Intelligent smelting system and operation method thereof

A smelting operation and intelligent technology, applied in foundry workshops, metal processing equipment, manufacturing tools, etc., can solve problems such as low efficiency, poor working environment, and high risk, and achieve the goals of ensuring operation safety, shortening the pouring process, and reducing labor intensity Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

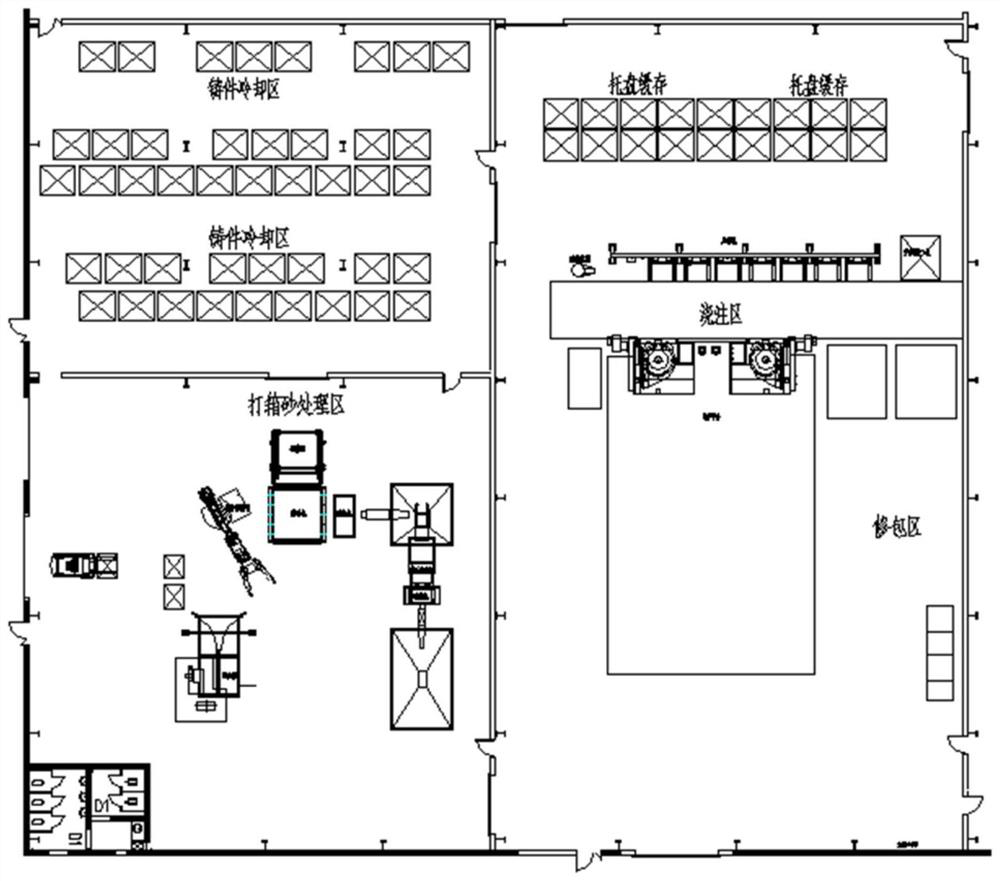

[0046] See Figure 1-3The present invention provides a technical solution: an intelligent smelting operation method, including the following steps:

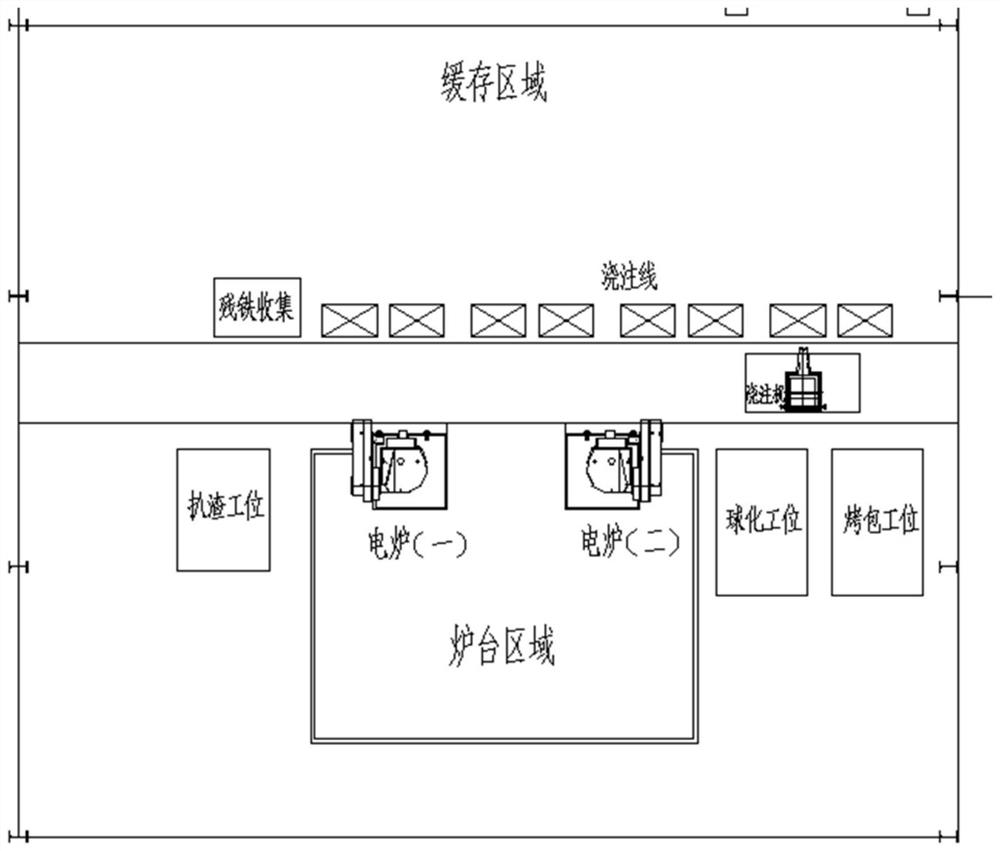

[0047] S1, smelting: slagm → furnace front slag → toll plate → iron water bag (oven) → furnace out of iron → sphericalization (spheroidization station) → post-tilt 渣 (扒 位) → Automatic pouring → back iron water bag (烤 器)

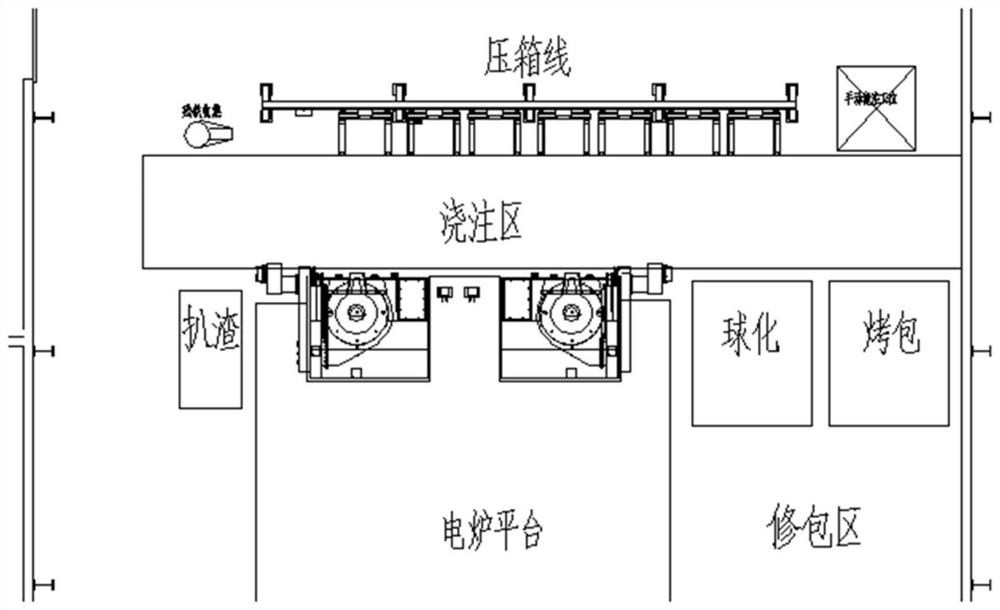

[0048] A,: Stove (electric furnace one, electric furnace 2), spheroid station, oven, 渣 位 位 位 位 位 位 形 位 位 形 位 位 形 形 位 位 位 位 位 位 形

[0049] B,: The stove and the spheroidization station, the oven, the slag position, and the pouring line can be provided on both sides.

[0050] S2, transfer: Use the sneaked AGV transport sand type, casting, logistics direction as follows: Core station → furnace front buffer → Pouring station → cooling zone → Turn box machine → cooling area (empty tray) → Core station ( Empty tray) uses AGV, by modifying the software, you can change the site logistics route and direction, and effectively ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com