Three-down coal mining method for concentrated filling roadway in near-horizontal extra-thick coal seam and step-by-step mining

A technology of extra-thick coal seam and thick coal seam, which is applied in the field of three-down coal mining, can solve the problems of top-coal caving mining filling difficulties, unsuitability for three-down mining, and difficulty in mining connection, so as to improve mining efficiency and economic benefits, and save mining Cost, the effect of improving mining efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

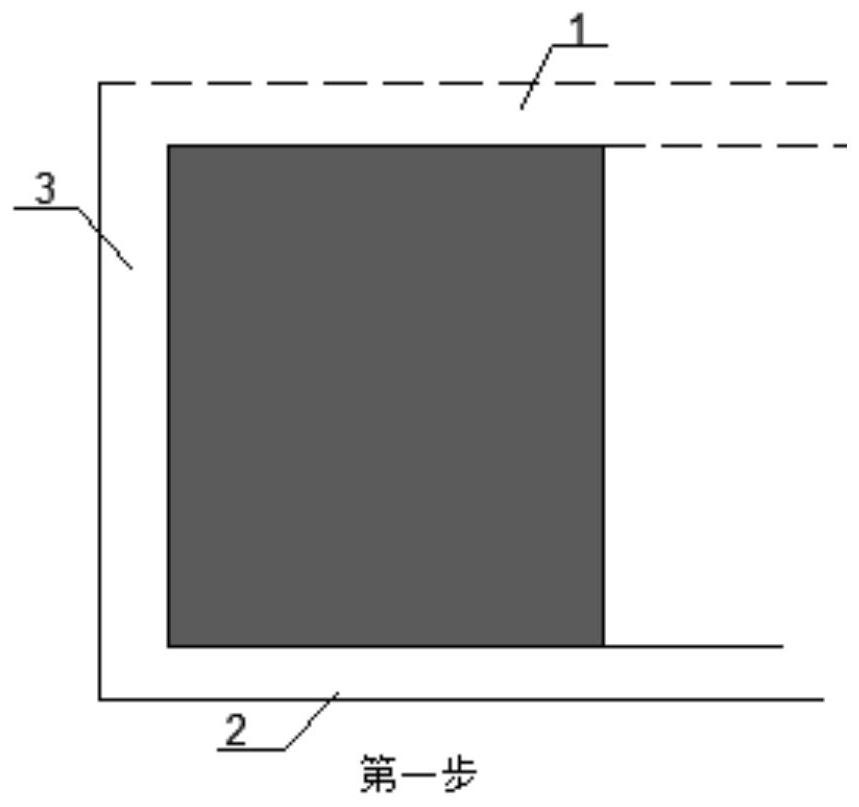

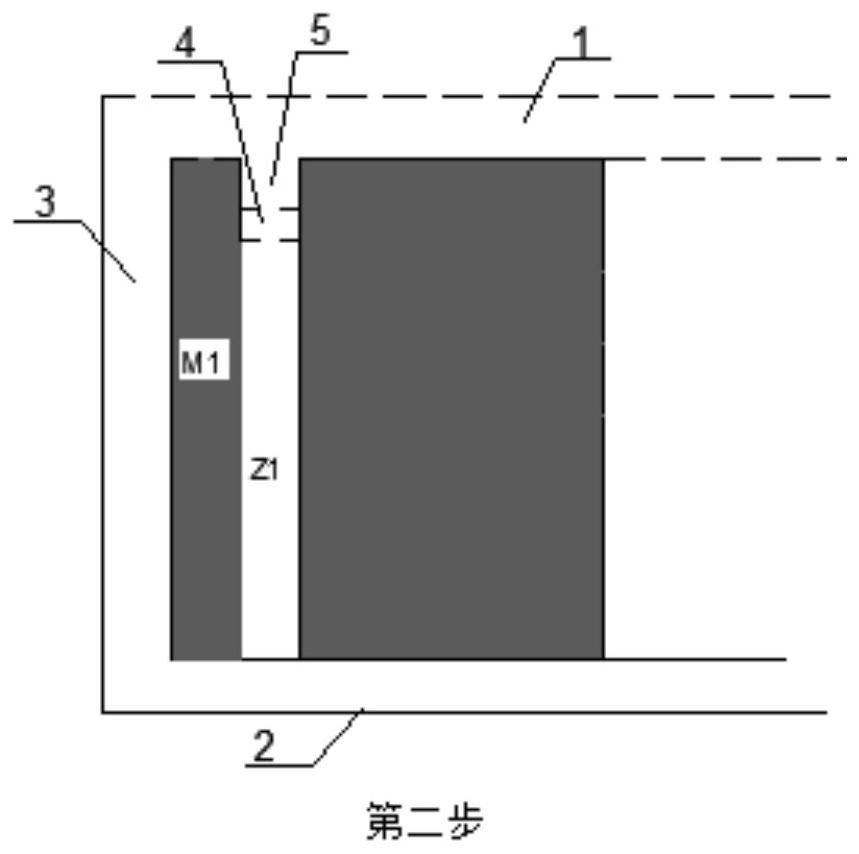

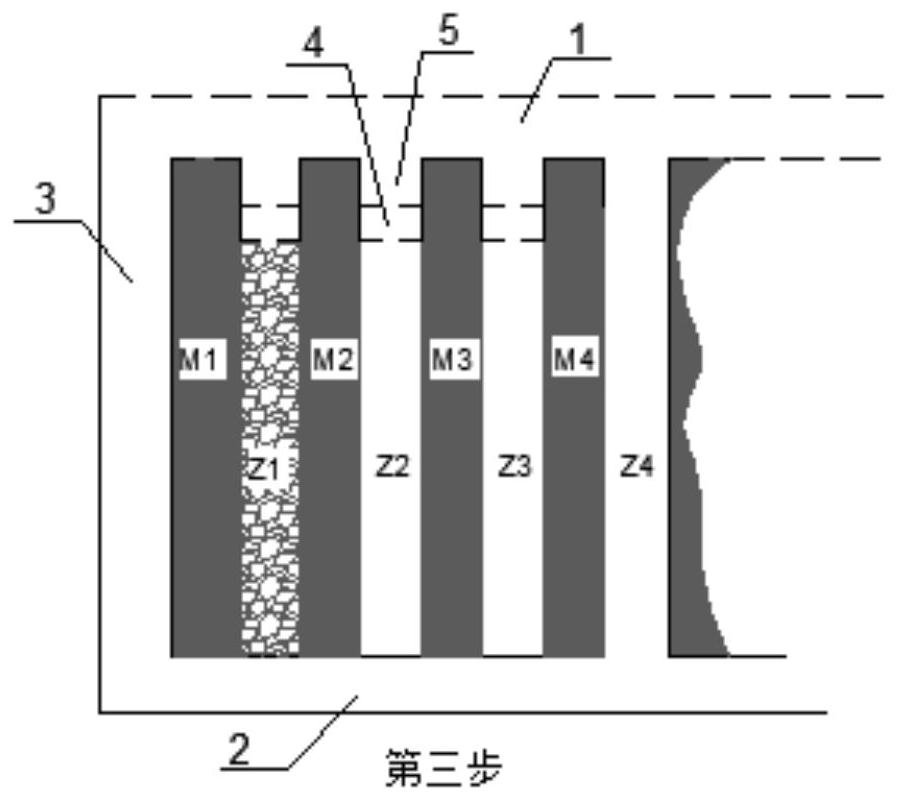

[0031] Three-lowering coal-cutting law, a layering of the collision of the thick coal seam concentration, such as Figure 1 to 6 As shown, the thick coal seam is divided into multiple mining layers, and the specific steps include:

[0032] Step A. Concentrate along the coal grade top plate 1, arrange the transport order of transport along the coal seam floor, and cut the eye 3 in the working surface boundary of 5 to 7 °. Specifically, it is cut from the transport ordering groove 2, and the length of the open eye 3 is specifically determined according to the filling capacity of the lane-filled device.

[0033] Step B. By setting the concentrated filling lane 4 and the filling chamber 5 and the concentrated filling alley 1, wherein the inclination angle of the filled lane 4 is 50 to 60 °, using the inclination angle to achieve the self-slip material, and can be divided The layered filling service of the laminated layer is formed, forming a transport tank 2-cutting 3-concentrated fill...

Embodiment 2

[0040]In order to further illustrate the beneficial effects of the coal mining method, solve a further description of this method, a mining has a near level coal seam, its thickness is 24 meters, the mine design capacity is 10 million tons / year, and the coal gangue is 2 million. / Year, industrial squares and government development zones 50 million tons, which effectively solved the problem of coal gangue after using this method. At the same time, the coal gangue is still recycled, and the coal is 18 million tons / year, which has both social benefits and economic benefits.

[0041] The mining process of the mine specifically, a 24-meter-thick coal seam is specifically divided into 5 mining layers, and the bottom-up is sequentially C1, C2, C3, C4 and C5, and each mining layer has a thickness of less than 5 meters. After dividing the boundaries of the work surface, its mining steps include:

[0042] Step A. Centralize the roller along the top plate of the coal seam, arrange the t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com