Post-treatment method for precipitation strengthening metal additive manufacturing thin-wall component without solid solution

A thin-walled component and metal additive technology, which is applied in the direction of manufacturing tools, additive manufacturing, additive processing, etc., can solve problems such as deformation, and achieve the effects of reducing energy consumption, accelerating precipitation behavior, and shortening time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

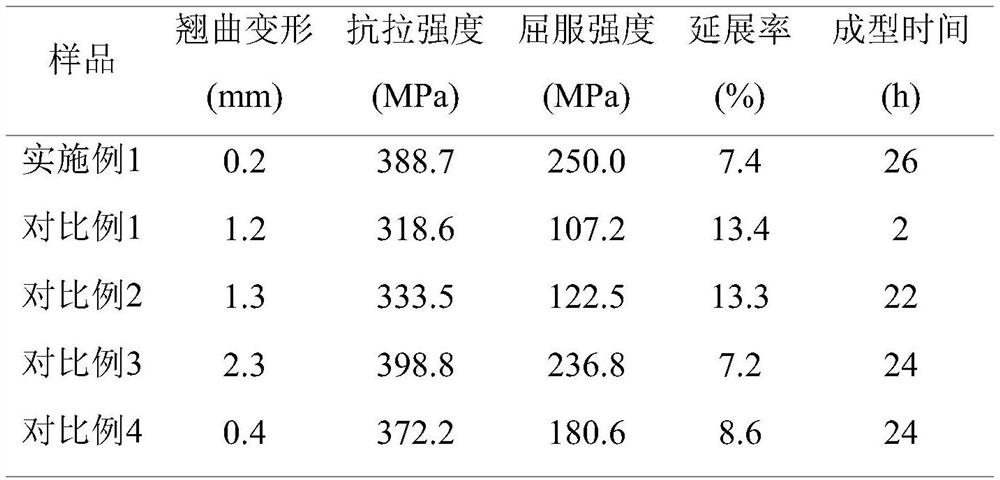

Examples

Embodiment 1

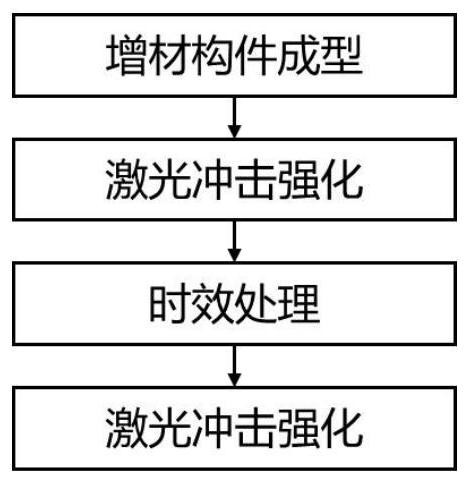

[0022] Embodiment 1, with reference to figure 1 , a solution-free precipitation strengthening metal additive manufacturing thin-walled component post-processing method, comprising the following steps:

[0023] Step 1. Additive manufacturing of thin-walled components:

[0024] In this embodiment, computer CAD software is used for three-dimensional modeling to obtain a thin-walled component with a size of 100mm*5mm*50mm, and the model is layered and path-planned using the slice layer software of the arc fuse metal additive manufacturing system;

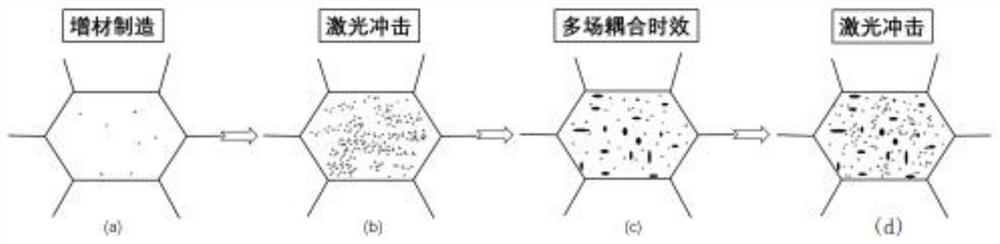

[0025] Carry out the arc fuse additive manufacturing process, choose 2319 aluminum alloy wire as the raw material, the diameter of the wire is 1.2mm, the shielding gas is argon, and a well-formed thin-walled component with a thickness of 5mm, a height of 30mm, and a length of 80mm is obtained. After the fabrication is completed, there are a small amount of dislocations and precipitated phases inside the thin-walled components, such as ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Spot diameter | aaaaa | aaaaa |

| Wavelength | aaaaa | aaaaa |

| Pulse width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com