Deep Well High Stress Coal Rock Ladder Roller

A high-stress, ladder-shaped technology, applied in the field of shearer drums for deep well high-stress coal rock cutting, can solve the size limit of the shearer cutting motor, the size of the shearer should not be too large, and cannot meet the high stress of deep wells Coal and rock cutting needs and other issues, to achieve the effect of improving mining efficiency and safety conditions, simple hub form, and strong cutting ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

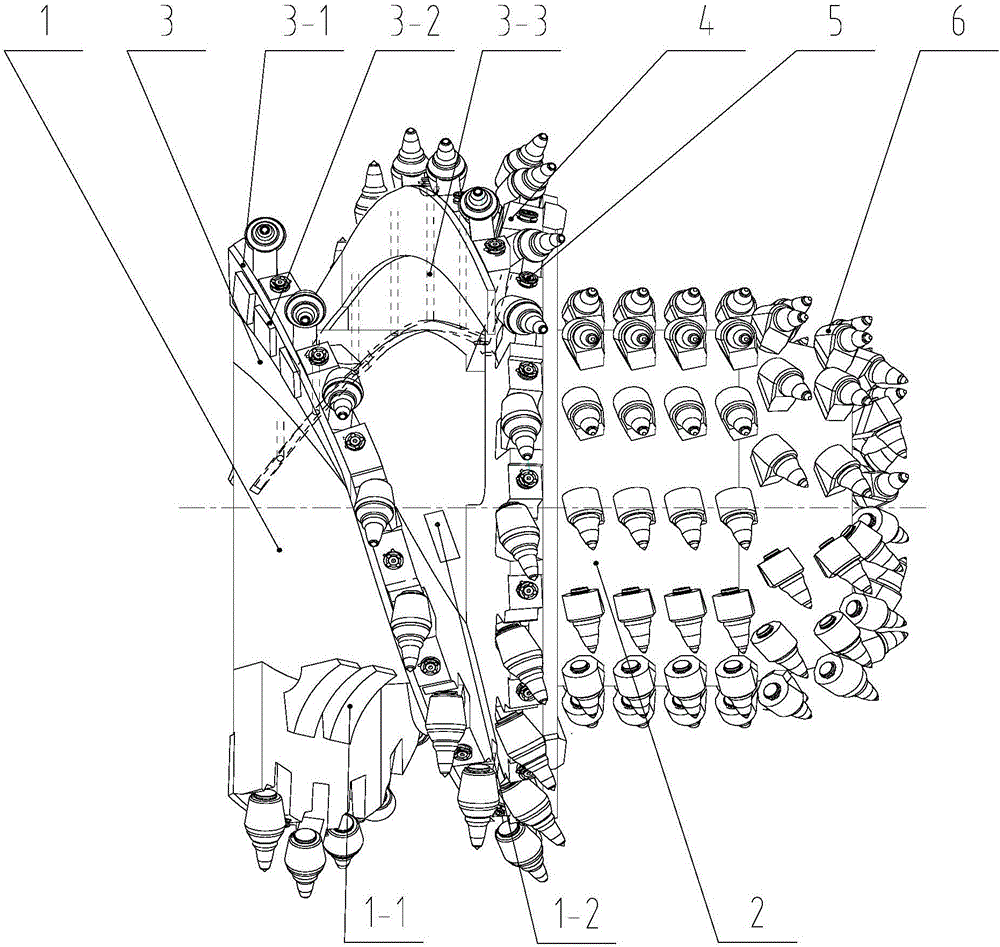

[0012] An embodiment of the present invention will be further described below in conjunction with accompanying drawing:

