Gas well storage type integrated layered production allocation pressure gauge

A storage type and pressure measuring instrument technology, which is applied in the direction of measurement, production fluid, wellbore/well components, etc., can solve the problems of inability to realize long-term pressure monitoring and production capacity allocation at the same time, and achieve the effect of avoiding interlayer interference and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

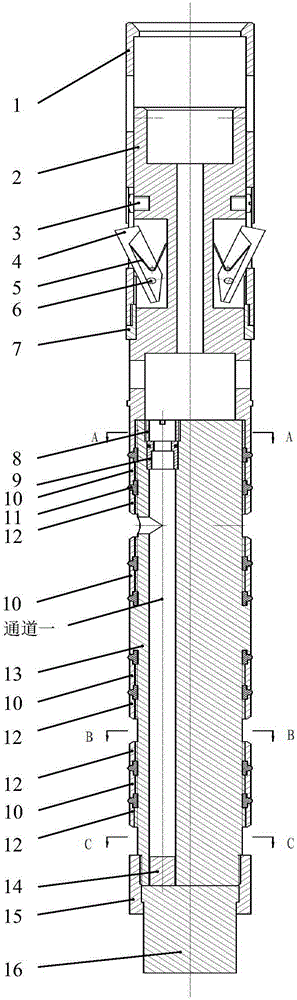

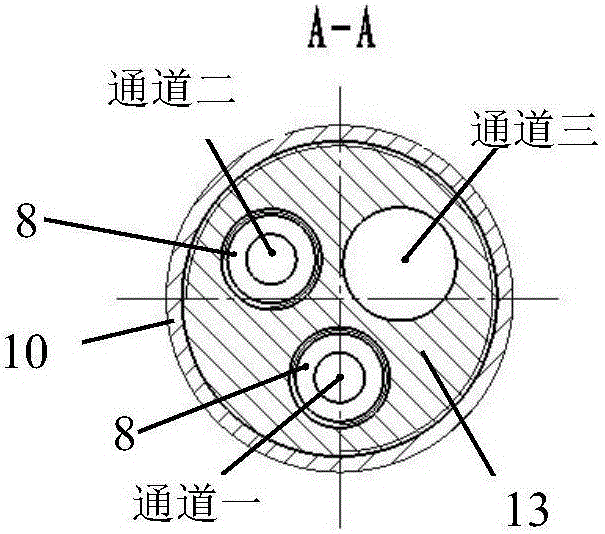

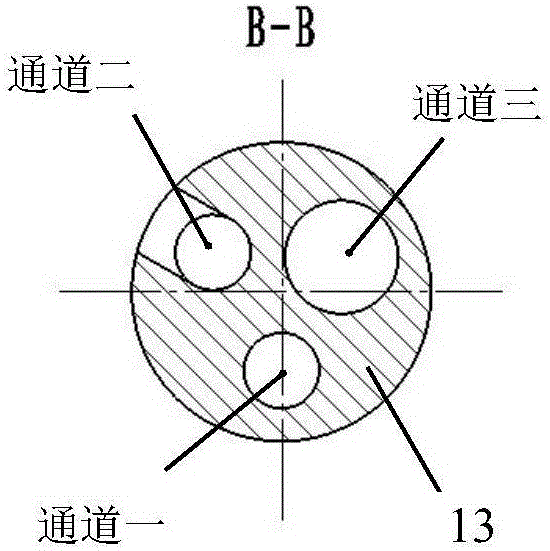

[0015] Specific embodiments: The present invention will be further described in detail below in conjunction with the accompanying drawings: it consists of a fishing joint 1, a positioning body 2, an anti-rotation pin 3, a positioning scissors 4, a torsion spring 5, a scissors pin 6, an adjustment sleeve 7, a pressure cap 8, Air nozzle 9, adjusting ring 10, sealing packing 11, pressure ring 12, distribution main body 13, sensor 14, spare cap 15 and pressure gauge cabin 16; wherein the salvage joint 1 is threadedly connected with the adjusting sleeve 7, and they are set in the On the outer wall of the positioning body 2, the anti-rotation pin 3 passes through the side hole of the fishing joint 1 and is fixed on the upper end of the positioning body 2, the positioning scissors 4 are fixed in the slot of the positioning body 2 by the scissor pin 6, and the torsion spring 5 is installed on the positioning scissors 4, the lower end of the positioning body 2 is threadedly connected to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com