High-molecular polymer oil displacement surfactant for oil field and preparation method of high-molecular polymer oil displacement surfactant

A high-molecular polymer and surfactant technology, applied in the direction of drilling compositions, chemical instruments and methods, etc., can solve the problem of low descaling rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0048] The preparation method of polymer flooding surfactant of the present invention:

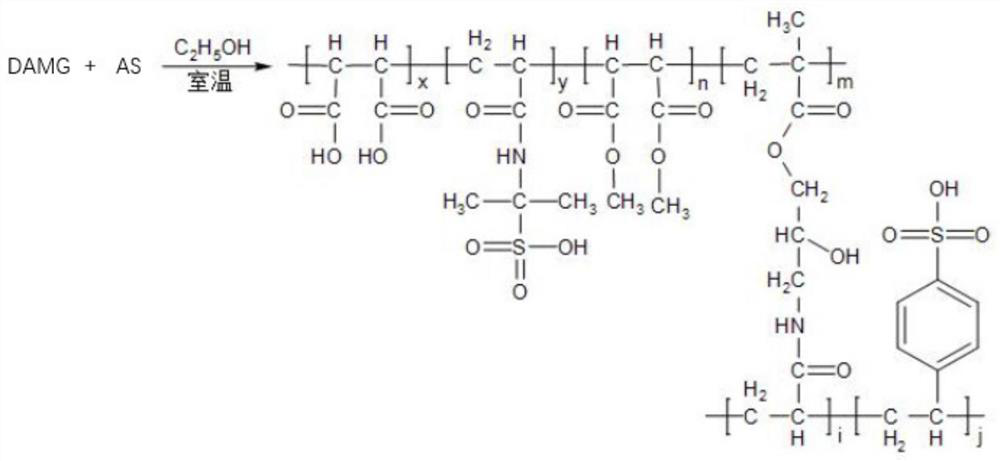

[0049] The first step, the synthesis of DMAG polymer

[0050] From the three aspects of the functional groups contained, the unsaturated hydrocarbon bonds contained and the cost of use, dimethyl maleate (DDM) and 2-acrylamide-2-methylpropanesulfonic acid (AMPS) containing hydrophilic groups are selected. ), dehydrated glycerol methacrylate (GMA) and maleic anhydride (MA) as reactive monomers.

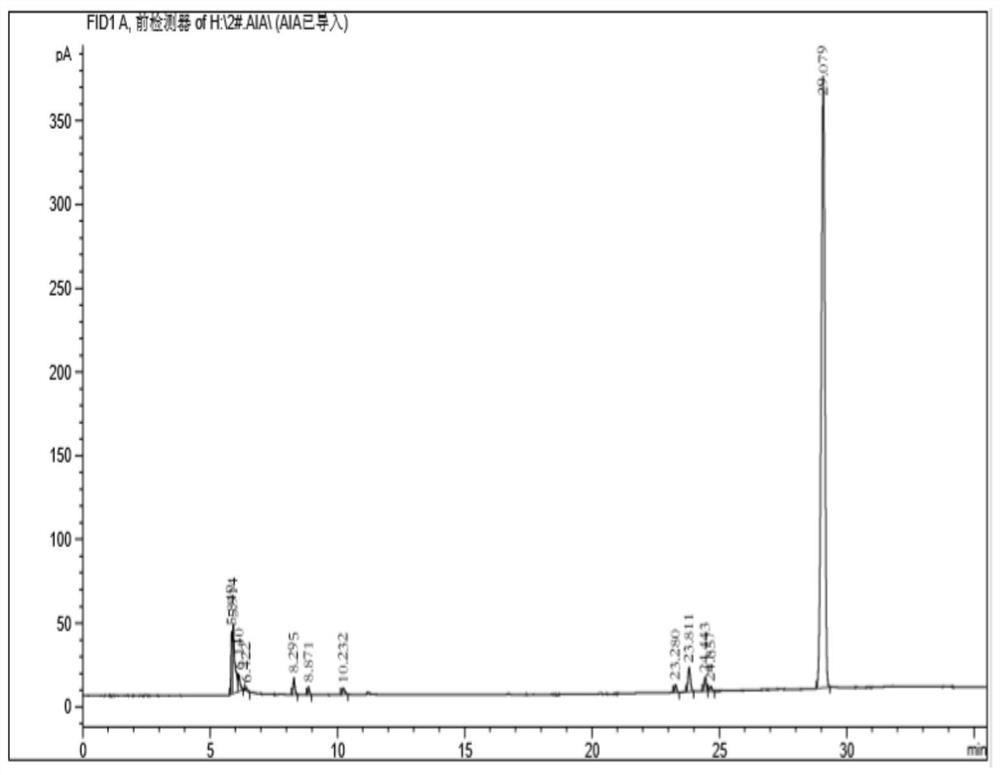

[0051] The synthetic experiment adopts aqueous solution polymerization technology, and initiator selects water-soluble initiator azobisisopropyl imidazolinate (AIBI), and experiment first reacts monomer (in this embodiment DDM:MA:AMPS:GMA) with 10g different proportions The mass ratio is 1:6:2.5:0.5) into 50mL of distilled water to dissolve, then pass nitrogen gas for 30min to remove the oxygen in the device, heat and stir and add 5% of the total amount of monomer dropwise, the temperature is selecte...

Embodiment 2

[0057] The difference from Example 1 is that in the synthesis of DMAG polymer, the mass ratio of DDM:MA:AMPS:GMA is 3:4:2.5:0.5 in sequence.

Embodiment 3

[0059] The difference from Example 1 is that in the synthesis of DMAG polymer, the mass ratio of DDM:MA:AMPS:GMA is 4:3:2.5:0.5 in sequence.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Viscosity | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

| Surface tension | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com