Patents

Literature

62results about How to "Reduce dust removal efficiency" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

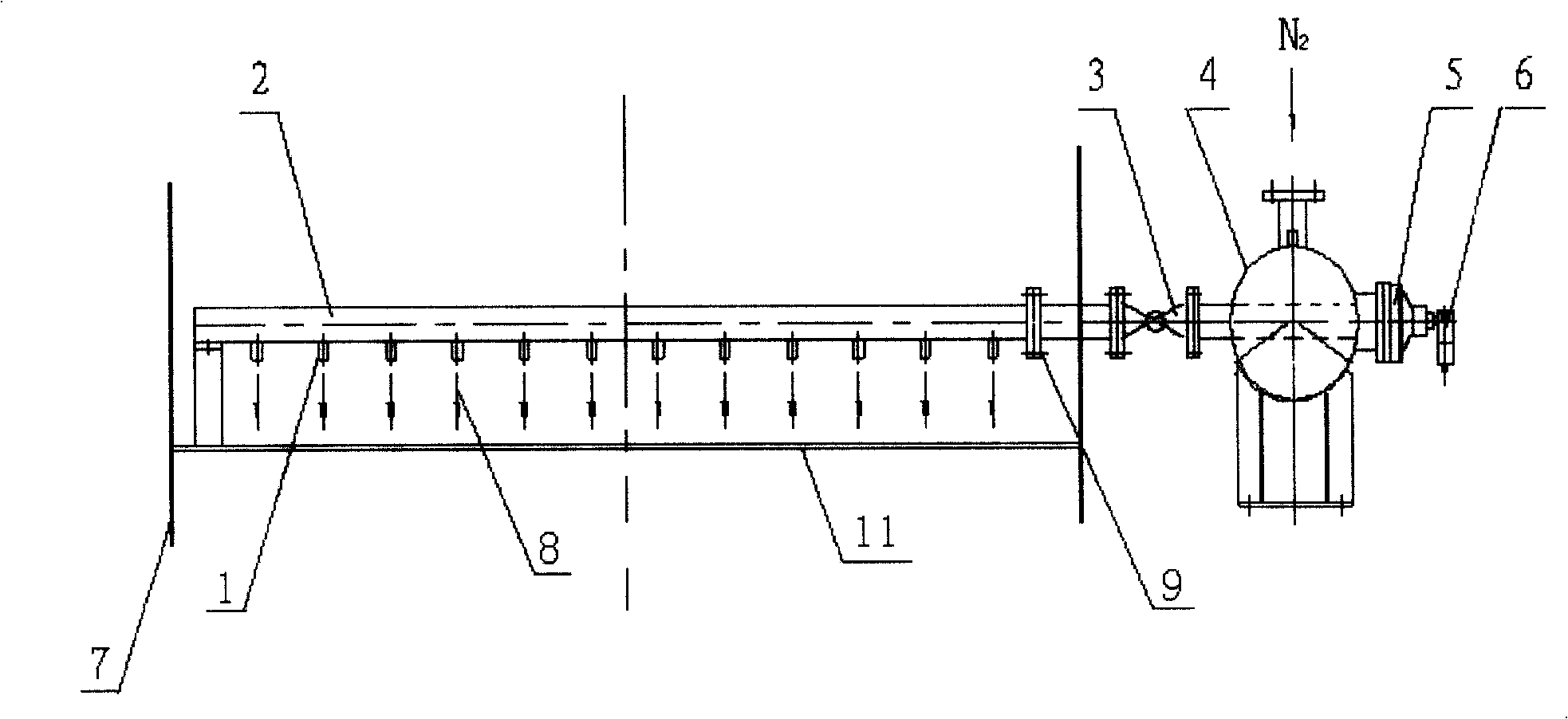

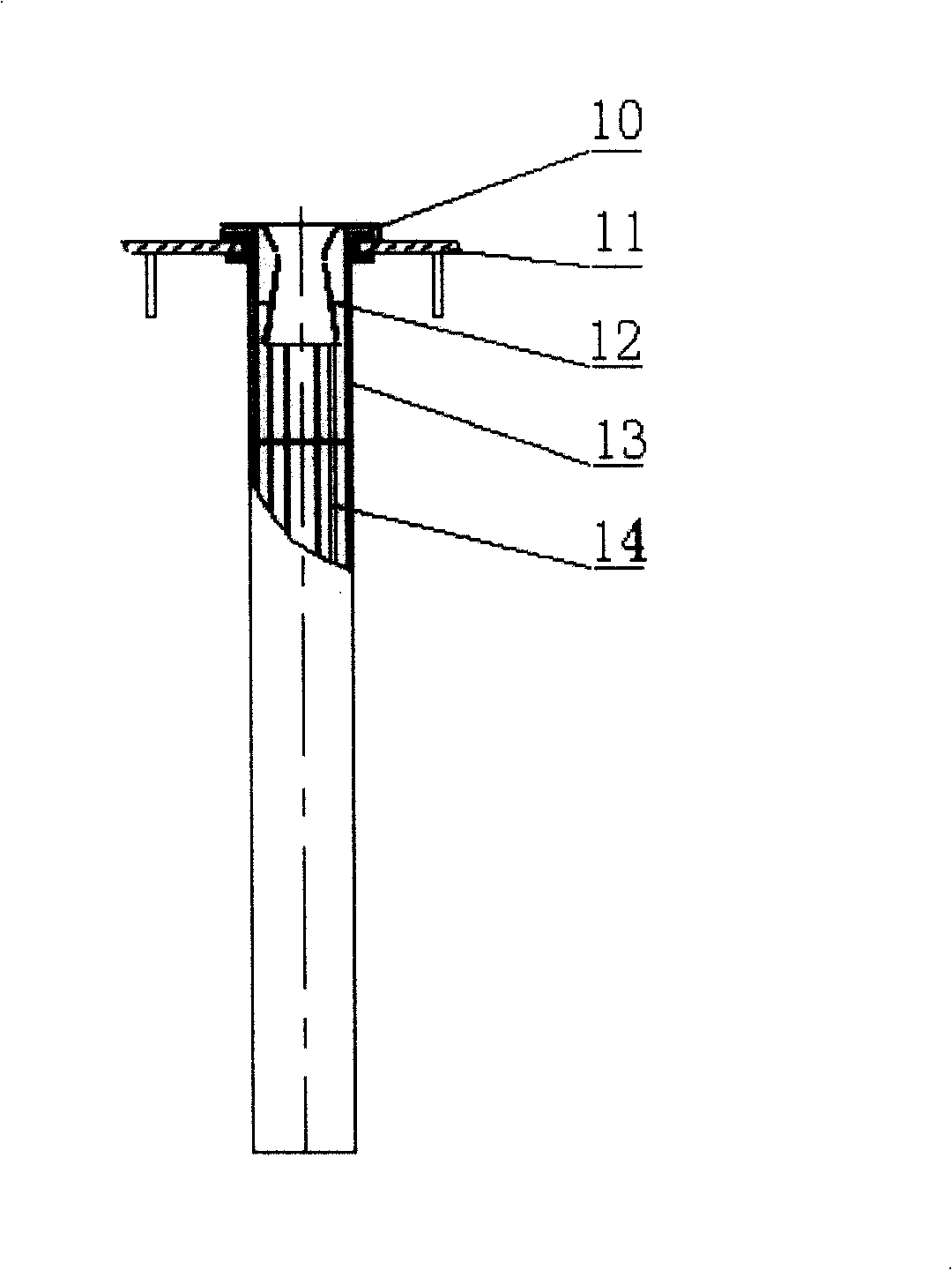

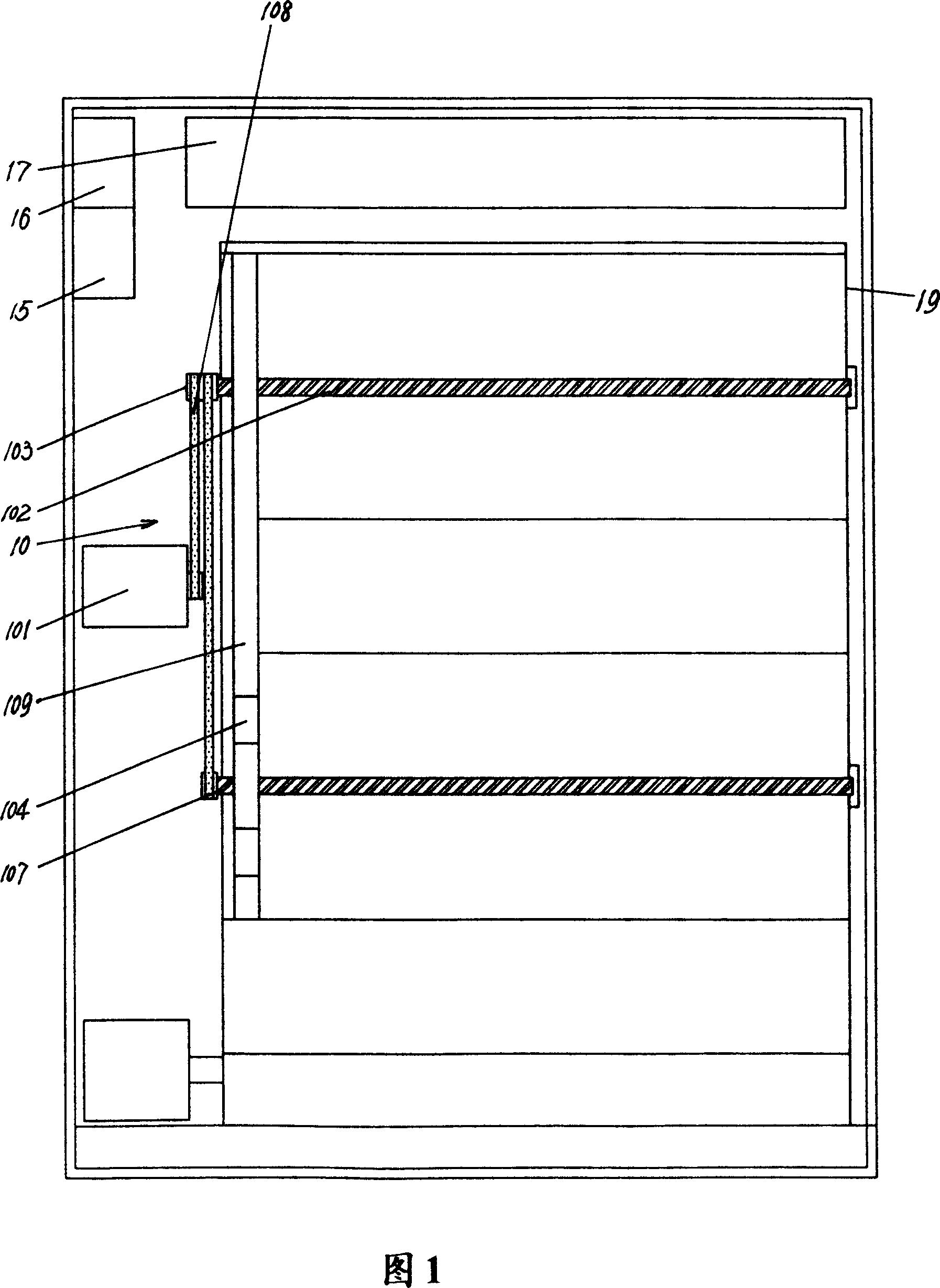

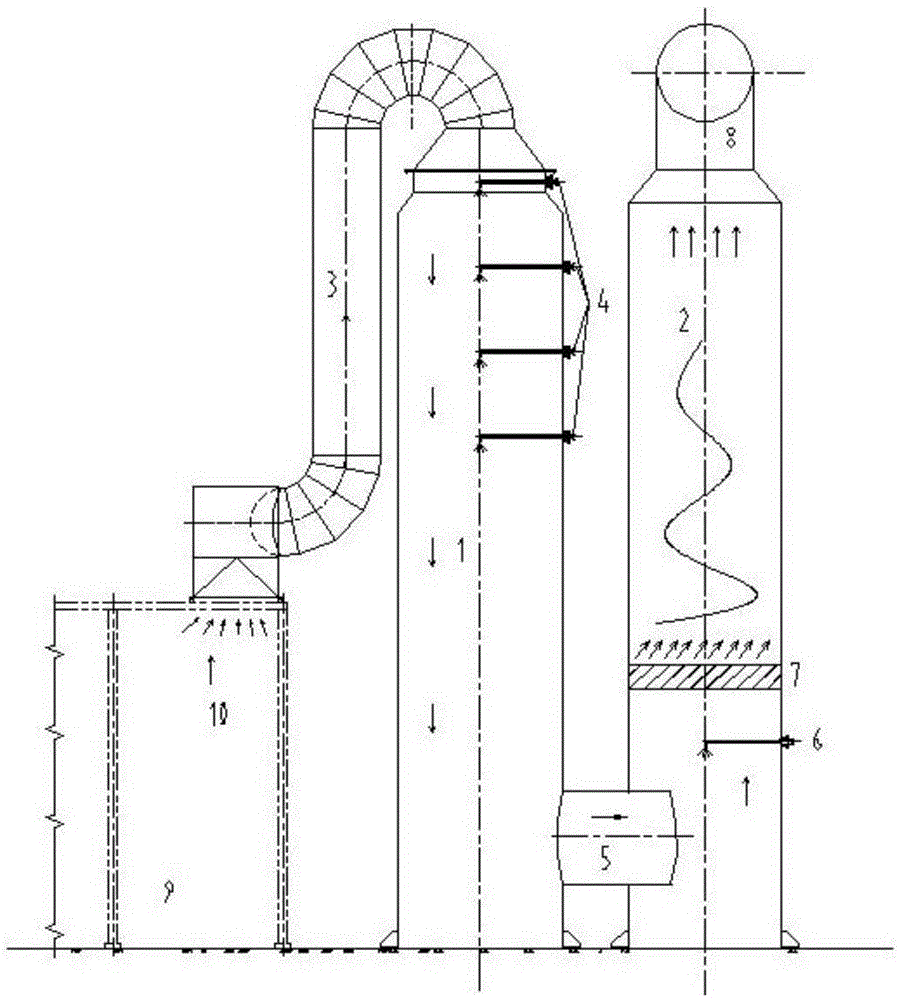

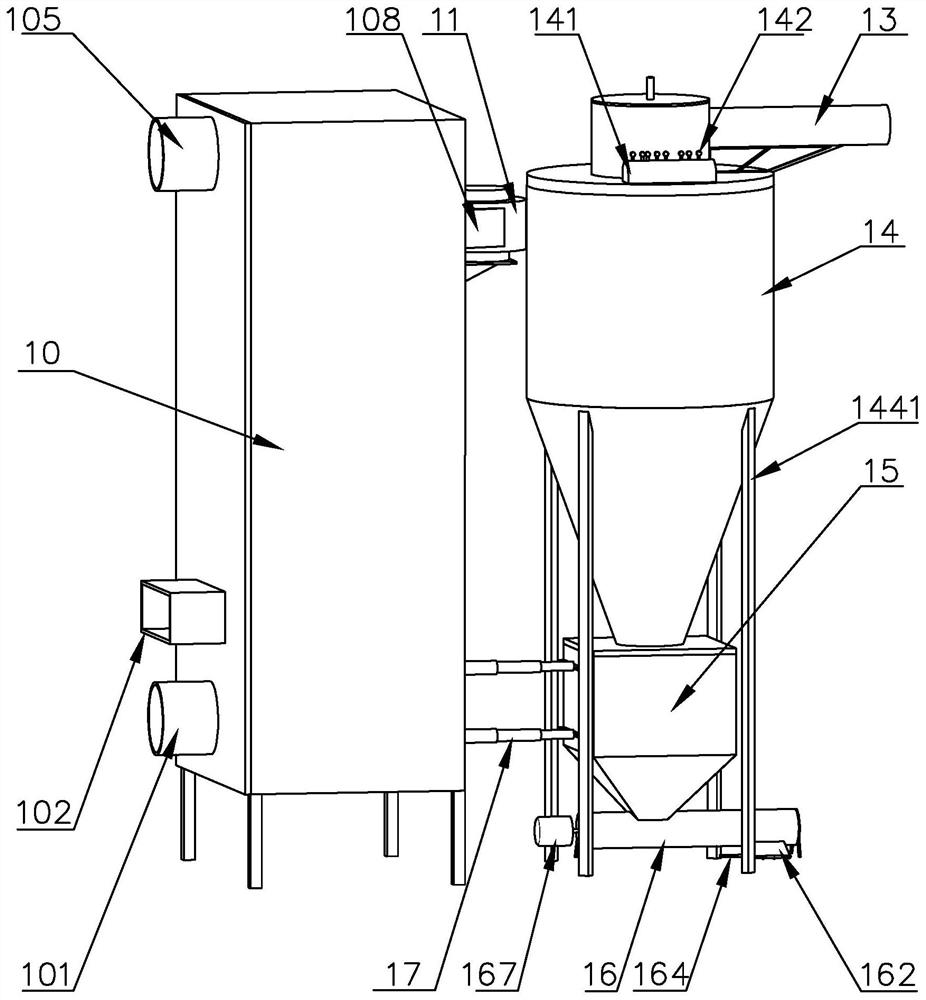

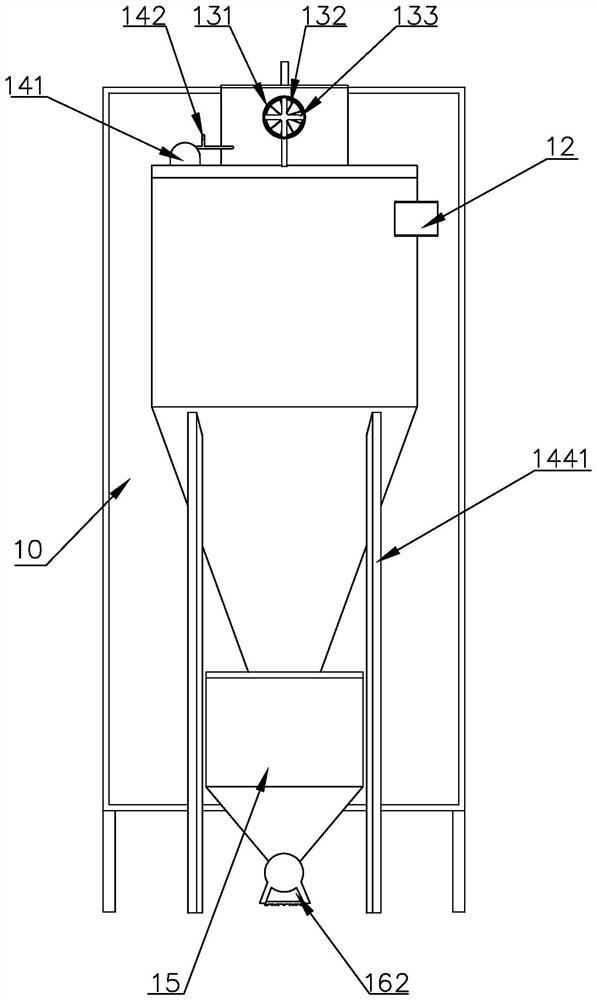

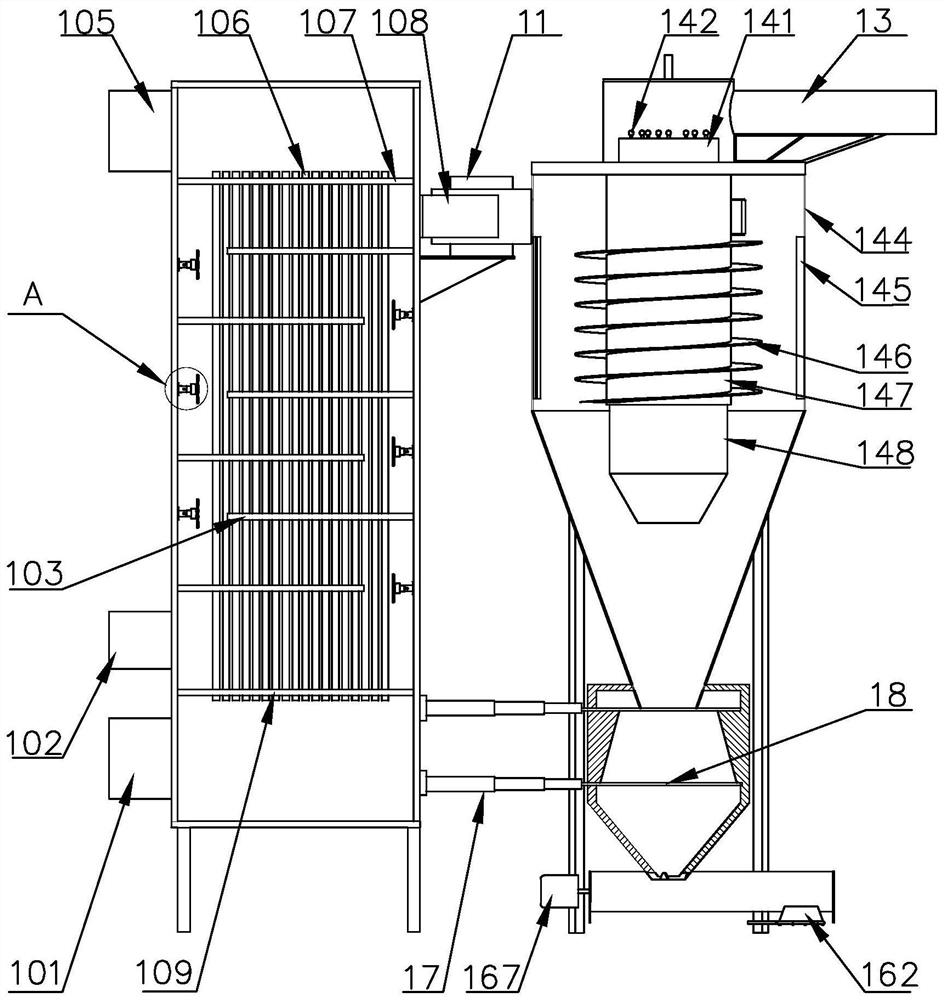

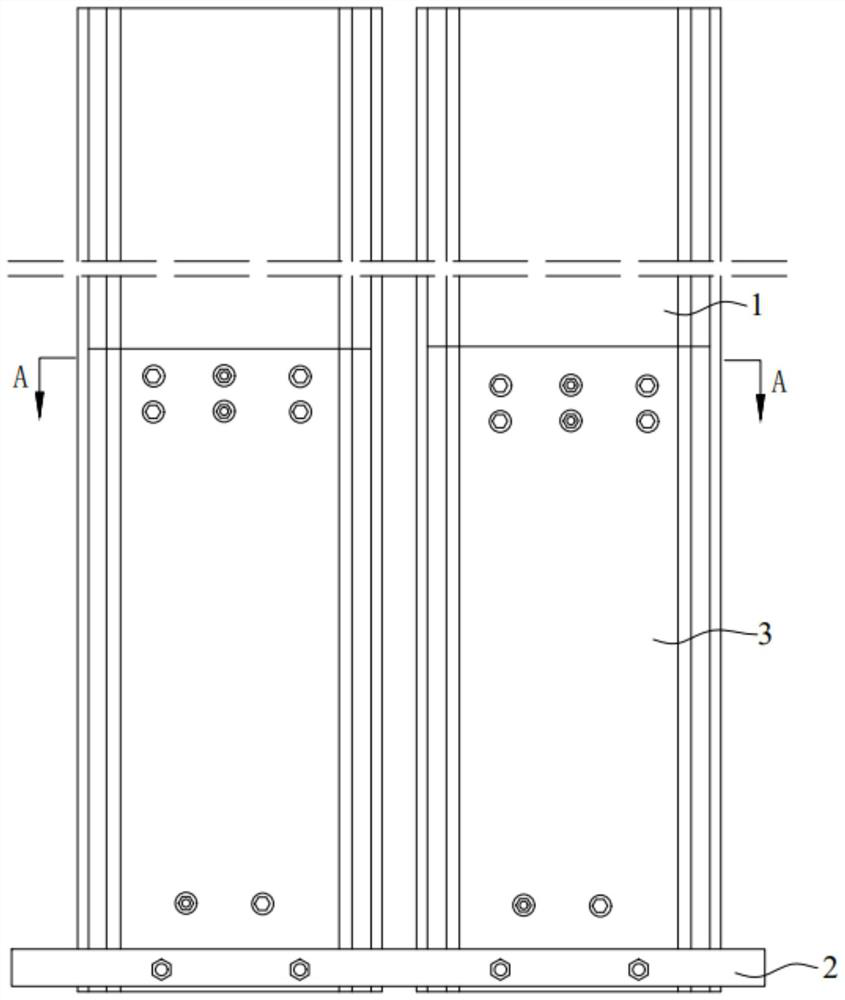

Blast furnace gas dust removing device and technique by dry method

ActiveCN101260322AEnsure safetyGet rid of dependenceChemical industryGas dust removalAutomatic controlProcess engineering

