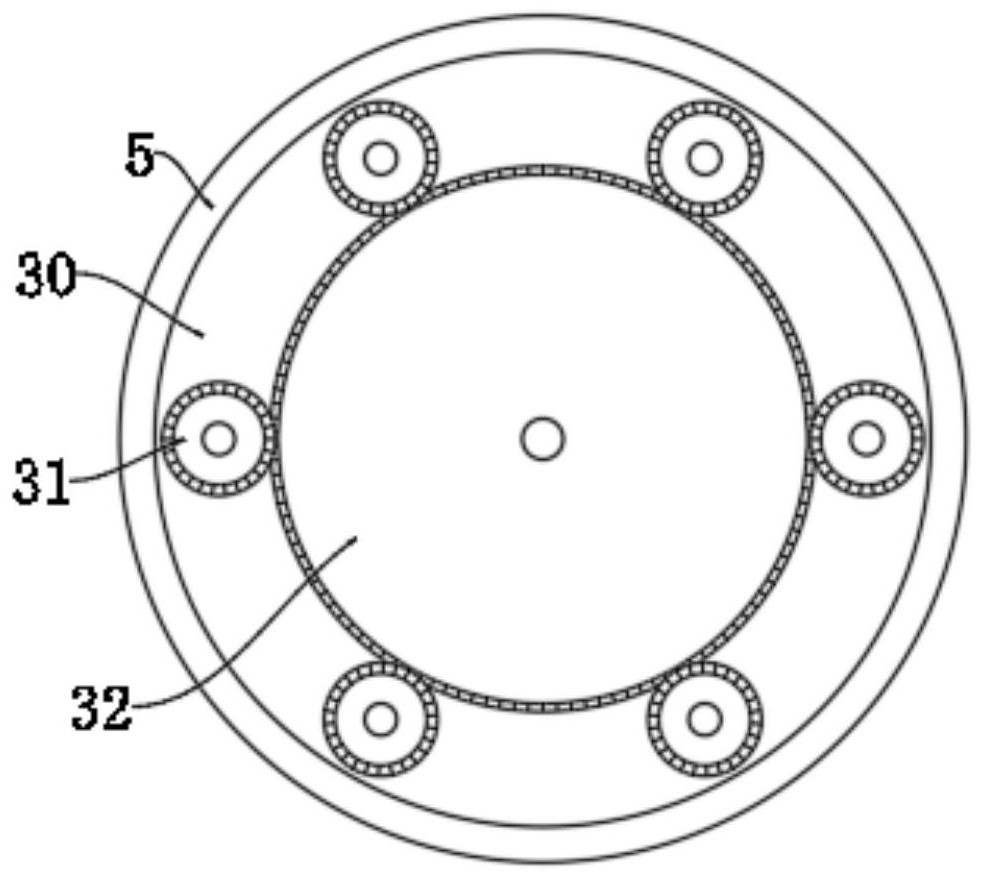

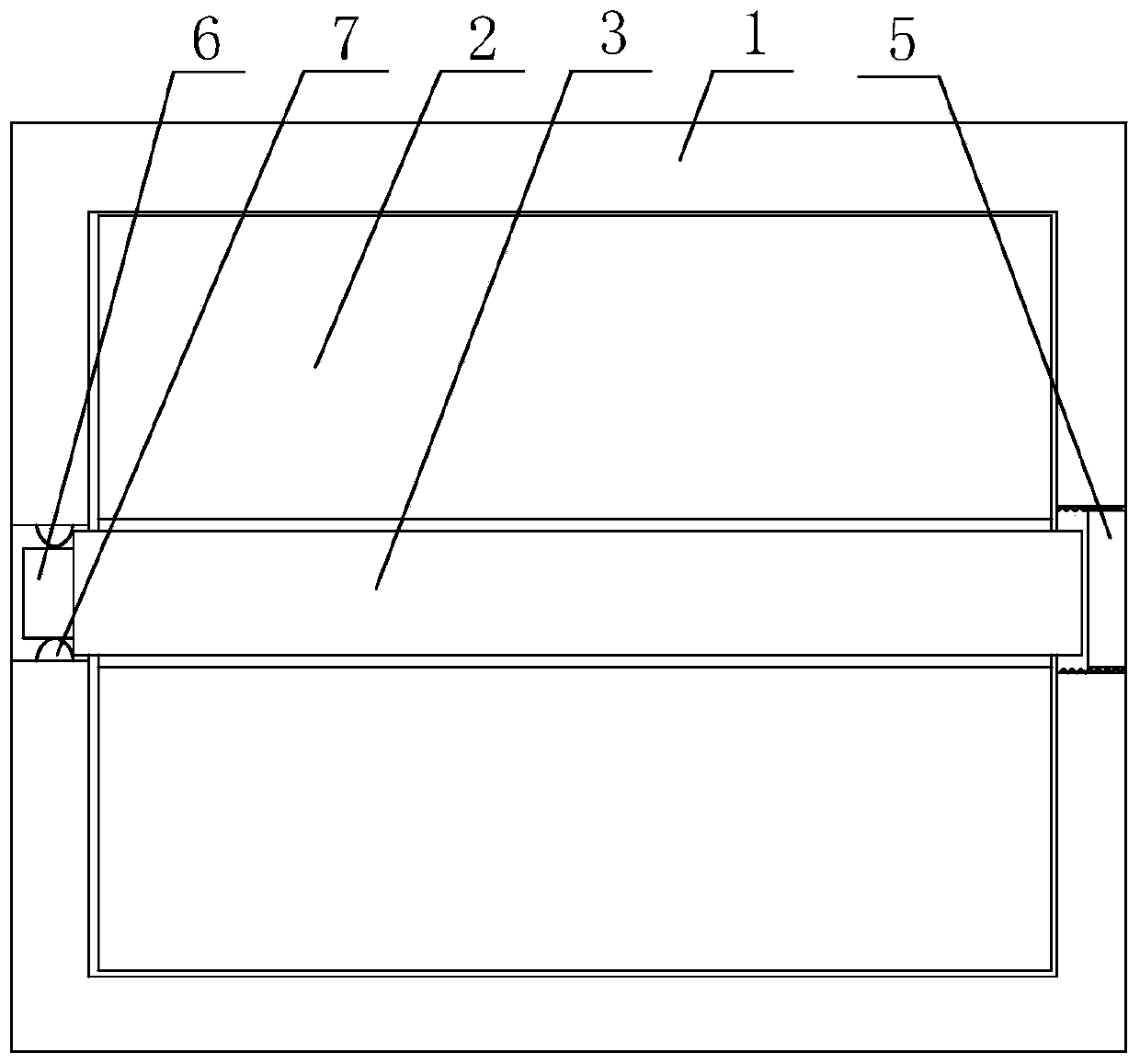

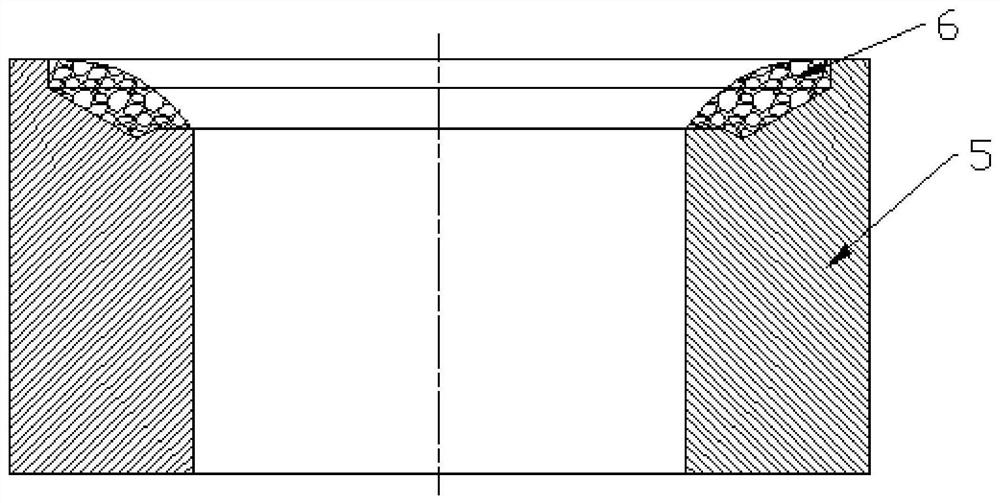

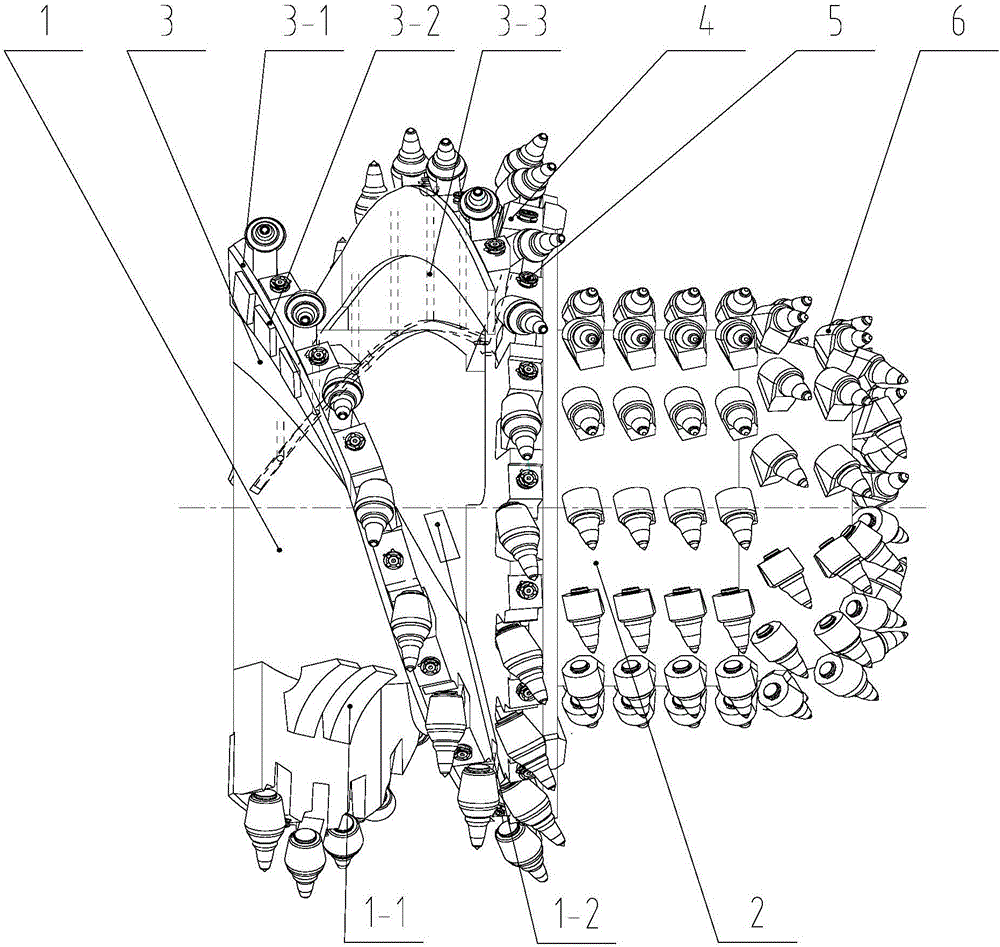

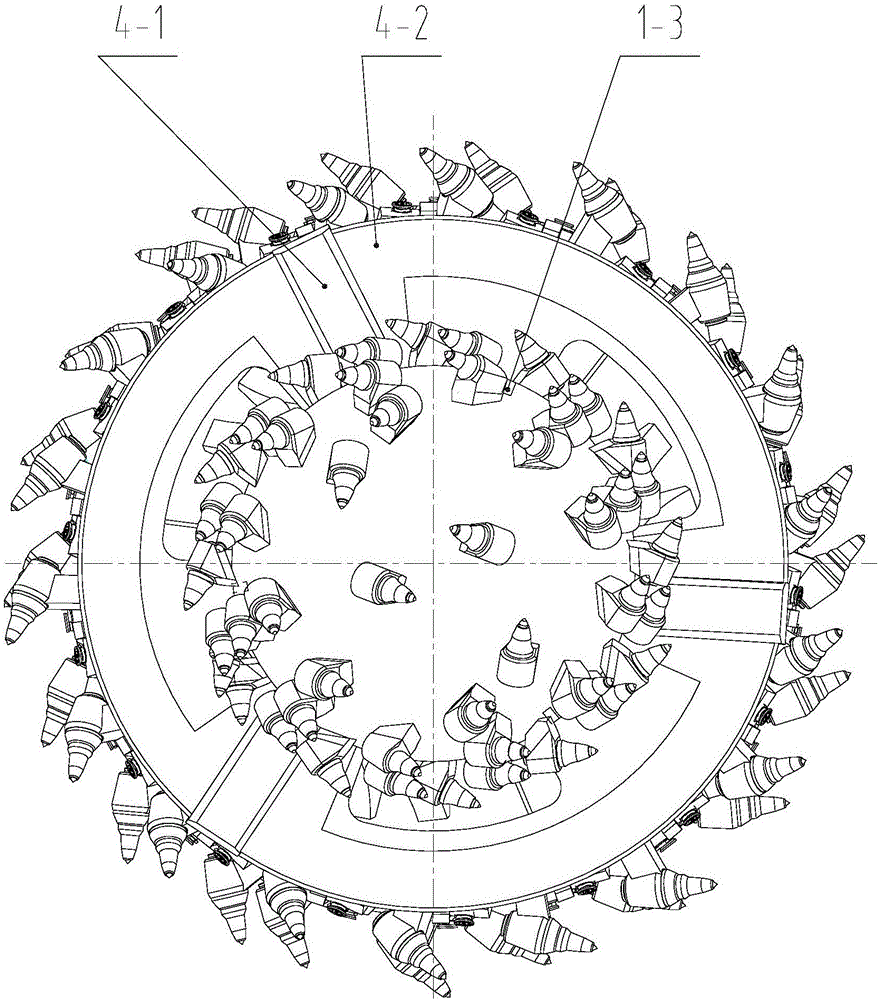

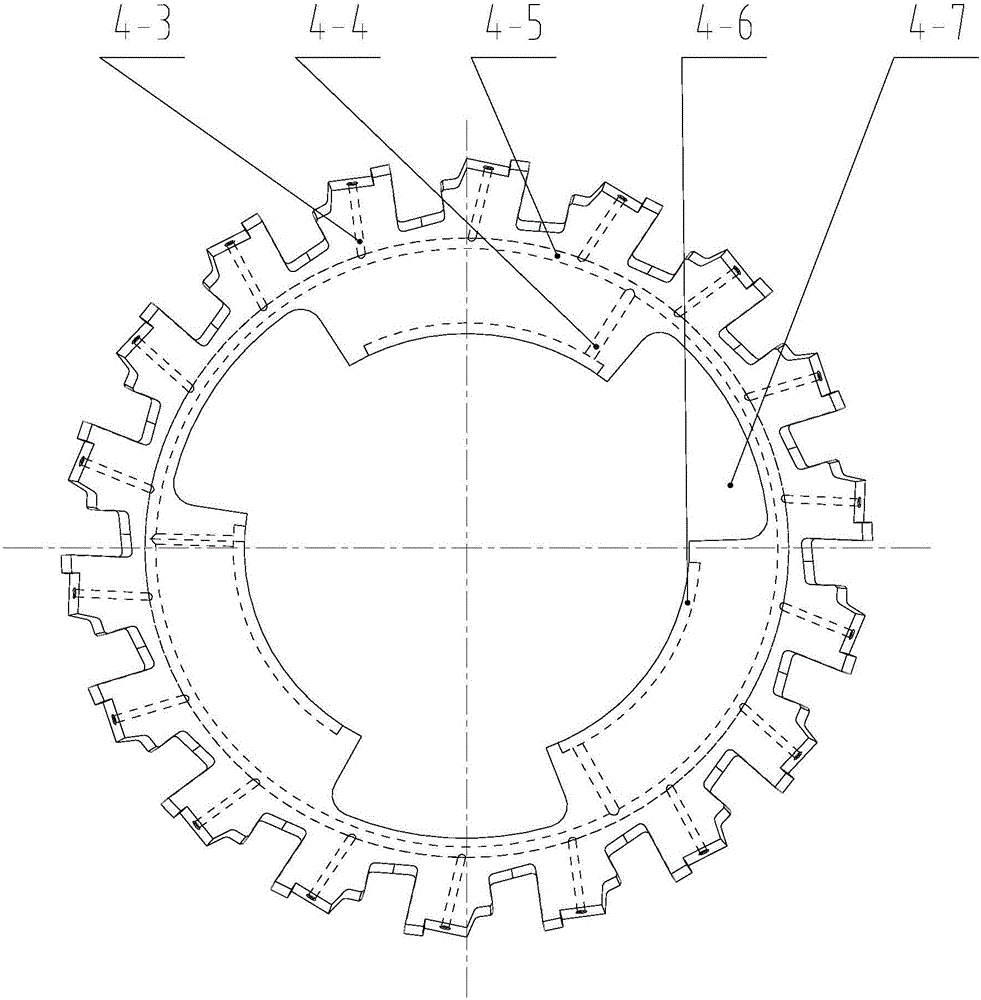

Deep Well High Stress Coal Rock Ladder Roller

ActiveCN104712334BGuaranteed water supplyMeet mining needsSlitting machinesCutting machinesMotor driveSpiral blade

Disclosed is a deep-well high-stress coal rock stepped drum, comprising a rear cylinder hub (1), a front cylinder hub (2), a spiral blade (3), an end plate (4), nozzles (5) and pick-shaped cutters (6). The end plate (4) is arranged at the joint of the rear cylinder hub (1) and the front cylinder hub (2), the spiral blade (3) connected to the