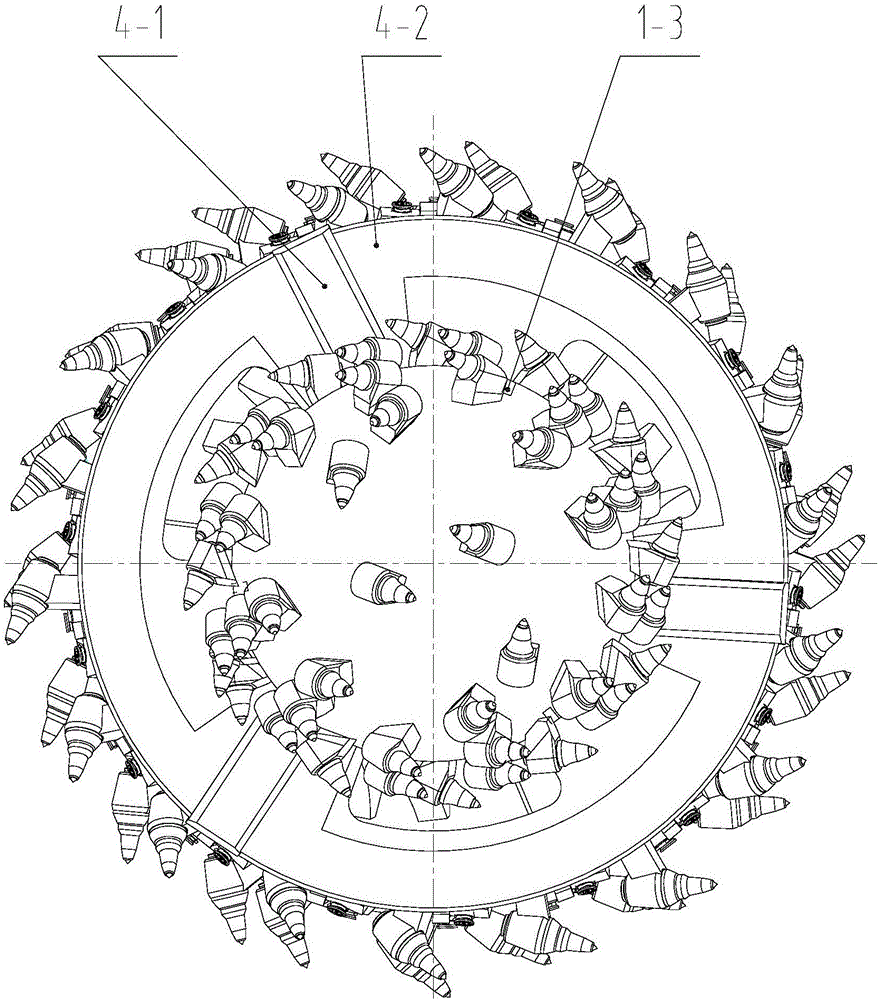

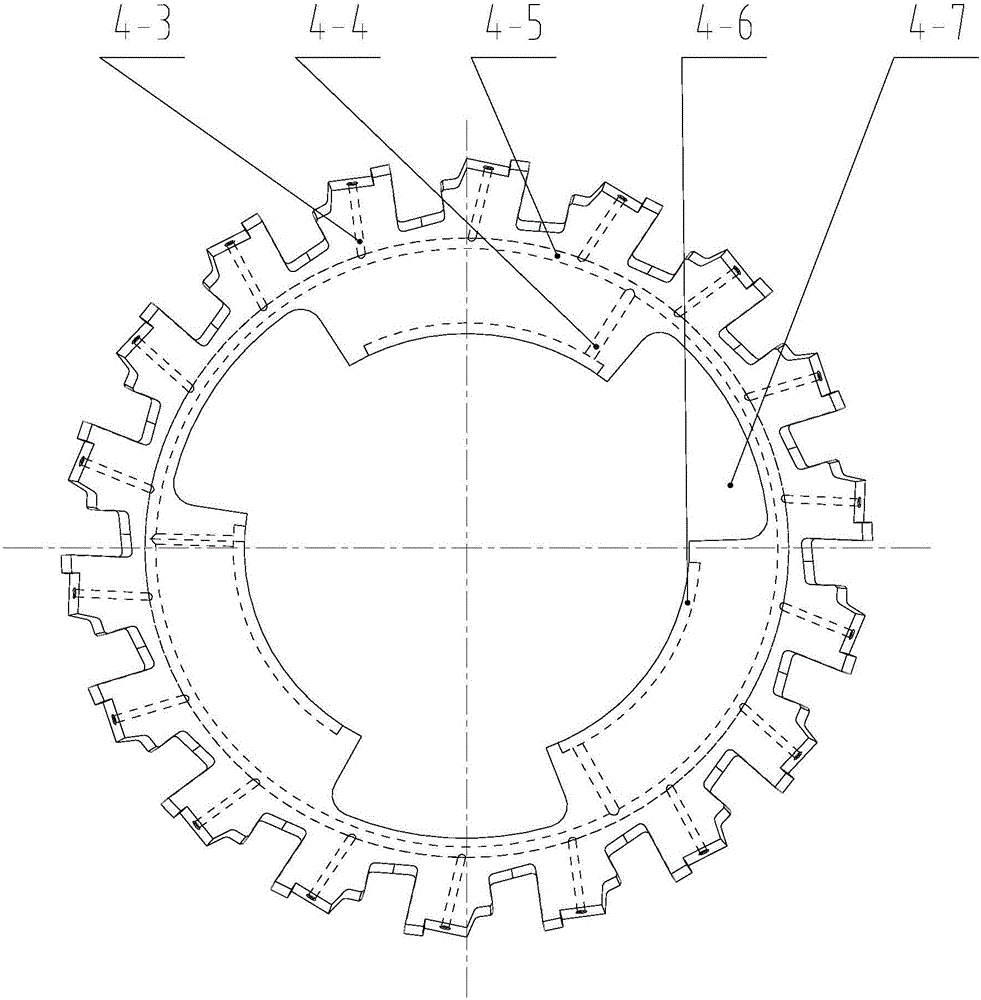

[0013] Such as figure 1 As shown, the deep well high-stress coal rock stepped drum of the present invention is mainly composed of a rear cylinder hub 1, a front cylinder hub 2, a spiral blade 3, an end plate 4, a nozzle 5, and a pick-shaped pick 6. The rear cylinder hub 1 is connected with the front cylinder hub 2, the rear cylinder hub 1 and the front cylinder hub 2 have the same outer diameter and equal length, and are connected by welding; the rear cylinder hub 1 and the front cylinder hub 2 are connected There is an end plate 4; the rear hub 1 is provided with a helical blade 3 connected with the end plate 4, and a plurality of grooves are arranged on the outer edge of the helical blade 3 and the end plate 4 at intervals. A pick pick 6 and a nozzle 5 are respectively fixed between two adjacent grooves; a spiral blade guard plate 3-1 and a wear-resistan...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com