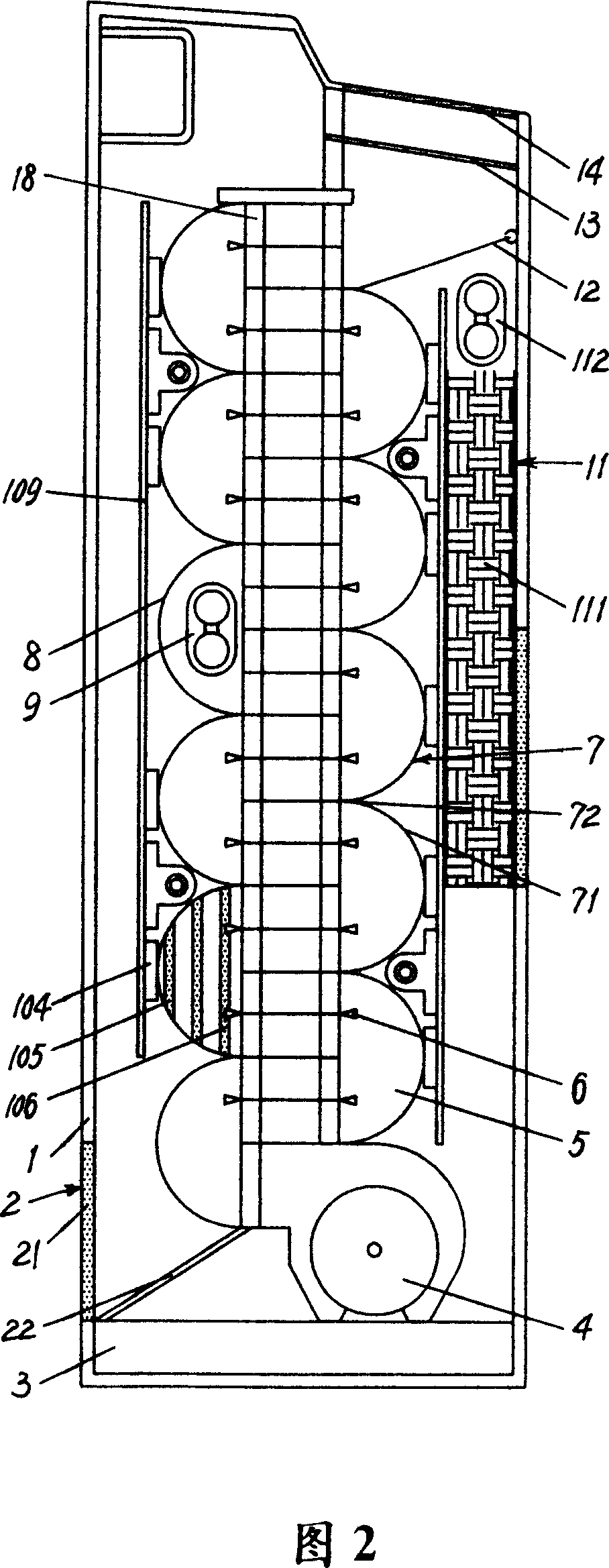

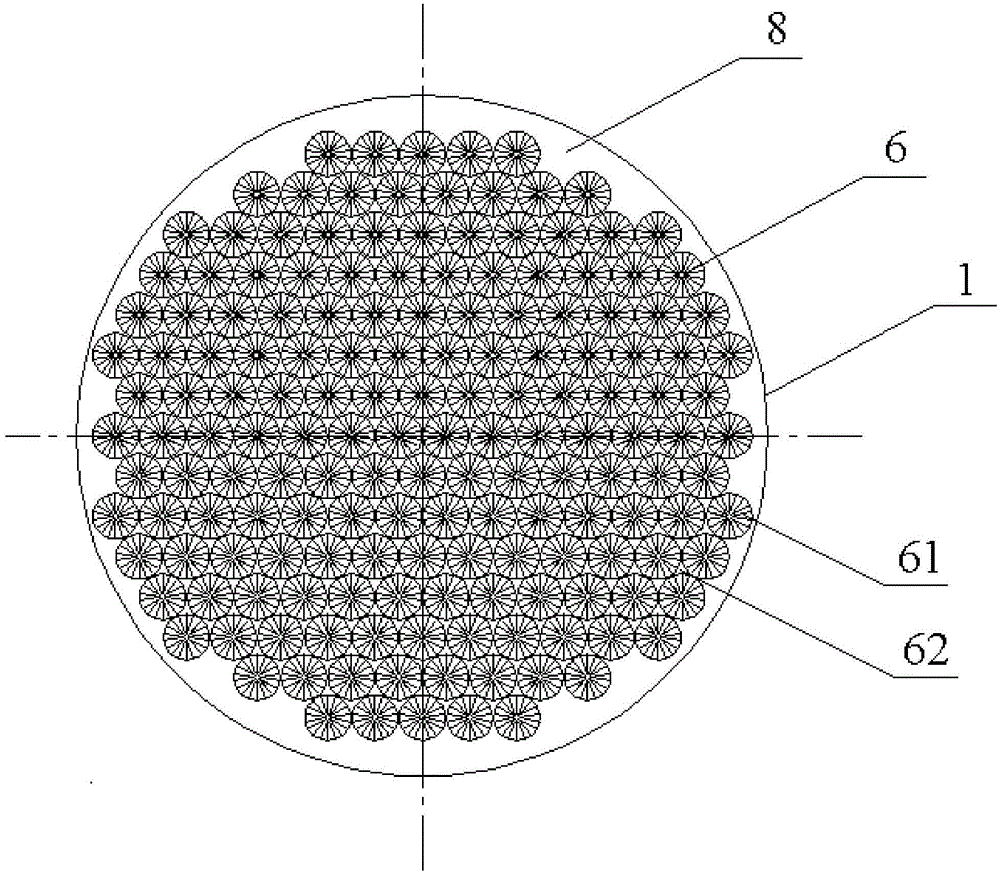

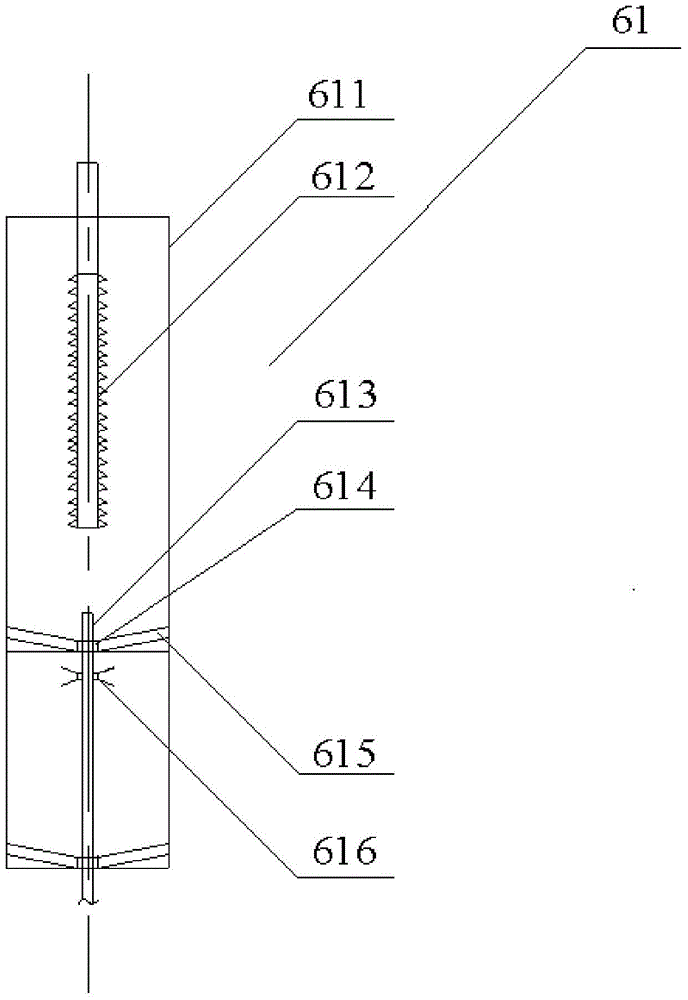

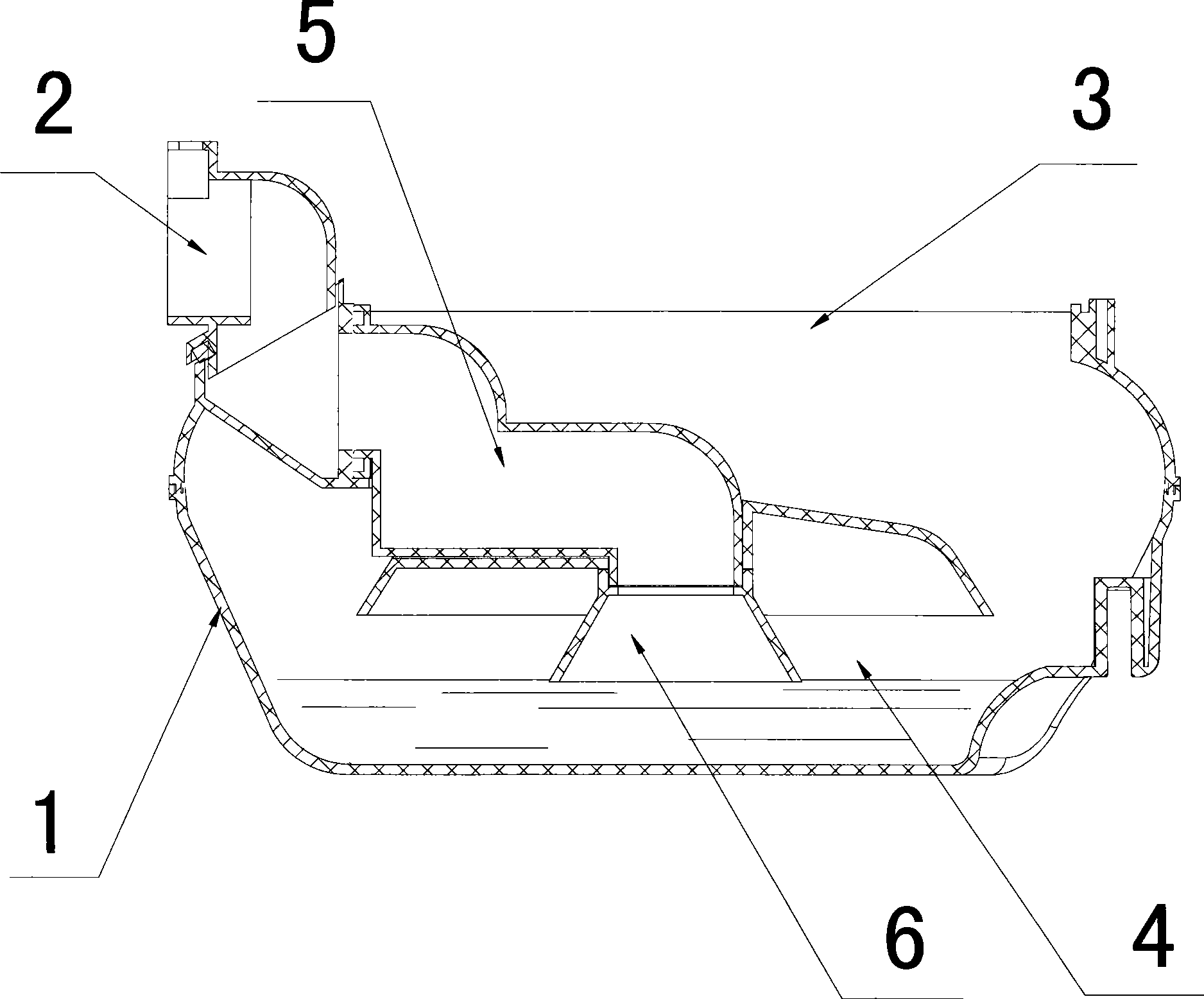

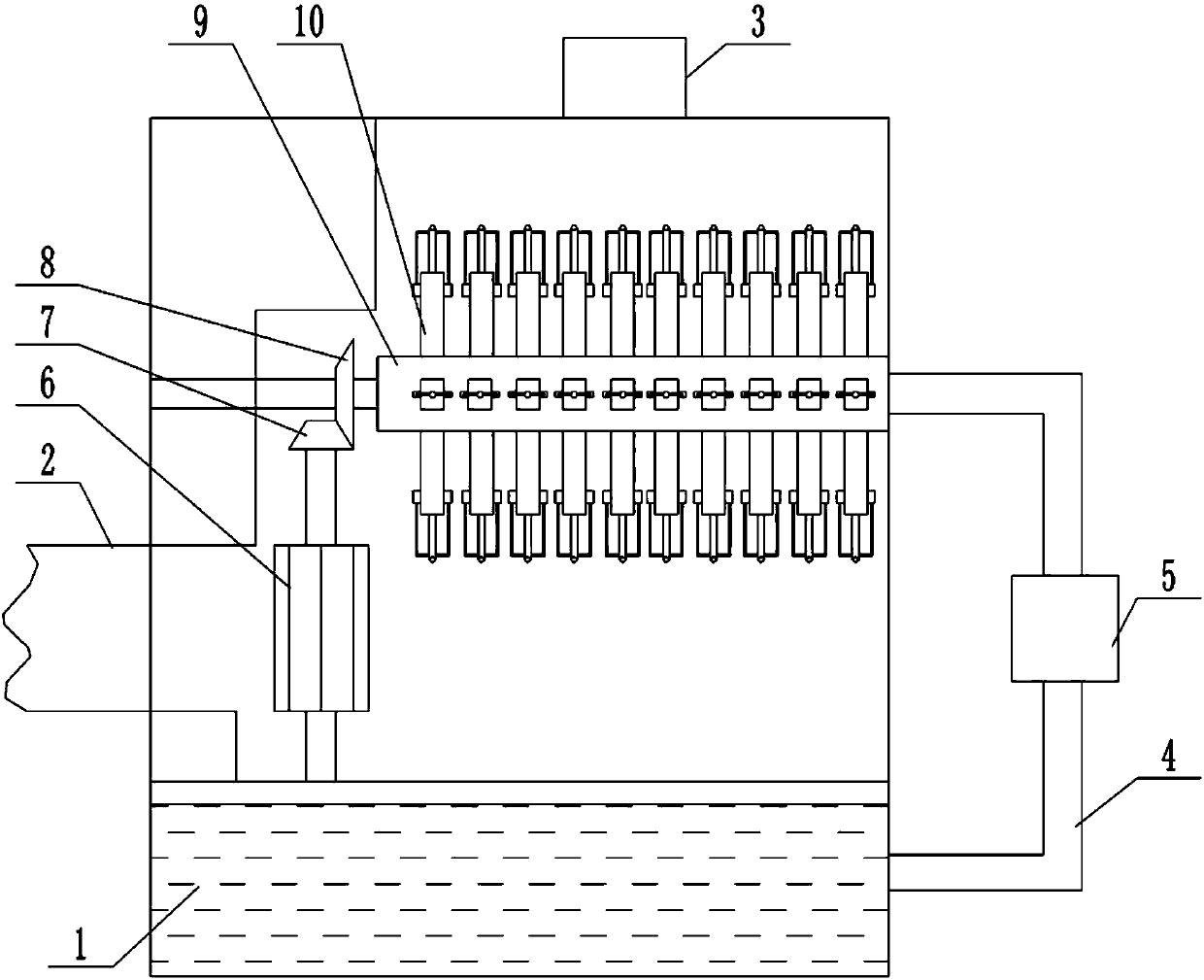

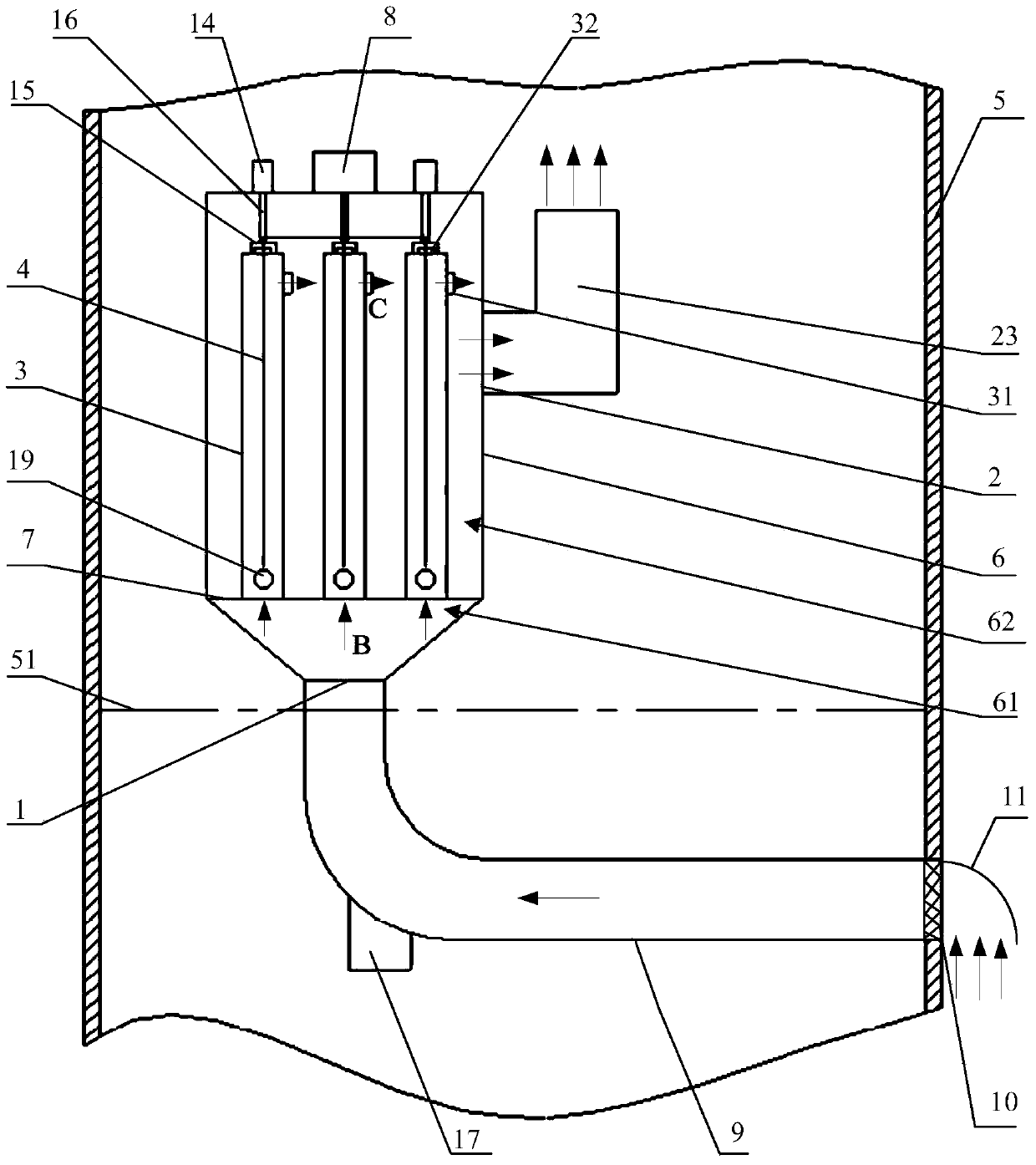

The invention relates to a blast furnace gas dry cloth-bag dust-removing device and technology, belonging to the metallurgy environmental protection dust removing technical field. The blast furnace gas dry cloth-bag dust-removing device and technology mainly comprise devices such as a dust-removing filtering device, an ash-clearing device, a dust-unloading and transporting device, an automatic control device, a gas dispersion device, and technologies such as large filtering wind speed, nitrogen or pure coal gas pulse current back-blowing and ash-clearing, pneumatic unloading and transporting ash and backup for nitrogen and pure coal gas, wherein, coal gas is filtered and purified by a filtering bag, the ash is back-blown by nitrogen or pure coal gas pulse current so as to control the resistance of the dust remover, thereby the filtering bag has the ideal dust removing effect, which is a dry dust-removing purification system having the advantages of high dust-removing efficiency, low dust content of the pure coal gas, low energy consumption of the dust-removing system, high heat efficiency of the pure coal gas and high automation degree; the filtering bag with over-long specification and a biserial pulse back-blowing system are adopted to meet the requirements of the dust-removing system upon a large filtering area and an excellent back-blowing efficiency; a crude gas bleeding valve group is increased to ensure that the coal gas with overproof temperature can not enter to a case of the dust remover, which protects the cloth-bag, controls effectively the high furnace roof pressure and operates the system more safer; the whole course waterless operation is realized so as to prevent the possibility of water containing coal gas dust to paste the filtering bag, thereby having the characteristics of less occupied area, short technology process, strong ability of clearing the ash, simple equipment and low labor intensity.

