Steel for petroleum valve body and preparation method thereof

A valve body and petroleum technology, applied in metal rolling, manufacturing tools, temperature control, etc., can solve problems such as unsatisfactory impact energy, achieve good comprehensive mechanical properties, improve internal quality, and improve the effect of low-temperature impact performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

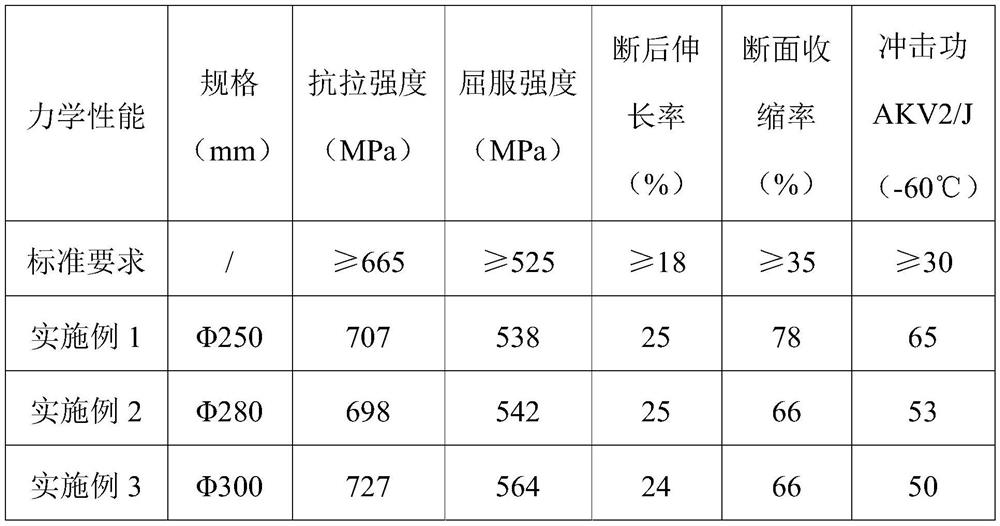

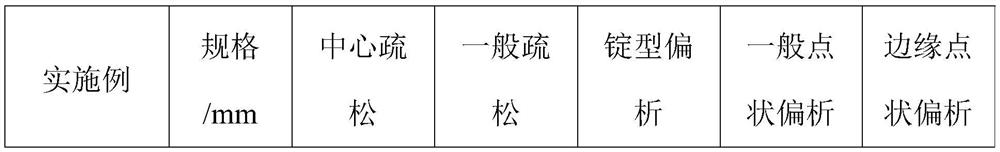

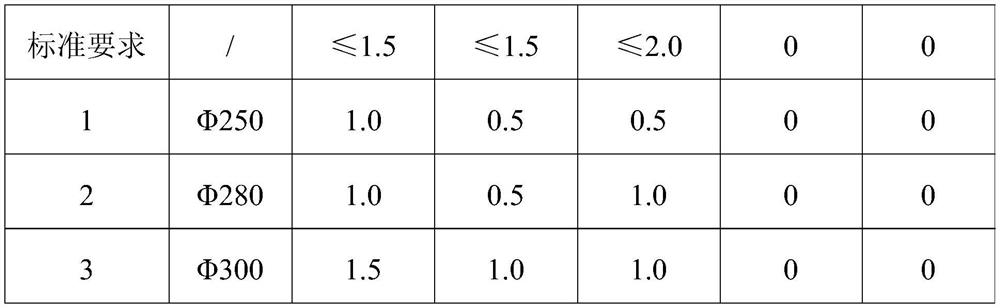

Embodiment 1

[0024] A steel for petroleum valve body, including the following components by mass percentage: C: 0.32%, Si: 0.25%, Mn: 0.73%, P: 0.008%, S: 0.003%, Cr: 1.02%, Ni: 0.21%, Mo: 0.23%, Cu: 0.02%, Al: 0.025%, V: 0.016%, Nb: 0.010%, As: 0.0036%, Sn: 0.0007%, Sb: 0.0024%, Bi: 0.0006%, Pb: 0.001%, Ti: 0.0017%, H: 0.00008%, O: 0.0015%, N: 0.0066%, and others are Fe and unavoidable impurities.

[0025] The preparation method of the steel for the above-mentioned petroleum valve body comprises the following steps:

[0026] (1) electric furnace smelting

[0027] It is smelted in a 110-ton ultra-high-power electric arc furnace. In order to control harmful elements such as As, Sn, Sb, Bi, and Pb in molten steel, high-quality molten iron + scrap steel is selected, and hot-metal hot charging technology is adopted, and the hot-metal hot-charging ratio is ≥80%. . The electric furnace smelting process uses oxygen blowing on the furnace wall and carbon powder injection to stably control the e...

Embodiment 2

[0042] A steel for petroleum valve body, including the following components by mass percentage: C: 0.28%, Si: 0.28%, Mn: 0.76%, P: 0.008%, S: 0.002%, Cr: 1.06%, Ni: 0.48%, Mo: 0.22%, Cu: 0.02%, Al: 0.025%, V: 0.014%, Nb: 0.013%, As: 0.0035%, Sn: 0.0006, Sb: 0.0023, Bi: 0.0006%, Pb: 0.001%, Ti: 0.0016%, H: 0.00010%, O: 0.0011%, N: 0.0057%, and others are Fe and unavoidable impurities.

[0043] The preparation method of steel for above-mentioned petroleum valve body, except following difference, all the other are identical with embodiment 1,

[0044] (1) In the electric furnace smelting step: tapping end point C: 0.11%, tapping temperature: 1620°C.

[0045] (2) In the LF refining step: the retention time of white slag is 55 minutes.

[0046] (3) In the VD vacuum treatment step: the vacuum degree is 47Pa, the holding time is 19min, and the soft blowing time is 46min.

[0047] (4) In the continuous casting step: the degree of superheat is 23°C.

[0048] (5) In the rolling step...

Embodiment 3

[0050] A steel for petroleum valve body, including the following components by mass percentage: C: 0.31%, Si: 0.30%, Mn: 0.75%, P: 0.004%, S: 0.002%, Cr: 1.08%, Ni: 0.35%, Mo: 0.23%, Cu: 0.01%, Al: 0.026%, V: 0.011%, Nb: 0.018%, As: 0.0034%, Sn: 0.0005%, Sb: 0.0022%, Bi: 0.0006%, Pb: 0.001%, Ti: 0.0015%, H: 0.00007%, O: 0.0007%, N: 0.0059%, and others are Fe and unavoidable impurities.

[0051] The preparation method of steel for above-mentioned petroleum valve body, except following difference, all the other are identical with embodiment 1,

[0052] (1) In the electric furnace smelting step: tapping end point C: 0.14%, tapping temperature: 1624°C.

[0053] (2) In the LF refining step: the retention time of white slag is 60 minutes.

[0054] (3) In the VD vacuum treatment step: the vacuum degree is 50Pa, the holding time is 17min, and the soft blowing time is 37min.

[0055] (4) In the continuous casting step: degree of superheat: 25°C.

[0056] (5) In the rolling step: th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com