High efficient short-wall coal-winning machine

A short-wall shearer, high-efficiency technology, applied to cutting machinery, earth drilling and mining, etc., can solve problems such as poor reliability, complex structure, and difficult equipment maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

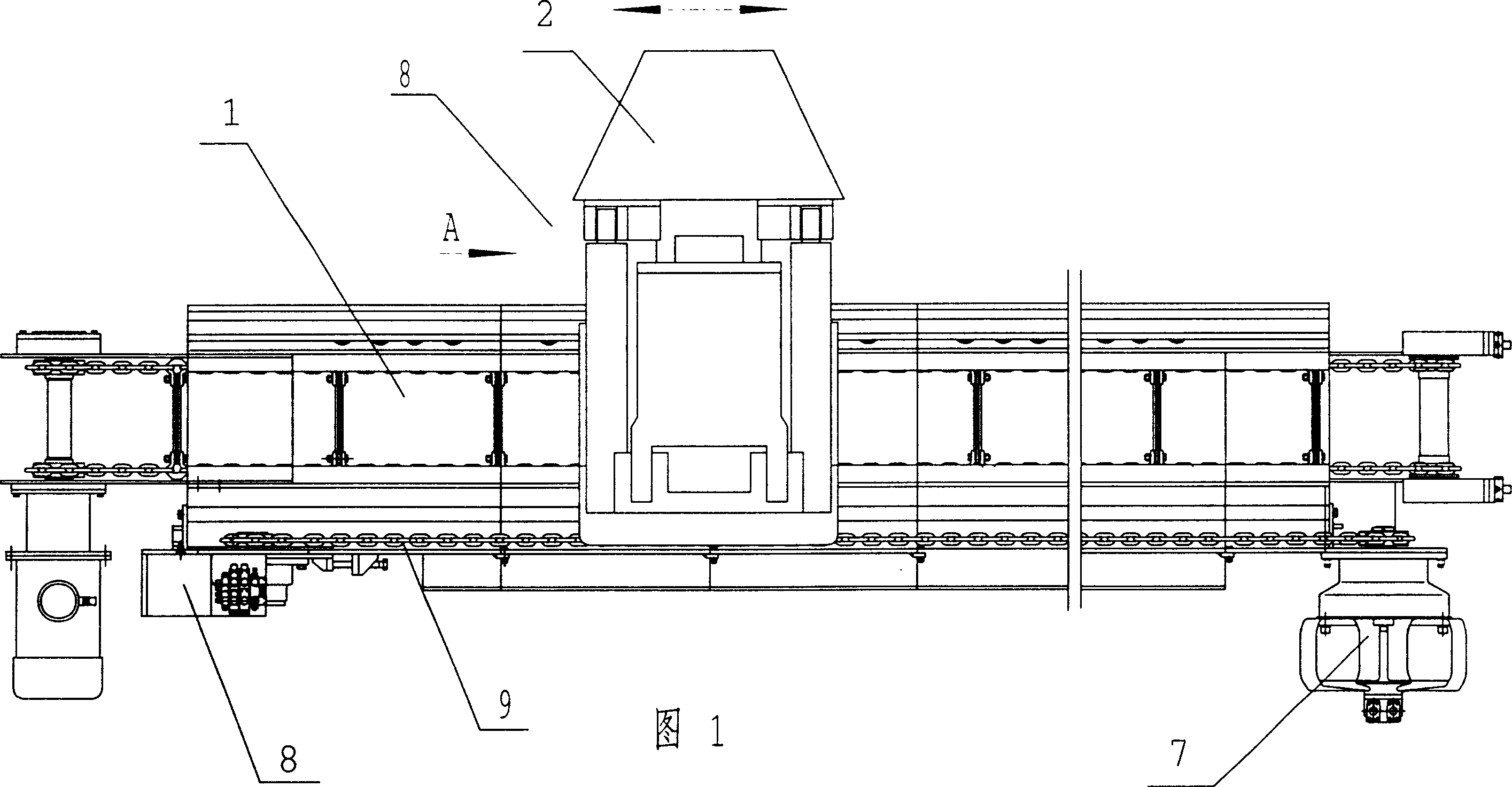

[0011] The present invention relates to a short-wall shearer with a longitudinally swinging cutting arm. The longitudinal swinging means that the cutting arm swings up and down perpendicular to the direction of the coal wall. The wall shearer is also different. After the improvement, the shortest body of the shearer is achieved, and the efficient, safe and comprehensive mechanized mining of the short-wall coal seam is realized. It can be seen from Fig. 1 that the present invention is installed on the bottom conveyor 1, and its sliding chassis 6 rides on the track of the special conveyor, and can slide back and forth along the track. The traction chain 9 is driven, and the traction chain is connected with the sliding underframe, changing the oil-in direction of the motor can realize the reciprocating motion of the cutting part.