Owner:BAOTOU IRON & STEEL GRP

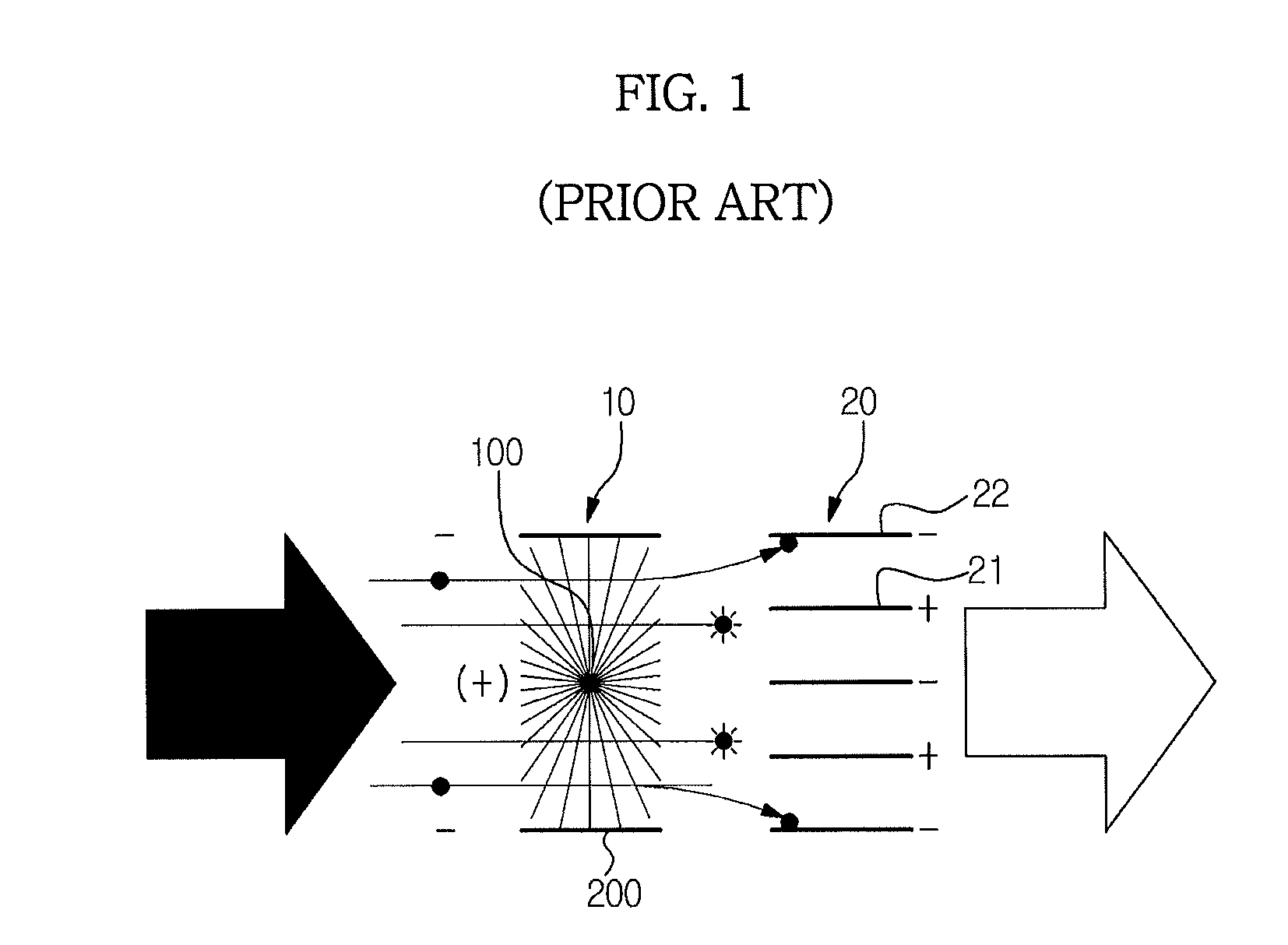

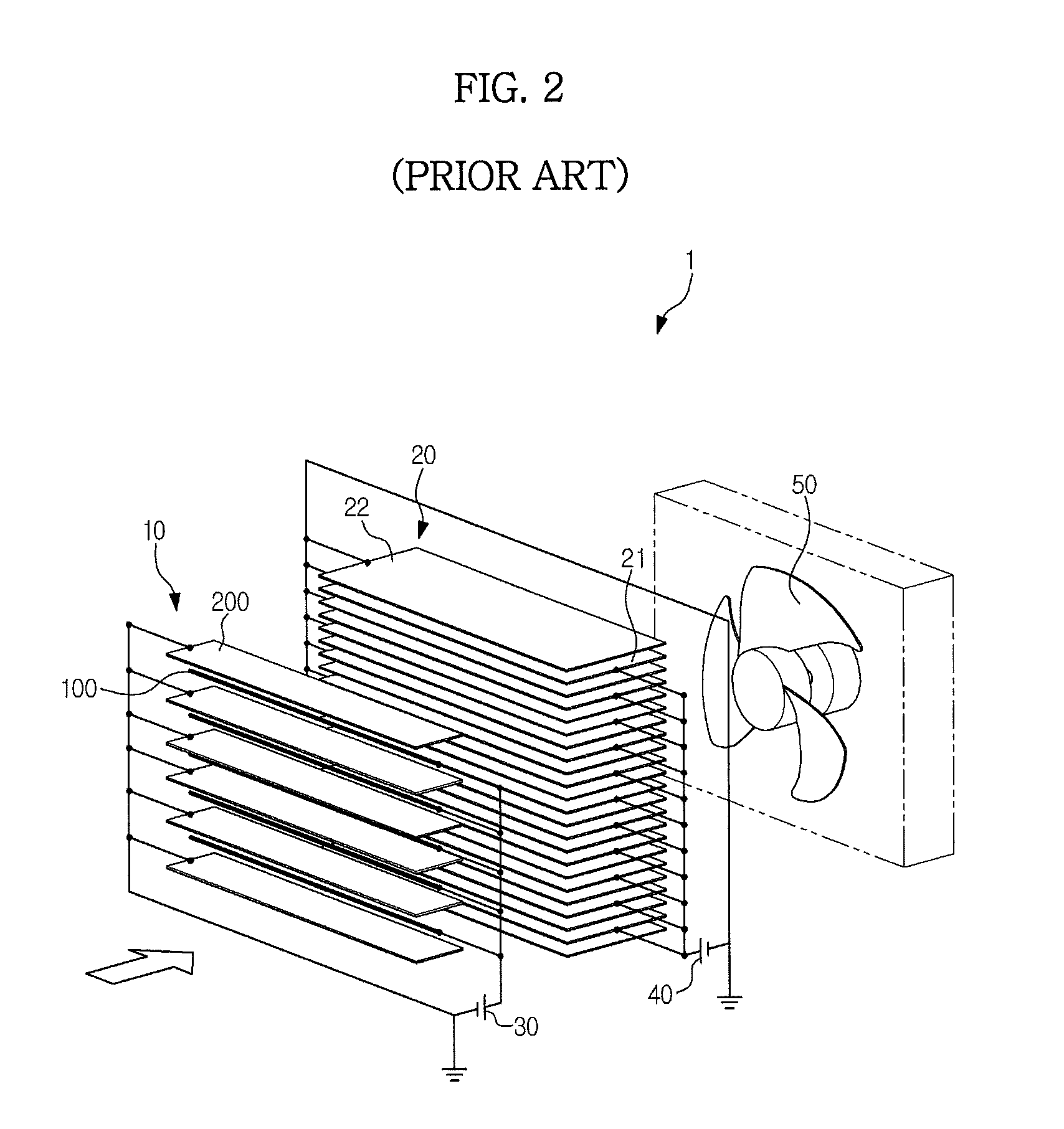

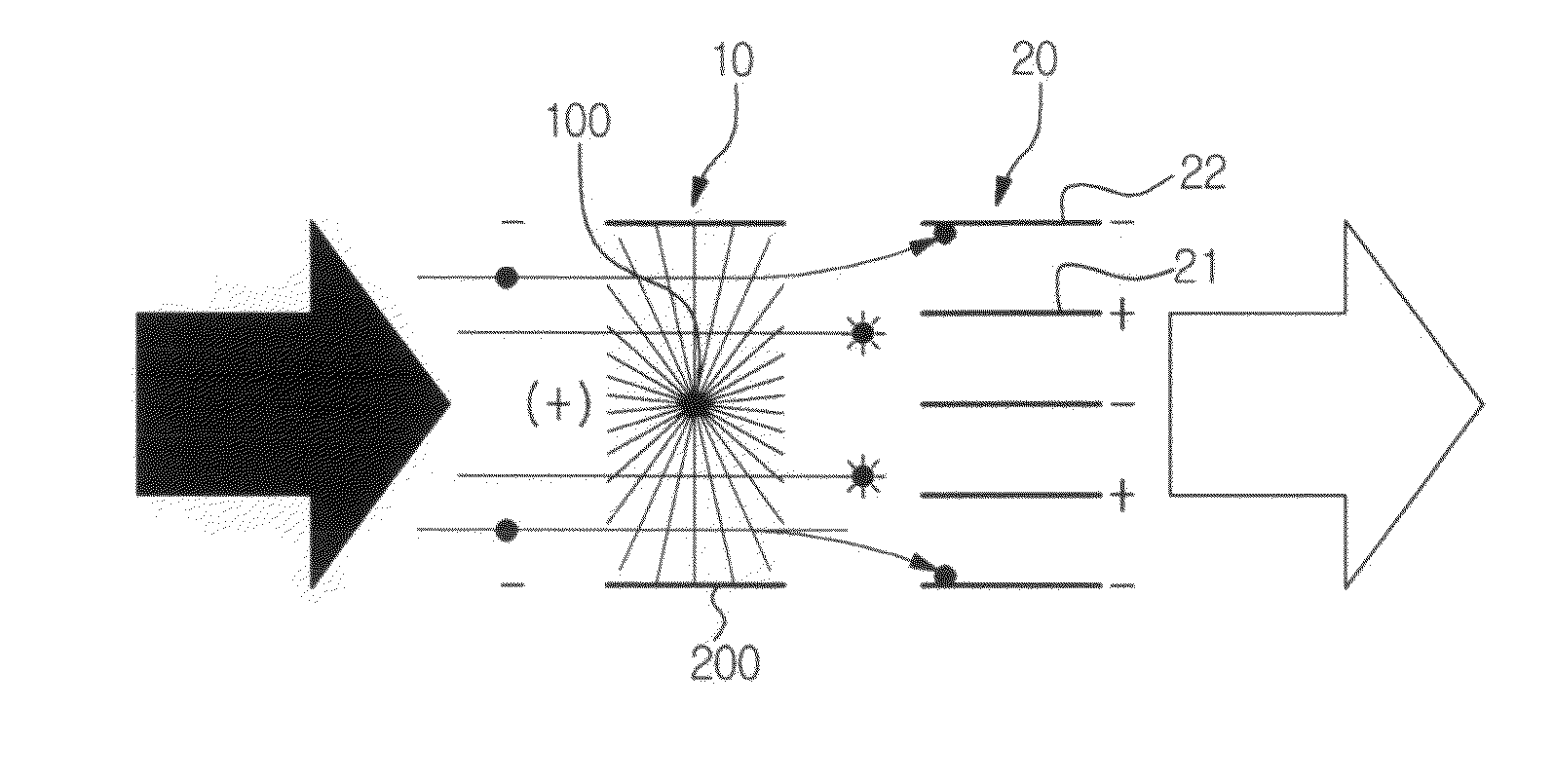

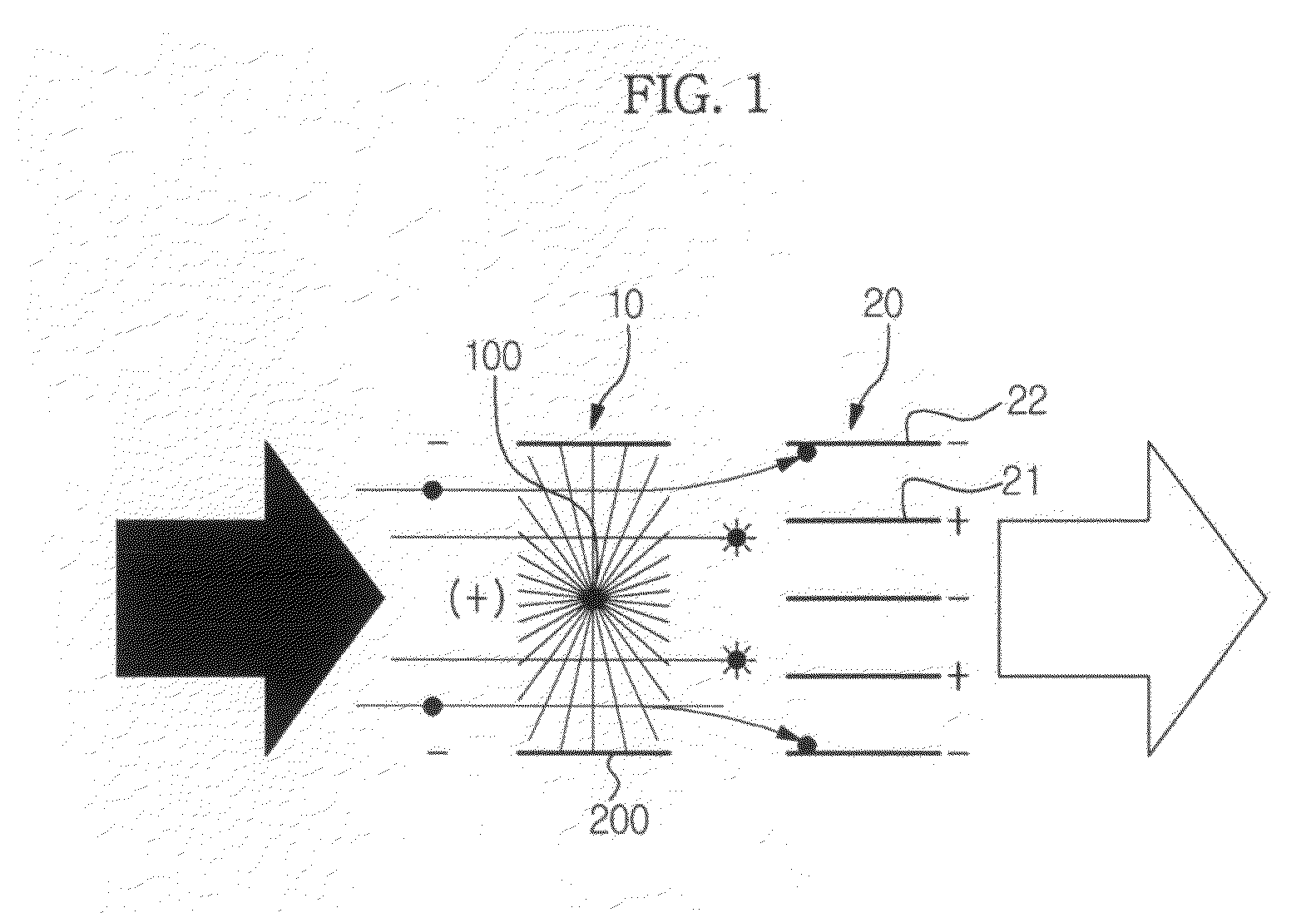

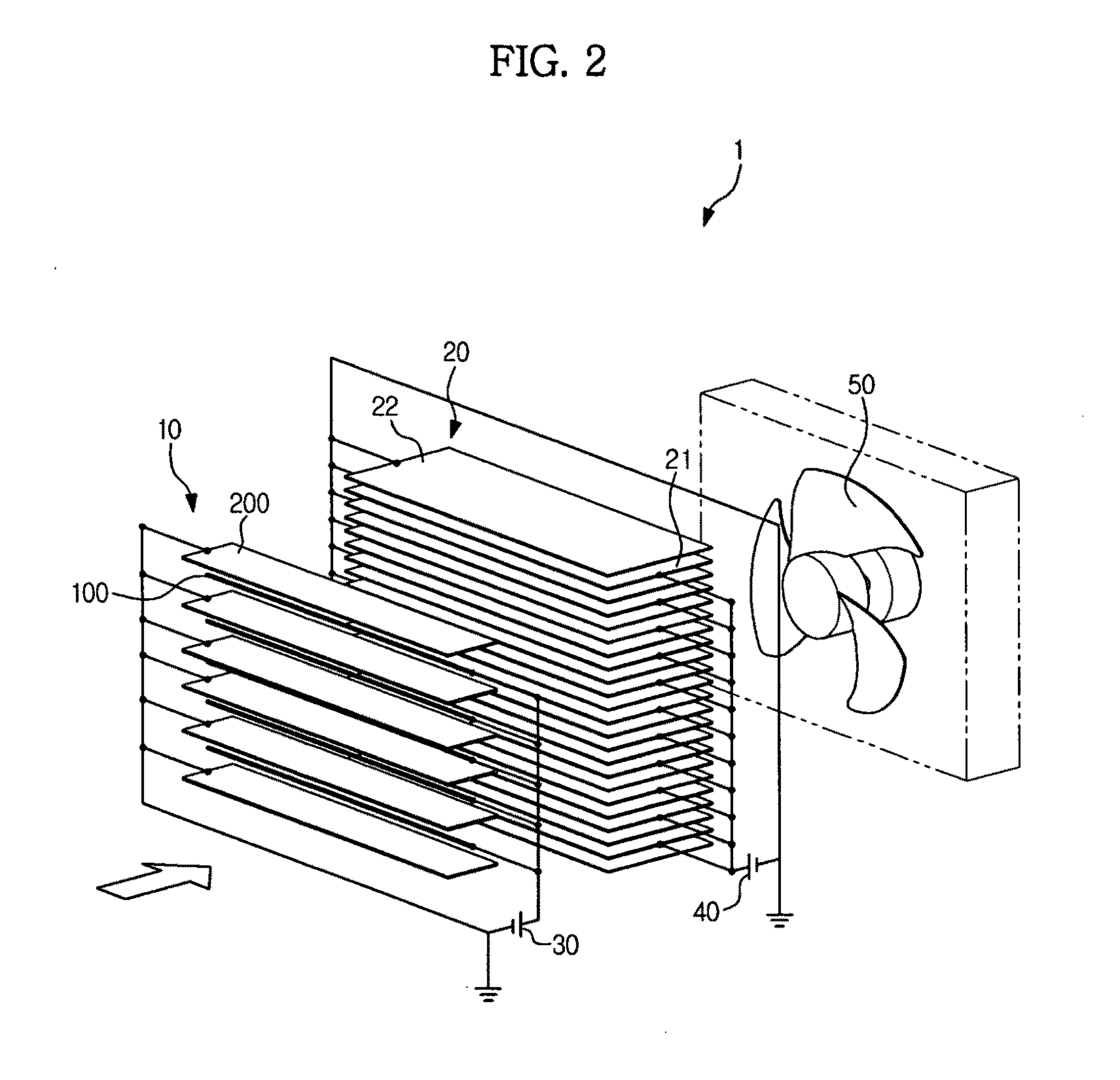

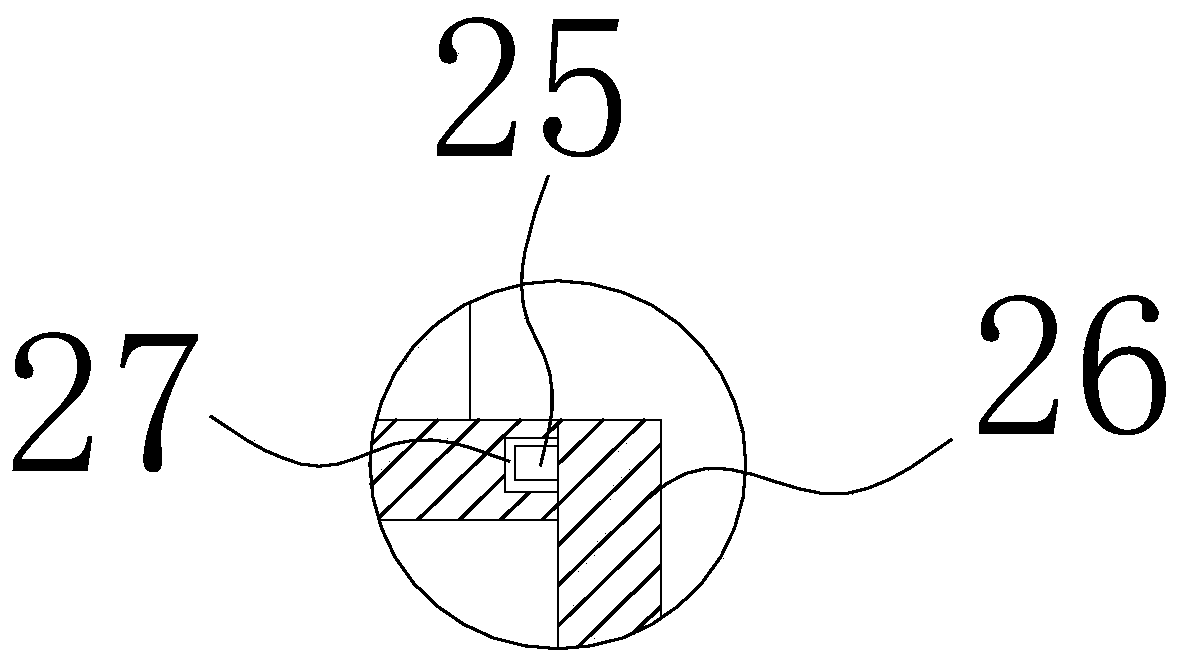

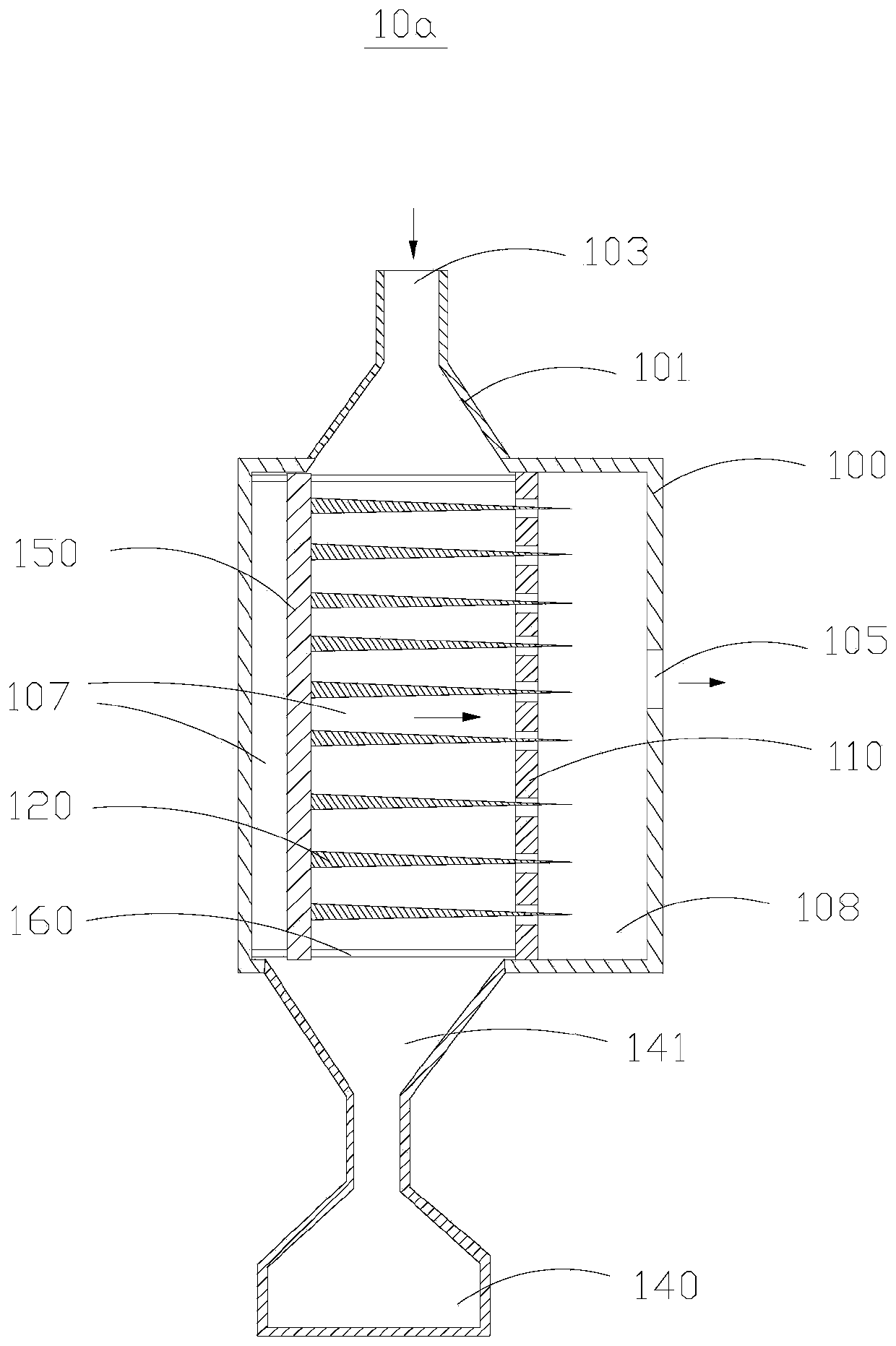

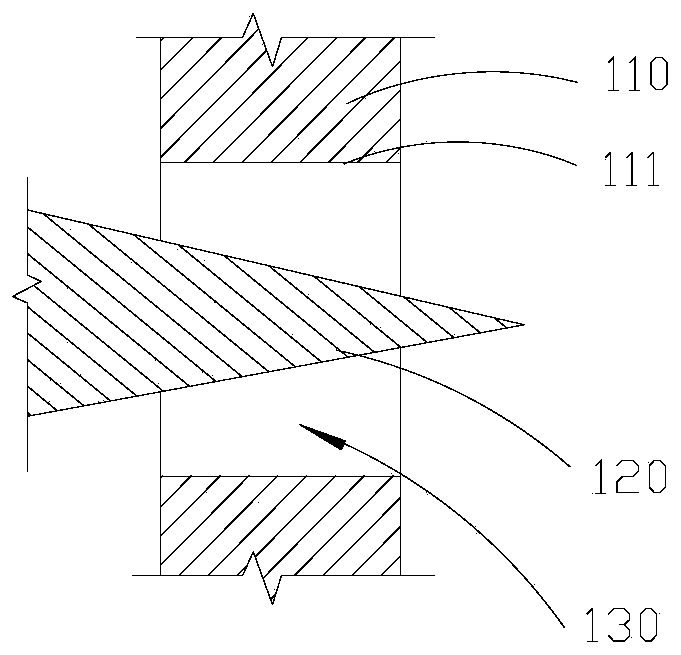

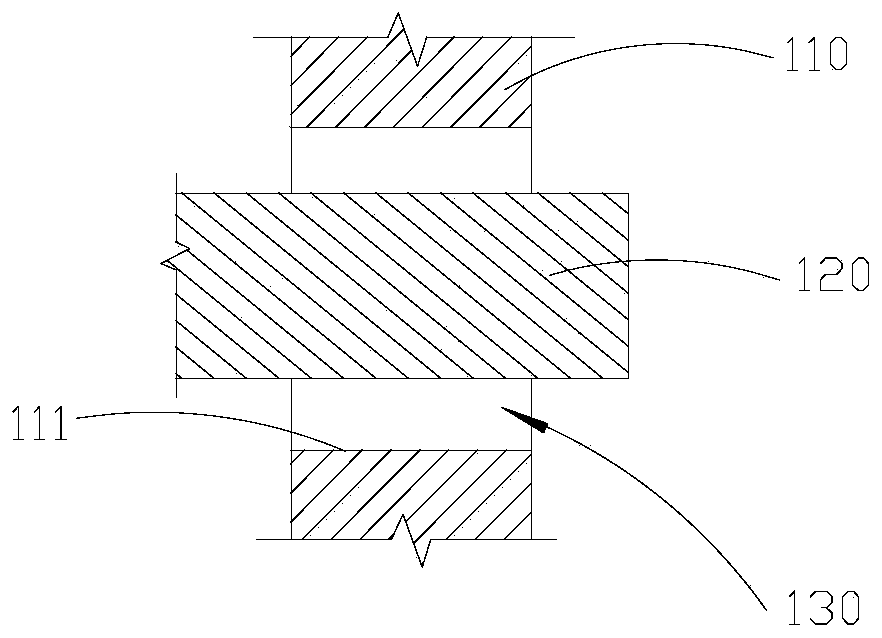

Electric precipitator and air cleaner having the same

ActiveUS8597415B2Efficient chargingReduce dust removal efficiencyDispersed particle filtrationExternal electric electrostatic seperatorElectricityEngineering

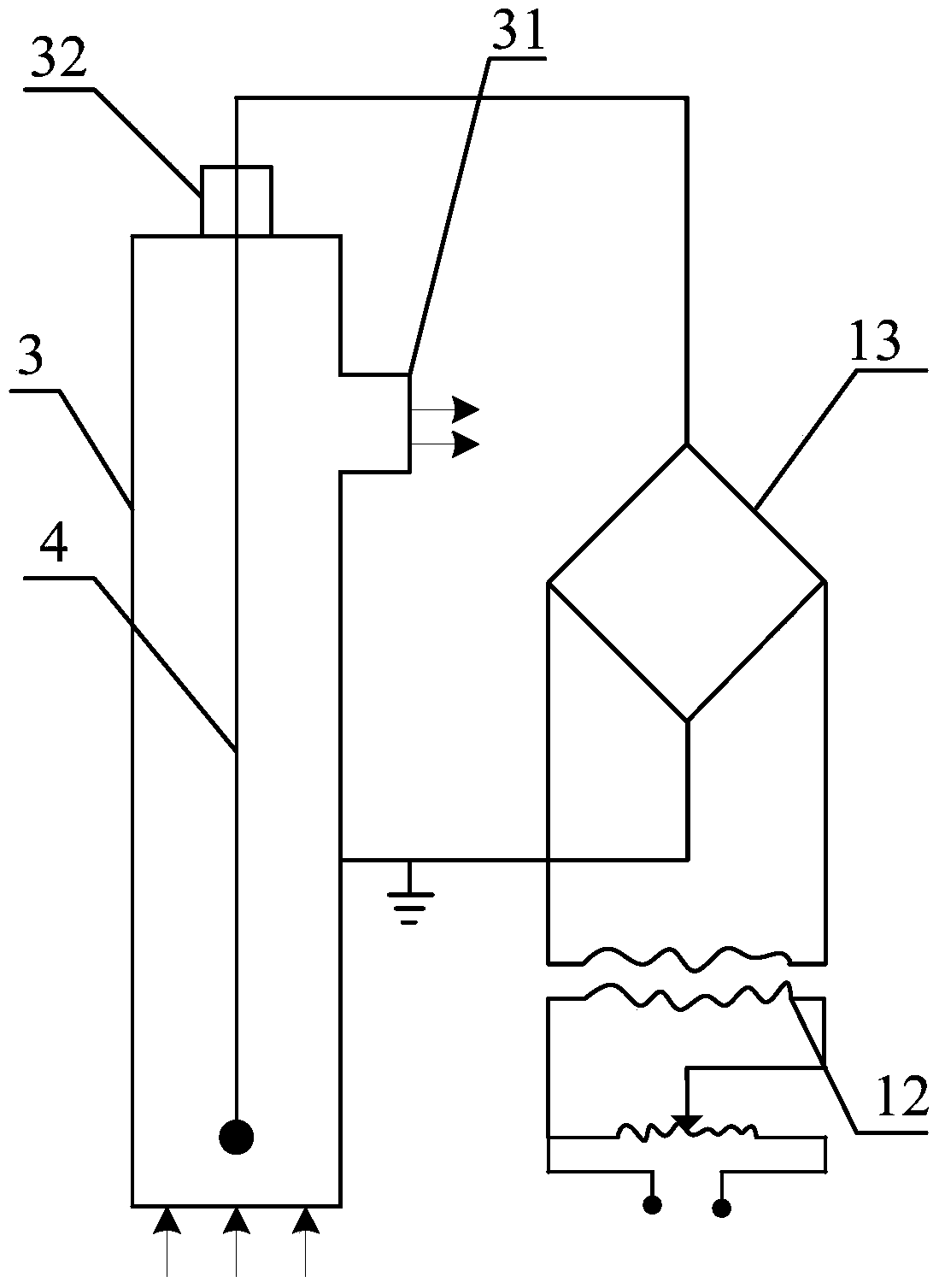

Disclosed herein are an electric precipitator, which efficiently charges dust particles without lowering dust collecting efficiency, although a velocity of an air current is not uniform, and an air cleaner having the same. The electric precipitator includes a charger unit including at least two charge cells to charge dust particles contained in air, and a collector unit to collect the dust particles charged by the charger unit. The at least two charge cells include a first cell, through which the dust particles pass at a first velocity, and a second cell, through which the dust particles pass at a second velocity different from the first velocity.

