Dust falling device for building blasting

A dust suppression device and construction technology, which is applied in the field of construction, can solve the problems of inability to deal with dust and dust, and achieve the effect of preventing the reduction of dust removal efficiency and facilitating dust removal and treatment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

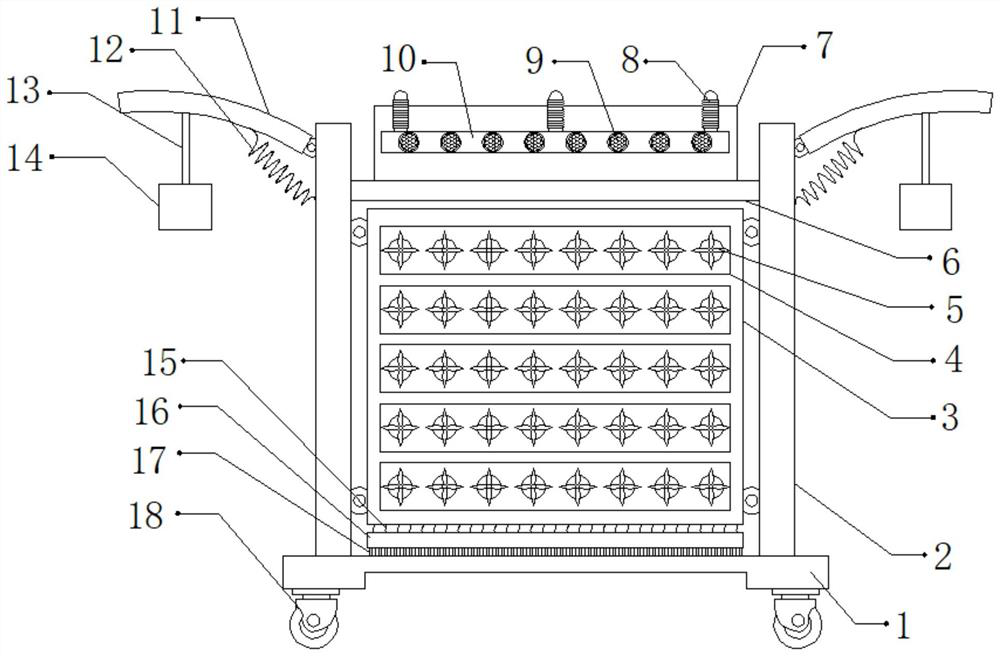

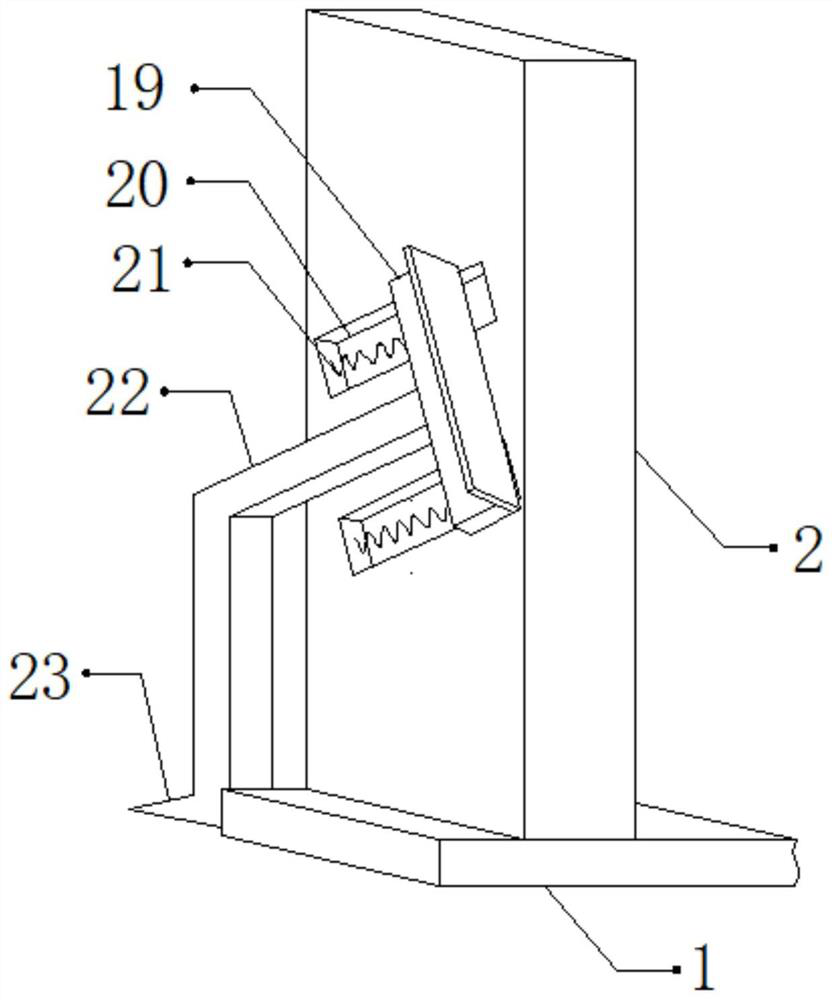

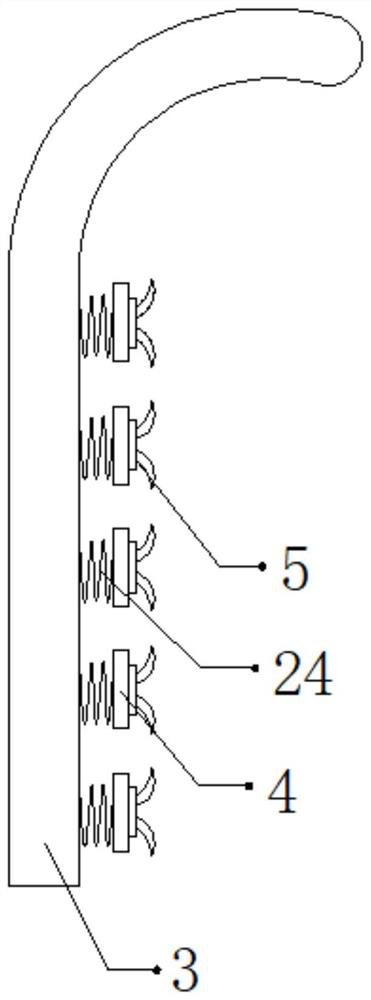

[0028] refer to Figure 1-3 , a dust suppression device for building blasting, comprising a fixed base 1, the two sides of the top outer wall of the fixed base 1 are connected with a fixed plate 2 by bolts, and the outer walls of one side of the two fixed plates 2 are connected with blades 11 through a hinge, the blades 11 and one side outer wall of the fixed plate 2 are connected with a first spring 12 by bolts, the bottom outer walls of the two blades 11 are bolted with suspension ropes 13, and the bottom outer walls of the two suspension ropes 13 are bolted with fixed blocks 14. A baffle plate 3 is connected by a hinge between the outer walls on the opposite side of the two fixed plates 2, and a support plate 6 is connected by bolts between the outer walls on the opposite side of the two fixed plates 2, and the top of the support plate 6 The outer wall is connected with a water storage tank 7 by bolts, a water inlet is provided on one side of the top outer wall of the water...

Embodiment 2

[0038] refer to Figure 4, a dust suppression device for building blasting. Compared with Embodiment 1, the outer wall of the bottom of the fixed base 1 is connected with a hydraulic rod 27 by bolts, and the outer wall of the bottom of the hydraulic rod 27 is connected with an anti-skid plate 25 by bolts. The anti-skid plate The bottom outer wall of 25 is provided with a plurality of equidistantly distributed tooth blocks 26 .

[0039] Working principle: When in use, move the device to a suitable position through the moving wheel 19, start the hydraulic rod 27, and the hydraulic rod 27 will drive the anti-skid plate 25 to move down, and the friction between the device and the ground can be increased through the gear block 26 , in order to fix the device, when the blasting is completed, the fixed block 14 will swing due to the impact force, so that the swing of the fixed block 14 will drive the blade 11 to swing up and down, so that the wind force generated when the blade 11 sw...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com