Ground ditch excavating equipment for construction site

A technology for construction sites and excavation equipment, which is applied to the field of ground trench excavation equipment for construction sites, can solve the problems of high excavation difficulty, time-consuming and laborious excavation process, multi-manpower and other problems, and achieves the advantages of reducing excavation difficulty, improving excavation efficiency and facilitating excavation operations. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

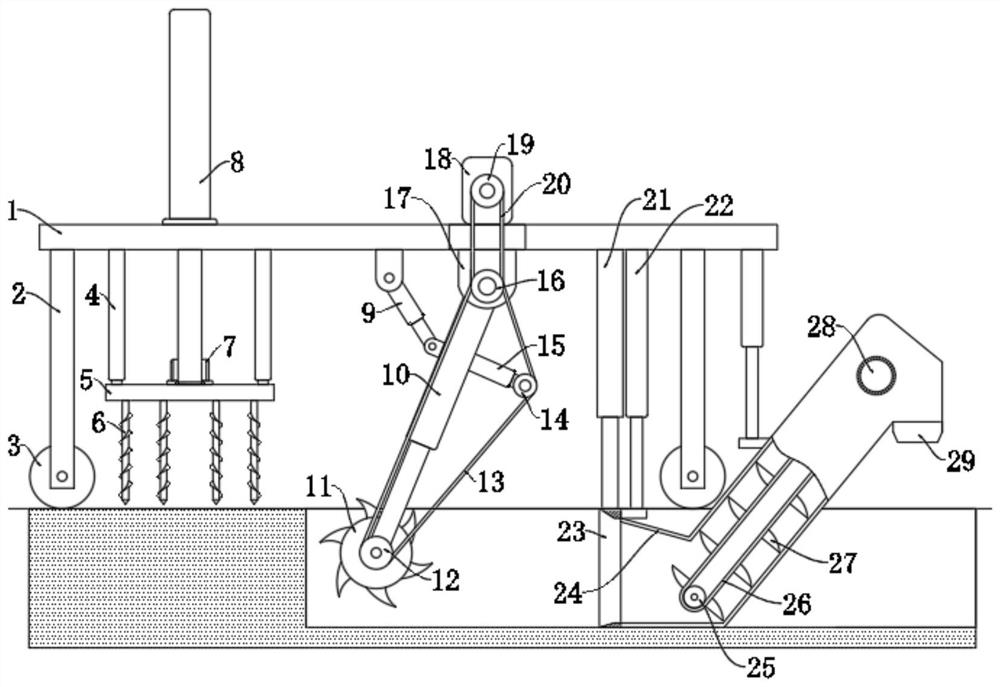

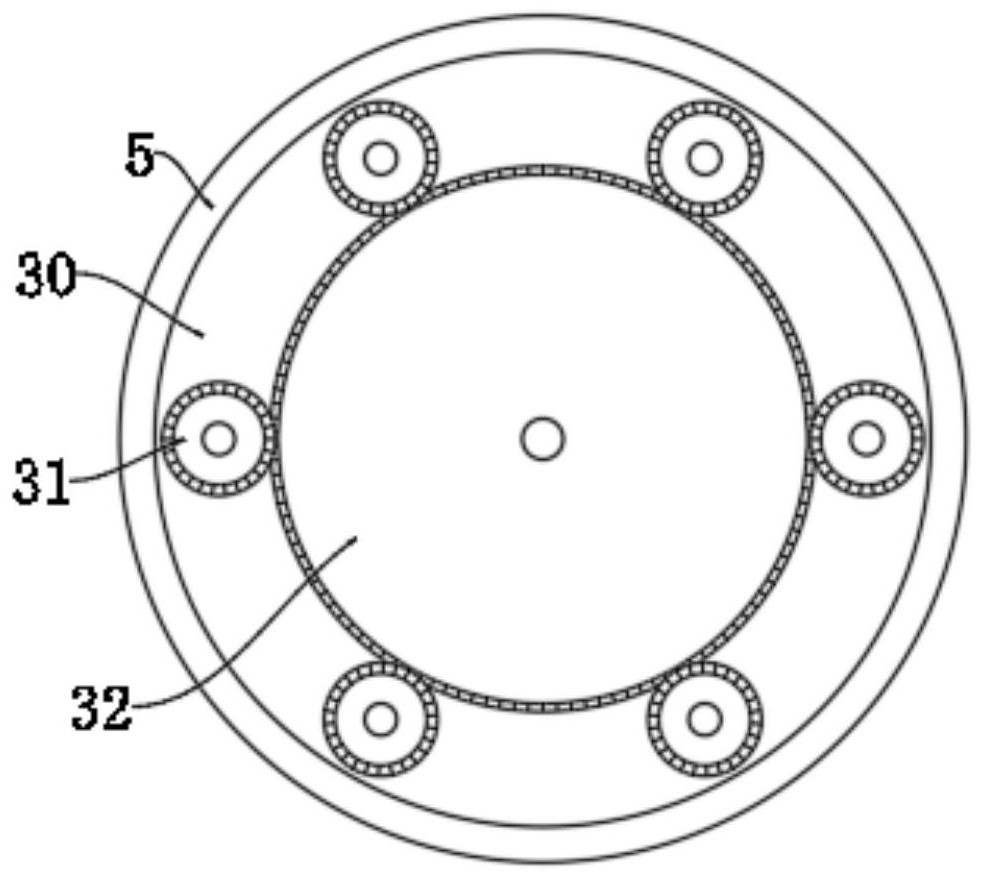

[0025] refer to figure 1 , 2 , a kind of ground ditch digging equipment for a construction site, comprising a top frame 1, legs 2 are arranged at the four corners of the lower end of the top frame 1, moving wheels 3 are installed on the bottom of the legs 2, the moving wheels 3 are electric drive wheels, and the top frame 1 is provided with a mounting plate 5 below the front part, and the upper end of the mounting plate 5 is fixedly connected with two symmetrical first guide telescopic rods 4, and the other end of the first guide telescopic rod 4 is fixedly connected to the lower side of the top frame 1, and the top frame 1. Two first lifting cylinders 8 are arranged on the upper end, and the telescopic ends of the two first