Owner:SAMSUNG ELECTRONICS CO LTD

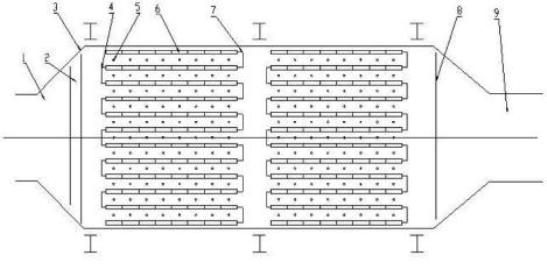

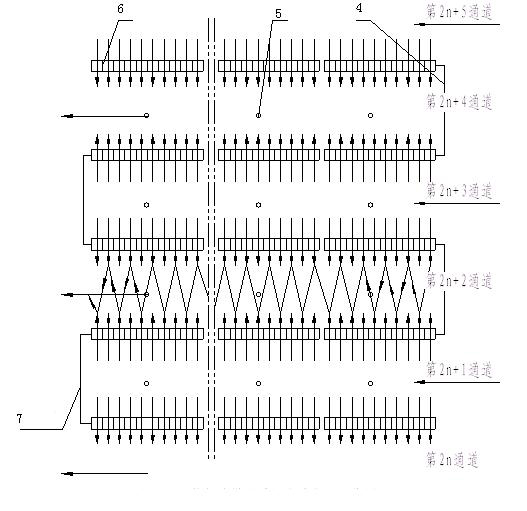

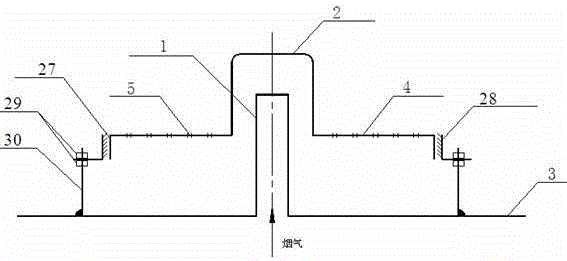

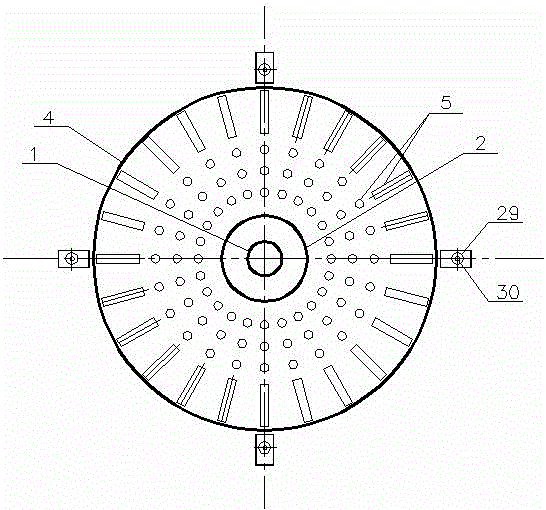

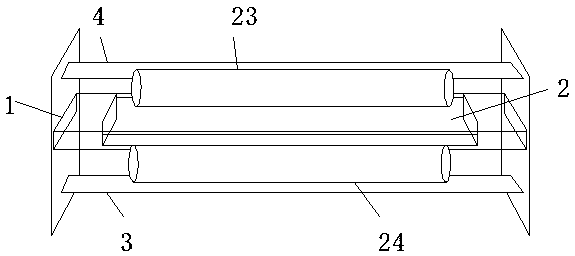

Grid type transverse air-intake turbulent flow type electric dust remover

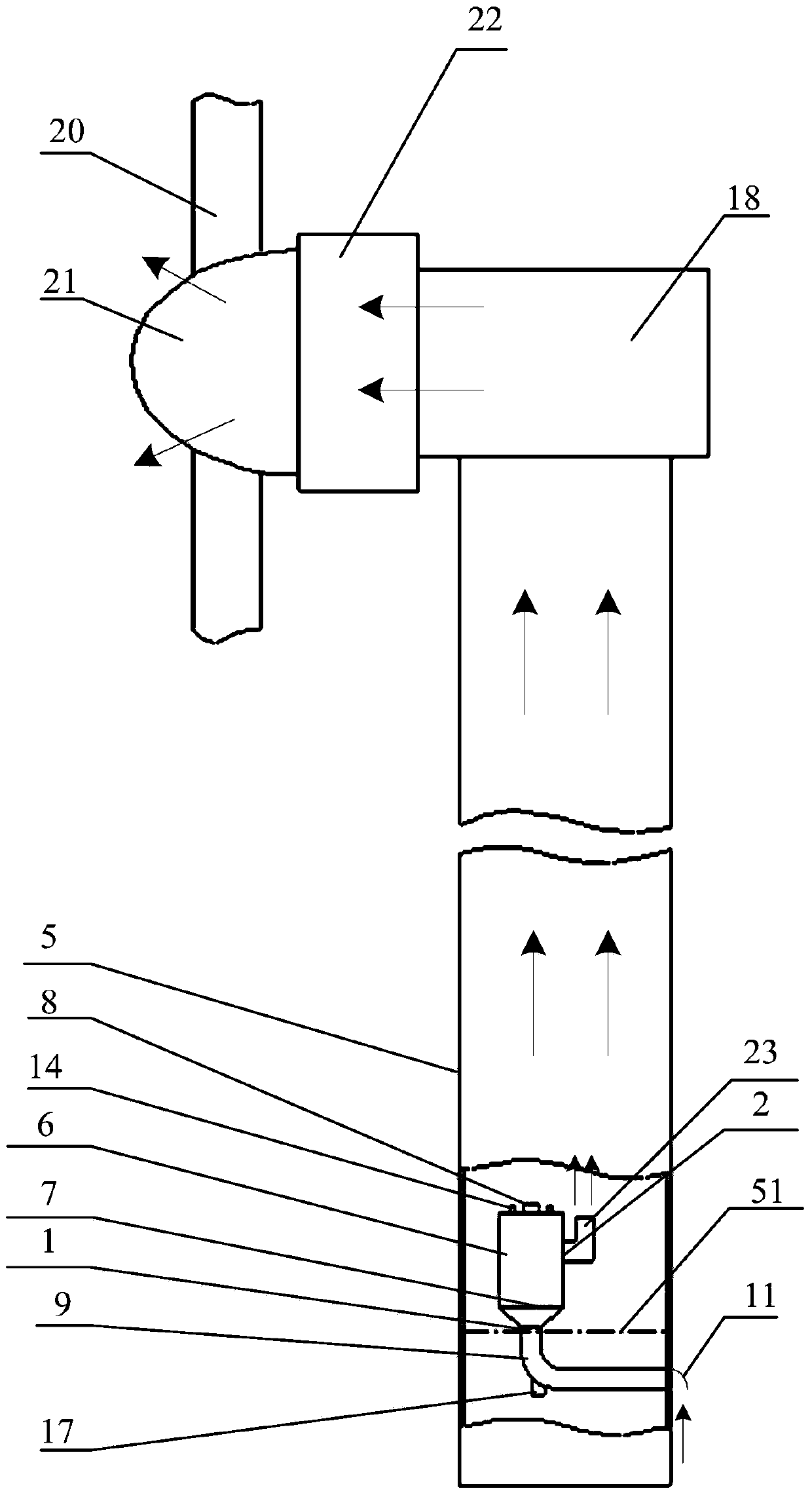

ActiveCN101804384AImprove dust removal efficiencyReduce dust removal efficiencyElectrode carrying meansExternal electric electrostatic seperatorInlet channelFlue gas

The invention relates to a grid type transverse air-intake turbulent flow type electric dust remover comprising a dust removing device and a vibrator, wherein the dust removing device uses mutliple rows of transverse turbulent flow air-intake grid plates as anode plates, the transverse turbulent flow air-intake grid plates are parallel to an air flow, a cathode wire and a gap used as a flue gas channel are arranged between the adjacent transverse turbulent flow air-intake grid plates in each row, the front ends of the flue gas channels formed by each row of transverse turbulent flow air-intake grid plates are provided with front seal plates at intervals to form a high-voltage electric field outlet channel, the back ends are provided with back seal plates at intervals to form a high-voltage electric field inlet channel, and the high-voltage electric field outlet channel is adjacent to the high-voltage electric field inlet channel. The invention adopts grid type transverse air intake to replace the longitudinal air intake of the conventional dust remover so that tail gas in the electric dust remover is changed into a novel turbulent flow state from the conventional basic layer flow state, the moving route and the running time of charged particles in the dust remover are prolonged so that the opportunity of capturing the charged particles close to or even directly contacting an easy-absorption pole is greatly increased, and meanwhile, a vibration system has a good effect to ensure that the polar plates of the dust remover are clean.

Owner:LIAOCHENG LUXI CHEM ENG DESIGN

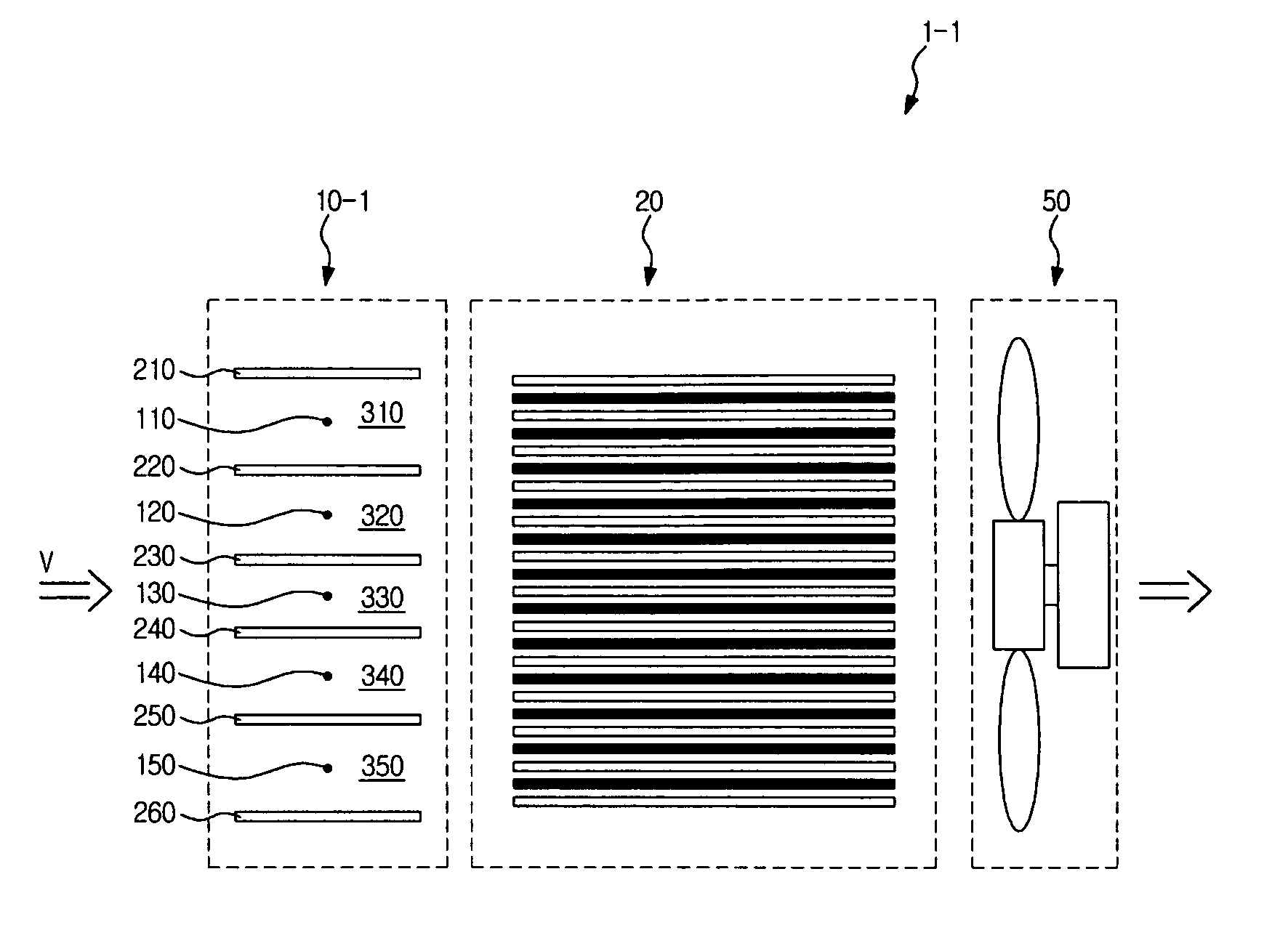

Electric precipitator and air cleaner having the same

ActiveUS20110094383A1Efficient chargingReduce dust removal efficiencyDispersed particle filtrationExternal electric electrostatic seperatorElectricityEngineering

Disclosed herein are an electric precipitator, which efficiently charges dust particles without lowering dust collecting efficiency, although a velocity of an air current is not uniform, and an air cleaner having the same. The electric precipitator includes a charger unit including at least two charge cells to charge dust particles contained in air, and a collector unit to collect the dust particles charged by the charger unit. The at least two charge cells include a first cell, through which the dust particles pass at a first velocity, and a second cell, through which the dust particles pass at a second velocity different from the first velocity.

Owner:SAMSUNG ELECTRONICS CO LTD

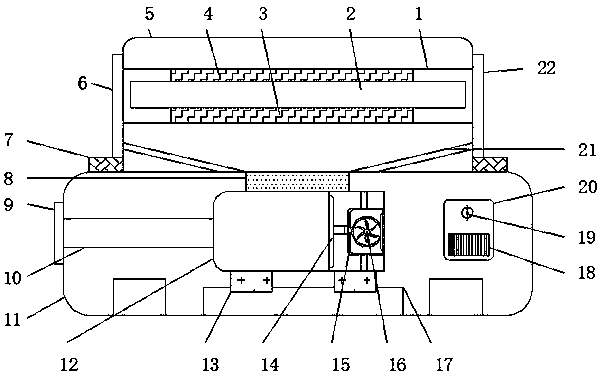

Air purifier with high concentration negative ions radiation

InactiveCN101011593AIncrease concentrationImprove dust removal efficiencyDeodrantsRadiationHigh concentrationUltraviolet lights

The invention relates to an air purifier with high-density anion radiation, which comprises a frame, a dust-collecting box, a fan, a plasma generator, a static dust-collecting plate and an ultraviolet disinfection lamp mounted on the frame, an air inlet, an air channel, an air door, and an air outlet, an automatic dust cleaner, a dust collector, a high-density anion generator mounted at the air outlet, a power source, and a display. The air channel is mounted on the frame as S-shaped laminated boosting channel, while each layer is independent and laminated with others to form multilayer unit. The plasma generator is mounted on each independent unit. The invention can release high-density anion, with low electricity consumption, high efficiency and stable output power, while the output airflow contains uniform high-density anion. The purifier can disinfect caught dust via ultraviolet light.

Owner:许海宁

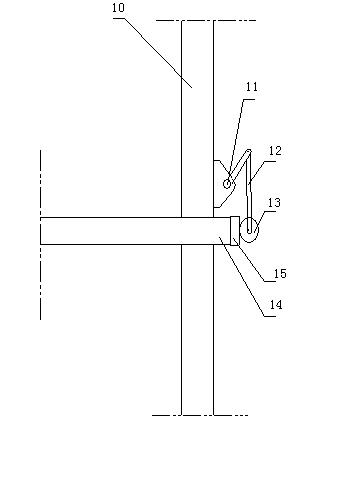

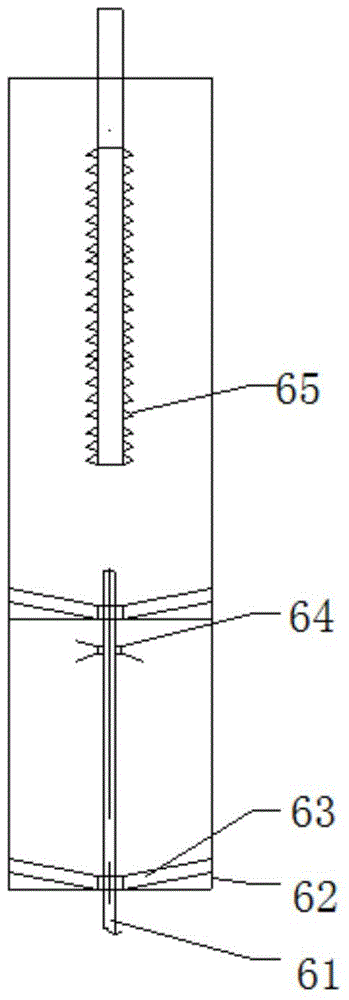

Mechanical-electrical integration dust removal demister

InactiveCN104888564ASpeed up the flowReduce the overall heightCombination devicesElectricityFlue gas

The invention relates to a mechanical-electrical integration dust removal demister used for a wet desulphurization device, and belongs to the field of flue gas purification. The mechanical-electrical integration dust removal demister comprises a plurality of dust removal demisting units, wherein each dust removal demisting unit comprises a rotational flow barrel, a wet-type dust removal device and a rotational flow plate-type mechanical dust removal demisting device, the wet-type dust removal device is positioned at the upper part of the interior of the rational flow barrel, the rotational flow plate-type mechanical dust removal demisting device is positioned at the lower part of the interior of the rational flow barrel, the wet-type dust removal device comprises a discharge electrode tube, the rotational flow plate-type mechanical dust removal demisting device comprises a water pipe, a flange, blades and nozzles, the water pipe is positioned on the central axis of the rotational flow barrel, one or more flanges are sleeved on the water pipe at intervals, a plurality of blades are arranged between the flange and the barrel wall of the rotational flow barrel, and a plurality of nozzles are arranged on the water pipe. The mechanical-electrical integration dust removal demister fully integrates the advantages of rotational flow plate-type mechanical dust removal and electric dust removal, and is simple in structure, simple in maintenance and high in efficiency.

Owner:田鹏程

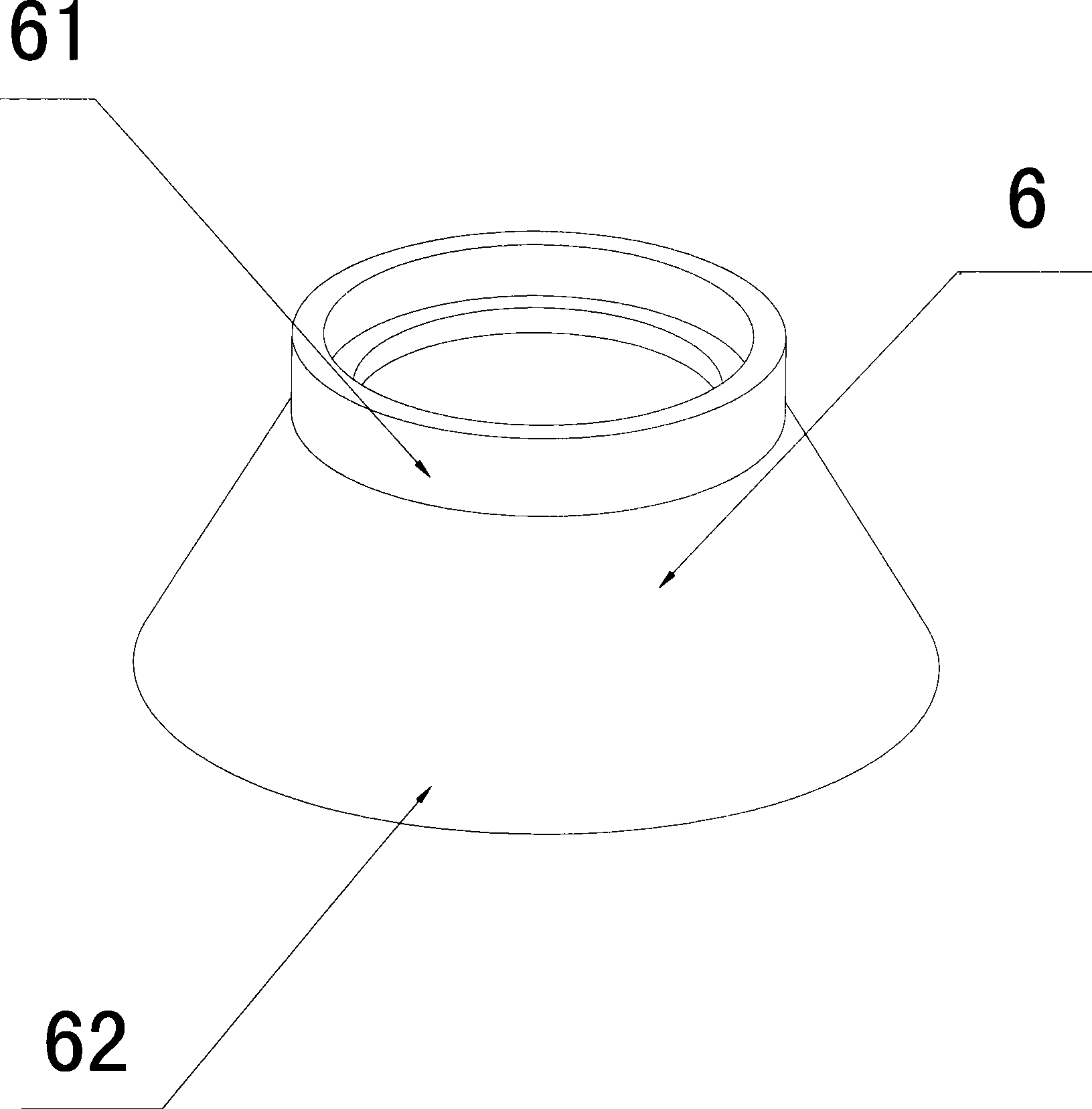

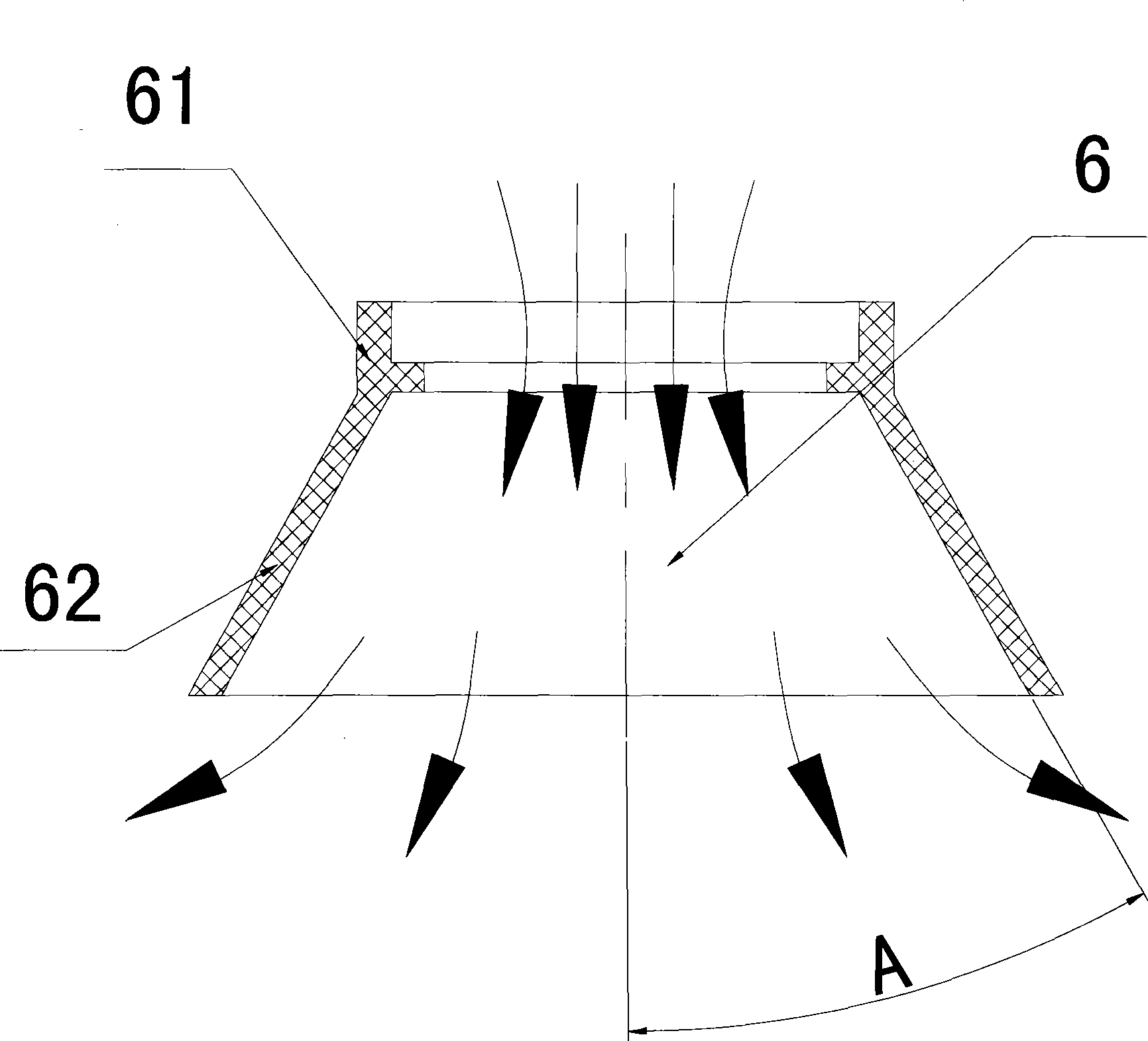

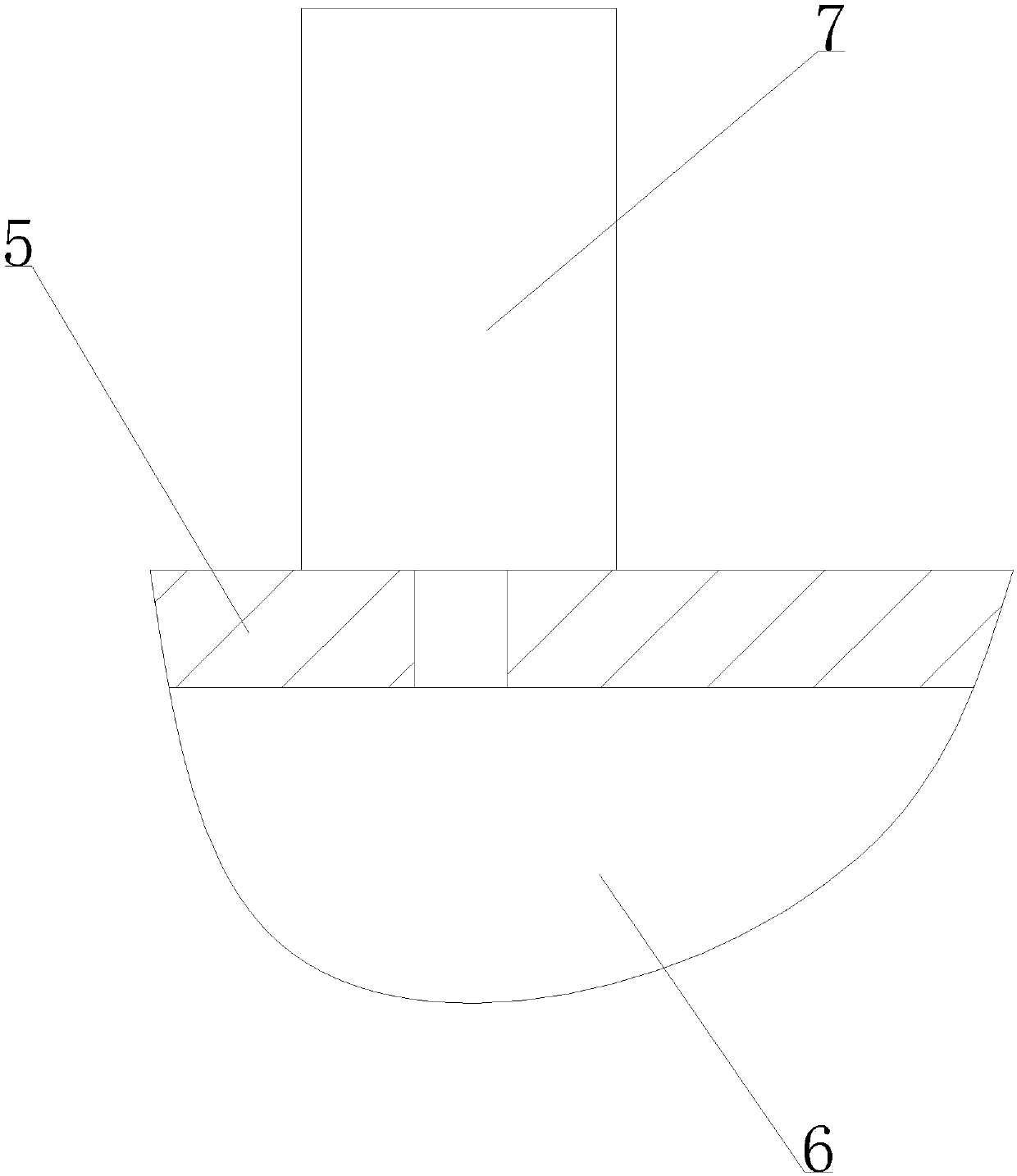

Water filtering and dust removing device of dust collector

The invention discloses a water-filtering dedusting device of a dust catcher, which is mainly featured in that the end of an air inlet pipe in a dust cup is provided with a diffusion element with a downward opening. When the dust catcher catches dust, dusty gas with a certain speed passes through the air inlet pipe and then reaches the diffusion element; under the diffusion effect of the diffusion element, the speed of the dusty air is slowed down, the contact surface with water is enlarged and the contact is more complete, so dust in the dusty air can be filtered by water more completely and the filter quality of the water-filtering dedusting device of the dust catcher can be improved. Meanwhile, the invention also discloses a water-filtering dust catcher. Three baffles arranged in a water-gas separation chamber of the water-filtering dust catcher form a twisted wind channel which can obstruct moist air and change the flowing direction of the moist air after water filtering, and fine grains in the air can be further attached and filtered so as to greatly improve the filtering quality and dedusting effect of the water-filtering dust catcher.

