A stable bucket tooth for an excavator

An excavator and stable technology, which is applied to the field of excavator stable bucket teeth, can solve the problems of easy insertion and inconvenient removal, and achieve the effects of easy insertion and removal, easy operation, and convenient disassembly and installation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

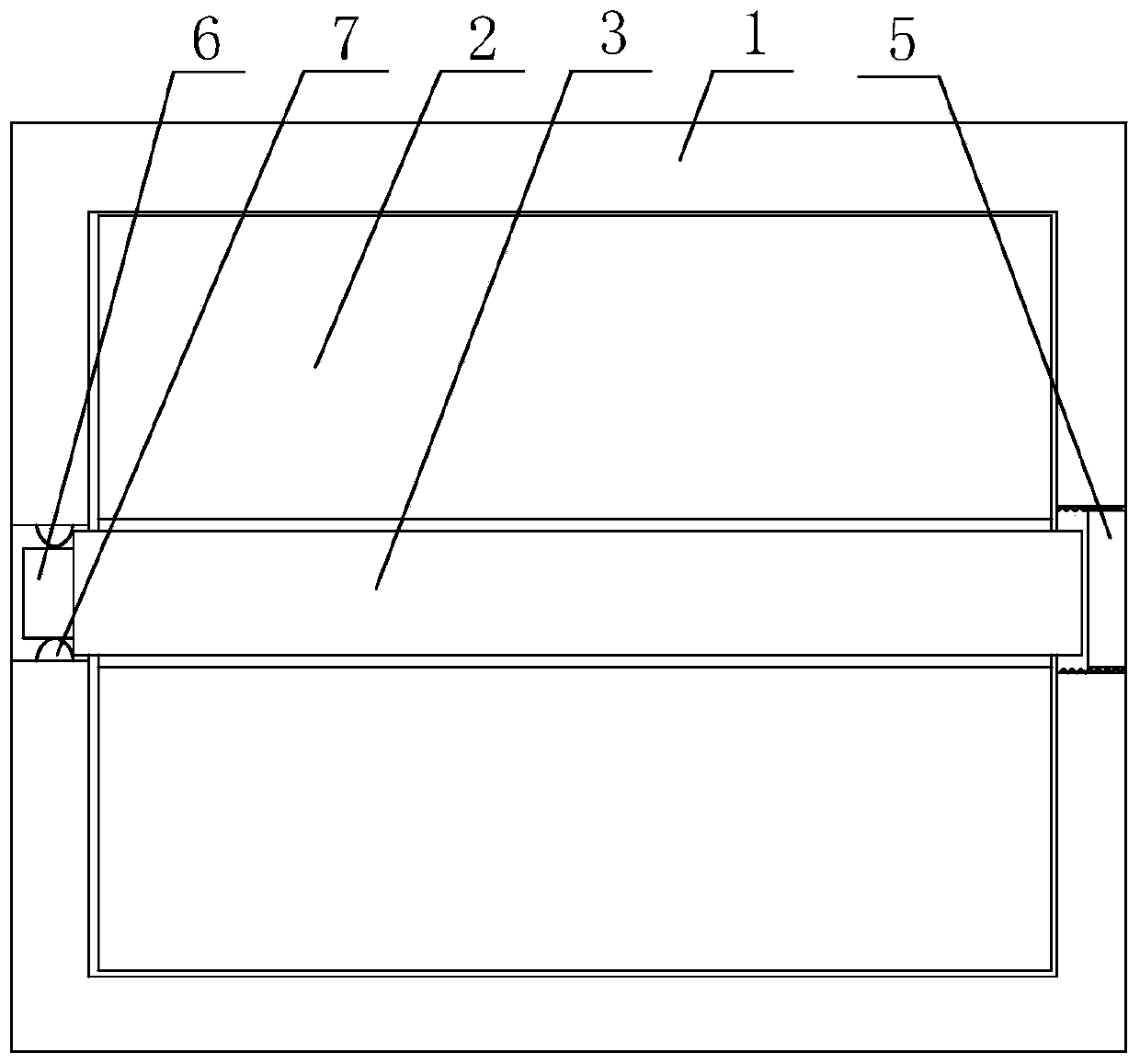

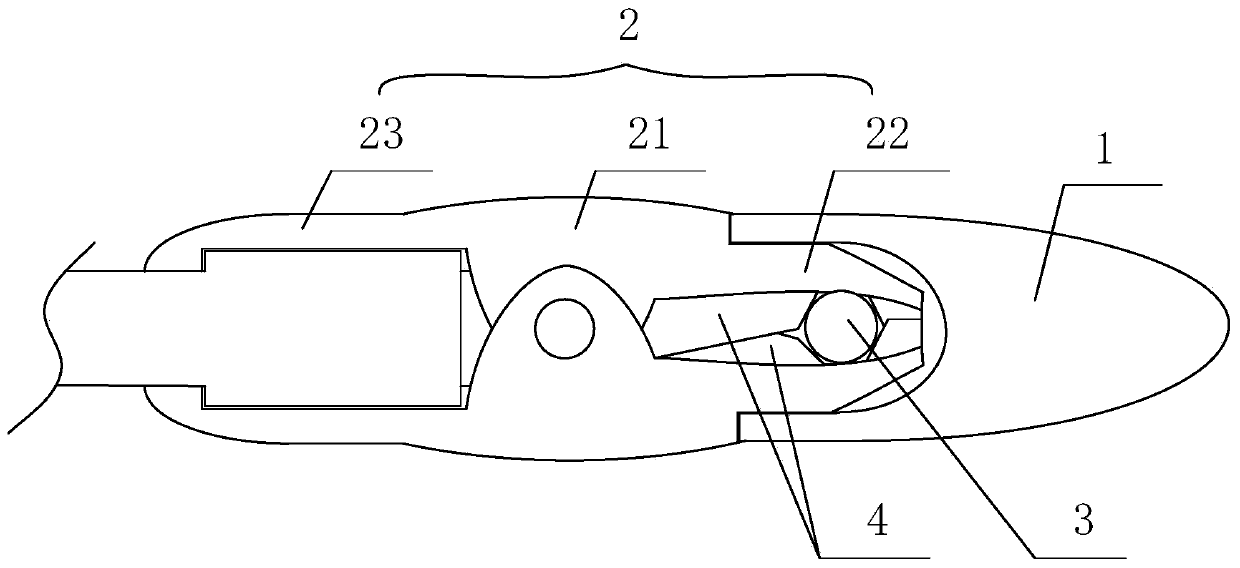

[0035] A stable bucket tooth for an excavator comprises a gear seat 2, a tooth tip 1 with a pin hole, and a pin shaft 3 passing through the pin hole to connect the tooth tip 1 and the tooth seat 2.

[0036] Such as figure 1 As shown, one of the pin shaft holes on the tooth tip 1 is provided with a plugging connector 5, and the pin shaft 3 at one end away from the plugging connector 5 is provided with a slot diameter end 6, and the tooth tip 1 is provided with a The protruding spring part 7 matched with the slot diameter end 6 is screwed with the plugging connecting part 5 and the pin shaft hole.

[0037] In this embodiment, the protruding spring member 7 is composed of a groove arranged on the tip of the tooth, a spring arranged in the groove, and a block fixed on the spring. One end of the block is located in the groove and is fixed with the spring. The other end of the block stretches out of the groove by the elastic force of the spring. The protruding spring part 7 of thi...

Embodiment 2

[0046] The difference between this embodiment and Embodiment 1 is that in this embodiment, the structure between the excavator bucket and the tooth seat 2 is optimized, and the structure between the upper tooth portion and the lower tooth portion is optimized at the same time. The specific settings are as follows:

[0047] The excavator bucket is provided with a protruding part at the connection with the tooth seat 2, and the connection with the excavator bucket on the lower clamping part or / and the upper clamping part is provided with a matching protruding part. groove.

[0048] The upper tooth portion or / and the lower tooth portion are provided with a blocking member 4 that prevents the pin shaft 3 from moving between the upper tooth portion and the lower tooth portion.

