Manufacturing process method of valve seat for fracturing pump

A manufacturing process and technology for fracturing pumps, which is applied in the field of valve seat manufacturing process for fracturing pumps, can solve the problems of repair layer peeling, delamination and wear, and unsatisfactory results, so as to improve product life, uniform hardness, and reduce replacement The effect of the number of overhauls

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

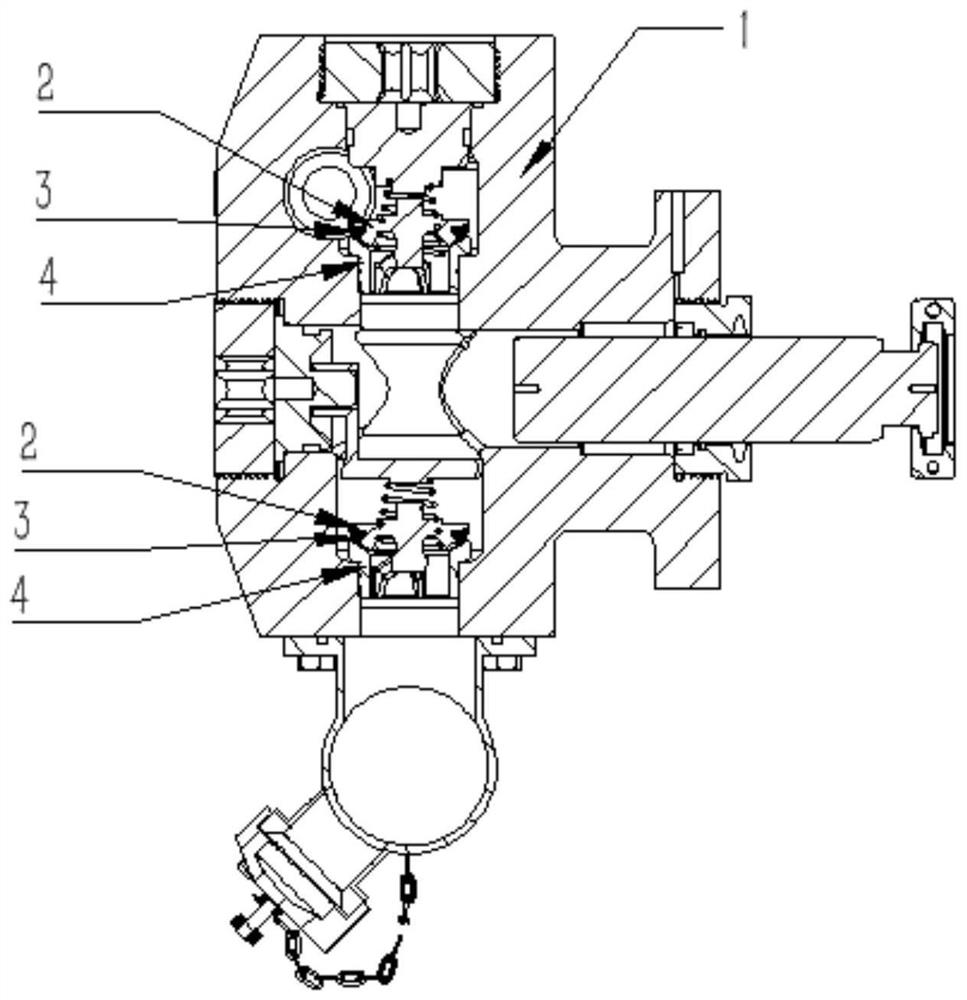

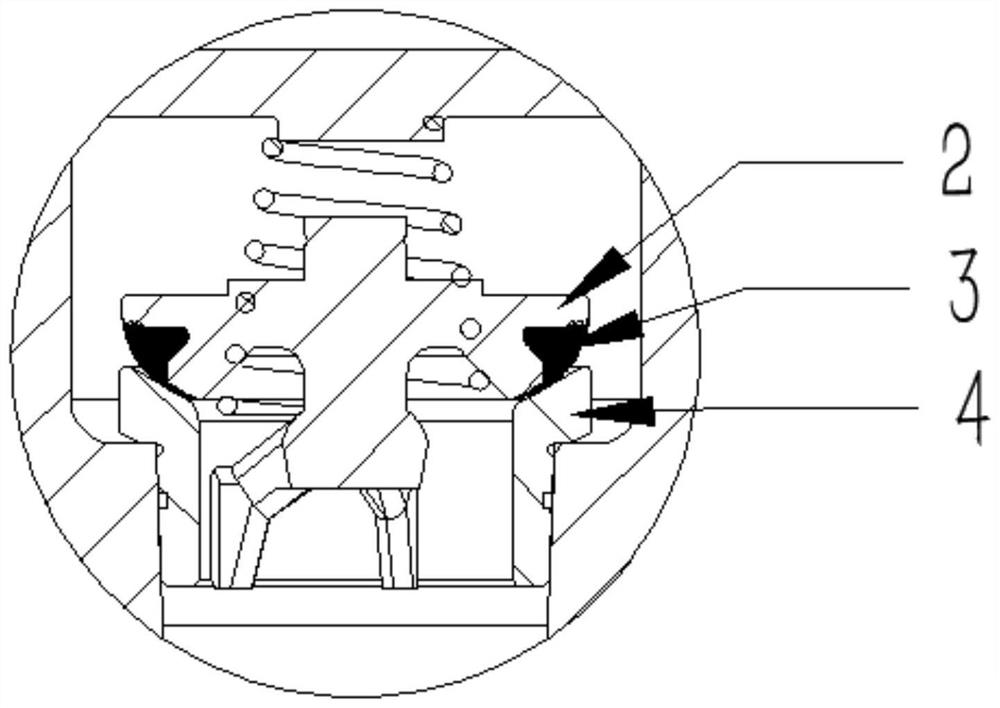

[0014] The following will further describe the accompanying drawings of the present invention in conjunction with the embodiments.

[0015] For the position valve rubber 3 where the valve body 2 of the hydraulic cylinder 1 is in contact with the valve seat 4, wear