Owner:KINGCLEAN ELECTRIC

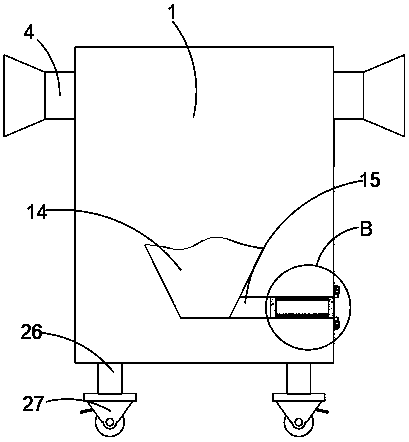

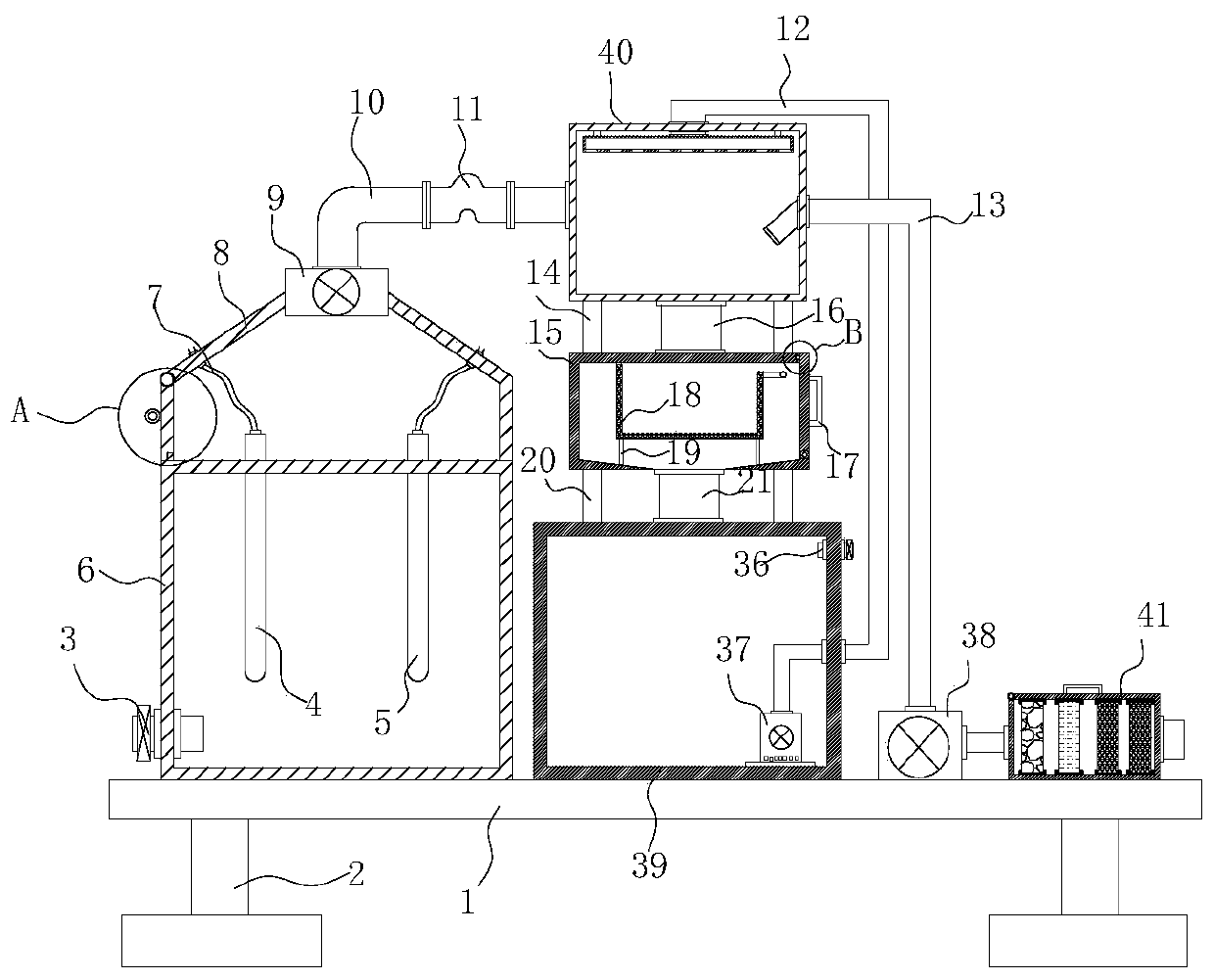

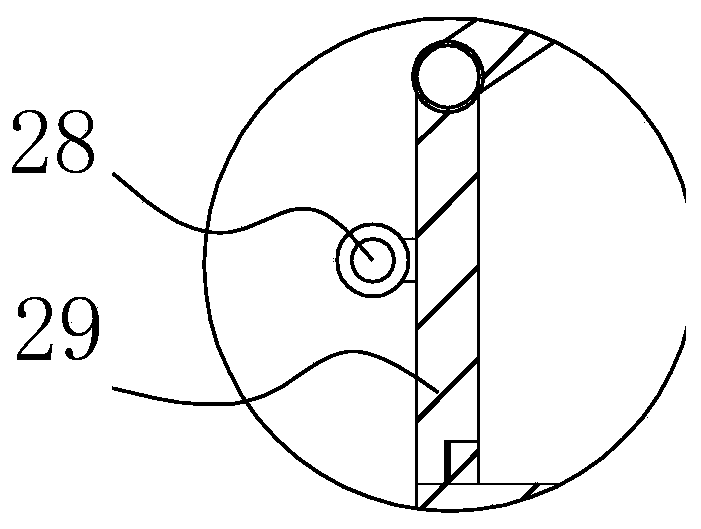

Flue gas dust removal device

InactiveCN107890739AImplement automatic cleanupGuaranteed adsorption effectCombination devicesWater pipeWheel drive

The invention relates to a flue gas dust removal device comprising a casing and a filter element. The filter element comprises a rotating part and a blade, a first cavity is arranged in the rotating part, a second cavity is arranged in the blade, the blade is provided with an opening, the rotating part is in communication with the blade, a conical vertical rod connected with the rotating part is arranged in the second cavity, a baffle is slidably arranged on the inner wall of the second cavity, a tension spring is connected between the baffle and the rotating part, the baffle is provided witha through hole, a water pipe is connected with the baffle, the water pipe extends through the opening to the outside of the blade, a pressure valve is arranged on the side wall of the water pipe, andthe water pipe is connected with an internal hollow water ball. The water ball has a water outlet hole, a cleaning block is slidably arranged on the outer wall of the blade, a connecting rod is connected between the cleaning block and the water ball, a pressure block is slidably arranged on the inner wall of the opening, a spring is connected between the inner wall of the blade and the pressure block, a wind wheel is arranged in the casing, the wind wheel drives the rotating part to rotate, the bottom of the casing is provided with a water tank, and the rotating part is communicated with the water tank by a connecting pipe. Th e flue gas dust removal device realizes the automatic cleaning of the filter element.

Owner:ZUNYI CITY GUI KE TECH

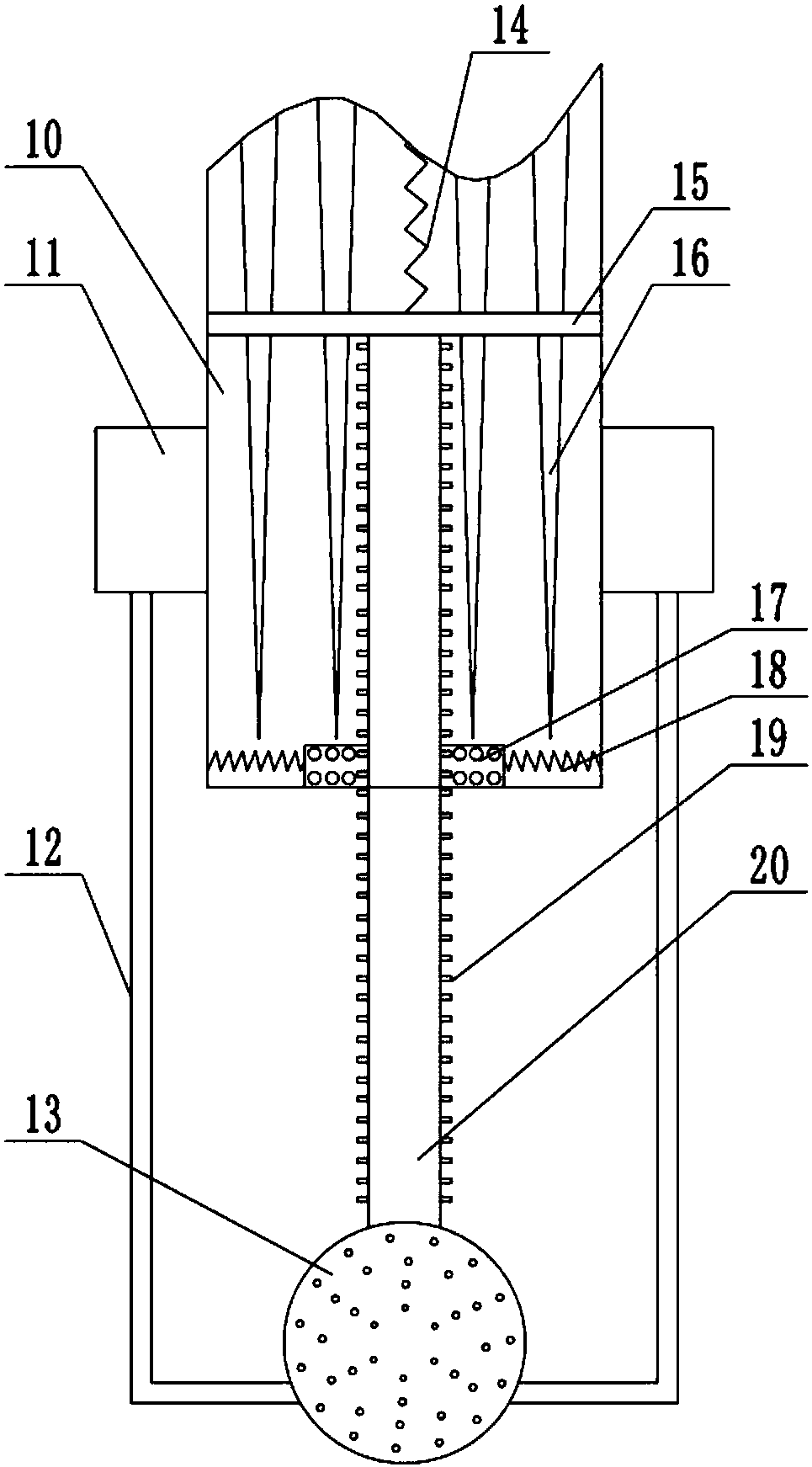

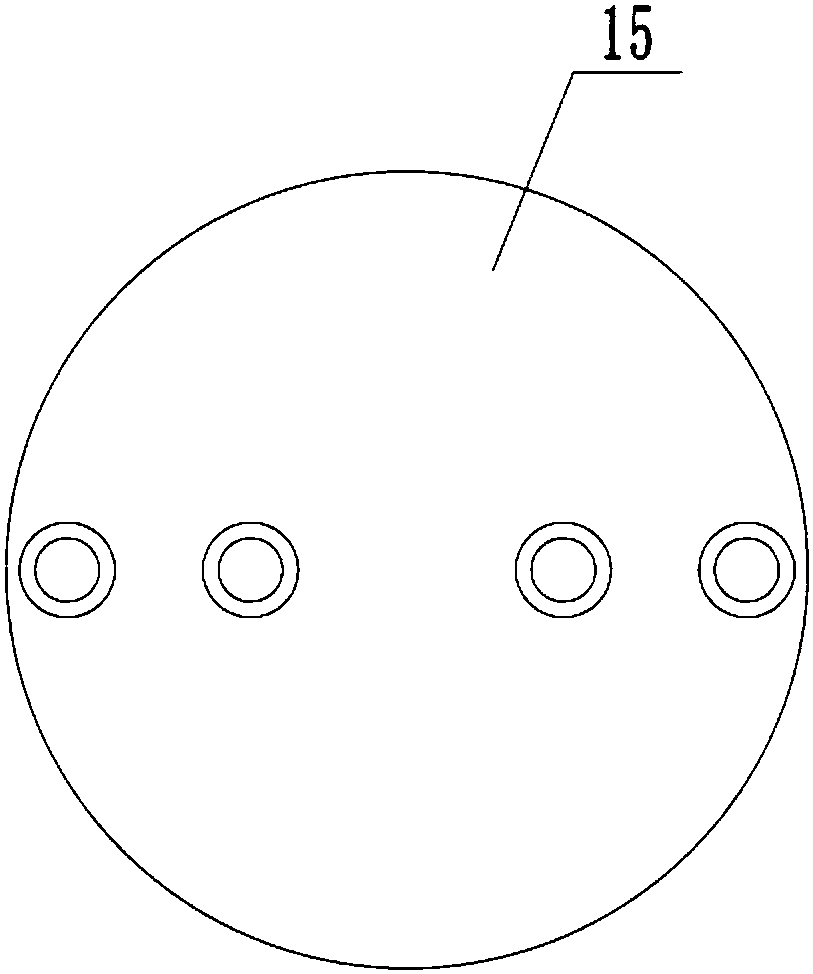

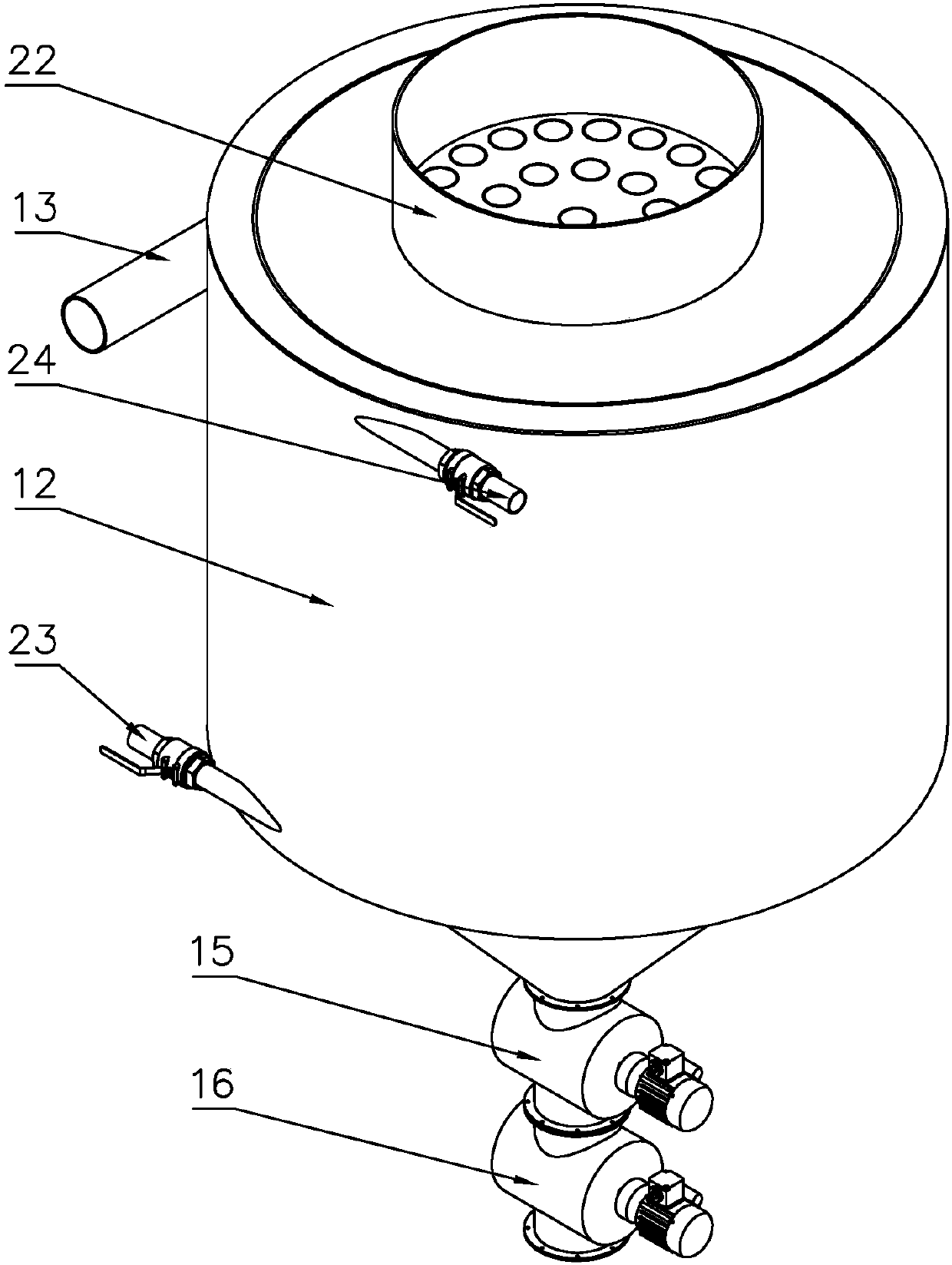

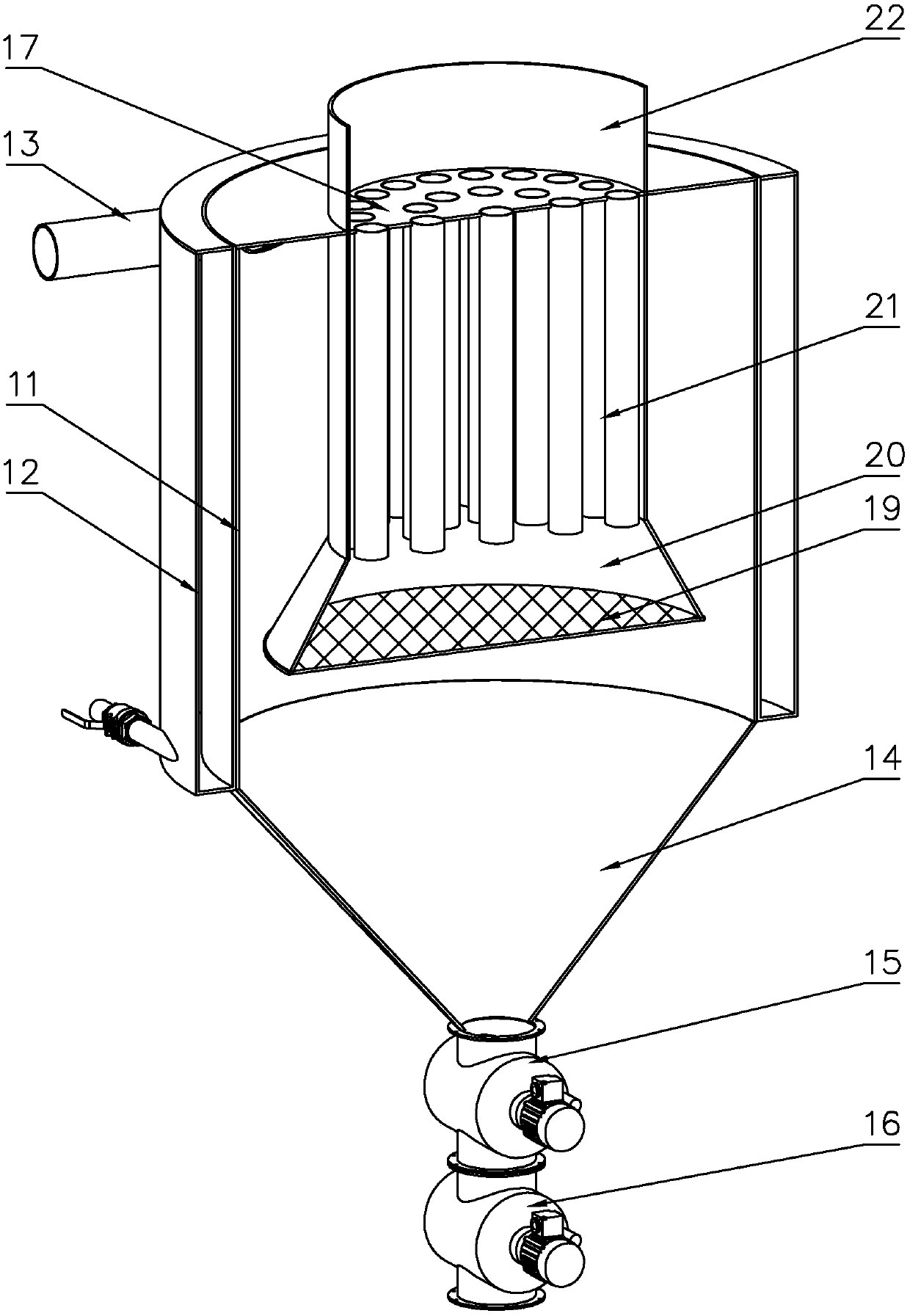

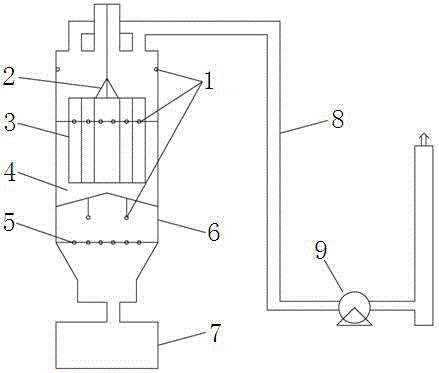

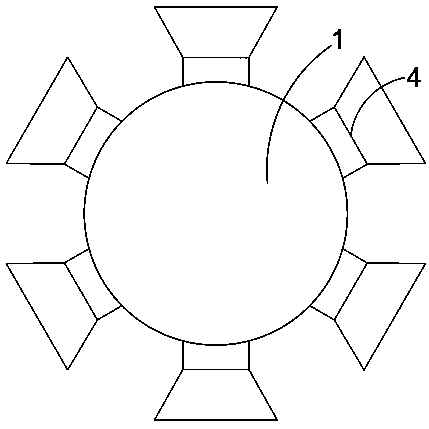

Cyclone-type and bag-type composite dust remover

The invention discloses a cyclone-type and bag-type composite dust remover. The cyclone-type and bag-type composite dust remover comprises a cyclone, a gas inlet pipe, a conical hopper, a star-shapeddust discharging valve I, a tube nest, filter bags and a gas outlet pipe, wherein the gas inlet pipe is arranged on one side of the upper part of the cyclone; the gas inlet pipe is tangentially connected with the cyclone; the conical hopper is arranged on the lower side of the cyclone; the star-shaped dust discharging valve I is arranged on the lower side of the conical hopper; the gas outlet pipeis arranged inside the cyclone; the tube nest is arranged on the upper side of the gas outlet pipe; the tube nest is positioned inside the gas outlet pipe; a plurality of uniformly distributed filterbags are arranged on the lower side of the tube nest; the filter bags are positioned inside the gas outlet pipe. The cyclone-type and bag-type composite dust remover firstly performs cyclone dust removal on dust-containing waste gas through the cyclone so as to remove large-particle dust in the waste gas, and then filters small-particle dust through bag dust removal, so that reduction in the dustremoving efficiency, caused by dust accumulation in the filter bags, is avoided, and the service lives of the filter bags are prolonged; in addition, through the integration of cyclone dust removal and bag dust removal, the structure is compact, the floor area of equipment is reduced and the production cost of an enterprise is lowered.

Owner:张士伟

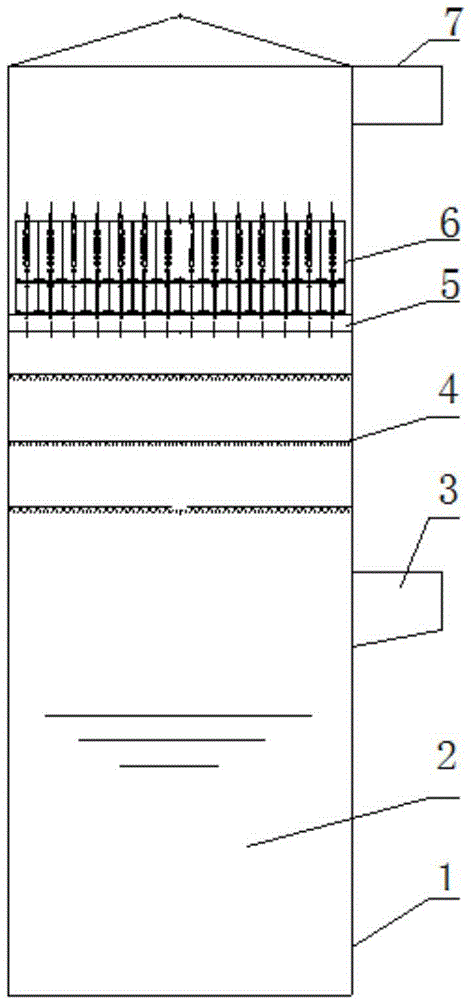

Method and device for electromagnetic collaborative electrofiltration dust removal

ActiveCN105727676AEconomical and efficient removalEfficient dust removal efficiencyCombination devicesGas treatmentParticulatesElectricity

The invention discloses a method and device for electromagnetic collaborative electrofiltration dust removal.Dust-laden waste gas passes through a corona discharging area for charging, collaborative intensification is carried out through electric field force and magnetic field force, charged particles are made to move towards electrofiltration cloth with electric dust collection and adsorption filtering functions and are intercepted through the adsorption and filtering effects of the electrofiltration cloth, and gas penetrates through the electrofiltration cloth to be purified.In the dust removal process, corona electrodes carry out discharging to charge the particles, the conductive electrofiltration cloth serves as a dust collection electrode to attract the charged particles under the effect of electric field force and carries out filtration and capture, and the intensity and the direction of the magnetic field can be regulated and controlled through a magnetic field generator to reinforce removal of the particles.According to the method and device for electromagnetic collaborative electrofiltration dust removal, the advantages of electric dust removal, cloth bag dust removal and other technologies are ingeniously coupled through the two functions of the electrofiltration cloth, the efficiency for removing the particles in industrial waste gas is greatly improved, and especially the efficiency for removing fine particles (PM2.5) which are difficult to remove can be higher than 99.9%.