end plate (4) is arranged on the rear cylinder hub (1), a plurality of pick-shaped cutters (6) and nozzles (5) are distributed on the outer edge of the spiral blade (3) and the end plate (4) at intervals, and the pick-shaped cutters (6) in spiral arrangement are fixed on the front cylinder hub (2); and the end plate (4) is provided with an annular water delivery channel (4-5), and is provided with a nozzle water delivery channel (4-3), a wheel hub water delivery channel (4-4) and an end plate blade water delivery channel (4-6) which are in communication with the annular water delivery channel (4-5). With the drum, the mechanical mining problem of deep-well high-stress coal rock is solved, and deep-well high-stress coal rock cutting efficiency is increased in the case that explosion-proof motor power is not greatly increased. The structure uses an explosion-proof motor drive, such that underground explosion-proof requirements can be satisfied, and the shearer drum has a simple and compact structure.

Owner:江苏中矿汇弘科技有限公司

Three-down coal mining method for concentrated filling roadway in near-horizontal extra-thick coal seam and step-by-step mining

ActiveCN110145308BEasy to transportGuaranteed stabilityUnderground miningSurface miningMining engineeringCoal pillar

The invention provides a centralized filling roadway layering stepping mining and filling "three under" mining method for an approximately horizontal superhigh seam, and relates to the mining method technology field. The approximately horizontal superhigh seam is first divided into multiple mining layers, and the centralized filling roadway layering stepping mining and filling "three under" miningmethod for the approximately horizontal superhigh seam specially includes steps: A, arranging a centralized filling roadway along a coal seam roof, arranging a transport gate road along a coal seam floor, and opening a cutting hole at a dip angle of 5-7 degrees on a boundary of a working face; B, by arranging a centralized filling inclined roadway, a filling chamber and the centralized filling roadway in communicating mode, forming a transport gate road-cutting hole-centralized filling inclined roadway-filling chamber-centralized filling roadway air return system; C, alternately arranging a plurality of branch roadways Z and a plurality of coal pillars M at the lowest mining layer along the cutting hole, completing mining of the branch roadways Z first, and filling the branch roadways Z;D, mining the coal pillars M after completing filling of the roadways Z, and filling the coal pillar areas, a transport roadway and the transport gate road; E, repeating the steps from A to D, and completing mining of all the mining layers. The centralized filling roadway layering stepping mining and filling "three under" mining method for the approximately horizontal superhigh seam achieves filling and mining of the approximately horizontal superhigh seam, and is safe and efficient.

Owner:山东威斯特矿山工程科技股份有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com