[0049] Through the optimization of the above structure, the connection between the excavator bucket and the tooth holder 2 and between the tooth holder 2 and the tooth tip 1 is effectively promoted to be mo...

Embodiment 3

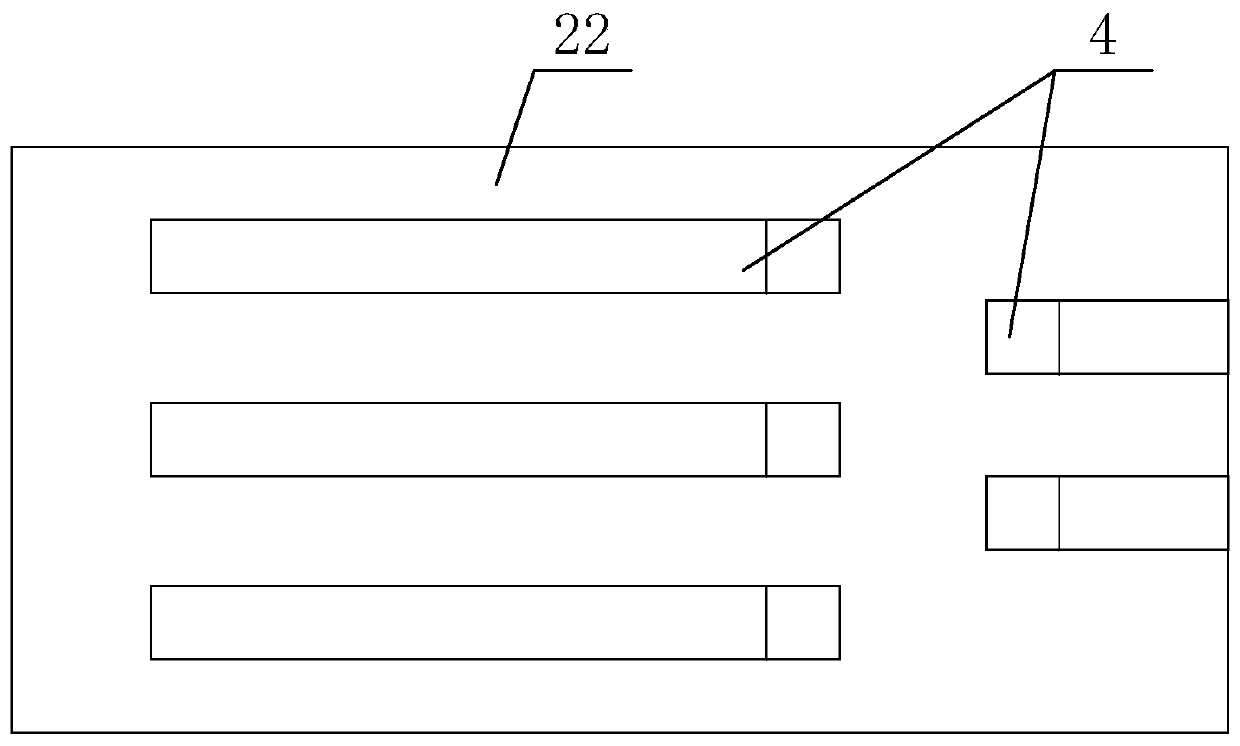

[0051] The difference between this embodiment and Embodiment 2 is that the specific structure of the resistance member 4 is optimized in this embodiment, and the specific settings are as follows:

[0052] There are more than two resistance members 4 , all of which are arranged along a direction perpendicular to the central axis of the pin shaft 3 . In this embodiment, both the upper teeth and the lower teeth are provided with resistance members 4, and the number of upper resistance members 4 on the upper teeth and the lower teeth is respectively set to five, as image 3 shown. In the upper tooth portion, three of the resistance members 4 are arranged on one side of the central axis of the pin shaft 3, and the other two are arranged on the other side of the central axis of the pin shaft 3, such as image 3 shown. Similarly, two stoppers 4 are provided on one side of the lower teeth corresponding to the upper teeth with three stoppers 4, and one side of the lower teeth corresp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com