Owner:KUNMING UNIV OF SCI & TECH

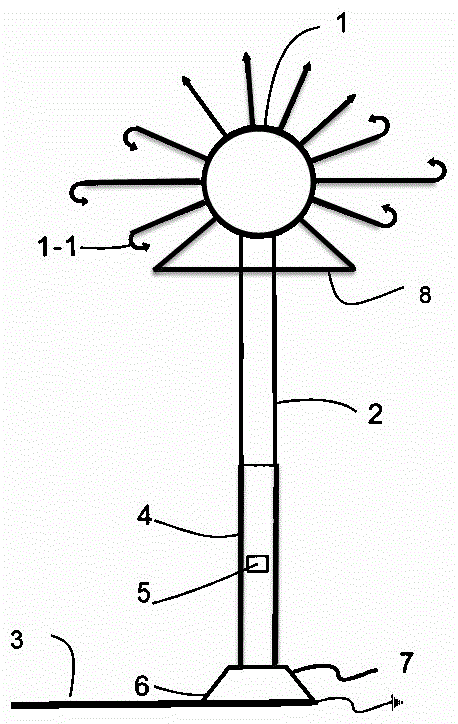

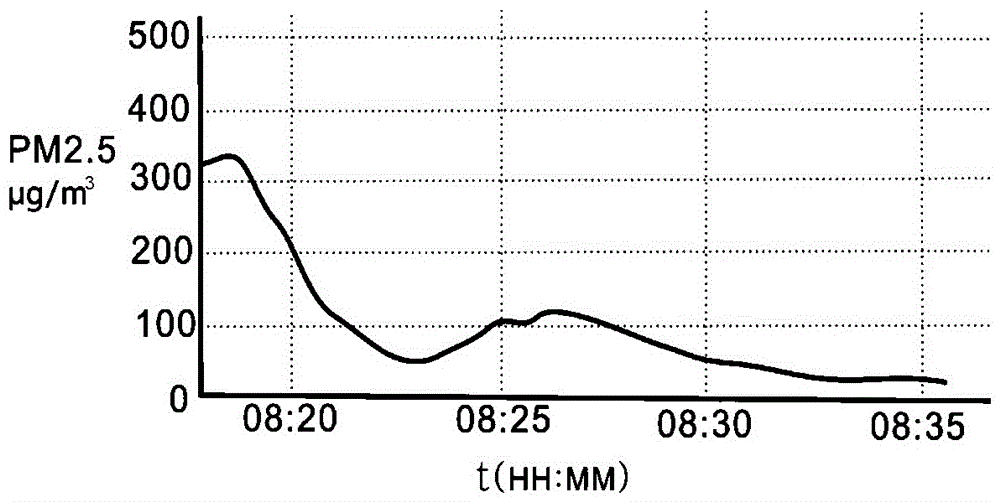

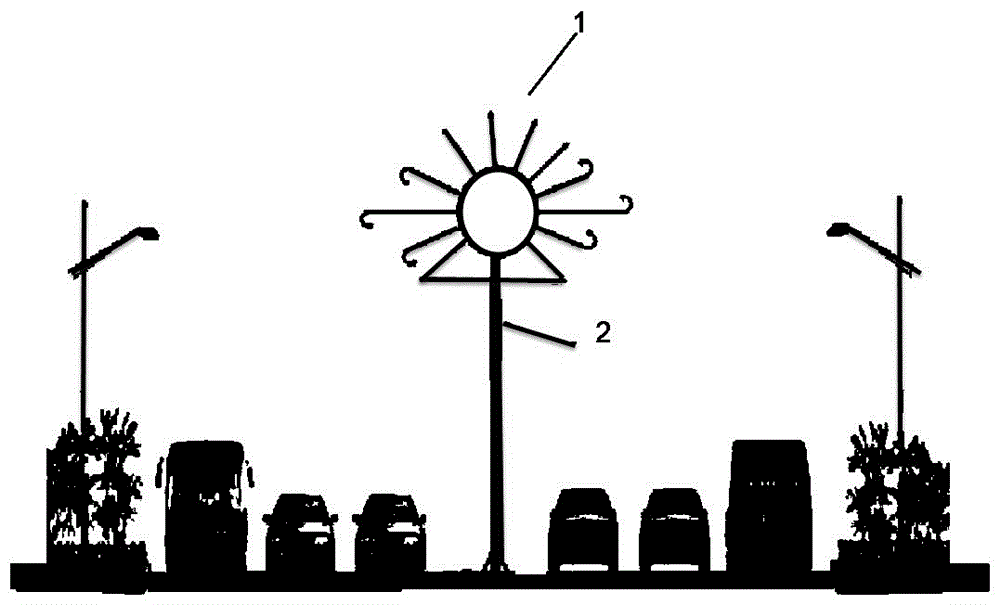

Efficient air purifier and purifying method

InactiveCN106000644AExpand the scope of spaceNo costExternal electric electrostatic seperatorElectric supply techniquesParticulatesElectrical conductor

The invention discloses an efficient air purifier and a purifying method. The efficient air purifier comprises a conductor which is insulated against the ground, and a power source transmitting electric charges to the conductor. The output end of the power source is connected to the conductor. The grounding end of the power source is connected with the ground. The purifying method includes that the conductor which is insulated against the ground is suspended or supported in air; the power source transmits the electric charges to the conductor continuously; the conductor generates an electric field; and particle matter in the air is fast settled to the ground under the effect of electric field force. Almost all electric energy on the conductor is converted into work done by the electric field force borne by the particle matter, the purifying efficiency on fine particle matter in air is high, in addition, noise, vibration and interference are not generated, pollution is avoided, and due to the high efficiency, the efficient air purifier and the purifying method are suitable for purifying fine particle matter in large-area high airspace of cities and industry zones or construction sites or the like.

Owner:北京华晶汇科技有限公司

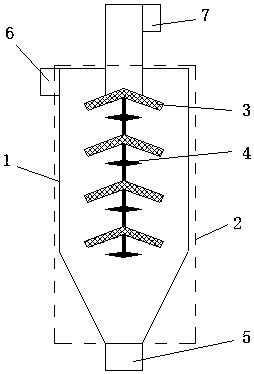

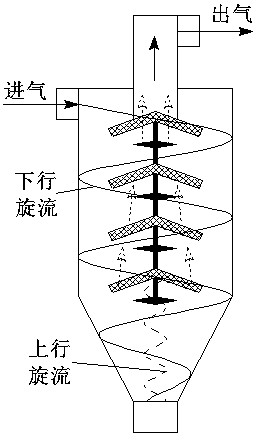

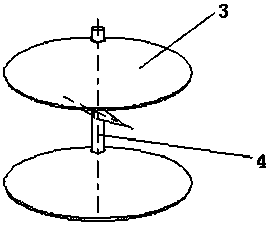

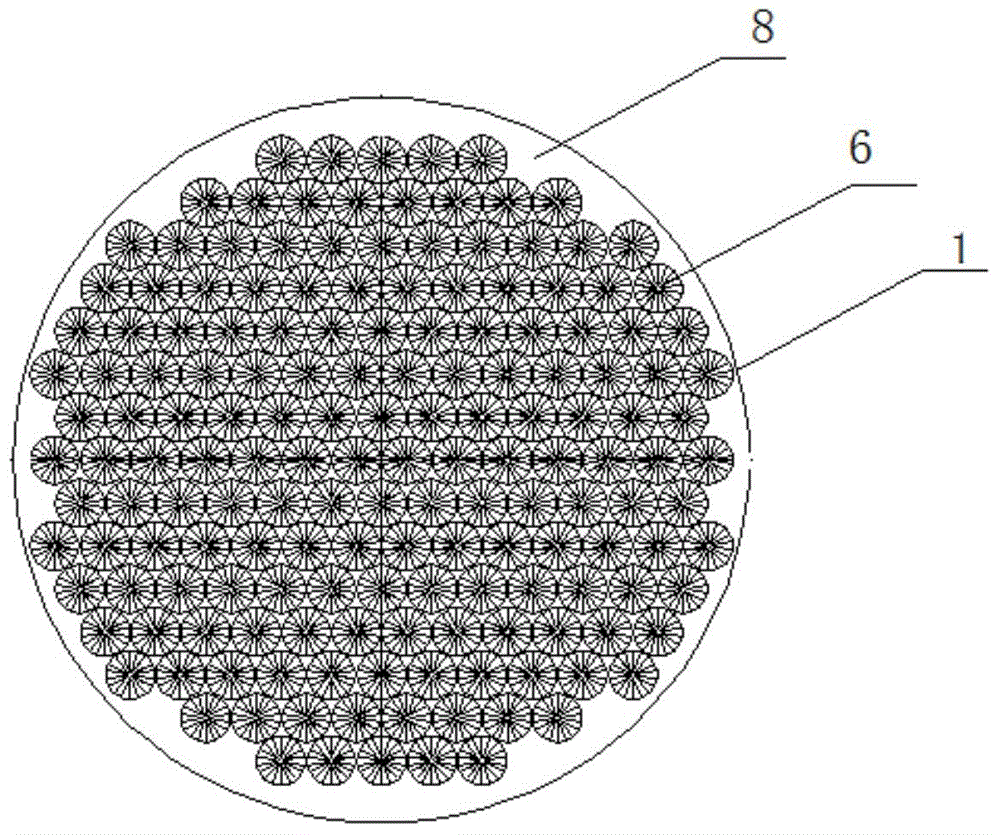

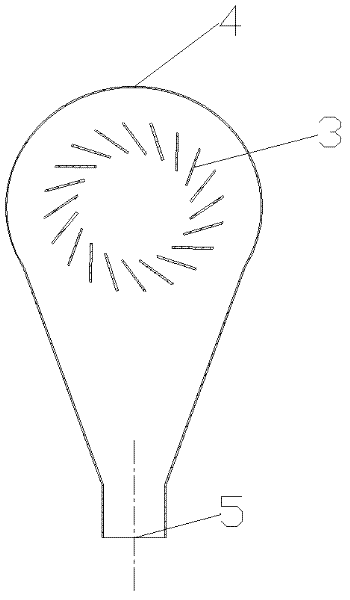

Device for deep purification of wet desulphurization absorption towersmoke

ActiveCN104906949AReduce the overall heightSpeed up the flowCombination devicesParticulatesEngineering

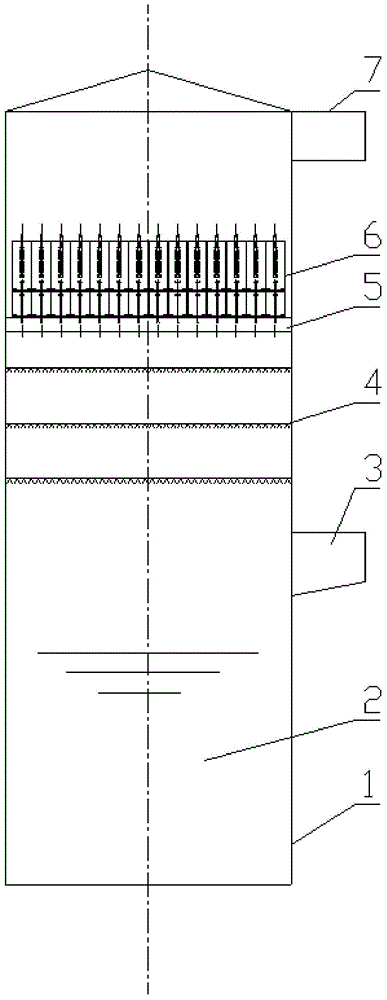

The inventionrelates to the technical field ofsmoke purification and in particular relates to a device for deep purification of wet desulphurization absorption towersmoke. The device comprises an absorption tower, wherein a slurry tank is arranged at the bottom of theabsorption tower; a smoke outlet is formed in the top of the side wall of theabsorption tower; a smoke inlet is formed in the side wall, higher than the liquid level of the slurry tank, of the absorption tower; a spraying layer and a supporting plate are arranged from bottom to up in sequencebetween the smoke inlet and the smoke outletabsorption tower; and themaximum number of deep purifiers are arranged on the support plate.Kinetic energy of the smoke in the absorption towercan be utilized; gas-liquidimpact isgenerated at blades of rotational flow plates andwalls of rotational flowcylinders when the smoke passes through the rotational flow plates of thepurifiers so thattiny particulate matters such asthin liquid drops, tiny dust particles and aerosol in the smoke impact,aggregate andagglomerate with one another to form large liquid drops; the large liquid drops are captured by surface liquid films of therotational flowcylinders, thusremovingthe tiny particulate matters and reachingthe aim of deep purification of the smoke.

Owner:BEIJING ZHONGNENG NUOTAI ENERGY SAVING & ENVIRONMENTAL PROTECTION CO LTD

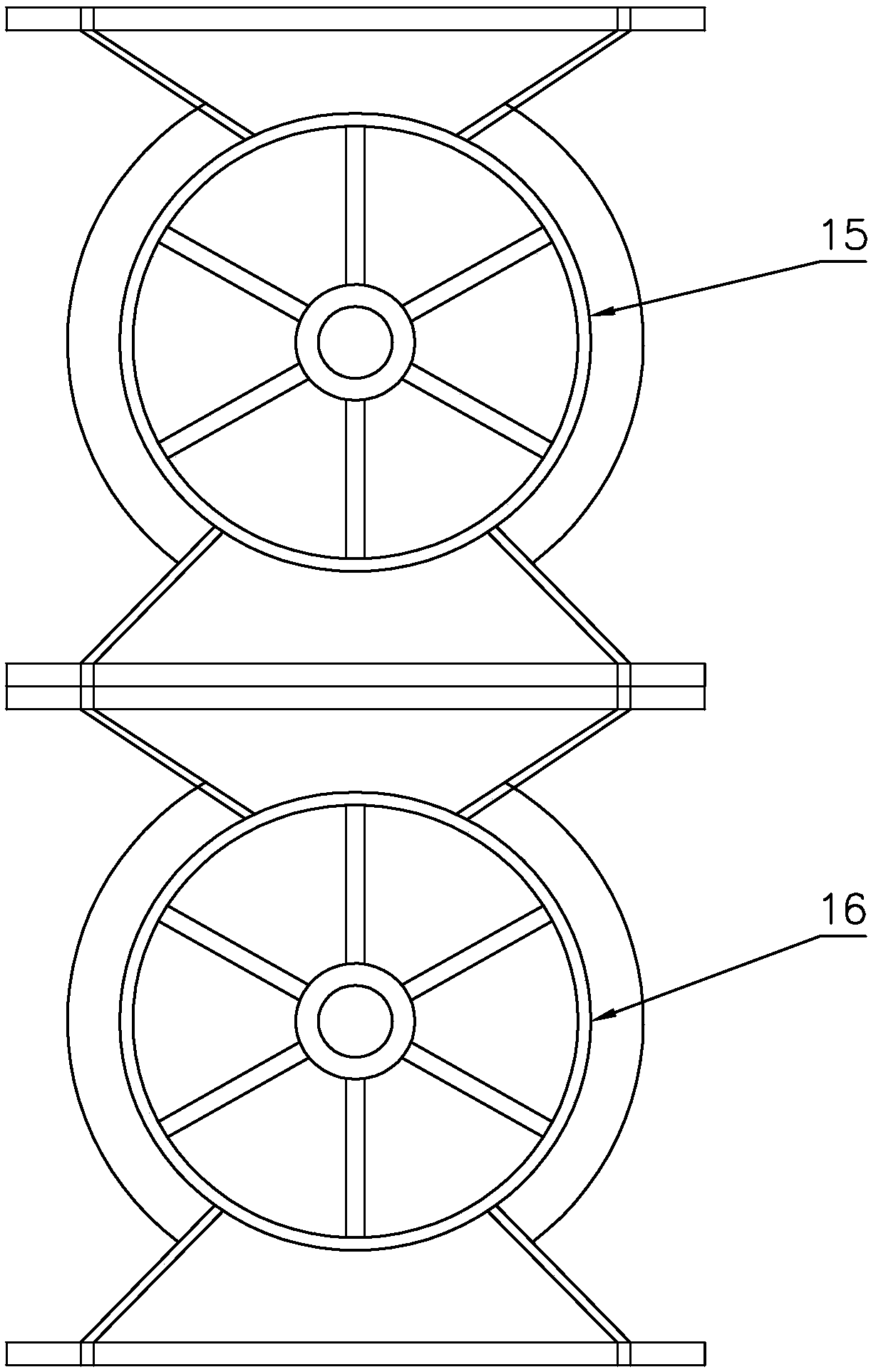

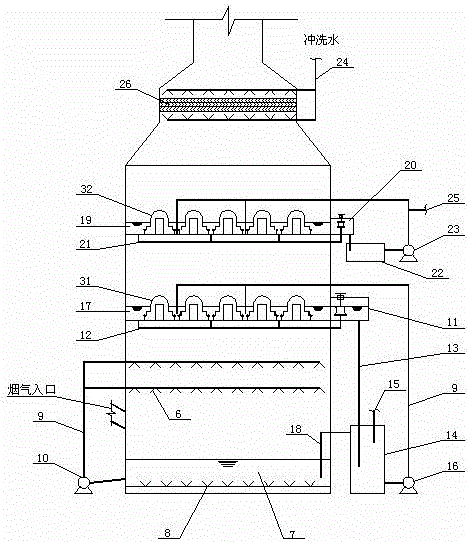

Ultra-low emission type desulfurization and dust removal rotational flow tray jet tower

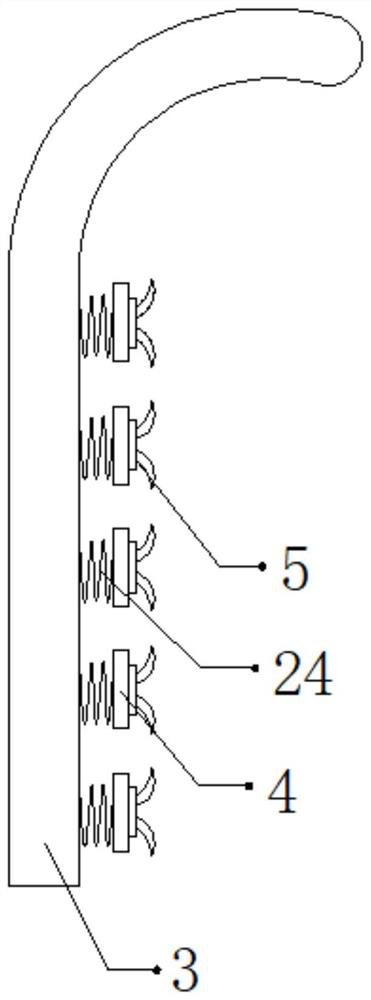

ActiveCN106237824AImprove desulfurization efficiencyLow running costGas treatmentUsing liquid separation agentEngineeringLiquid storage tank

The invention relates to an ultra-low emission type desulfurization and dust removal rotational flow tray jet tower. The ultra-low emission type desulfurization and dust removal rotational flow tray jet tower comprises a desulfurization tower, wherein a sprinkling system is located on the lower portion of the desulfurization tower, a demister is located on the upper portion of the desulfurization tower, a size rotational flow tray mixer is arranged between the sprinkling system and the demister and located in a rotational flow tray mixer liquid storage tank, the size rotational flow tray mixer comprises a standpipe and a bubble cap, and the standpipe is covered with the bubble cap; multiple tray holes are formed in a tray of the size rotational flow tray mixer. The four desulfurization techniques including sprinkling, rotational flow, tray and bubbling are combined, the characteristics that the rotational flow tray can be used for uniform mixing and a bubbling technique absorbent is of a continuous phase and can achieve deep desulfurization are utilized, and deep desulfurization and deep dust removal are achieved. When the concentration of flue gas SO2 at an inlet of an absorption tower is below 10000 mg / Nm3, the requirement for ultra-low emission that the concentration of SO2 at an outlet is smaller than 35 mg / Nm3 can be met.

Owner:济南金孚瑞热能设备制造有限公司

Device and method for carrying out dust removing treatment on dust-containing steam in steel slag treating and rolling zone

ActiveCN105642067AReduce dust removal efficiencyReduce equipment maintenanceCombination devicesSlagSpray tower

The invention relates to a device and a method for carrying out dust removing treatment on dust-containing steam in a steel slag treating and rolling zone. The device comprises a spray tower, a rotational flow tower and a pipeline, wherein the pipeline is used for connecting the spray tower with the rotational flow tower; a first high-pressure spray gun is arranged at the upper part of the spray tower; a first opening is formed in the top part of the spray tower; the first opening is connected with a rolling space through a pipeline, and is used for guiding the dust-containing steam generated in a rolling zone into the top part of the spray tower; the pipeline which is used for connecting the spray tower with the rotational flow tower is arranged at the bottom parts of the spray tower and the rotational flow tower, and is used for guiding the dust-containing steam which is treated by the spray tower into the rotational flow tower along the tangential direction so as to enable the dust-containing steam for continuous flowing; a second high-pressure spray gun is arranged at the bottom part of the rotational flow tower; a rotational flow cone is arranged at the middle part of the rotational flow tower; a second opening is formed in the top part of the rotational flow tower, and is used for discharging the steam which is treated by the rotational flow tower. The device disclosed by the invention has the advantage that the dust removing efficiency and the device maintenance quantity are greatly reduced.

Owner:MCC ENERGY SAVING & ENVIRONMENTAL PROTECTION +1

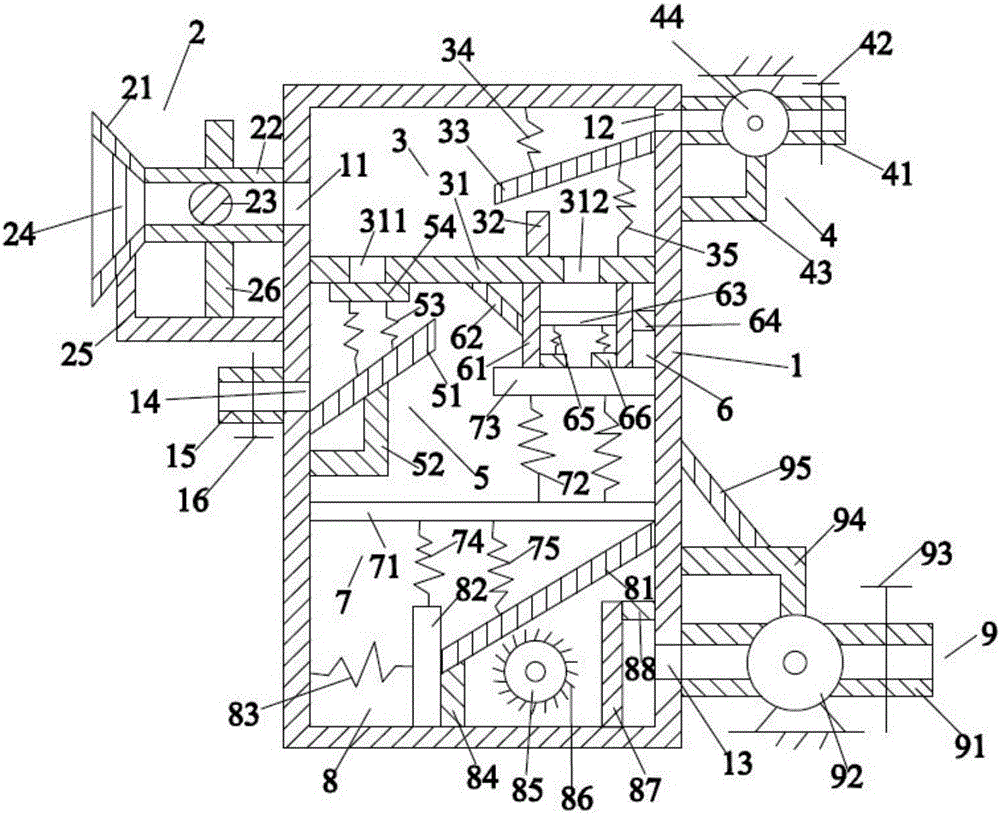

Aluminum ore crushing machine

PendingCN107744875AIncrease profitAchieve sievingGas current separationDirt cleaningMining engineeringDust control

The invention provides an aluminum ore crushing machine which comprises a machine body. The machine body is provided with a feeding port and a discharging port. A crushing mechanism used for crushingaluminum ore is arranged in the machine body. A dedusting mechanism is further arranged on the machine body and located above the crushing mechanism. The dedusting mechanism comprises a dedusting opening, a dedusting pipeline, a dedusting bag and an exhaust fan. One end of the dedusting pipeline is in seamless connection with the dedusting opening, and the other end of the dedusting pipeline is connected with the exhaust fan. Both the dedusting pipeline and the exhaust fan are located on the outer side of the machine body. The dedusting opening is provided with a first screen. The dedusting pipeline is internally provided with a second screen and a third screen in sequence. The dedusting bag is arranged in the dedusting pipeline and located between the third screen and the exhaust fan. Thededusting pipeline is further provided with a first collecting port, a second collecting port and a third collecting port. According to the aluminum ore crushing machine, dust generated during crushing is sucked into the dedusting pipeline through the exhaust fan and sequentially passes through the first screen, the second screen and the third screen to be filtered and screened, and thus, dust collection is achieved.

Owner:贵州金鑫铝矿有限公司

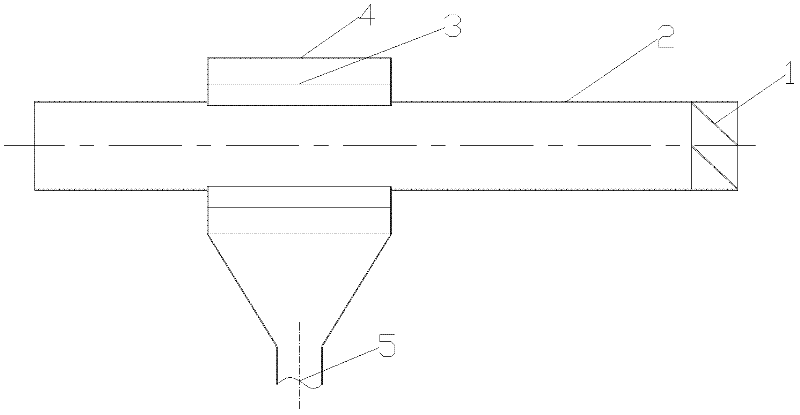

Dust removing device applied to pipeline

InactiveCN102343188ADoes not affect flowSimple structureDispersed particle separationParticulatesSolid particle

The invention discloses a dust removing device applied to a pipeline. A diversion component is connected with a conduit; a gas-solid separating fin is fixed on the side wall of a shell; the conduit is fixedly connected with the shell; both sides of the shell are provided with holes; a hole of the conduit is communicated with the holes of the shell; the gas-solid separating fin and the conduit are arranged concentrically; and the lower end of the shell is connected with a dust falling pipe. The dust removing device is used for removing entrained solid or liquid particles in the conveying process of various gases or liquids containing solid particles or liquid fog drops, so that influences on operation caused by dust or solid (liquid) particles in subsequent processes are reduced. In the invention, a fluid rotates while entering a pipeline through a pipeline embedded structural piece, so that the fluid moves forward spirally; and solid particles or liquid drops with large specific weights move towards a pipe wall side under the action of centrifugal force, move into an outer layer interlayer while passing through the blade gap of a dust removing component, and enter a recovering system under the action of gravity.

