Method for prolonging service life of oil extraction pump for oil field

A technology for oil production pumps and longevity, which is applied in jewelry, etc., can solve the problems that the rapid corrosion process cannot play an effective protective role, and the anti-corrosion coating cannot overcome stress cracking corrosion, so as to overcome stress cracking corrosion, suppress uniform corrosion, and prevent corrosion. The effect of electrochemical corrosion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

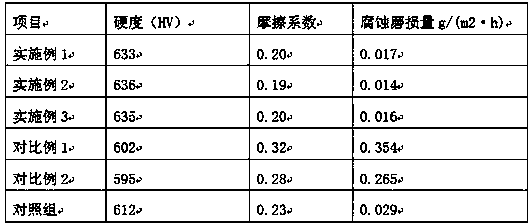

Examples

Embodiment 1

[0018] A method for improving the service life of an oil recovery pump used in an oil field, specifically, comprising the following process steps:

[0019] S1: Grind the metal surface of the pump body, use 200-mesh, 320-mesh, and 600-mesh sandpaper in sequence to remove the surface scale, then use acetone solution to ultrasonically clean for 10 minutes to remove surface oil stains, and dry in a 90°C drying oven for 10 minutes. hours; waiting for plating;

[0020] S2: Preparation of electroplating solution: Weigh silicon carbide powder and manganese oxide powder according to the mass ratio of 6.0:2.5, place them in a vibrating mill, vibrate and mix for 4 hours, and stop for 10 minutes every 30 minutes during the vibration, and mix the mixed The powder is taken out, and 1.4 times the volume of polyvinyl alcohol solution with a mass concentration of 3.0% is added to the powder, placed in a mixer and mixed at high speed for 20 minutes at a mixing speed of 3600 rpm, and passed thro...

Embodiment 2

[0028] A method for improving the service life of an oil recovery pump used in an oil field, specifically, comprising the following process steps:

[0029] S1: Grind the metal surface of the pump body of the oil production pump, use 200-mesh, 320-mesh, and 600-mesh sandpaper in sequence to remove the surface scale, then use acetone solution to ultrasonically clean for 12 minutes to remove surface oil stains, and dry in a 92°C drying oven for 11 hours; waiting for plating;

[0030] S2: Preparation of electroplating solution: Weigh silicon carbide powder and manganese oxide powder according to the mass ratio of 6.3:2.6, place them in a vibrating mill, vibrate and mix for 4.5 hours, and stop for 12 minutes every 35 minutes of vibration during the period. The powder is taken out, and 1.5 times the volume of polyvinyl alcohol solution with a mass concentration of 3.3% is added to the powder, placed in a mixer and mixed at high speed for 25 minutes at a mixing speed of 3700 rpm, and...

Embodiment 3

[0038] A method for improving the service life of an oil recovery pump used in an oil field, specifically, comprising the following process steps:

[0039] S1: Grind the metal surface of the oil production pump body, use 200-mesh, 320-mesh, and 600-mesh sandpaper in sequence to remove the surface scale, then use acetone solution to ultrasonically clean for 15 minutes to remove surface oil stains, and dry in a 95°C drying oven for 12 hours; waiting for plating;

[0040] S2: Preparation of electroplating solution: Weigh silicon carbide powder and manganese oxide powder according to the mass ratio of 6.5:2.8, place them in a vibrating mill, vibrate and mix for 5 hours, and stop for 15 minutes every 40 minutes during the vibration, and mix the mixed The powder is taken out, and 1.6 times the volume of polyvinyl alcohol solution with a mass concentration of 3.5% is added to the powder, placed in a mixer and mixed at high speed for 30 minutes at a mixing speed of 3800 rpm, and passe...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com