is prone to occur during the working process. When repairing after wear, the conventional technology is to use surface carburizing treatment to improve the surface hardness, but When the surface hardness meets the requirements, there will be a problem that the hardness will drop sharply with the depth of the carburized layer, and the depth of the carburized layer is shallow, so the service life is low. In order to solve this problem, the welding method of plasma surfacing is used in the present invention. Surfacing repair.

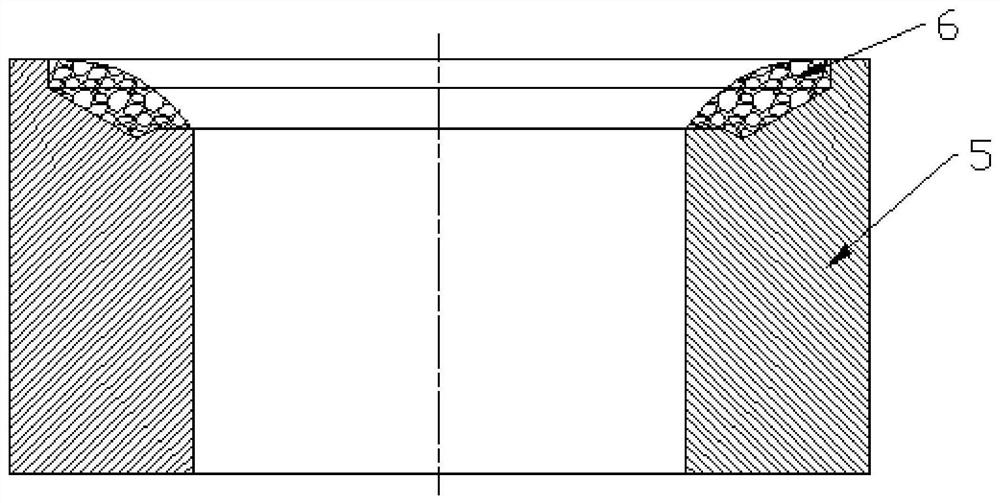

[0016] On the blank of the valve seat 4, a concave groove is left in the contact surface area, and the high-strength alloy powder is surfacing welded in the concave groove by a plasma surfacing p...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com