Owner:北京德天御投资管理有限责任公司

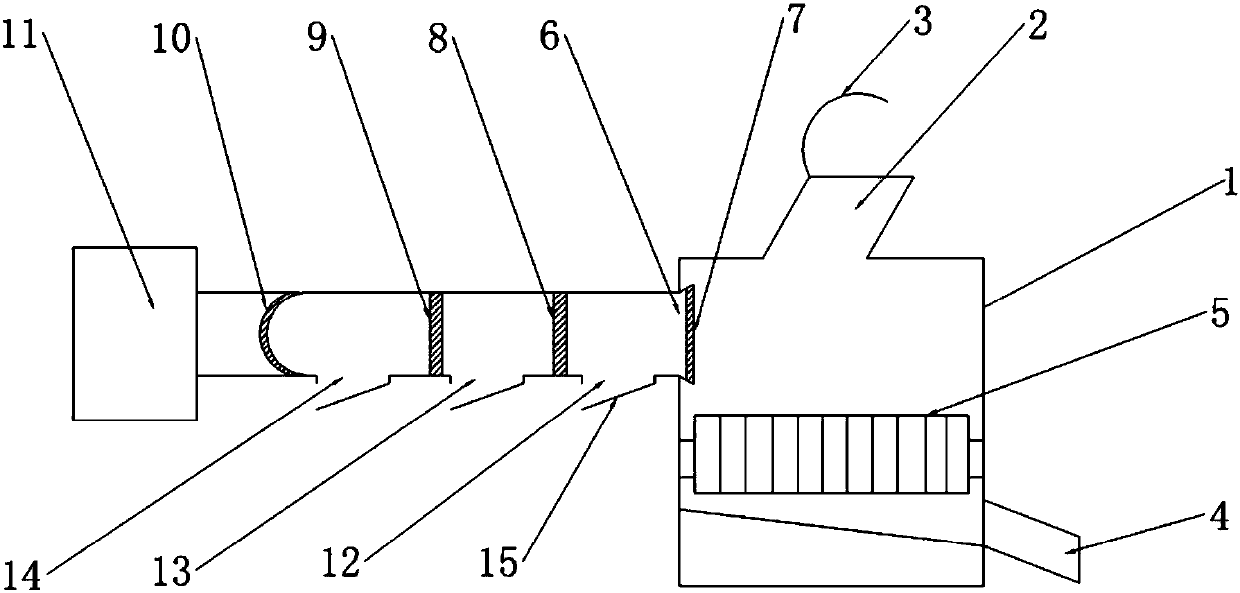

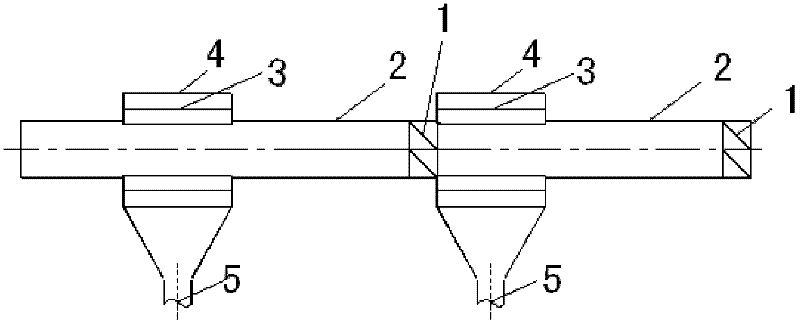

Equipment for removing nano-grade dust in gas and dust removing method of equipment

ActiveCN104587780AIncrease dust collecting areaEasy to cleanCombination devicesWater pipeOptical communication

The invention relates to equipment for removing nano-grade dust in gas and a dust removing method of the equipment. According to the dust removing equipment, a separation force is directly applied to particles so that the nano-grade dust in the gas can be removed; and the dust removing equipment is suitable for optical communication and new energy source industries. The dust removing equipment comprises a plate type positive electrode, a pipe type negative electrode, a spraying device, a gas flow distribution device, a shell, a buffering groove, an exhausting pipe and a draught fan; a plate type positive electrode mounting bracket and a pipe type negative electrode mounting bracket are mounted in the shell; the plate type positive electrode is mounted on the plate type positive electrode mounting bracket; the pipe type negative electrode is mounted on the pipe type negative electrode mounting bracket; the pipe type negative electrode is located in the middle of the plate type positive electrode; the spraying device comprises water pipes and spraying heads; the water pipes are distributed at the upper, middle and lower parts in the shell; the spraying heads are uniformly distributed on the water pipes and the spraying heads are distributed in a 360-degree direction; the gas flow distribution device is composed of a gradually-expanded pipe and a gas flow distribution plate; the buffering groove is formed in the lower part of the shell; and the exhausting pipe is mounted at the top of the shell and the draught fan is mounted on the exhausting pipe.

Owner:ZHONGTIAN TECH ADVANCED MATERIALS CO LTD +1

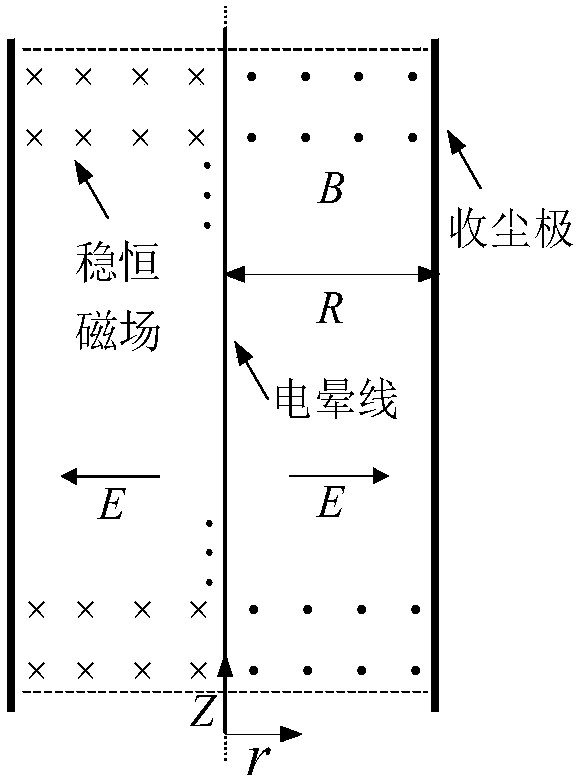

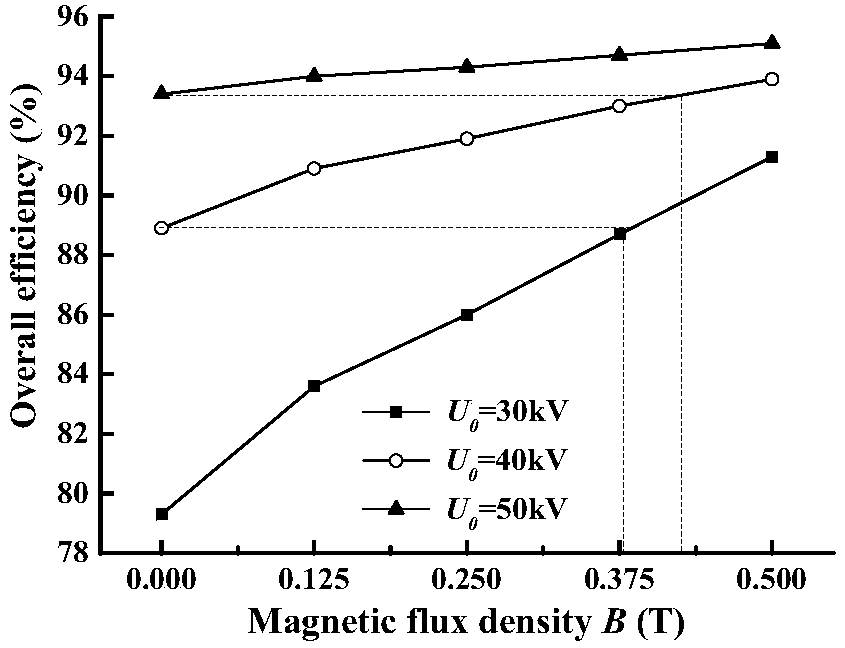

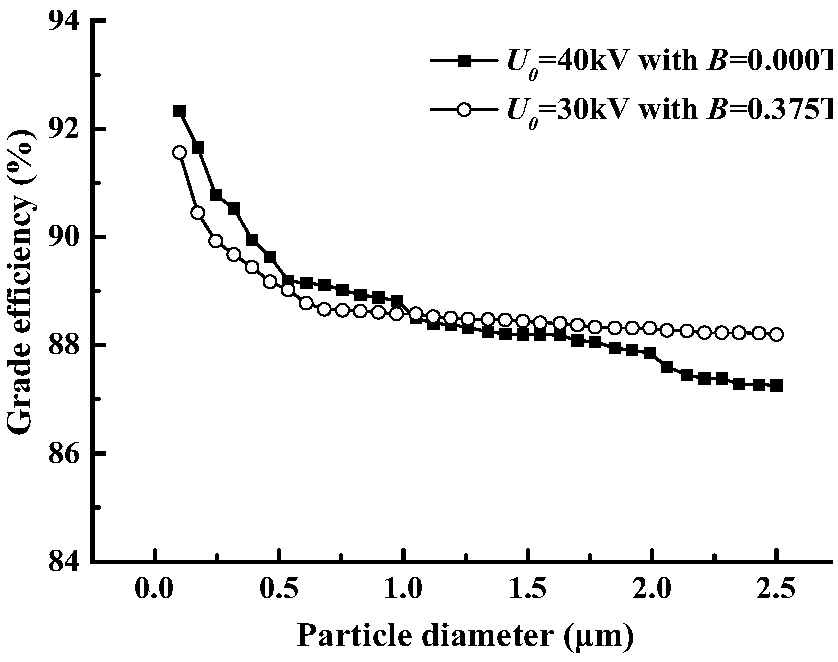

Wire tube type electrostatic precipitator performance improvement method introducing magnetic field

InactiveCN108554634AReduce dust removal efficiencyReduced operating power consumptionExternal electric electrostatic seperatorLow voltageEngineering

The invention relates to a wire tube type electrostatic precipitator performance improvement method introducing a magnetic field. According to the method, the magnetic field is introduced into a wiretube type electrostatic precipitator; the dust removal efficiency of the wire tube type electrostatic precipitator which runs under a low-voltage working condition is improved by prolonging the stay time of fine particles in the wire tube type electrostatic precipitator by virtue of Lorentz force; and FLUENT software is adopted for simulation to obtain the dust removal efficiency of the wire tubetype electrostatic precipitator under different working voltages in the magnetic field environment. Compared with the prior art, the wire tube type electrostatic precipitator performance improvement method provided by the invention has the advantages of realizing the aims of not reducing the dust removal efficiency and only reducing the running power consumption by introducing a stable and constant magnetic field into a particle motion region of the electrostatic precipitator.

Owner:SHANGHAI UNIVERSITY OF ELECTRIC POWER

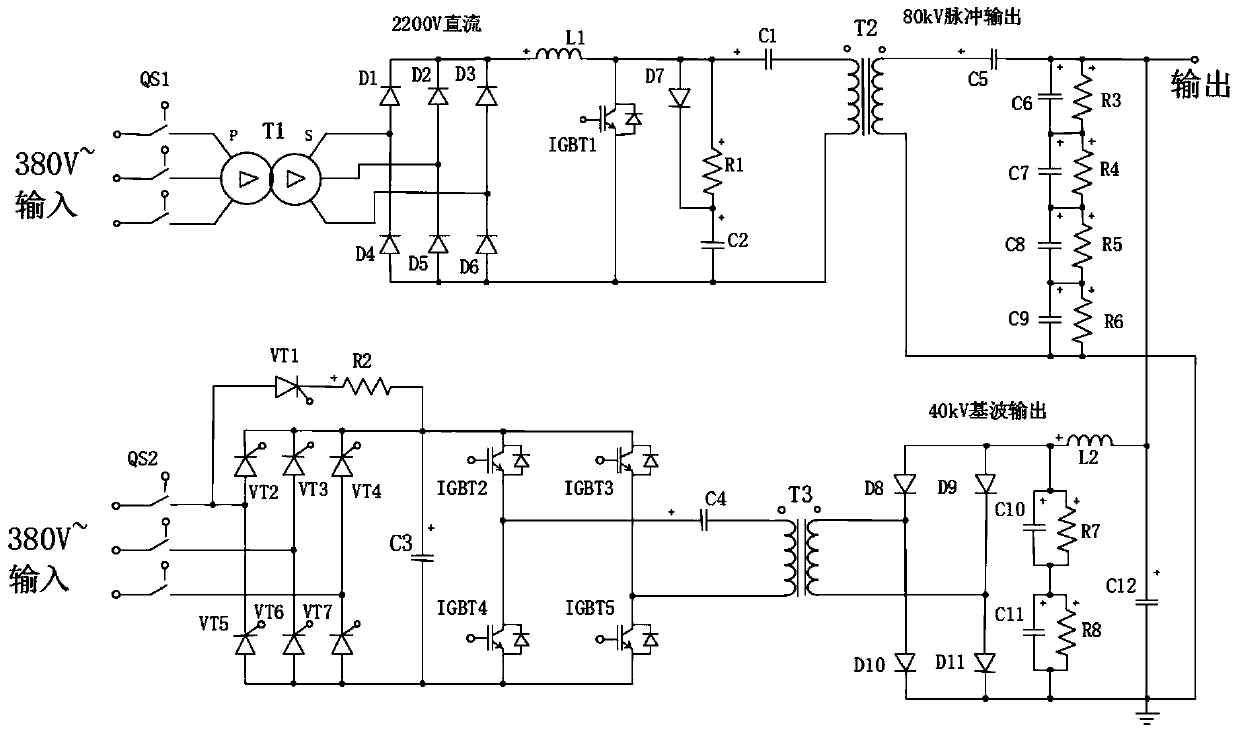

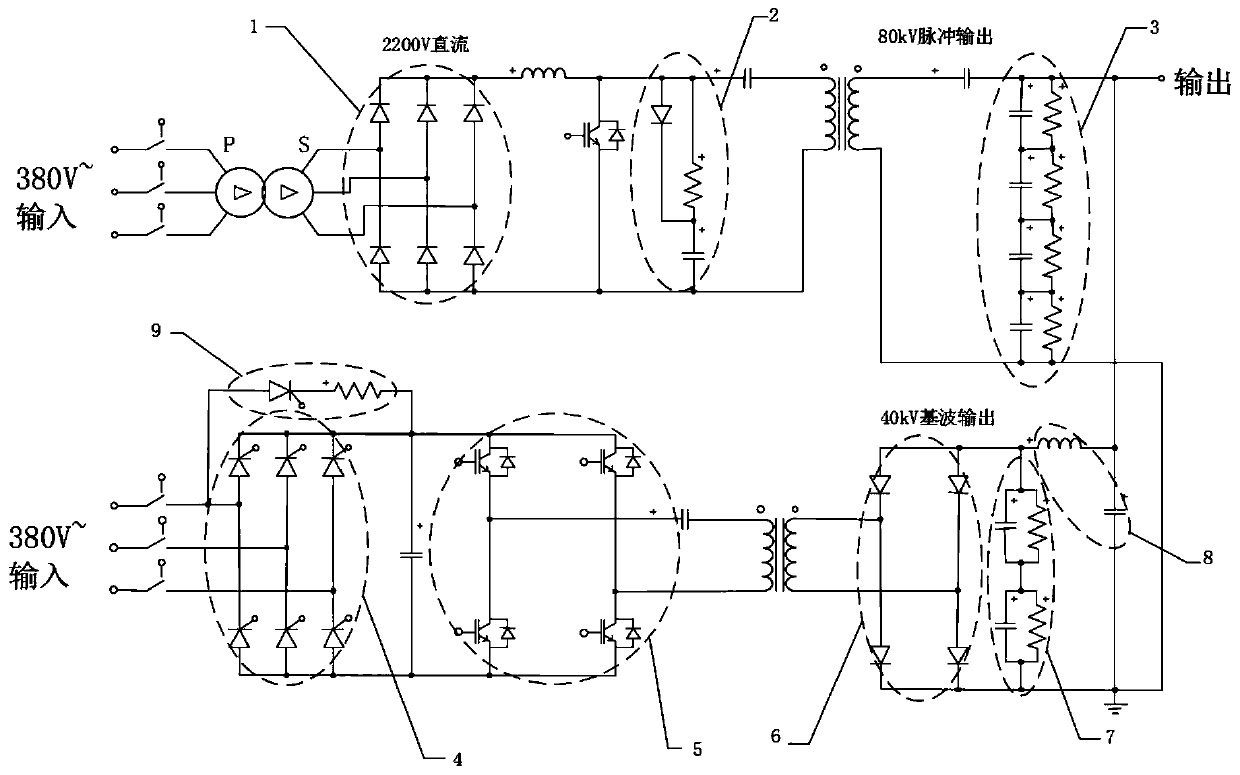

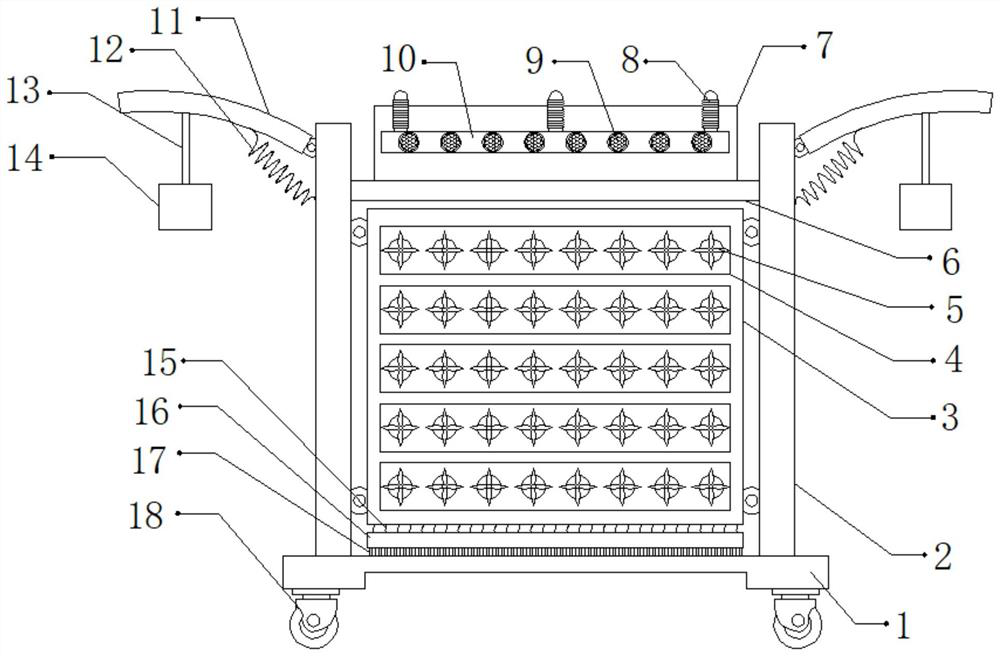

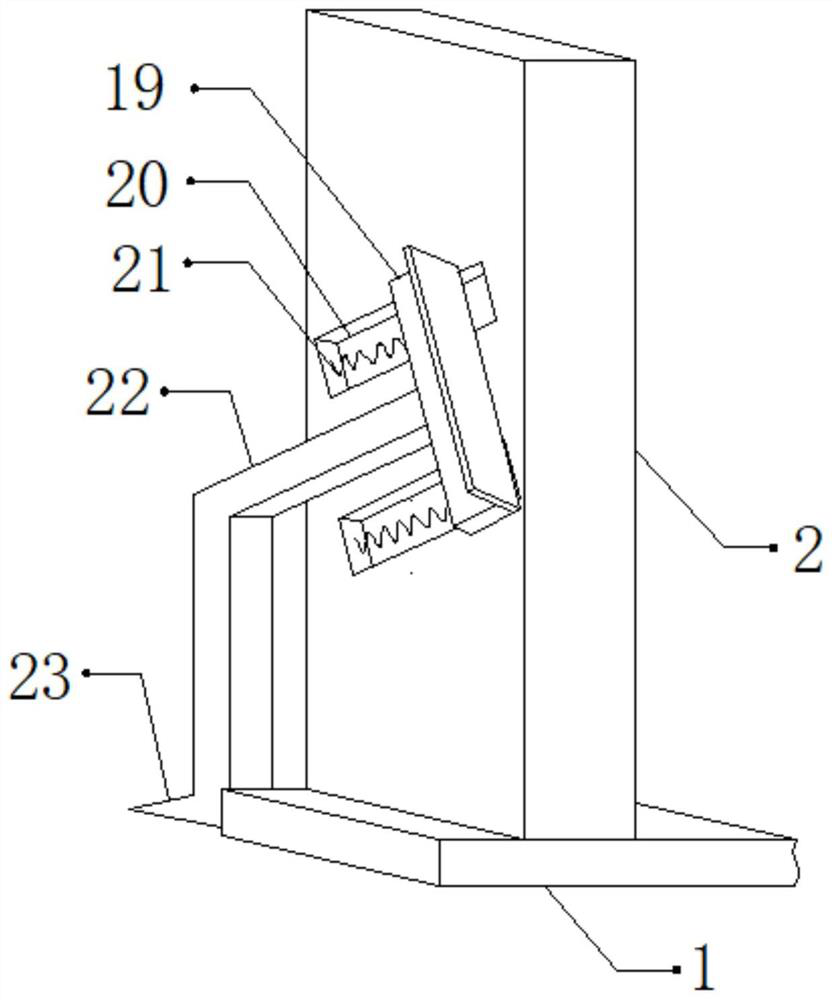

High-power DC superimposed pulse power source

InactiveCN110420758AAvoid back corona phenomenonAvoid flashoverPulse generation by energy-accumulating elementElectric supply techniquesCapacitanceUltra fine

The invention relates to a high-power DC superimposed pulse power source, which comprises a high-frequency high-voltage DC power source and a high-voltage pulse power source connected to each other through an inductor L2, wherein the high-voltage output end of the superimposed power source is connected with a dust collector; the high-voltage pulse power source comprises a first rectifier bridge, an IGBT1, a first resonant capacitor C1, and a pulse transformer T2 connected in sequence; the AC input end of the first rectifier bridge is connected to the power frequency AC power source; the DC positive output end of the first rectifier bridge is connected to the drain of the IGBT1; the DC negative output end of the first rectifier bridge is connected to the source of the IGBT1; the drain of the IGBT1 is connected to one end of the first resonant capacitor C1; the other end of the first resonant capacitor C1 and the source of the IGBT1 are connected to two ends of a primary winding of the pulse transformer T2; and one end of the secondary winding of the pulse transformer T2 is connected with a DC blocking capacitor C5, and the other end is grounded. High-efficiency dust removing effectsare achieved, and remarkable dust removal effects are achieved especially for high specific resistance dust and ultra fine dust.

Owner:武汉东城新能源有限公司

Dust falling device for building blasting

The invention discloses a dust falling device for building blasting. The dust falling device comprises a fixing seat, wherein fixing plates are fixedly connected to two sides of the outer wall of thetop of the fixing seat; blades are connected to the outer walls of one sides of the two fixing plates through hinges; first springs are fixedly connected between the blades and the outer walls of onesides of the fixing plates; lifting ropes are bolted to the outer walls of the bottoms of the two blades; fixing blocks are bolted to the outer walls of the bottoms of the two lifting ropes; a baffleis connected between the outer walls of the opposite sides of the two fixing plates through hinges; and a supporting plate is fixedly connected between the outer walls of the opposite sides of the twofixing plates. According to the dust falling device disclosed by the invention, the condition that the device cannot effectively perform dust falling treatment on dust due to the fact that the dust flies upwards can be avoided, the condition that the device falls due to impact force generated during blasting so as to influence dust falling of the device can be avoided, and the condition that thedust removal efficiency of the device is reduced due to high flowing speed of the dust can be avoided.

Owner:袁国初

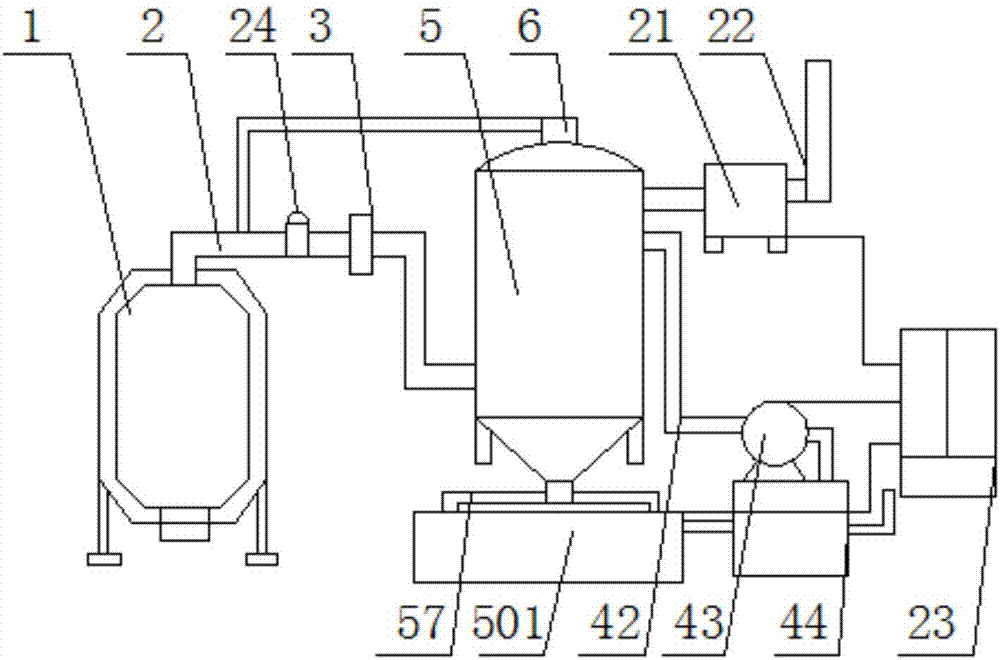

Intelligent wet-type aluminum magnesium dust removing system

InactiveCN107970730APrevent leakageEnsure safetyCombination devicesSedimentation settling tanksRelief valveMagnesium dust

The invention discloses an intelligent wet-type aluminum magnesium dust removing system. The intelligent wet-type aluminum magnesium dust removing system comprises a dust suction hood, an air suctionpipe, an explosion-proof valve, a filler absorbing tower and an induced draft fan, wherein the explosion-proof valve is fixedly connected to an outlet of the dust suction hood through the air suctionpipe; an outlet of the explosion-proof valve is fixedly connected with an inlet of the filler absorbing tower through a pipe; an outlet of the filler absorbing tower is fixedly connected with an inletof the induced draft fan through a pipe; an outlet of the induced draft fan is fixedly connected with a high-altitude discharge pipe. Through the closed dust suction hood and a glass door structure and in combination with an iron removing pipe, the intelligent wet-type aluminum magnesium dust removing system can guarantee complete absorption of operating dust so as to avoid leakage; in addition,through the explosion-proof valve and in combination with an explosion relief valve structure, and through recycling of sprinkling water by a sedimentation tank with a regulating barrel, waste is avoided, so that the dust removing convenience and stability can be greatly improved, the dust removing effect is guaranteed and the using cost is reduced.