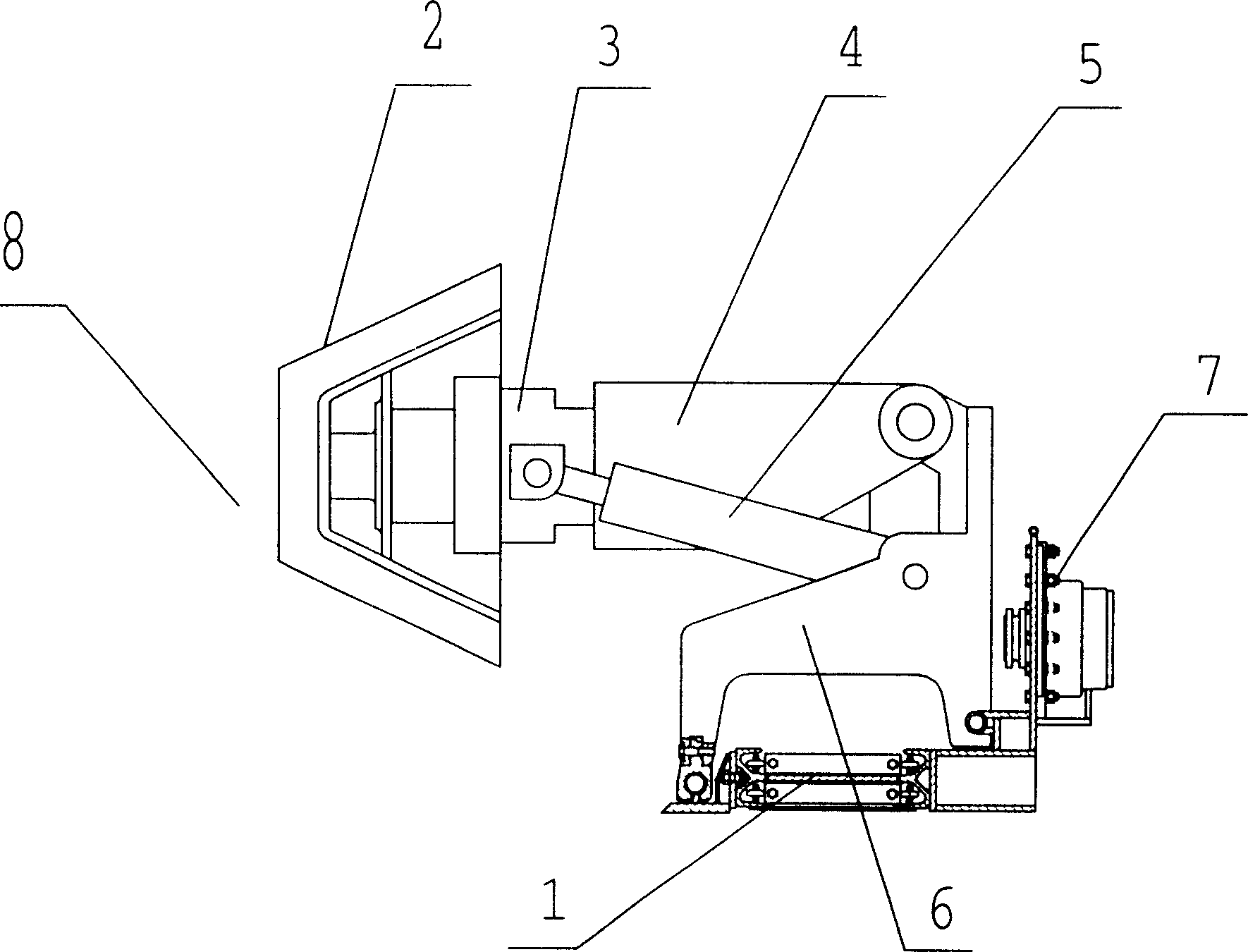

[0012] Key improvement of the present invention is the swing direction of cutting arm, referring to Fig. 1, figure 2 , the cutting arm is composed of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com