lifting cylinders 8 all penetrate the top frame 1 downwards and are fixedly connected to the mounting plate 5. The upper end of the mounting plate 5 is provided with a mounting groove 30 for installation. Loose soil mechanism is arranged in the groove 30,...

Embodiment 2

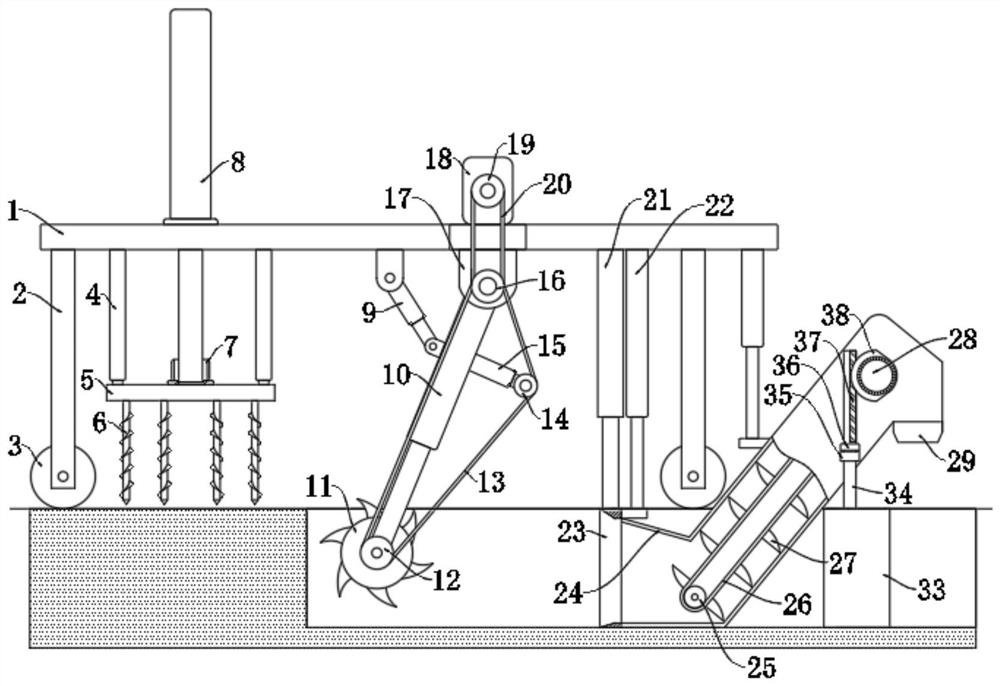

[0032] refer to image 3 , 4 Compared with Embodiment 1, the advantage of this embodiment is that an incomplete crown gear 38 is fixedly sleeved on the roller shaft of the rotating roller 25 at the rear end of the present embodiment, and a compacting plate 33 is provided below the soil lifting pipe 24 to compress the soil. Both sides of the upper end of the solid plate 33 are fixedly connected with movable rods 34, and the outer walls of both sides of the soil lifting pipe 24 are fixedly connected with fixed sleeves 35. 34 is fixedly sleeved with a limit sleeve 36 positioned above the fixed sleeve 35 , and a rack 37 is fixedly connected to the side wall of the movable rod 34 , and the rack 37 meshes with the incomplete crown gear 38 .

[0033] When this embodiment is working, the third motor 28 drives the rotating roller 25 to rotate, and drives the incomplete crown gear 38 to rotate. When the incomplete crown gear 38 meshes with the rack 37, the movable rod 34 can be moved u...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com