Owner:安徽祥源科技股份有限公司

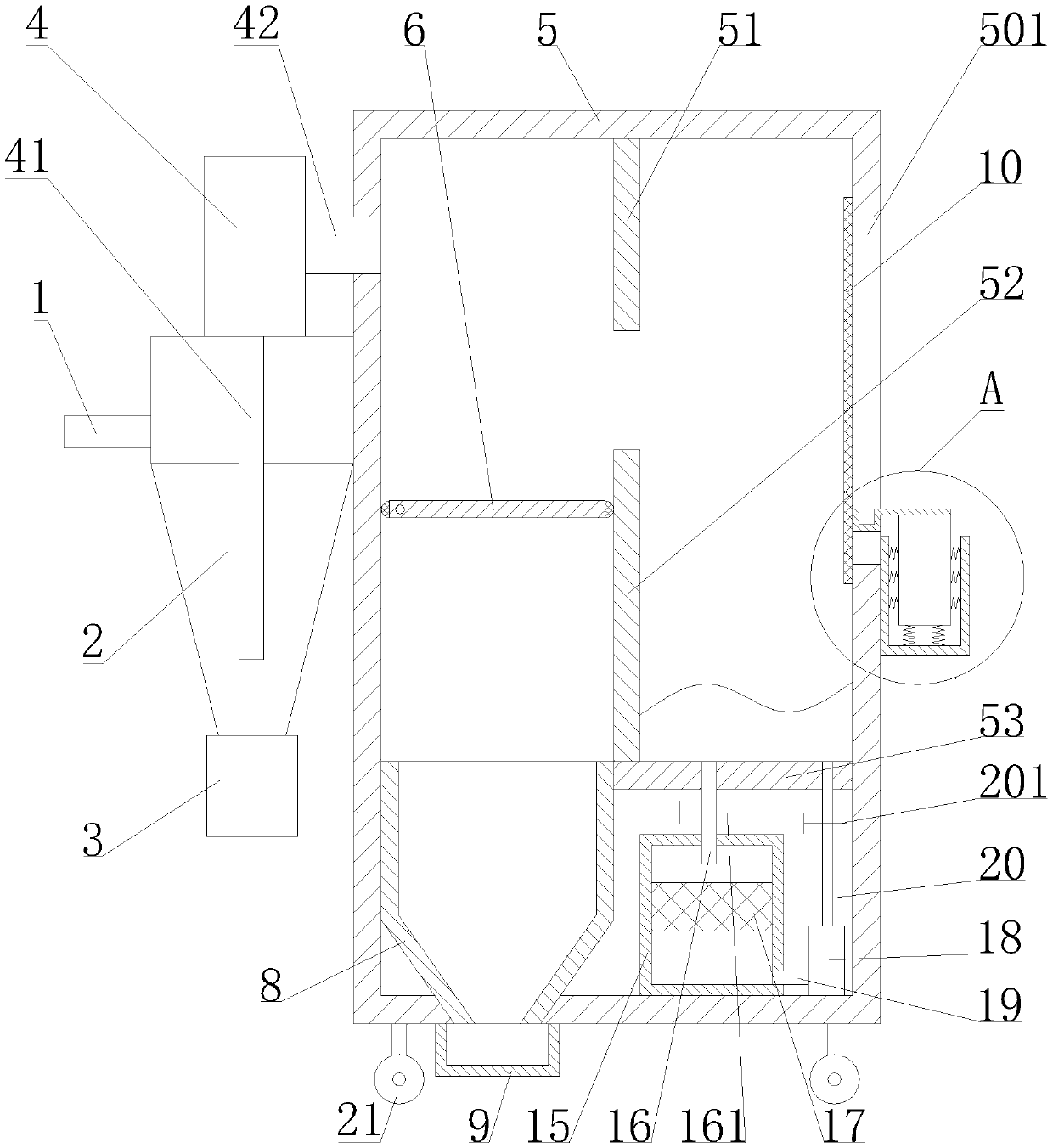

Ore dust collection and removal device

The invention provides an ore dust collection and removal device. The ore dust collection and removal device comprises a shell, an air inlet device, a first filtering device, a water inlet device, a collection device, a second filtering device, a third filtering device, a fourth filtering device and an air suction device; a first through hole, a second through hole, a third through hole, a fourth through hole, a drain pipe and a first valve are arranged on the shell, the air inlet device comprises an air inlet hopper, an air inlet pipe, a sponge ball, a first filter screen, a first support and a first fixing rod, the first filtering device comprises a first transverse plate, a first baffle, a first flow guide plate, a first spring and a second spring, the water inlet device comprises a water inlet pipe, a water pump, a second valve and a second support, the collection device comprises a second flow guide plate, a third support, third springs and a stop block, and the second filtering device comprises a pipeline, a second fixing rod, a second filter screen, a third fixing rod, a fourth spring and a first fixing block. The ore dust collection and removal device can collect dust generated in the ore mining process and conduct effective dust removal.

Owner:王杨

Industrial processing equipment dust collecting plant

InactiveCN109663448ARealize secondary dust removalReduce dust removal efficiencyCombination devicesIndustrial equipmentEngineering

An industrial processing equipment dust collecting plant comprises a cyclone dust collector, an exhaust blower, a box body, a chip collecting plate, a dust collecting screen, a support base, a vibration exciter and a connector; a barrier plate, a partition plate and a support plate are arranged on the inner surface of the box body; the cyclone dust collector is arranged on the box body, an air inlet end of the cyclone dust collector is connected with an air inlet pipe, and a chip collecting hopper is arranged at the bottom of the cyclone dust collector; the exhaust blower is arranged on the cyclone dust collector, is communicated with the same through a first air delivery pipe, and is communicated with the box body through a second air delivery pipe; a drive device for driving the chip collecting plate to rotate is arranged on the box body; the support base is provided with a plurality of elastic parts; the vibration exciter is arranged on the elastic parts, an output end of the vibration exciter is connected with one end of the connector, and the other end of the connector is connected with the dust collecting screen. As dust or chip containing gas can be cleaned by three times through the dust collecting plant, dust and chip generated in operating environment of industrial equipment can be removed effectively; besides, dust accumulated on the dust collecting screen can be vibrated to fall down through the vibration exciter.

Owner:JIANGSU HEHAI GRP

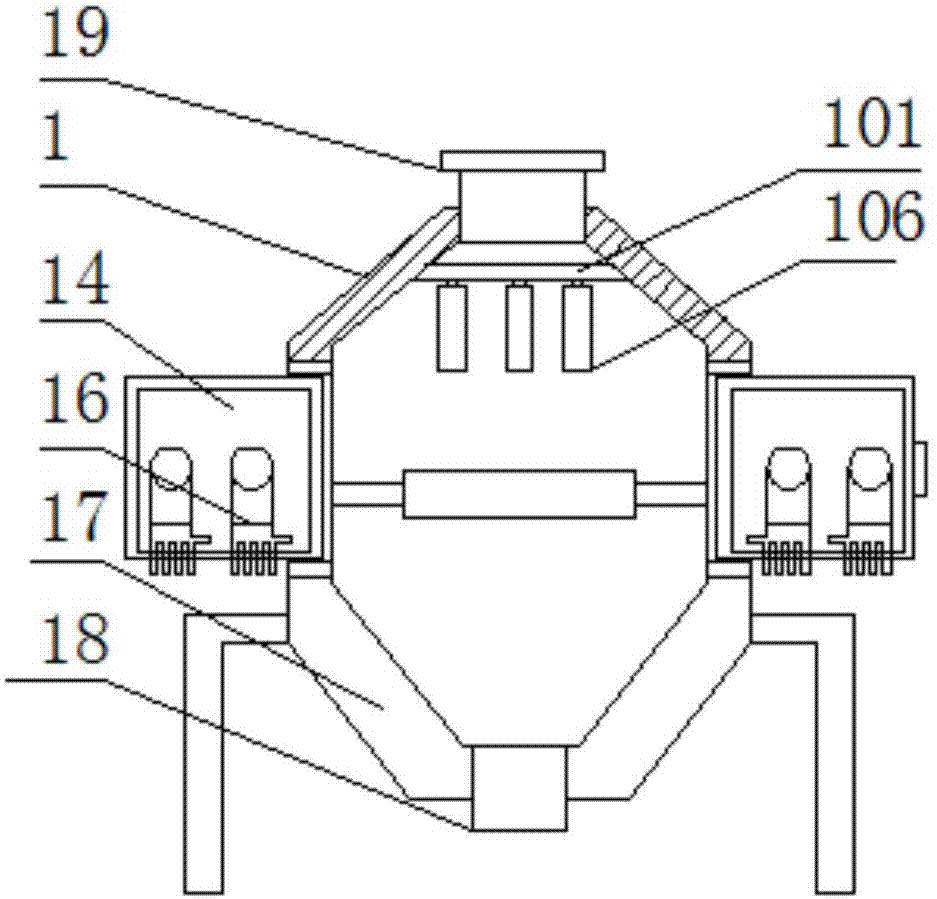

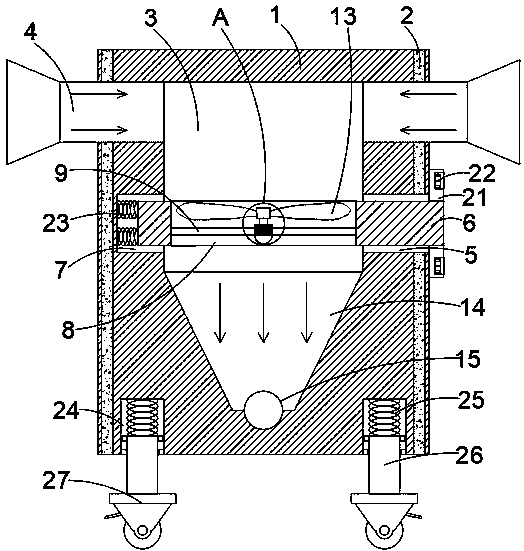

Ventilation and dust removal device for wind power generating set and wind power generating set

ActiveCN105149095BReduce dust removal efficiencyAchieve separationMachines/enginesWind energy generationDust controlEnvironmental engineering

The invention provides a ventilation dust removal device of a wind power generation set and the wind power generation set. The ventilation dust removal device comprises an air box and dust removal equipment. The air box is divided into an air inlet part and an air outlet part by a separation plate. The dust removal equipment comprises a plurality of dust collection deposition tubes arranged in the air outlet part of the air box, corona electrode wires arranged in the multiple dust collection deposition tubes, a power supply device providing voltage for the dust collection deposition tubes and the corona electrode wires and rapping devices arranged for the dust collection deposition tubes respectively; each dust collection deposition tube is communicated with the air inlet part and provided with a dust collection deposition tube air outlet which is communicated with the air outlet part; the air outlet part is provided with an air box air outlet. According to the ventilation dust removal device of the wind power generation set, ionization occurs to dust, smog and other particles in air by using an electric field generated between the dust collection deposition tubes and the corona electrode wires, so that the extra resistance of the ventilation dust removal device to the air is reduced.

Owner:BEIJING GOLDWIND SCI & CREATION WINDPOWER EQUIP CO LTD

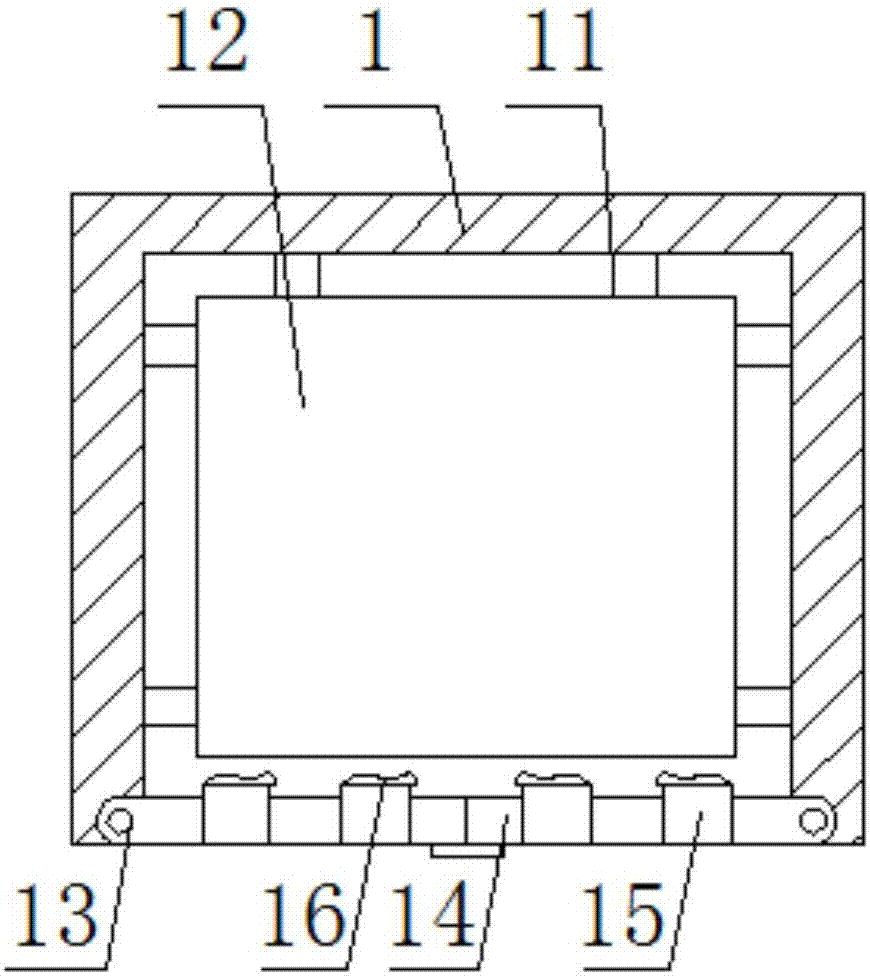

High-temperature-resistant anti-corrosion cleanable industrial dust removal device

InactiveCN109260848AAvoid erosionEasy to operateGas treatmentDispersed particle filtrationBiochemical engineeringDrive motor

The invention discloses a high-temperature-resistant anti-corrosion cleanable industrial dust removal device, which comprises a casing, wherein a heat insulation plate is arranged in the casing; anticorrosion paint coats the surface of the casing by brushing; a dust suction cavity is formed in the casing; a plurality of dust suction passages communicated with the dust suction cavity are arranged in a way of surrounding the side wall of the casing; a slide groove in transverse arrangement is formed in the side wall of one side of the casing; an installing plate is glidingly connected into the slide groove; a fixing mechanism matched with the installing plate is arranged on the installing plate; a clamp groove matched with the installing plate is formed in the inner wall of one side of the dust suction cavity; an installing opening is formed in the installing plate; the inner wall of the installing opening is fixedly connected with a driving motor through a fixing rod; the output end ofthe driving motor is connected with a rotating shaft; an installing block is fixedly connected onto one end, far away from the driving motor, of the rotating shaft. The high-temperature-resistant anti-corrosion cleanable industrial dust removal device has the advantages that the operation is simple; the use is convenient; the device has high-temperature resistance and anti-corrosion performance; the installation plate can be dismounted; the inside of the device can be conveniently cleaned; the service life of the device is prolonged.

Owner:绍兴不忘初心机械设计有限公司

Dust discharge processing device for electrolytic aluminum processing

InactiveCN110917784AImprove dust removal efficiencyImprove practicalityCombination devicesFiltration separationToxic gasElectrolysis

The invention discloses a dust discharge processing device for electrolytic aluminum processing, and relates to the field of electrolytic aluminum processing. The dust discharge processing device comprises a base. Support legs are fixedly arranged on the bottom of the base. An electrolytic chamber is welded on the top of the base. A molten aluminum pipe is fixedly mounted on one lateral wall of the electrolytic chamber. A stop valve is welded on the molten aluminum pipe. An anode rod and a cathode rod are arranged in the electrolytic chamber. The anode rod and the cathode rod both horizontallypenetrate the top of the electrolytic chamber and extend to the exterior of the electrolytic chamber. The tops of the anode rod and the cathode rod are both electrically connected to wires. Through the cooperation among a collection hood, a dust depositing chamber, a spraying plate, a first blower fan, a first drainpipe, a submerged pump, a water inlet pipe, and a filter frame, the dust collection performance of the device is improved, the dedusting efficiency of the device is improved to a certain degree, at the same time, the device is provided with a toxic gas filtering device, and the practicality of the device is largely improved.

Owner:HUZHOU ZHILI XINFEI ALUMINUM IND

High-temperature industrial waste gas multi-stage dust removal system

PendingCN112337243AReduce dust removal efficiencyAvoid secondary pollutionCombination devicesHydraulic cylinderThermodynamics

The invention discloses a high-temperature industrial waste gas multi-stage dust removal system which comprises a heat exchange box, a draught fan, an air guide pipe, a dust removal box, an ash storage box, a hydraulic cylinder, a baffle, a spiral conveying device and an exhaust device, the heat exchange box comprises a water inlet, an air inlet, a water outlet, an air outlet, a lower partition plate, an upper partition plate, flow guide plates, heat exchange pipes and turbulence fans; the water inlet is arranged at one side of the heat exchange box and below the lower partition plate; the water outlet is formed in the same side and located above the upper partition plate; the air inlet is formed in one side of the heat exchange box and located between the flow guide plates and the lower partition plate, the flow guide plates and the turbulent fans are distributed on the two sides in the heat exchange box in a staggered mode, and the heat exchange pipes are evenly distributed in the heat exchange box and penetrate through the upper partition plate, the lower partition plate and the flow guide plates; and the air outlet is formed in one side of the heat exchange box and communicateswith the draught fan, and the draught fan is fixedly installed on the heat exchange box and communicates with the dust removal box through the air guide pipe. Cyclone dust removal and cloth bag dustremoval are integrally designed, the occupied area is small, the dust removal efficiency is high, and flying dust can be prevented.

Owner:山东天智信息科技有限公司

Dust removal device for zinc oxide powder production

InactiveCN108097619AEasy to handleImprove dust removal effectCleaning using toolsEngineeringBlock structure

The invention discloses a dust removal device for zinc oxide powder production. The dust removal device comprises a base, wherein a power supply box is arranged on one side of the front surface of thebase, a main shell is fixed at the top end of the base, and a feeding opening and a discharging opening are formed in the two sides of the main shell respectively. A mounting plate is arranged between the feeding hole of the main shell and the side wall of the discharging hole, a fixing groove is formed in the center of the top of the mounting plate, an upper sliding groove and a lower sliding groove which are fixed at the upper end and the lower end of the fixing groove are cooperatively used with the fixing groove, an inclined plate is arranged on the side wall of the bottom end of the inner part of the main shell, a first dust outlet arranged at the position of the inner top end of the base is cooperatively used with the inclined plate, and a dust collecting box is fixed below the first dust outlet through a sliding block installed on a sliding rail. An upper dust removal brush, a lower dust removal brush, the dust collection box, the sliding rail and a sliding block structure arearranged, so that the dust removal device has the advantages that the dust removal efficiency is high, dust is properly treated, and the device for treating the dust is convenient and fast to mount and dismount.

Owner:XINGHUA SANYUAN ZINC

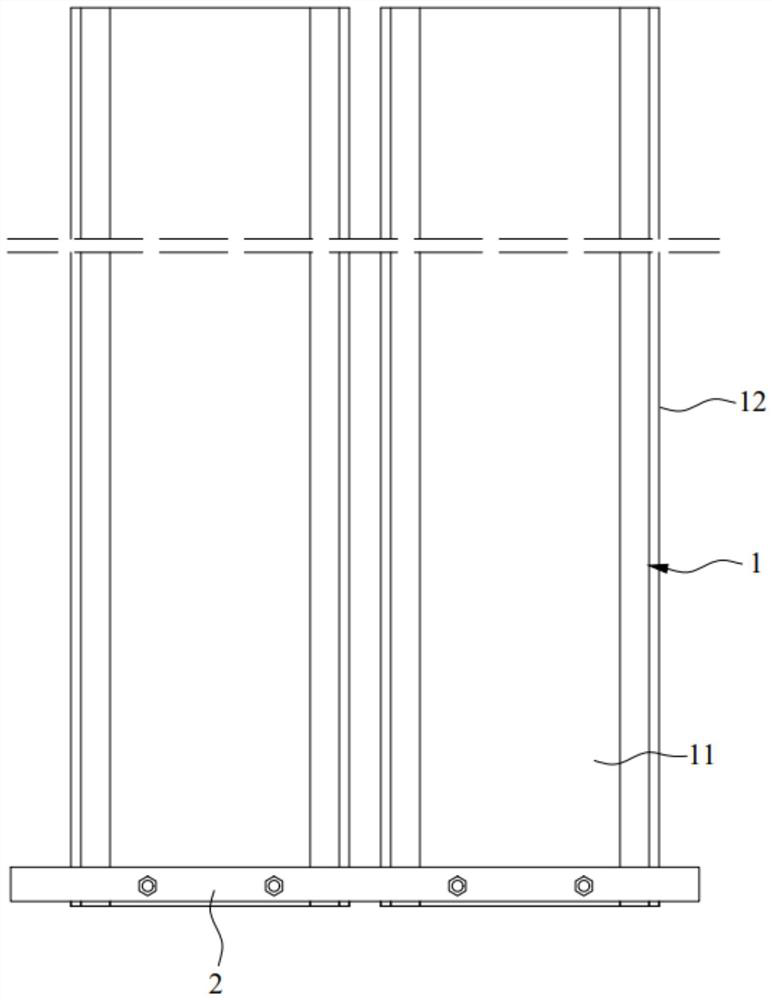

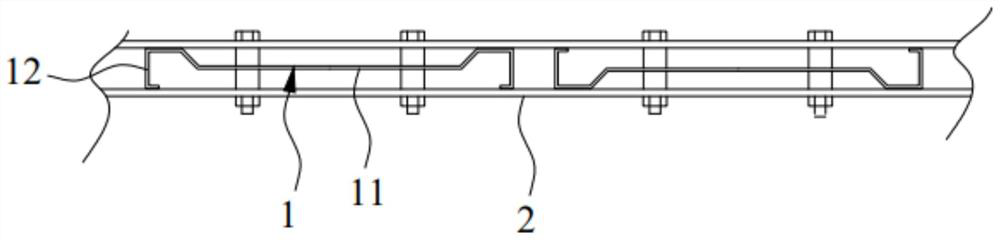

Electric precipitator anode plate repairing method

InactiveCN112718249AReduce dust removal efficiencyLow costElectrode constructionsStructural engineeringMechanical engineering

The invention belongs to the technical field of electric precipitator maintenance, and particularly relates to an electric precipitator anode plate repairing method which comprises the following steps: S1, detaching connecting steel plates on two sides of the bottom of a to-be-repaired anode plate of an electric precipitator; S2, fixedly connecting a first protection plate to one side of the anode plate to be repaired, wherein the first protection plate is attached to one side surface of the anode plate; S3, fixedly connecting a second protection plate to the other side, deviating from the first protection plate, of the to-be-repaired anode plate, and the second protection plate being attached to the other side face, deviating from the first protection plate, of the to-be-repaired anode plate; and S4, fixedly connecting the disassembled connecting steel plates to the two sides of the bottoms of the repaired anode plates, and connecting the multiple repaired anode plates in series. According to the repairing method, the first protection plate and the second protection plate are used for connecting and covering the damaged part of the anode plate, long-time shutdown is not needed in the repairing process, normal production operation is not affected, a special lifting appliance is not needed, the whole anode plate does not need to be replaced, the repairing method is simple, and the cost is low.

Owner:SGIS SONGSHAN CO LTD

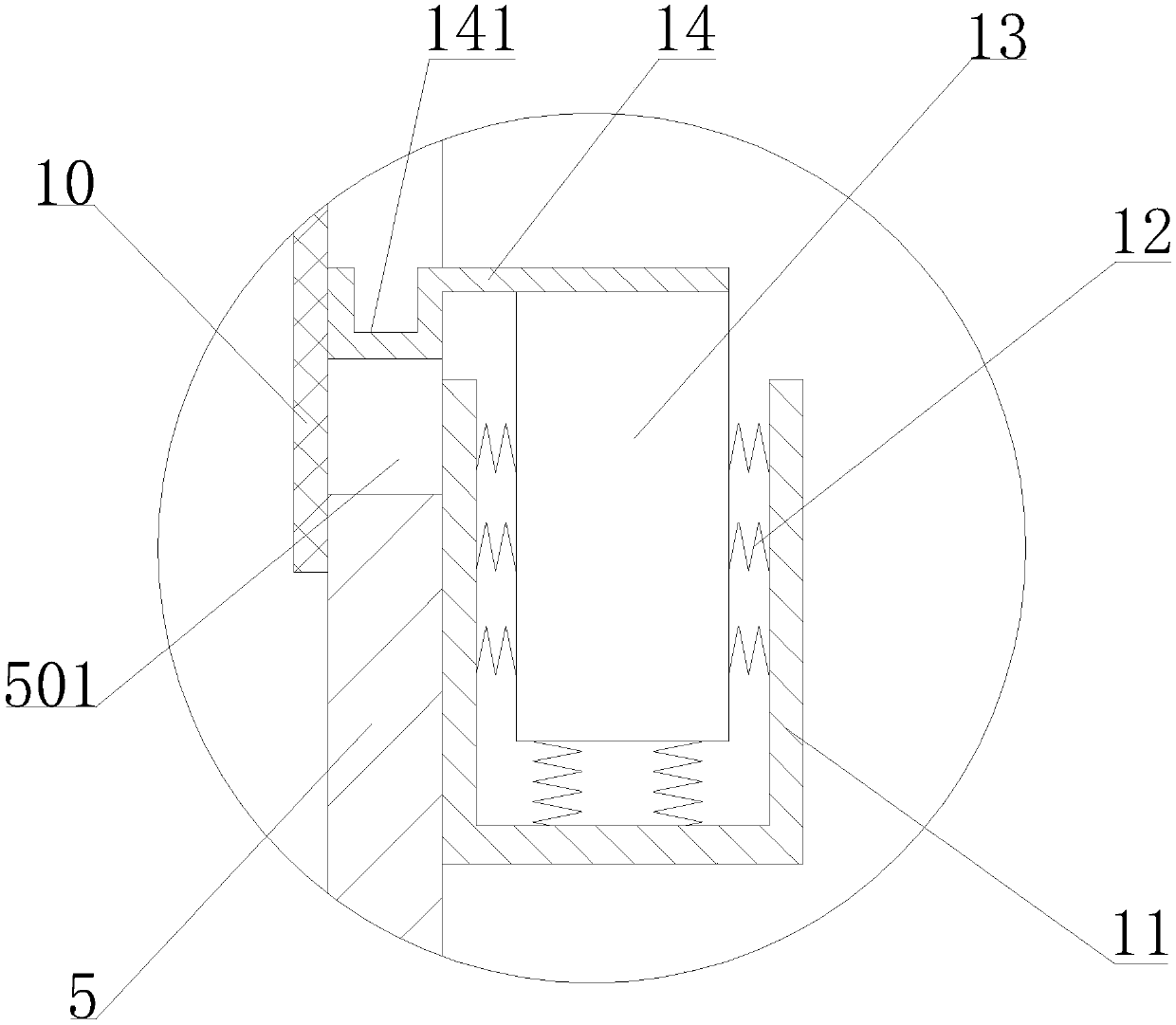

Dust-removal filter bed

PendingCN111375256AAvoid consumptionFreely adjust the pore sizeCombination devicesDispersed particle filtrationParticulatesDust control

The invention relates to a dust-removal filter bed, which relates to the field of dedusting devices. The dust-removal filter bed comprises a body, a filter plate, a plurality of pore adjusting piecesand a dust collection bin. Wherein the body is provided with a containing cavity limited by a shell wall, and the shell wall is provided with an inlet and an outlet which are communicated with the containing cavity; the filter plate is provided with a plurality of filter holes, is arranged in the accommodating cavity and divides the accommodating cavity into a first accommodating cavity and a second accommodating cavity, so that fluid input through the inlet sequentially flows through the first accommodating cavity, the filter holes, the second accommodating cavity and the outlet to be output;the plurality of pore adjusting pieces are positioned in the first accommodating cavity and / or the second accommodating cavity, and can be operated to be inserted into the filtering holes to form a pore adjusting state and to be separated from the filtering holes to form a pore non-adjusting state; and the dust collection bin communicates with the bottom of the first containing cavity. Accordingto the dust removal filter bed, the filter aperture can be freely adjusted, the dust-removal filter bed adapts to removal of different particulate matters and is convenient to clean, and meanwhile, the service life of the filter bed is prolonged.

Owner:LANZHOU UNIVERSITY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com