Dragging part of torque shunting thin coal layer mining machine

A thin coal seam and shearer technology, which is applied to cutting machinery, earthwork drilling, and propulsion, can solve the problems of difficult mechanization, poor working environment, and high cost, and achieve improved mining efficiency and coal resource production capacity. The structure is simple and compact, and the effect of improving the coal passing space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0010] An embodiment of the present invention will be further described below in conjunction with accompanying drawing:

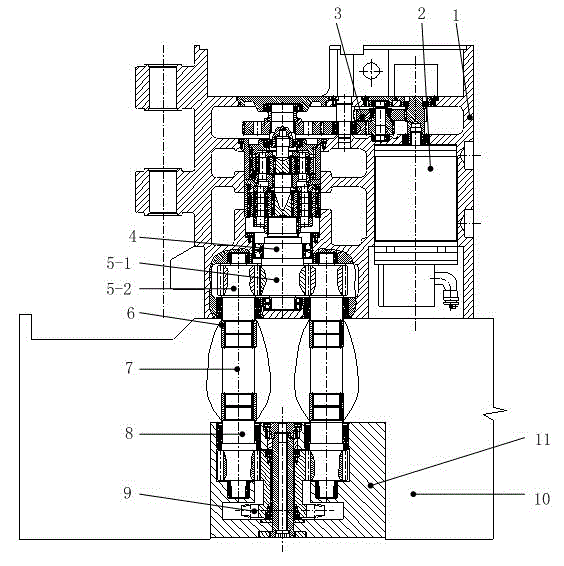

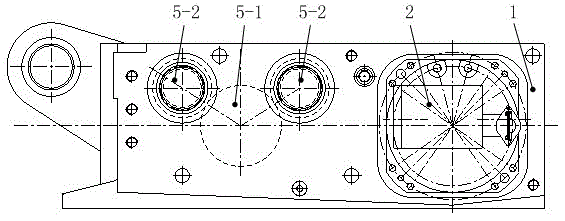

[0011] The traction part of the torque split type thin coal seam shearer of the present invention is mainly composed of a traction housing 1, a traction motor 2, a traction reduction box 3, an output shaft 4 of the traction reduction box, a torque splitting gear transmission mechanism 5, a transmission shaft 7, a Moment confluence gear transmission mechanism 8, road wheel 9 constitute. The traction motor 2 is directly horizontally installed in the traction housing 1 and fastened by bolts. The output shaft of the traction motor 2 is connected with the traction reduction box 3, and the output shaft is used as the input shaft of the traction reduction box 3. The axis of the output end of the traction reduction box 3 is parallel to the axis of the traction motor 2, and the output shaft 4 of the traction reduction box is connected with a torque splitting...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com